Stabilization of flatband voltages and threshold voltages in hafnium oxide based silicon transistors for CMOS

a technology of silicon transistors and threshold voltages, which is applied in the field of semiconductor structure, can solve problems such as non-ideal thresholds, and achieve the effect of promoting the necessary flatband voltage shift and altering the effective alignment of the workfunction of the material stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

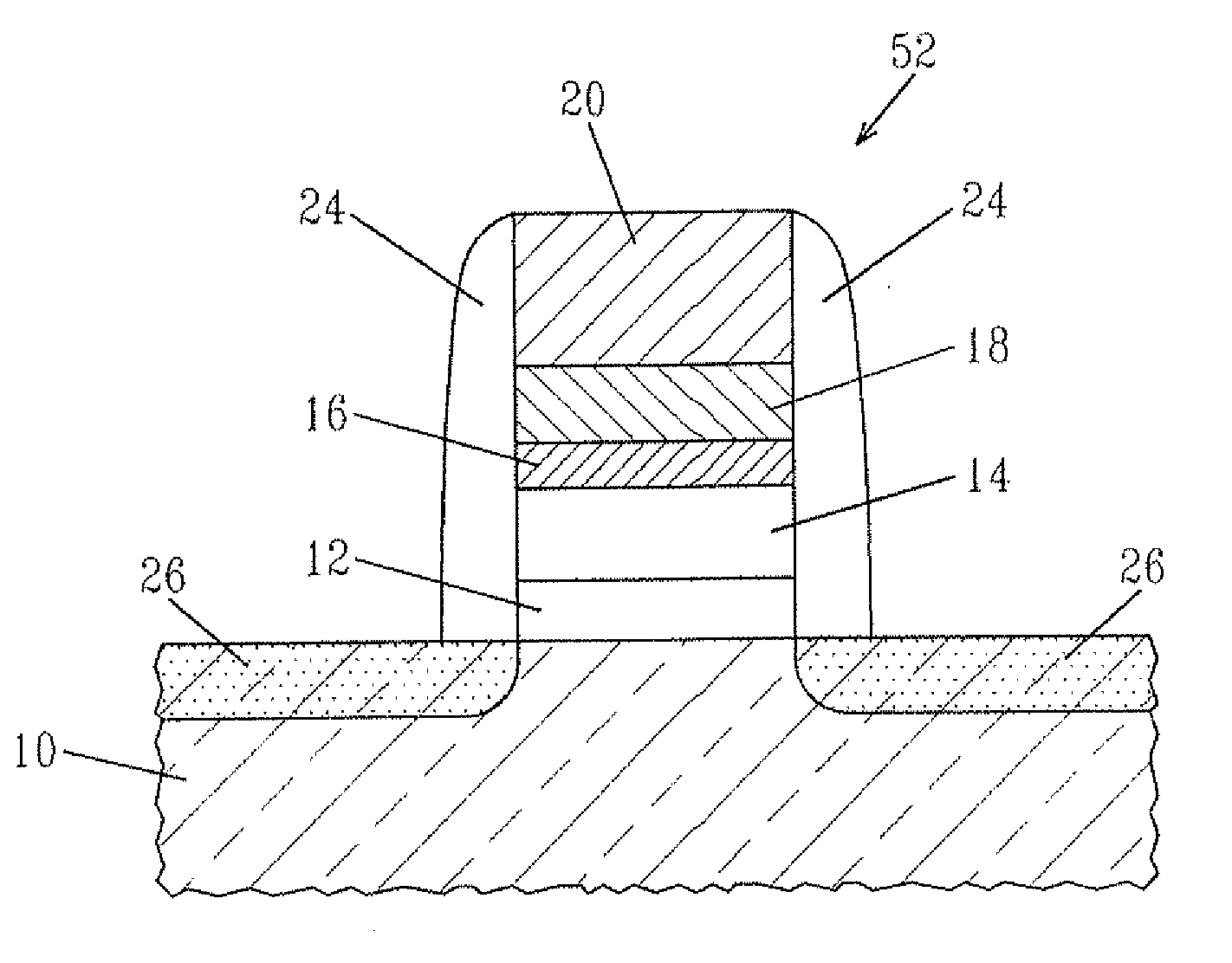

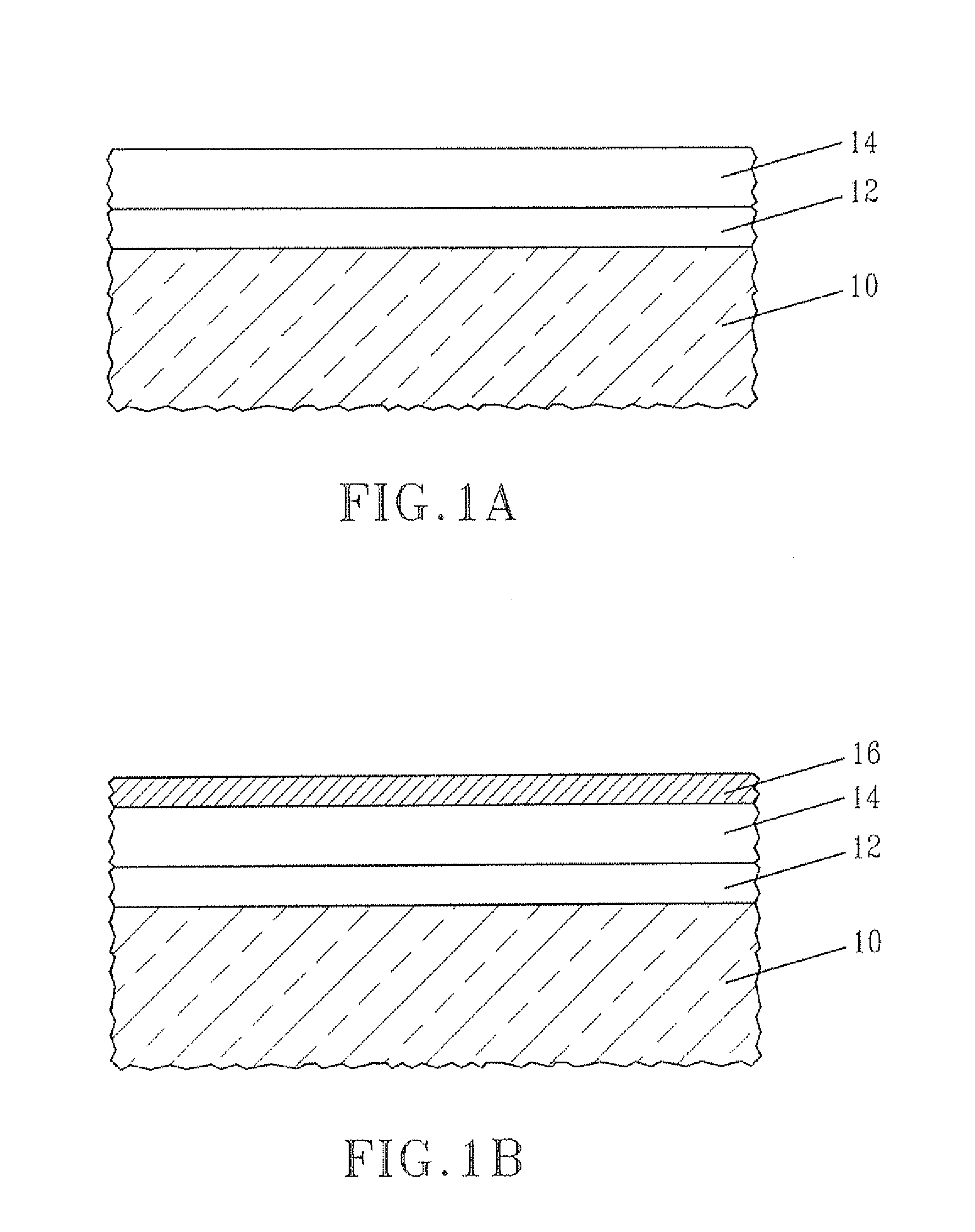

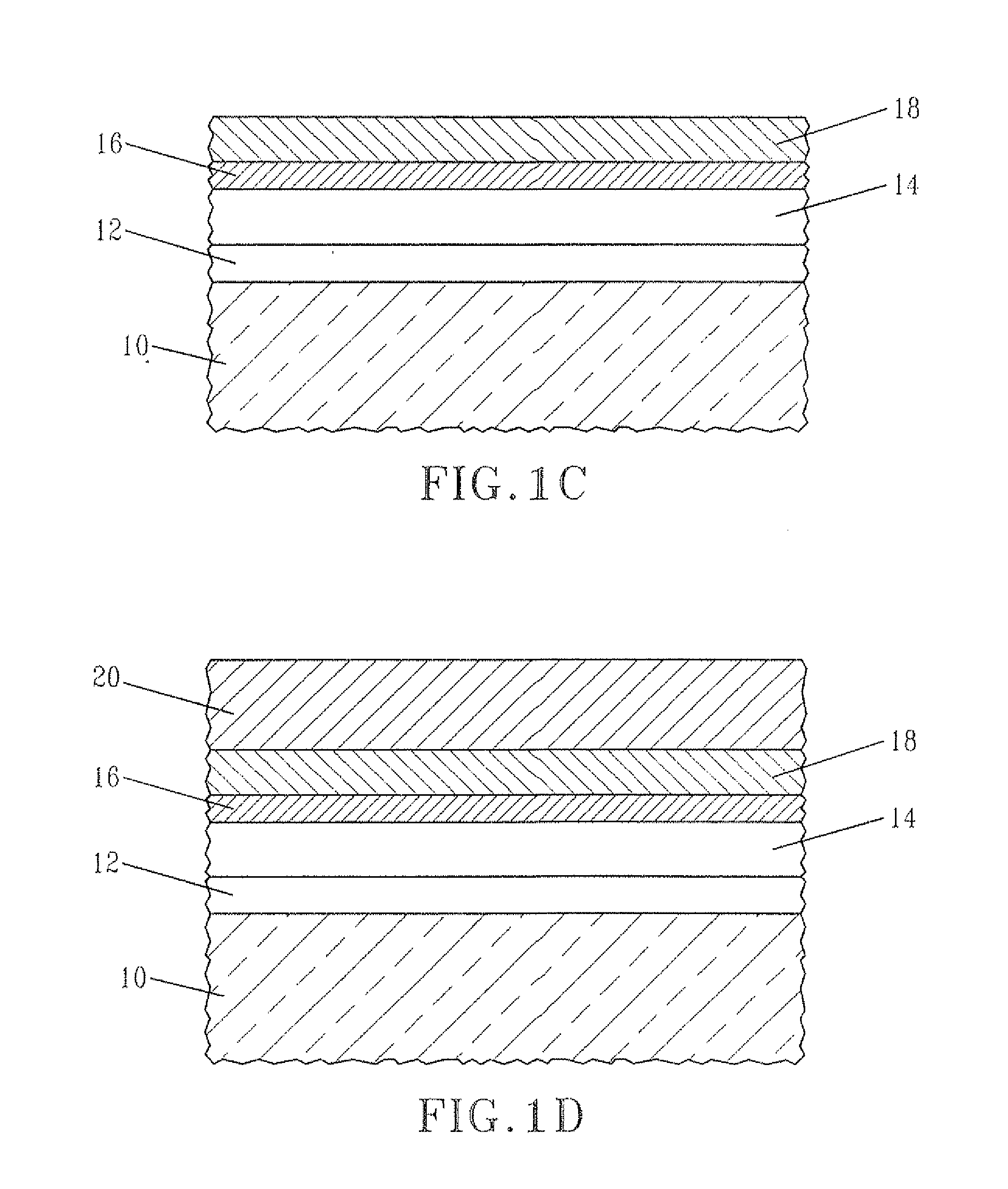

[0059]In this example, an nMOSCAP was prepared utilizing a material stack of the present invention and it was compared with a prior art nMOSCAP which did not include the inventive material stack. Specifically, a material stack comprising SiO2 / HfO2 / 0.8 nm La2O3 / 30 nm TiN / PolySi stack (Inventive) was prepared utilizing the processing steps mentioned above and that material stack was used as a component of an nMOSCAP. A prior art material stack, not including La oxide was prepared and was used a component for a prior art nMOSCAP (Prior Art). Each material stack after processing on a Si substrate was subjected to a 1000° C. rapid thermal anneal in nitrogen, followed by a 500° C. forming gas anneal.

[0060]FIG. 3 shows the CV curves of the two nMOSCAP. The CET (Capacitance Equivalent Thickness) and the EOT (Equivalent Oxide Thickness) of the Inventive material stack were 10.2 Å and 6.5 Å, respectively. The CET and the EOT of the Prior Art material stack were 14.7 Å and 10.5 Å, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com