Rare-earth La added high-conductivity ternary aluminum alloy foil material and manufacture method thereof

A technology of aluminum alloy foil and high conductivity, which is applied in the field of aluminum alloy and can solve problems such as low conductivity, insufficient deep drawing performance, and poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

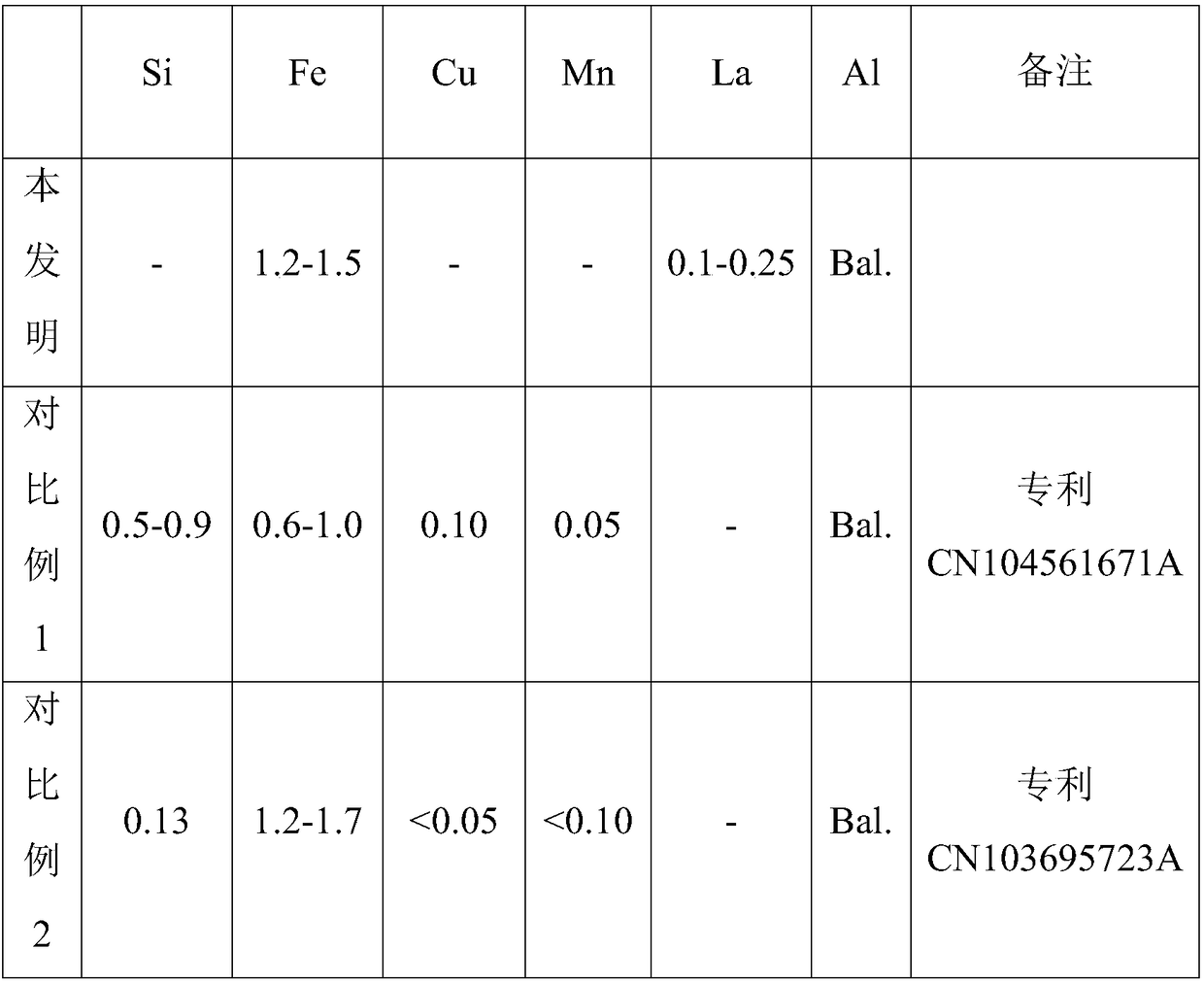

Examples

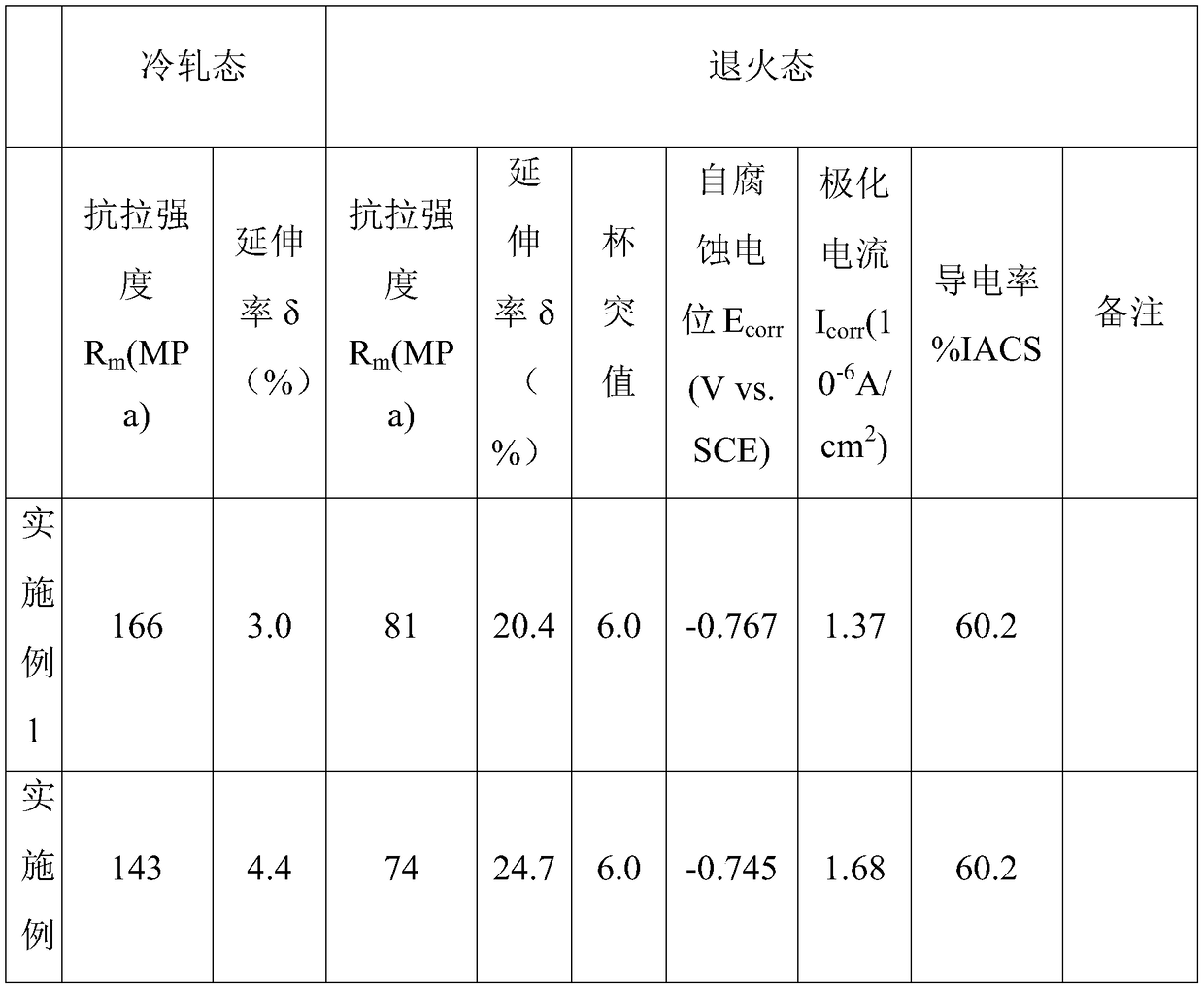

Embodiment 1

[0029] In this example, an Al-1.5Fe-0.1La alloy ingot with a thickness of 30mm was prepared by smelting and casting methods, kept at 590°C for 8 hours, milled to a thickness of 25mm, heated at 500°C for 1 hour, and then hot-rolled into a 4mm plate. , then cold-rolled to 0.15mm, annealed at 380°C for 2 hours and then cold-rolled into a foil with a thickness of 0.08mm. The tensile strength of the cold-rolled alloy is 166MPa and the elongation is 3%. After annealing at 250°C for 2 hours, the tensile strength of the alloy foil is 81 MPa, the elongation is 20.4%, and the electrical conductivity is 60.2% IACS.

Embodiment 2

[0031] In this example, an Al-1.5Fe-0.25La alloy ingot with a thickness of 30 mm was prepared by melting and casting methods, kept at 590 ° C for 8 hours, milled to a thickness of 25 mm, heated at 500 ° C for 1 hour, and then hot rolled into a 4 mm plate. , then cold-rolled to 0.15mm, annealed at 380°C for 2 hours and then cold-rolled into a foil with a thickness of 0.08mm. The tensile strength of the cold-rolled alloy is 143MPa and the elongation is 4.4%. After annealing at 250°C for 2 hours, the tensile strength of the alloy foil is 74 MPa, the elongation is 24.7%, and the electrical conductivity is 60.2% IACS.

Embodiment 3

[0033] In this example, smelting and casting methods are used to first prepare an Al-1.2Fe-0.1La alloy ingot with a thickness of 30mm, heat it at 590°C for 8 hours, mill it to a thickness of 26mm, heat it at 500°C, and hot-roll it to 2.6mm. Then cold rolled to 0.15mm, annealed at 380°C and then cold rolled to a foil with a thickness of 0.08mm. The tensile strength of the cold-rolled alloy is 154MPa and the elongation is 2.8%. After annealing at 250°C for 2 hours, the tensile strength of the alloy foil is 80 MPa, the elongation is 23.2%, and the electrical conductivity is 59.4% IACS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com