Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Prevent oxidation and rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding fluid for metal processing and preparation method thereof

InactiveCN109536263AWith carrying capacityImprove permeabilityLubricant compositionChemical reactionHigh pressure

The invention relates to the field of metal cutting additives, in particular to a grinding fluid for metal processing and a preparation method thereof. According to a technical scheme adopted by the invention, the grinding fluid for metal processing is composed of the following components by weight percentage: 5-15% of a PH value stabilizer, 3-5% of a surfactant, 5-10% of a water-borne lubricant,5-15% of an antirust agent, 4-8% of a coupling agent, 0.2-1% of a bactericide, 0.1-1% of a defoamer, 1-3% of a corrosion inhibitor, 0.2-0.4% of a settling agent, and the balance deionized water. The invention has the advantages that: the grinding fluid for metal processing adopts triethanolamine oleate as the surfactant, has good permeability and wettability, is conducive to entering a high temperature and high pressure working face, and at the same time is also a lubricant, the molecule has strong polar groups, can achieve strong adsorption with the metal surface, and chemical reaction can becarried out to form a firm physical absorption film and chemical reaction film with certain carrying capacity.

Owner:上海加美实业有限公司

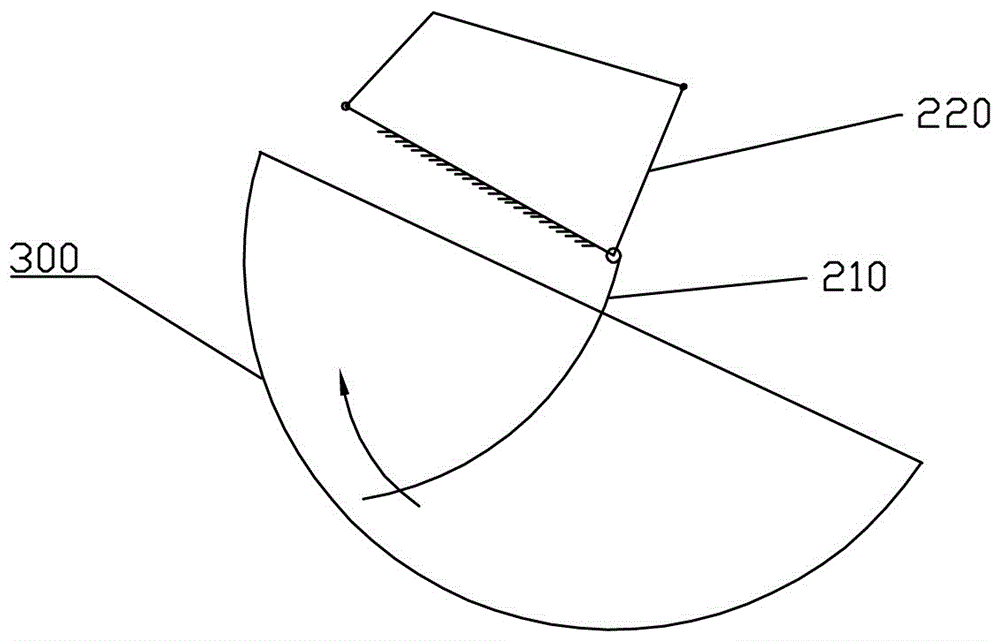

Spring

ActiveCN101338805AEliminate resonancePrevent oxidation and rustMultiple spring combinationsEngineeringDamping ratio

The present invention belongs to a spring. A damping structure, which can damp the motion of the spring and contains high-damp liquid material, is arranged on the body of the spring. Since the damping structure is arranged on the body of the spring, when the spring is stressed to generate vibration or deformation, the high-damp liquid material is also deformed, great internal friction is generated inside the high-damp liquid material to absorb partial energy, so that the deformation is hindered and the vibration is attenuated, and since noise is also caused by the vibration, the noise is greatly reduced as well. Since the spring adopts the highly viscous high-damp liquid material, the spring can provide a relatively high damping ratio, which is sufficient for the vibration reduction of most of mechanical devices and vehicle structures, and even in a case requiring a high damping ratio, the needed extra damp is much less. Normally, an additional damping device is no longer needed, and therefore the structure is simplified. Moreover, the spring effectively eliminates the sympathetic vibration of self under the inherent frequency.

Owner:尹学军

Enhancement paster matrix, enhancement paster and steel plate composite material

ActiveCN102206400APrevent oxidation and rustReduce adhesionSynthetic resin layered productsRubber layered productsEpoxyNitrile rubber

The invention provides an enhancement paster matrix, an enhance paster and a steel plate composite material. The enhancement paster matrix, which contains epoxy resin, nitrile rubber, a filling material and a curing agent, is characterized in that the enhance paster matrix also contains adhesion promoting resin and the adhesion promoting resin contains styrene-ethene / butylene-styrol copolymer or styrene-butadiene-styrene copolymer. The enhancement paster prepared by the enhancement paster matrix has a high adhesion on the surface of steel plates, and especially antirust oil on the surface of steel plates has no impact on the adhesion.

Owner:BYD CO LTD

Chemical detergent for clearing hard scales from air pre-heater and preparation method thereof

InactiveCN107674778AEasy to cleanNo corrosionInorganic/elemental detergent compounding agentsCationic surface-active compoundsPentaerythritolPhosphate

The invention discloses a chemical detergent for clearing hard scales from an air pre-heater, and belongs to the technical field of detergents. The chemical detergent is prepared from the following ingredients in parts by weight: 22-25.5 parts of 3-methoxy propylamine, 8.3-9.7 parts of pentaerythritol phosphate, 11.2-12.9 parts of N,N-dimethylacetamide, 1.4-2.6 parts of sodium hydroxide, 18.8-20 parts of trisodium phosphate, 7.3-8.8 parts of corrosion inhibitor, 5.6-6.4 parts of stripper, 3.2-4.1 parts of penetrant, 2.5-3.3 parts of surfactant, 8.7-9.6 parts of scale inhibitor, 3.5-4.4 parts of dispersant and 45-58 parts of water. The detergent provided by the invention has the advantages of good comprehensive performance, remarkable cleaning effect and stable performance, and can form a protective layer on the surface of the air pre-heater to play roles in inhibiting scales and preventing rust, and thus, the service life of the air pre-heater is prolonged.

Owner:NANYANG INST OF TECH

Thermal treatment method of martensitic stainless steel liner plate

ActiveCN104060054AReduce crackingImprove final organizationFurnace typesHeat treatment process controlMartensitic stainless steelRoom temperature

The invention provides a thermal treatment method of a martensitic stainless steel liner plate. The thermal treatment method comprises the following steps: quenching for the first time, namely increasing the temperature from the room temperature to 700 DEG C at a temperature increasing rate of less than or equal to 50 DEG C per hour, equalizing the temperature at 700 DEG C for 3 hours, increasing the temperature from 700 DEG C to 980 DEG C at a temperature increasing rate of less than or equal to 40 DEG C per hour, preserving heat at 980 DEG C for more than 5 hours, and then cooling to 60 DEG C; quenching for the second time, namely increasing the temperature from the room temperature to 700 DEG C at the temperature increasing rate of less than or equal to 50 DEG C per hour, equalizing the temperature of the liner plate at 700 DEG C for 4 hours, increasing the temperature from 700 DEG C to 980 DEG C by the temperature increasing rate of less than or equal to 40 DEG C per hour, preserving heat at 980 DEG C for more than 6 hours, and then cooling to 60 DEG C and carrying out medium-temperature tempering; medium-temperature tempering, namely increasing the temperature from the room temperature to 350 DEG C at a rate of less than or equal to 50 DEG C per hour, preserving heat at 350 DEG C for 1 hour, increasing the temperature from 350 DEG C to 500 DEG C at the temperature increasing rate of less than or equal to 50 DEG C per hour, preserving heat at 500 DEG C for more than 8 hours, and then taking out the liner plate out of an oil tank after the oil is cooled below 100 DEG C. The thermal treatment method has the advantages that the thermal treatment process of double continuous quenching is adopted and the twice quenching is carried out continuously without time interval, and therefore, the cracking of the liner plate during quenching is reduced, the grain size is refined to the utmost extent and the comprehensive mechanical properties of the liner plate are improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

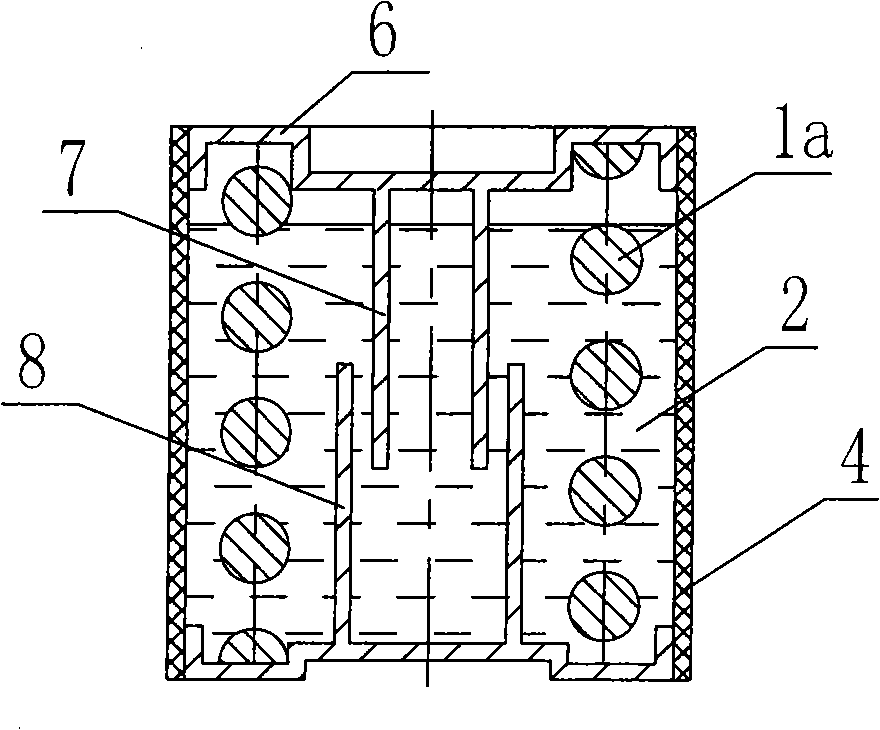

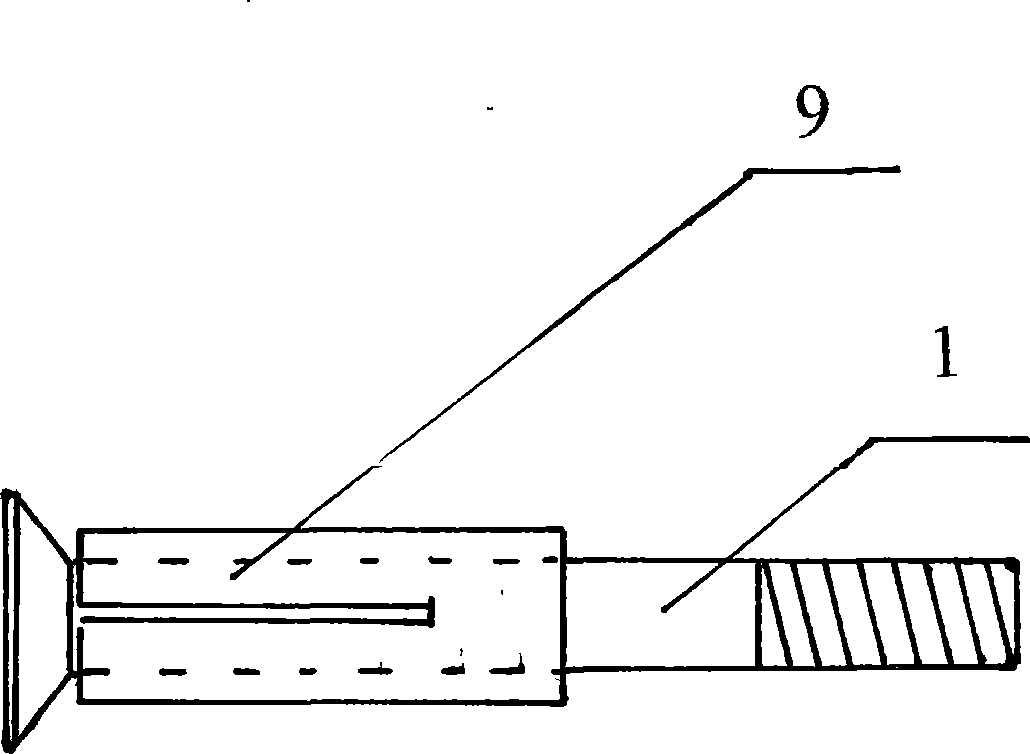

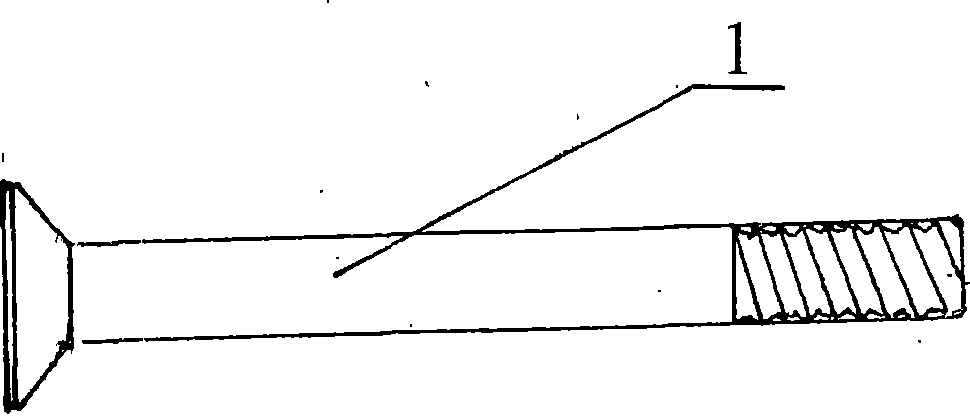

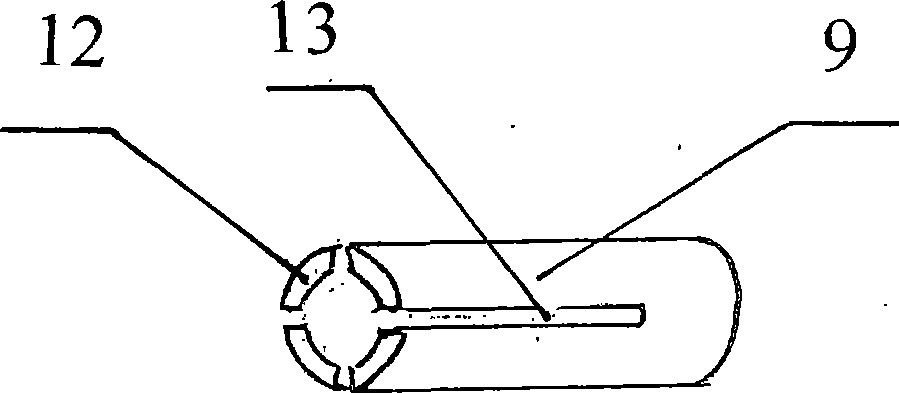

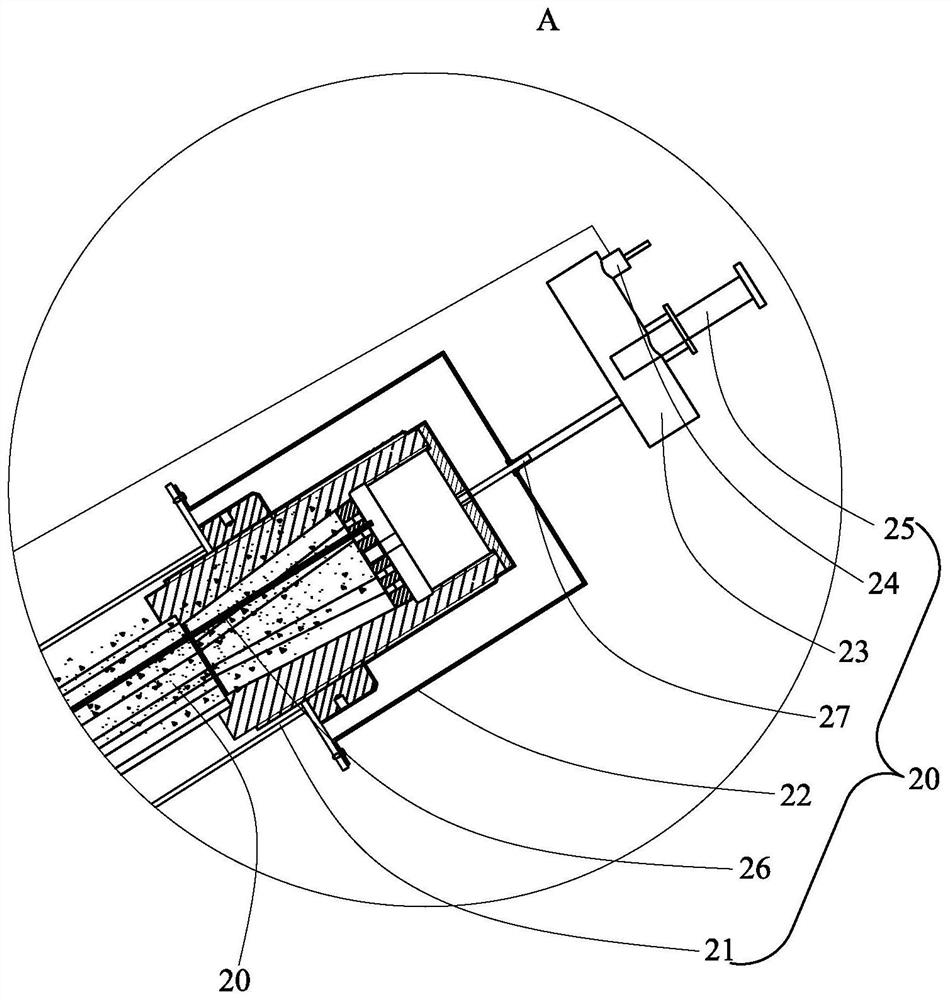

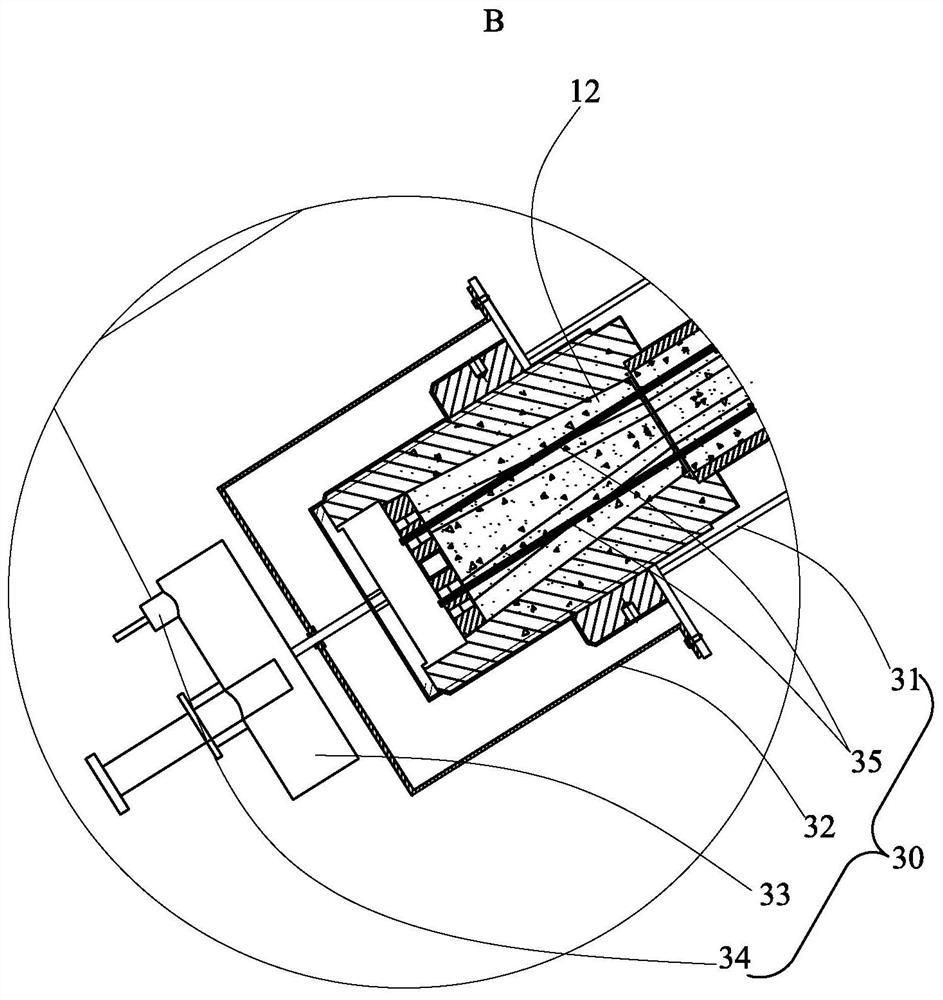

Extending-bulging type glue fixing nail and use method

The invention relates to an expansion adhesive fastening nail and a use method thereof, wherein the expansion adhesive fastening nail consists of a big-end tube expansion nail, an expansion sleeve, a hanging piece head and adhesive; the big-end tube expansion nail (1) is matched with the expansion sleeve (9) and is fixed with a wall body; an expansion plate (12) expands to exceed the nail head of the big-end tube expansion nail (1) and splits into the shape of petals; the nail head of the big-end tube expansion nail (1) is clamped at a petaloid bottom to increase pulling resistant and shear resistant; therefore, the nail is particularly suitable to install various equipment and veneers on floppier wall bodies such as an autoclaved aerated concrete wall body, thereby ensuring the longtime safety and steadiness of a project; moreover, the member saves raw material and reduces cost along with a reasonable and convenient use method. Obviously, the nail and the method have high use value and enormous social benefits and economic benefits.

Owner:郭祥山

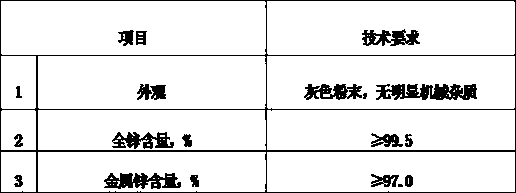

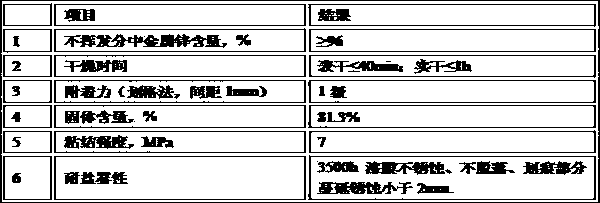

Cold-zinc-spray long-acting anti-corrosive coating

InactiveCN103965786AImprove water resistanceImprove aging resistanceAnti-corrosive paintsZincBonding strength

The invention discloses a cold-zinc-spray long-acting anti-corrosive coating. The coating comprises the components in a weight ratio: 11%-14% of silicone-grafted polymer, 78%-83% of ultrafine zinc powder and 6%-8% solvent gasoline. Compared with existing similar products, the product, of which the content of metallic zinc in dry paint film is greater than 96%, has the same antirust effect as hot galvanizing and a steel structure is protected from being corroding for 20-25 years in a severe marine-atmosphere environment; the anti-corrosive coating has the advantages of high bonding strength, salt-spray corrosion resistance, single component and convenience in construction and operation and the service life of the steel structure is significantly prolonged.

Owner:江苏山力漆业有限公司

Falling-off-preventing metal coating and preparation method thereof

InactiveCN106046868ACoating AdhesionEffective attachmentAnti-corrosive paintsMetal coatingHydrogen phosphate

The invention discloses a falling-off-preventing metal coating and a preparation method thereof. The falling-off-preventing metal coating comprises raw materials in parts by weight as follows: 10-20 parts of polyether silicate ester, 20-30 parts of gamma-valerolactone, 40-60 parts of 2-ethyl-1,6-hexanediol, 10-50 parts of zinc, 10-20 parts of calcium oxide, 2-5 parts of an anti-rusting agent, 100-120 parts of nano-silica, 50-80 parts of nano-titania, 10-60 parts of thiourea, 20-30 parts of diammonium hydrogen phosphate and 40-50 parts of water. The preparation method of the falling-off-preventing metal coating comprises steps as follows: polyether silicate ester, gamma-valerolactone, 2-ethyl-1,6-hexanediol, zinc, calcium oxide, the anti-rusting agent, thiourea, diammonium hydrogen phosphate and water are mixed uniformly, then the remaining components are added, and a metal surface subjected to deoiling, annealing and borax processing is coated with an obtained solution and is dried and sintered. The coating can be effectively attached to the metal surface, thereby preventing metal from rusting and oxidation.

Owner:WUXI EPIC TECH

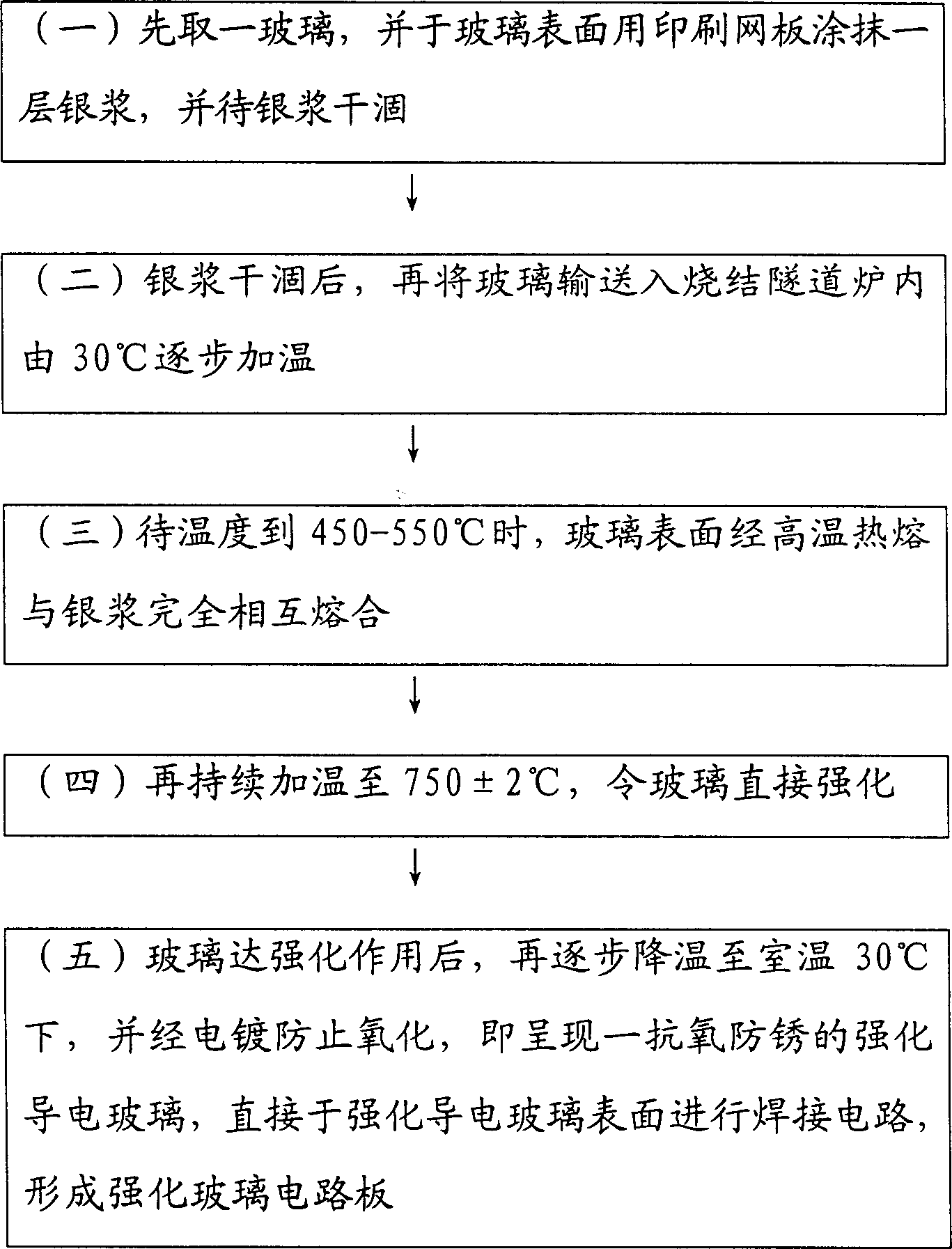

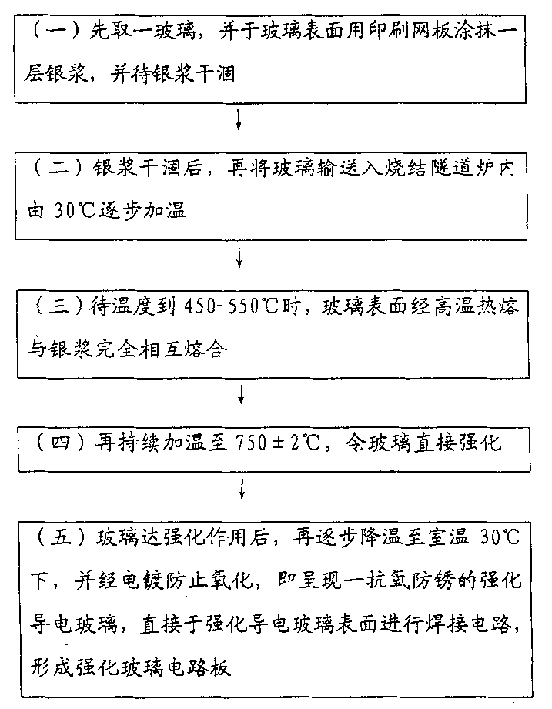

Technology for making strengthened glass circuit board and its product and application

InactiveCN1383355ATo achieve the purpose of environmental benefitsImprove convenienceTransparent/reflecting heating arrangementsConductive pattern formationRoom temperatureHot melt

This invention relates to a processing method and its appliances containing uniform coating a layer of silver brei on a glass surface by a printed raster. The glass is heated from 30 deg.c to 450-550deg.c after dried. This time the glass surface is completely fused with the silver brei under hot smelting again continuously heated to 750 minus or plus 2 deg.c to get the tempered glass. Then the temperature is reduced to room temperature and a tempered glass circuit board is finished. Circuit can be directly welded on the glass surface which substitutes any conductive tempered glass.

Owner:SHANG CHUEN WEIGHTING MACHINE

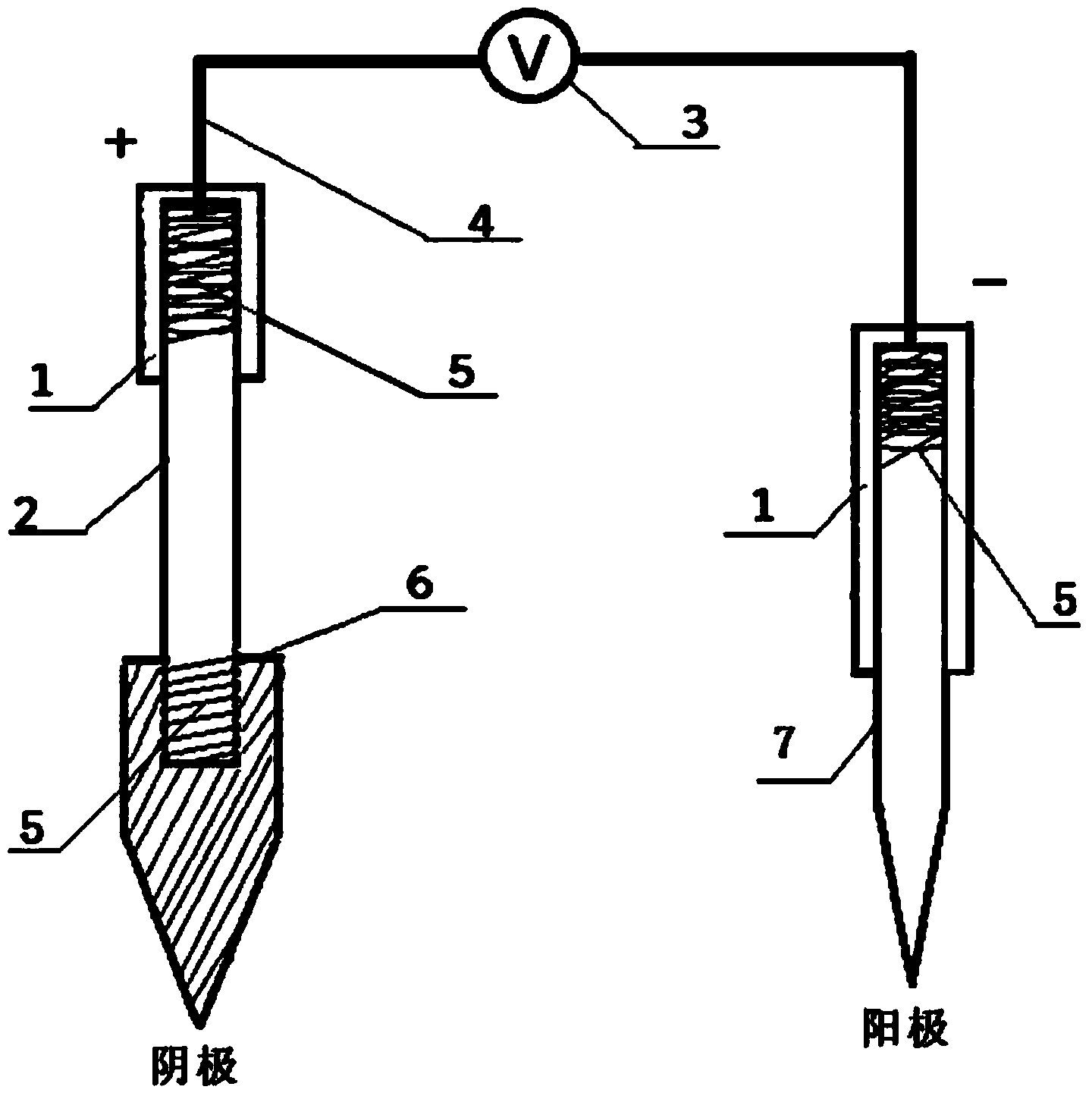

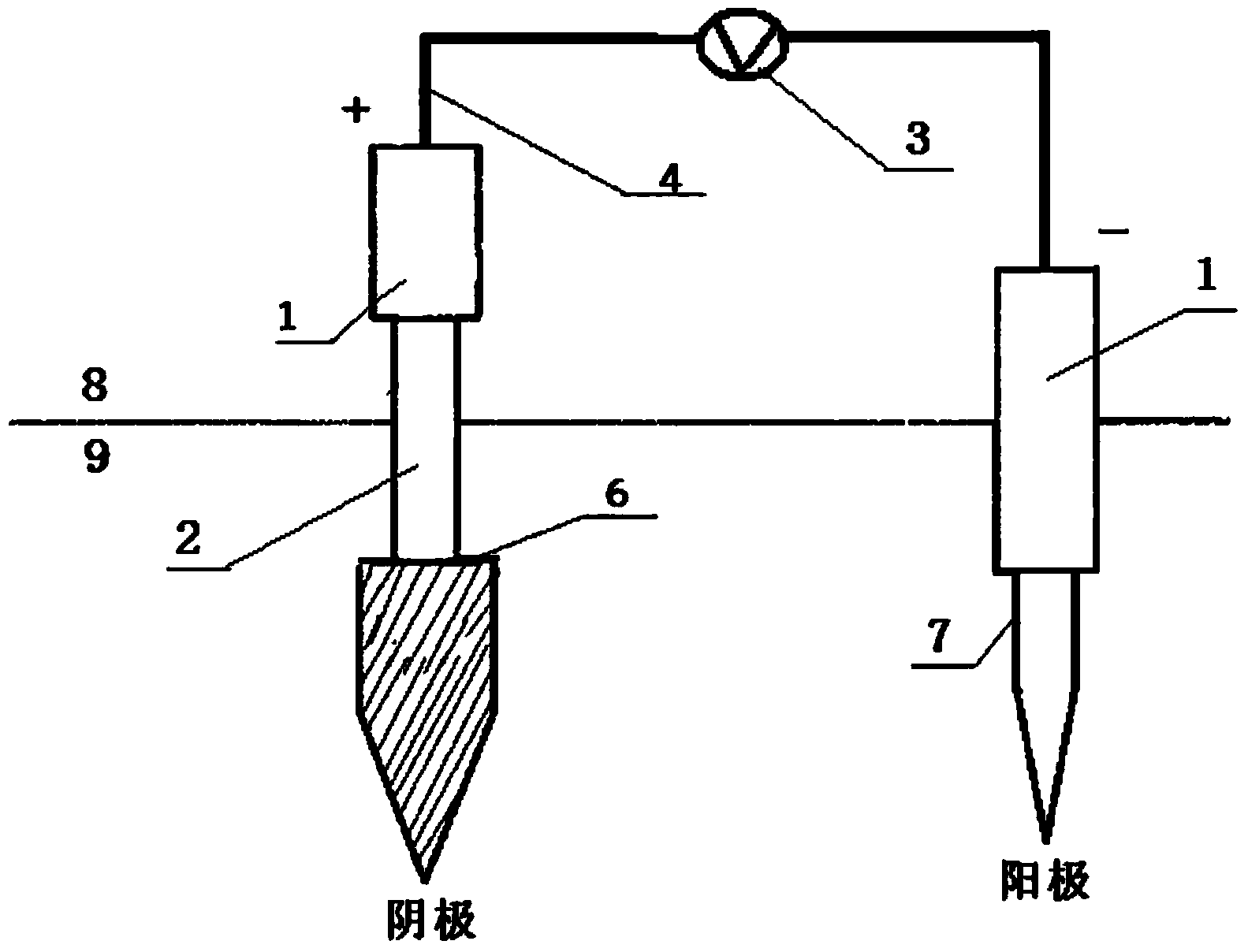

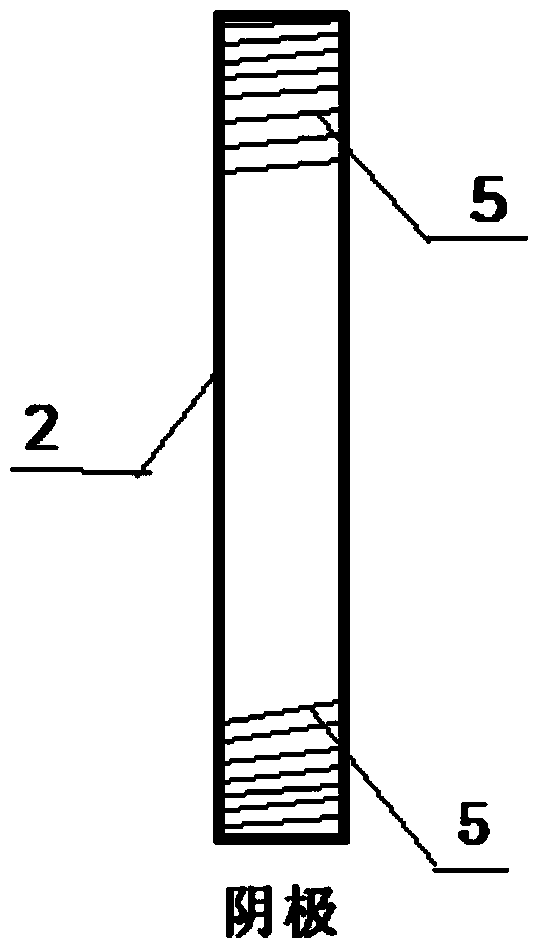

Soil microbial fuel cell taking graphite rods as electrodes and application of soil microbial fuel cell

InactiveCN104241669AEasy to insertNot easy to rust and wearCell electrodesBiochemical fuel cellsCopper wireVoltmeter

The invention relates to a soil microbial fuel cell taking graphite rods as electrodes. The soil microbial fuel cell comprises a cathode graphite rod, a voltmeter and an anode graphite rod, wherein the voltmeter is connected with the cathode graphite rod and the anode graphite rod respectively through a conductive wire, upper parts of the cathode graphite rod and the anode graphite rod are wound with copper wires connected with the conductive wire, the upper part of the anode graphite rod is sleeved with an insulating sheath, a thread is formed at the lower part of the cathode graphite rod, the lower part of the cathode graphite rod is matched and connected with the insulating sheath through the thread, and the lower parts of the insulating sheath and the anode graphite rod are tapered. The soil microbial fuel cell is inserted into soil more easily, greater damage to a soil structure and plant roots is avoided, the contact area of the anode graphite rod with an electrolyte in the soil is increased, and electron exchange and higher voltage output are facilitated; and the graphite rods which are low in cost, soft and easy to process, and materials are easy to obtain, so that the graphite rods are good electrode materials.

Owner:李一啸

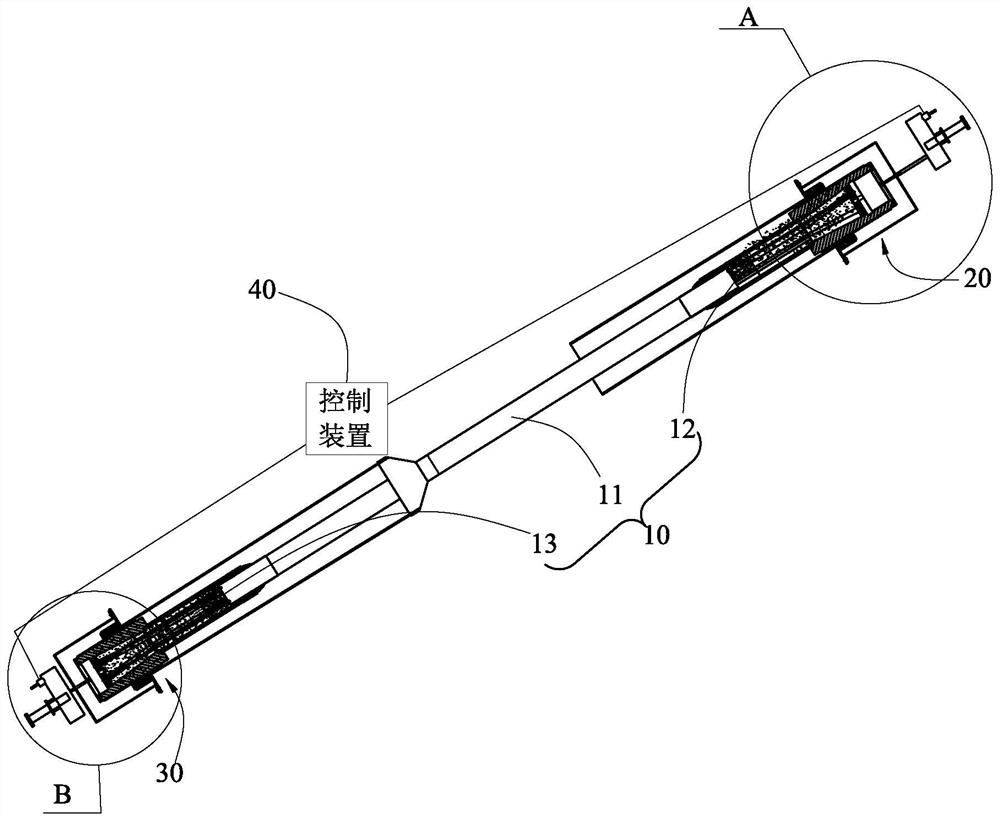

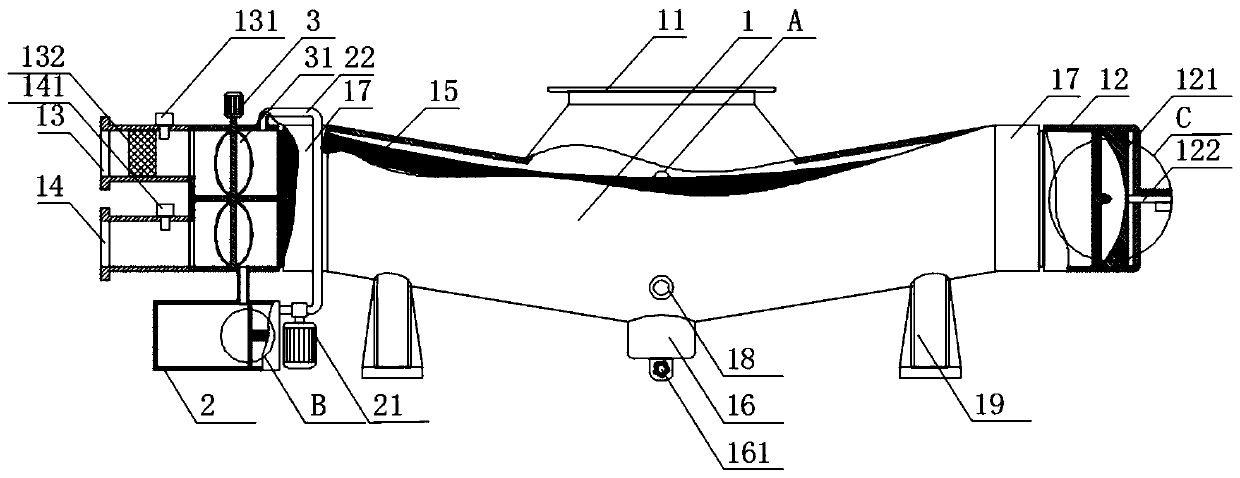

Dehumidification system used for inhaul cable protection, anchoring and air inflow

PendingCN111648242APrevent oxidation and rustExtended service lifeMeasurement devicesBridge structural detailsEngineeringMechanical engineering

A dehumidification system used for inhaul cable protection, anchoring and air inflow comprises an inhaul cable body, an upper anchorage device protection mechanism and a lower anchorage device protection mechanism. The upper anchorage device protection mechanism comprises an upper cable guide pipe, an upper anchorage device protection cover, an air inlet base, an air inlet pipe and a pressure sensor. The air inlet pipe is communicated with the inhaul cable body so as to press protective gas into the inhaul cable body. The lower anchorage device protection mechanism comprises a rainproof cover,a lower anchorage device protection cover, an air leakage base and a lower anchorage temperature and humidity sensor. The lower anchorage temperature and humidity sensor is used for detecting the temperature and humidity in the lower anchorage device protection cover, introducing protective gas from the air inlet pipe according to the temperature value and the humidity value, and then enabling the pressure in the inhaul cable body to reach a preset value under the monitoring of the pressure sensor. According to the dehumidification system for inhaul cable protection, anchoring and air inflow,oxidation corrosion of steel wires in the cable strands of the inhaul cable due to too high relative humidity can be prevented, so that the service life of the inhaul cable can be greatly prolonged,and the maintenance and operation cost of a bridge is saved.

Owner:SHANGHAI PUJIANG CABLE +1

Chemical polishing solution of sintered NdFeB permanent magnet material and processing method

The invention relates to a chemical polishing solution of a sintered NdFeB permanent magnet material and a processing method. The chemical polishing solution uses water as a solvent and mainly comprises three solutes of nitric acid, phosphoric acid and sulfuric acid. The processing method comprises the following steps: alkaline washing an NdFeB permanent magnet to degrease; dipping the sintered NdFeB permanent magnet into the chemical polishing solution to polish; and then washing and activating the chemically polished NdFeB permanent magnet to complete the whole polishing process, wherein thesintered NdFeB permanent magnet needs to be turned during chemical polishing, and the dipping polishing time of the sintered NdFeB permanent magnet is 10-120s. After the polishing, low-concentrationnitric acid can also be adopted to remove an oxidation film, and alkalescent trisodium citrate which is organic aluminate can be adopted to neutralize surface residual acid. The polishing solution hassimple component and convenient control; and an obtained chemical polishing surface has good glossiness and smooth surface and can be matched with other chemical processing links.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

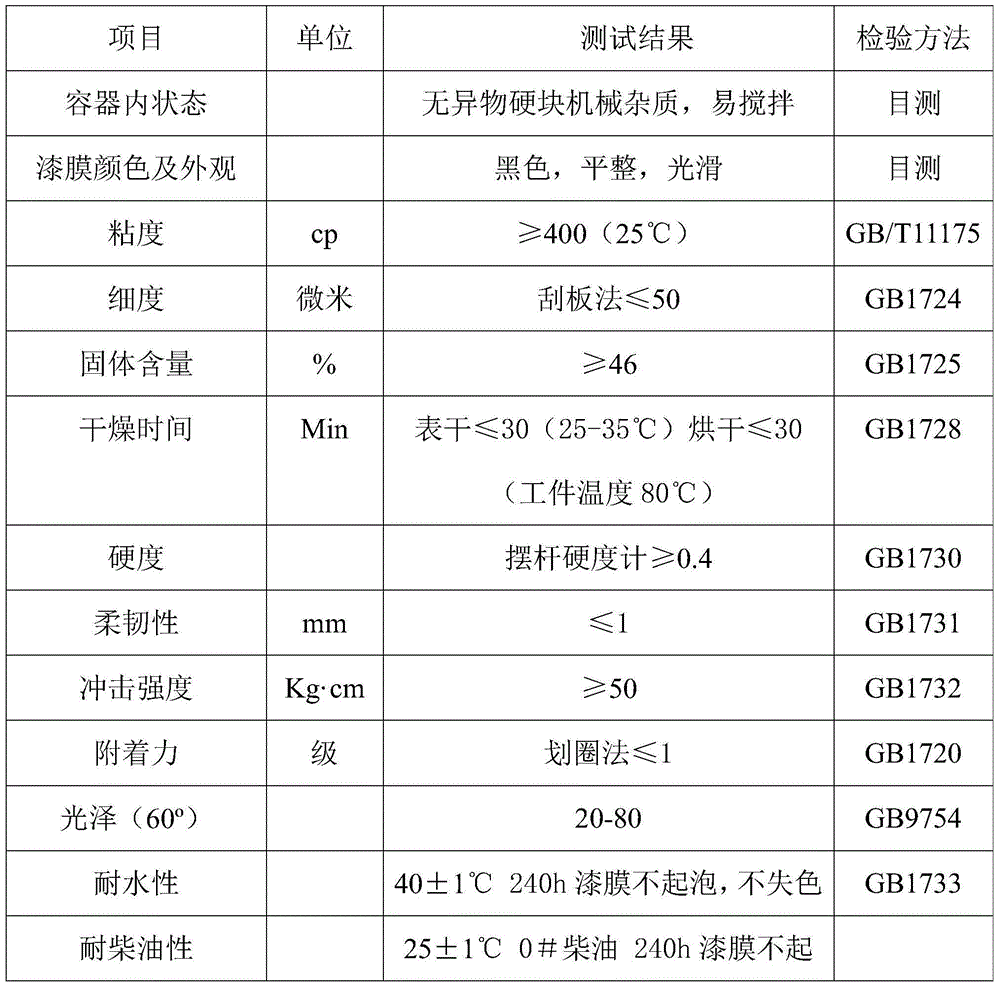

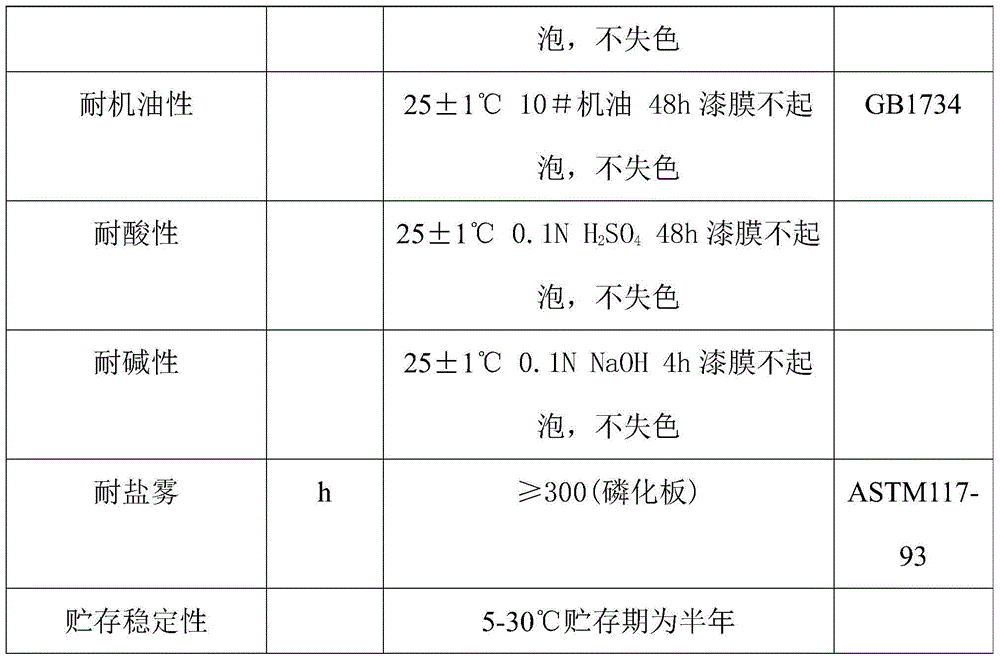

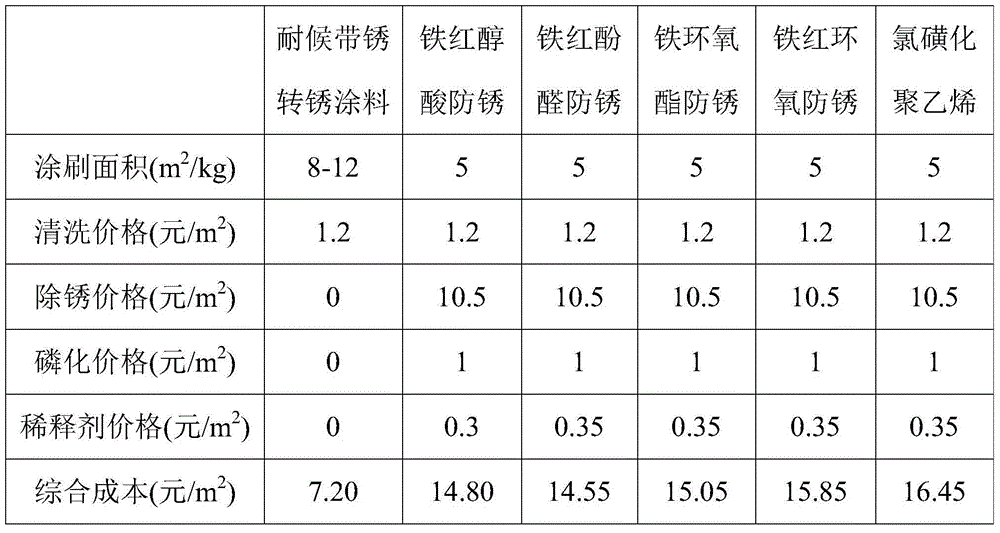

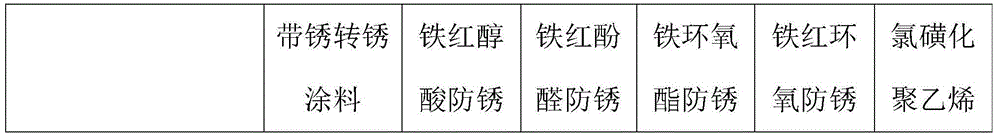

Weathering resistance rust-conversion coating material with rust

InactiveCN103980784APrevent oxidation and rustNo secondary pollutionAnti-corrosive paintsAdhesivePhosphoric acid

The present invention discloses a weathering resistance rust-conversion coating material with rust. According to the coating material, a rust-conversion agent, a wetting agent, a dispersing agent, an antifoaming agent, an anti-flashrust agent and a thickener are sequentially added to distilled water, and uniform stirring is performed to obtain a first material, wherein the rust-conversion agent comprises 75-80 wt% of phosphoric acid and 20-25 wt% of tannic acid; a pigment filler is added to the first material, and high speed and uniform stirring is performed to obtain a second material; a nature plant polyphosphate, potassium ferrocyanide and an acrylic acid adhesive liquid are subjected to copolymerization preparation synthesis to obtain a resin emulsion; and the resin emulsion and a film forming auxiliary agent are added to the second material, and uniform stirring is performed to obtain the weathering resistance rust-conversion coating material, wherein a weight ratio of the second material to the resin emulsion to the film forming auxiliary agent is 1-3:15-24:0.5-0.75, and the stirring speed is 35-42 r / min. The weathering resistance rust-conversion coating material has characteristics of low environmental pollution, strong weathering aging resistance, strong light aging resistance, and strong chemical corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Heat treatment method of transmission metal chain

InactiveCN107447093AImprove wear resistanceLess prone to stickingSolid state diffusion coatingFurnace typesTime rangeHeating furnace

The invention discloses a heat treatment method for a transmission metal chain, which relates to the technical field of chains; it includes the following steps: A. Carburizing treatment: each component of the transmission metal chain is put into a carburizing furnace for carburizing treatment, and the carburizing temperature is 750 ℃ ~ 800 ℃, carburizing time 50 minutes ~ 70 minutes, tempering temperature 360 ℃ ~ 400 ℃, tempering time 40 minutes ~ 50 minutes; B, quenching: put each part of the transmission metal chain into two heating Oil cooling after heating in the furnace; C. Tempering: Temper and heat all parts at medium temperature and then air cool with the furnace. Compared with the prior art, the present invention can solve the problem in the prior art that parts are easily damaged when heat treatment is performed to improve the wear resistance of the transmission metal chain.

Owner:河池桂嘉知识产权服务有限公司

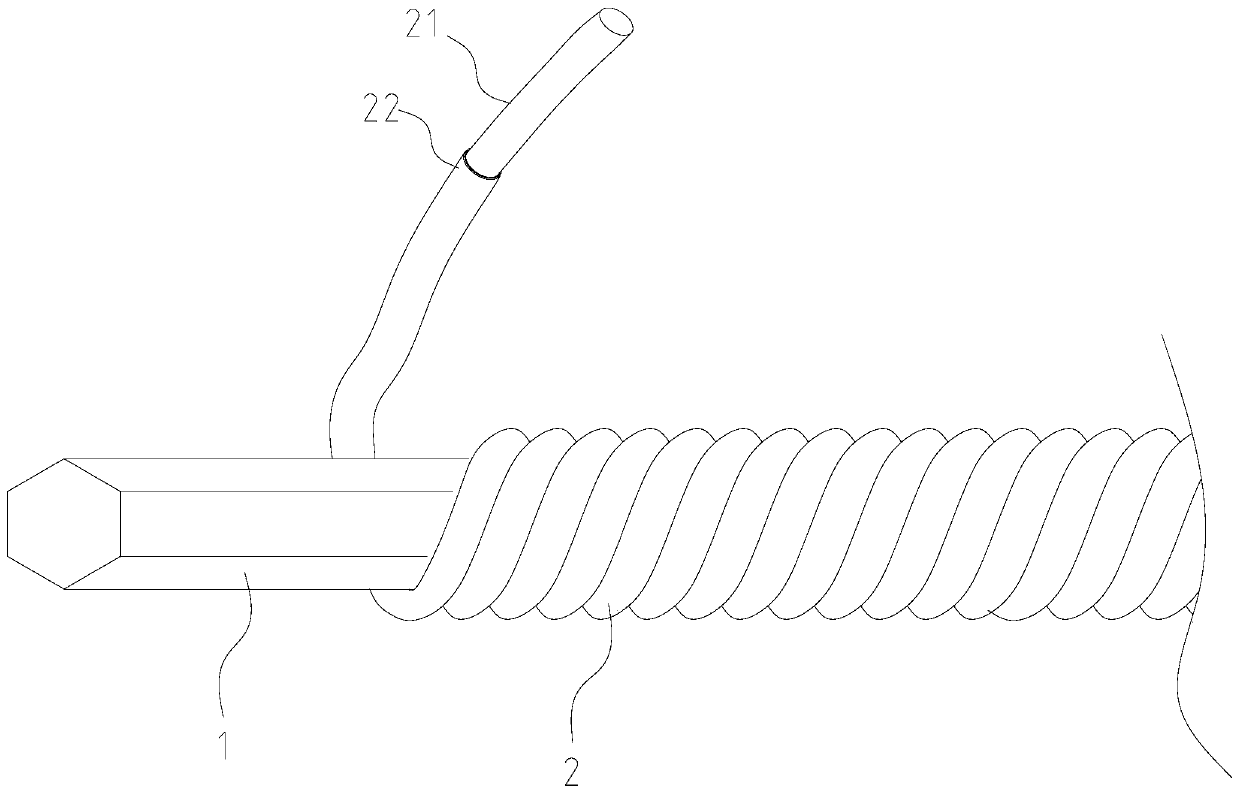

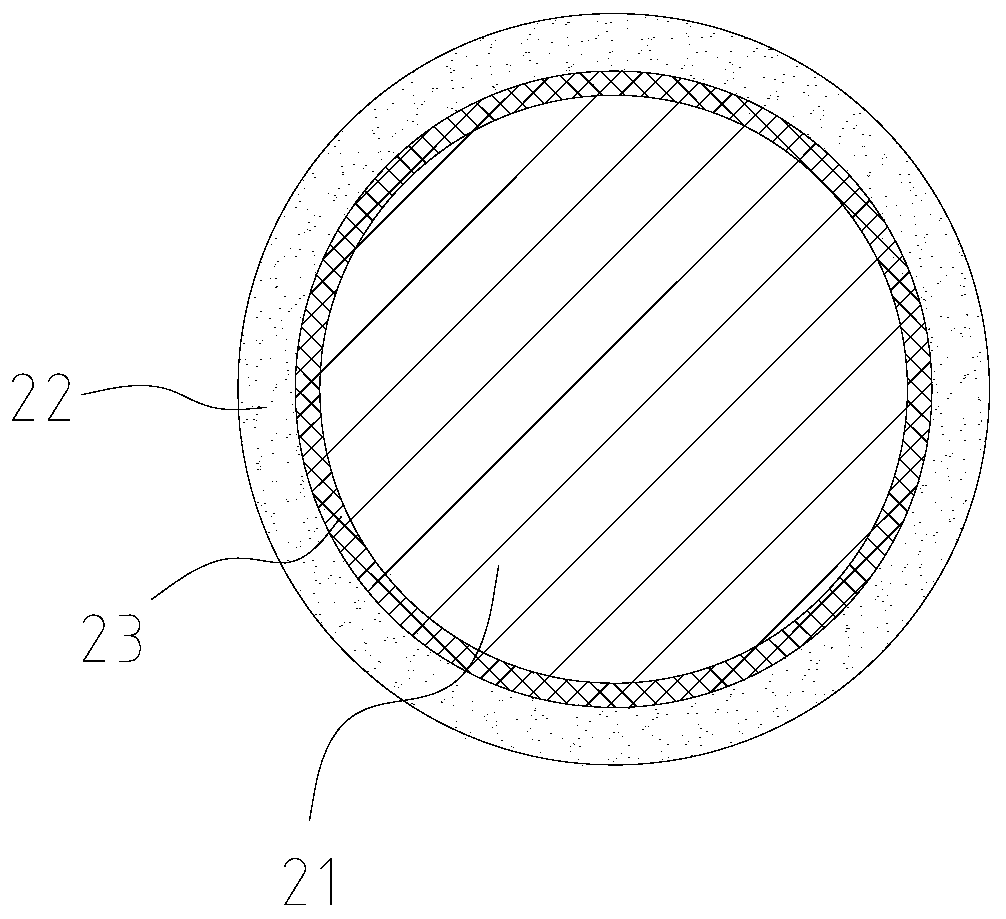

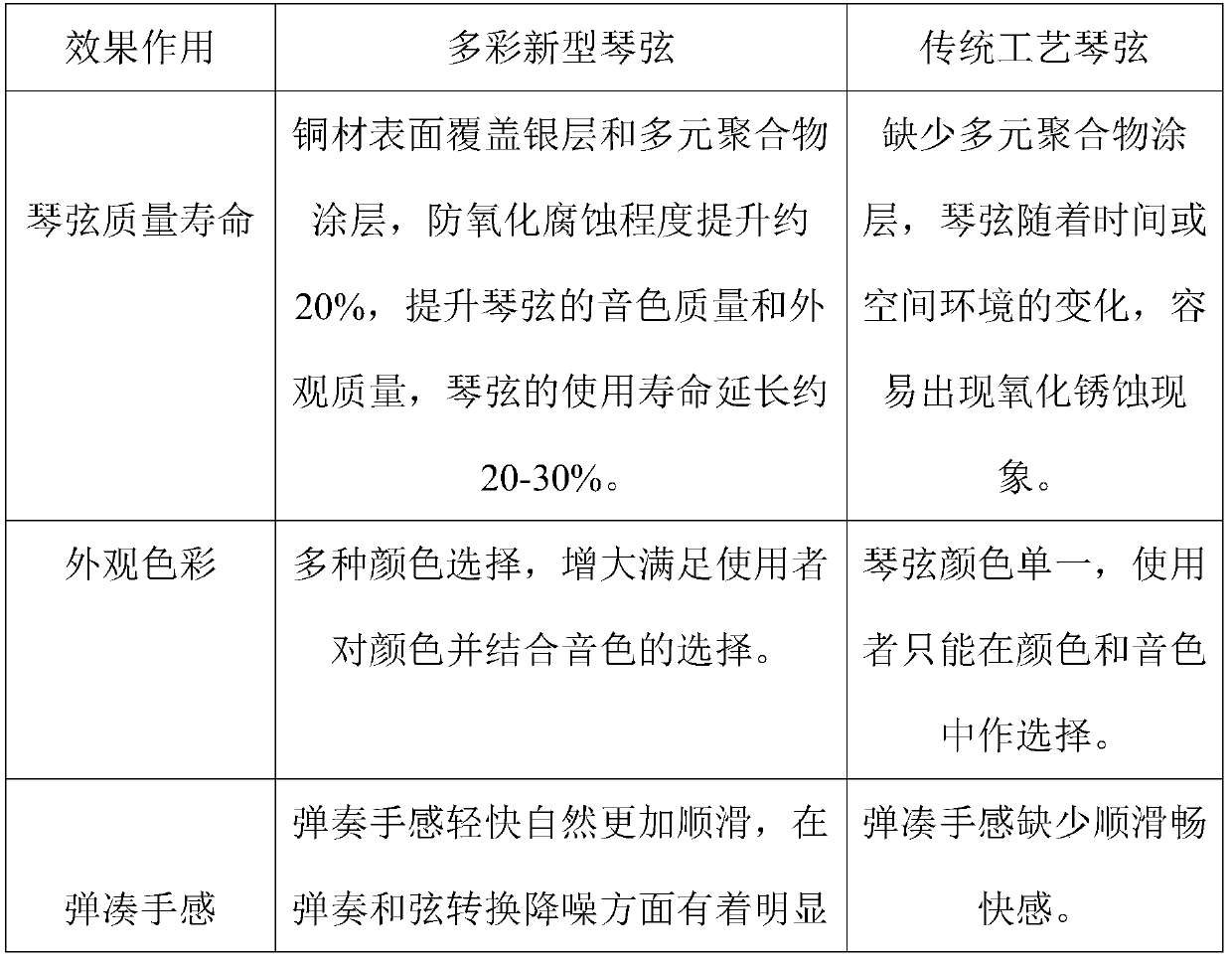

String and preparation method thereof

PendingCN110517651AImproved quality and anti-oxidation corrosionImproves tarnish resistanceStringed musical instrumentsCopper wireMetallurgy

The invention relates to a string and a preparation method thereof. The string comprises a string core and a winding string wound on the string core, the winding string comprises a copper wire, a silvered layer covering the surface of the copper wire and a protection layer covering the outside of the silvered layer, and the protection layer is formed by mixing paint and metal powder. The manufacturing method comprises the following steps: (1) manufacturing the string core and the winding string; and (2) winding the winding string on the string core, wherein the winding string manufacturing process comprises the following steps: (1.1) using a copper wire as a base material; (1.2) plating a silver layer on the copper wire; and (1.3) covering the protection layer on the silver layer, whereinthe protection layer is formed by mixing and blending the paint and the metal powder. According to the string and the preparation method thereof in the invention, on the premise of ensuring the tone of the string, the color of the string can be changed.

Owner:GUANGZHOU ROMANCE MUSICAL INSTR

Flange

The invention relates to a flange and belongs to the technical field of design of flange equipment. The flange comprises a first flange plate and a second flange plate; both the first flange and the second flange are provided with corresponding mounting holes; and bolts pass through the mounting holes in the first flange plate and the mounting holes in the second flange plate to be screwed down and connected with nuts. The flange is characterized in that the peripheries of the mounting holes at both sides of the first flange plate are provided with convex sealing gaskets; the periphery of each mounting hole at one side of the second flange plate, which is in contact with the first flange plate, is provided with a circle of groove matched with the convex sealing gaskets; the periphery of each mounting hole at the other side of the second flange plate is provided with a circle of convex sealing gasket; and 2 to 10 mounting holes are respectively formed in the first flange plate and the second flange plate. The flange has a reasonable and simple structure and is easy to produce and manufacture; and in the specific using process of the flange, water is often effectively prevented from being leaked into the mounting holes; and the condition that the bolts are oxidized and rusted and even cannot be taken out of the mounting holes is prevented.

Owner:扬州宝澄锻造法兰有限公司

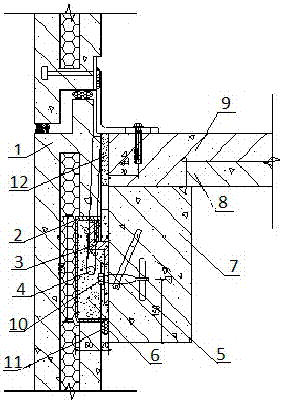

Anti-corrosion structure and construction method of dry-hanging node of prefabricated building exterior wall

ActiveCN105178451BWon't fall offImprove assembly efficiencyCovering/liningsBuilding material handlingCement slurryWall plate

An anti-corrosion structure and a construction method of a dry-hanging joint of an exterior wall of a prefabricated building, the dry-hanging joint of an exterior wall includes a pre-embedded box embedded in a prefabricated dry-hanging exterior wall panel and a hook seat fixedly connected to a building body The upper part of the hook seat passes through the side opening of the pre-embedded box and enters the upper part of the inner cavity of the pre-embedded box to support the entire prefabricated dry-hanging exterior wall panel; The grouting pipe in the inner cavity of the box, at the same time, in the construction gap between the prefabricated dry-hanging outer wall panel and the main body of the building, there are U-shaped foam rods surrounding the dry-hanging nodes of the outer wall, and the U-shaped foam rods in the pre-embedded box Inject filling cement slurry into the surrounding construction gaps to wrap the entire dry-hanging node. The invention can make the dry-hanging nodes long-term anti-corrosion, ensure that the external wall boards do not fall off, have a long service life, and ensure building quality and safety performance.

Owner:HUNAN YUANDA CONSTR ENG CO LTD

Full synthetic cutting fluid

InactiveCN109536264AImprove the lubrication effectDistributedLubricant compositionEngineeringShort terms

The invention relates to the field of metal cutting additives, in particular to a full synthetic cutting fluid. According to a technical scheme adopted by the invention, the full synthetic cutting fluid is composed of the following components by weight percentage: 5-10% of a water-soluble extreme pressure additive, 3-5% of a surfactant, 5-15% of a rust inhibitor, 4-8% of a lubricant, 5-20% of a cosolvent, 5-10% of a triazole corrosion inhibitor, 0.2-1% of a bactericide, 0.1-1% of a defoamer, 1-2% of a synthetic additive, and the balance deionized water. The full synthetic cutting fluid provided by the invention has the advantages of: strong anti-rust ability, good ability for preventing workpieces from oxidizing and rusting, a maximum three-month (indoor) short-term rust protection effectaccording to different storage conditions, and strong hard water adaptability and physicochemical stability at the same time.

Owner:上海加美实业有限公司

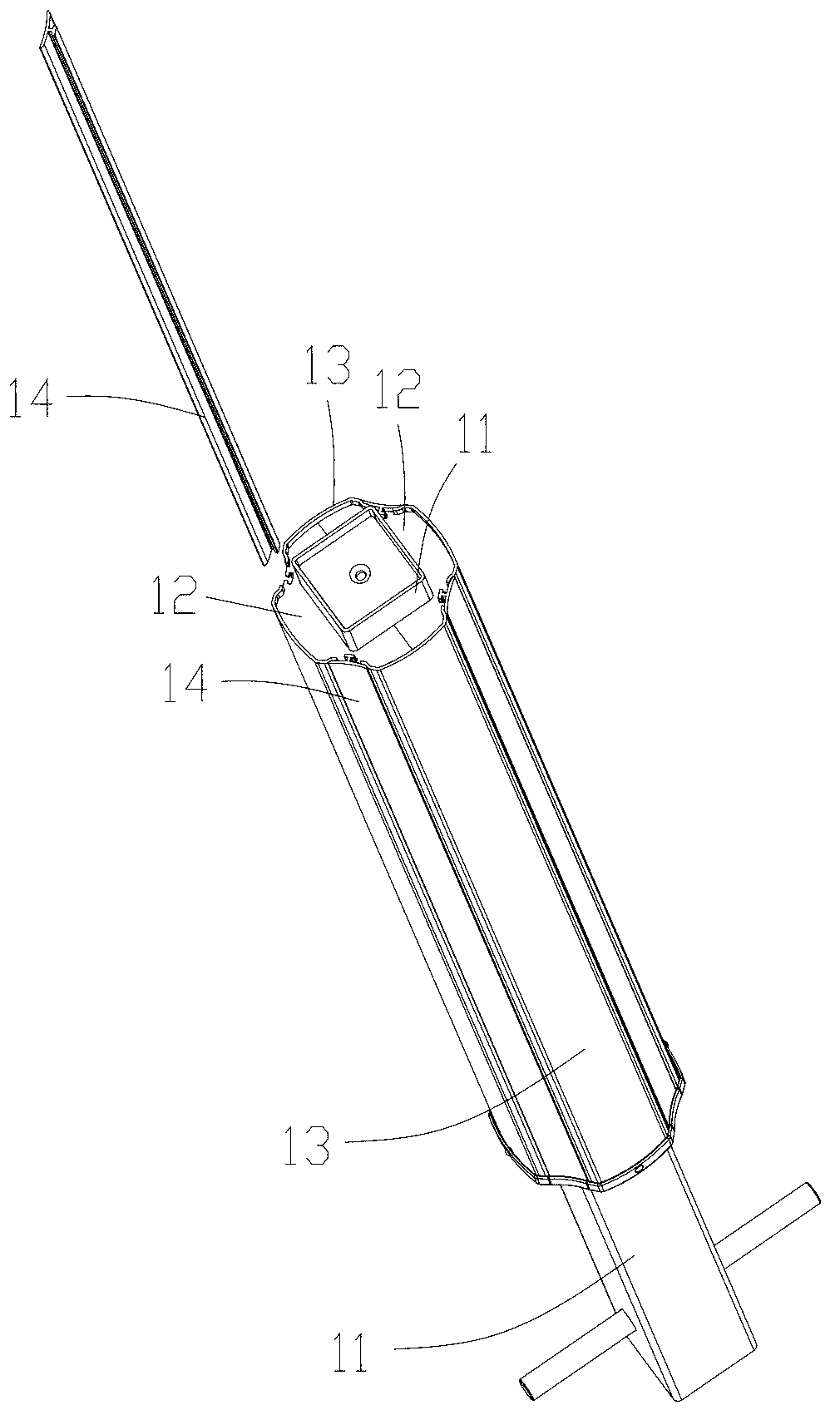

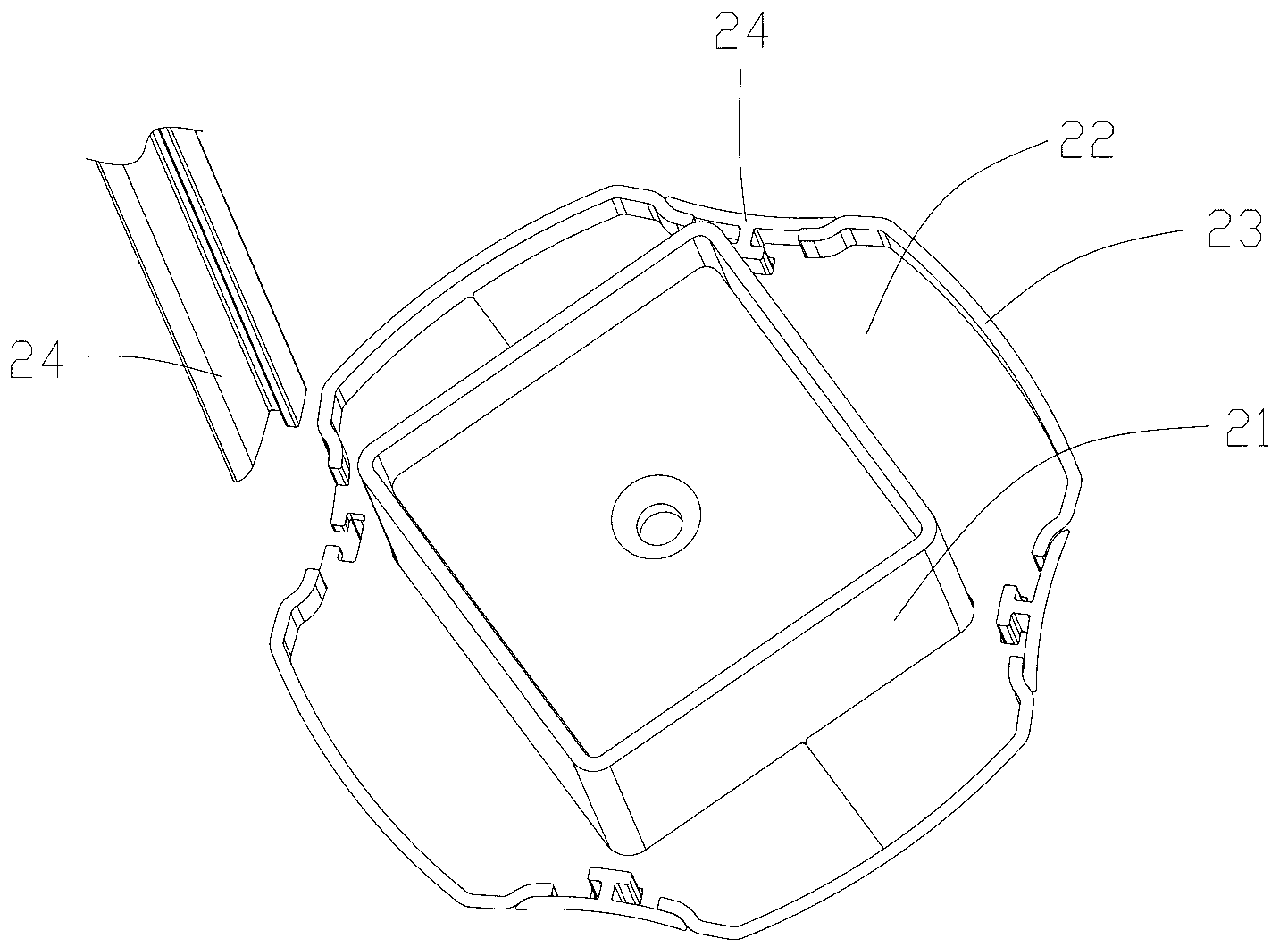

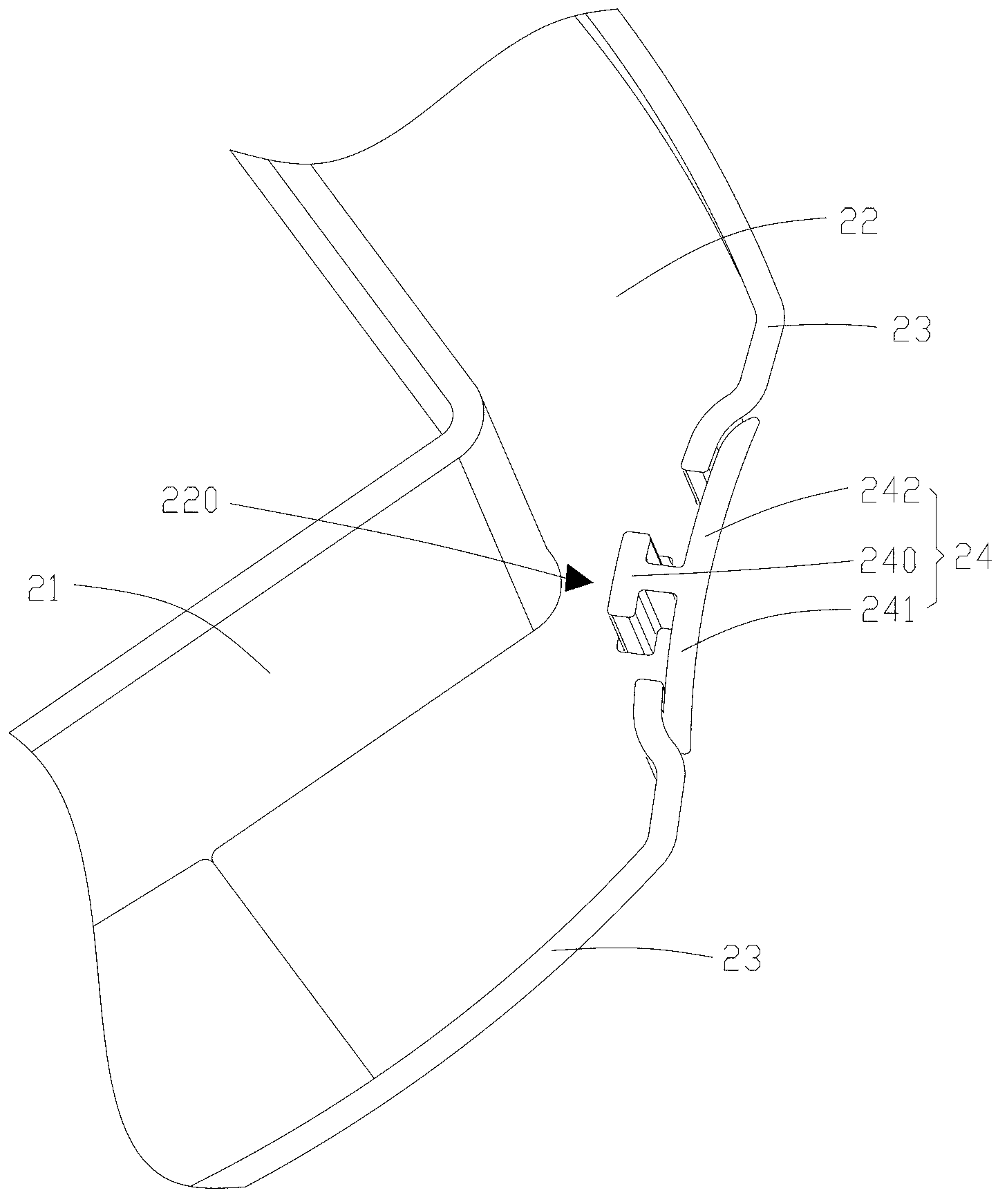

Fitness equipment stand column and fitness equipment

ActiveCN102840437AHigh mechanical strengthImprove qualityElongated constructional elementsMovement coordination devicesBiochemical engineeringUltimate tensile strength

The invention discloses fitness equipment stand column and fitness equipment. The fitness equipment stand column comprises an interior tube body, a tube body sleeve piece, a first connecting piece and a second connecting piece. The interior tube body is used to install and bear the fitness equipment, the first connecting piece is fixedly arranged on an outer profile of the interior tube body, the tube body sleeve piece is sleeved on the first connecting piece closely, and the second connecting piece is matched with the first connecting piece to fix the tube body sleeve piece on the first connecting piece. By arranging the tube body sleeve piece outside the interior tube body, mechanical strength of the fitness equipment stand column is improved, and oxidation rusting of the interior tube body and the like caused by being exposed to the weather can be effectively prevented. By adopting the fitness equipment stand column, the fitness equipment is high in whole quality, attractive in appearance and beneficial for environment protection, and improves user experience.

Owner:深圳市好家庭健康科技有限公司

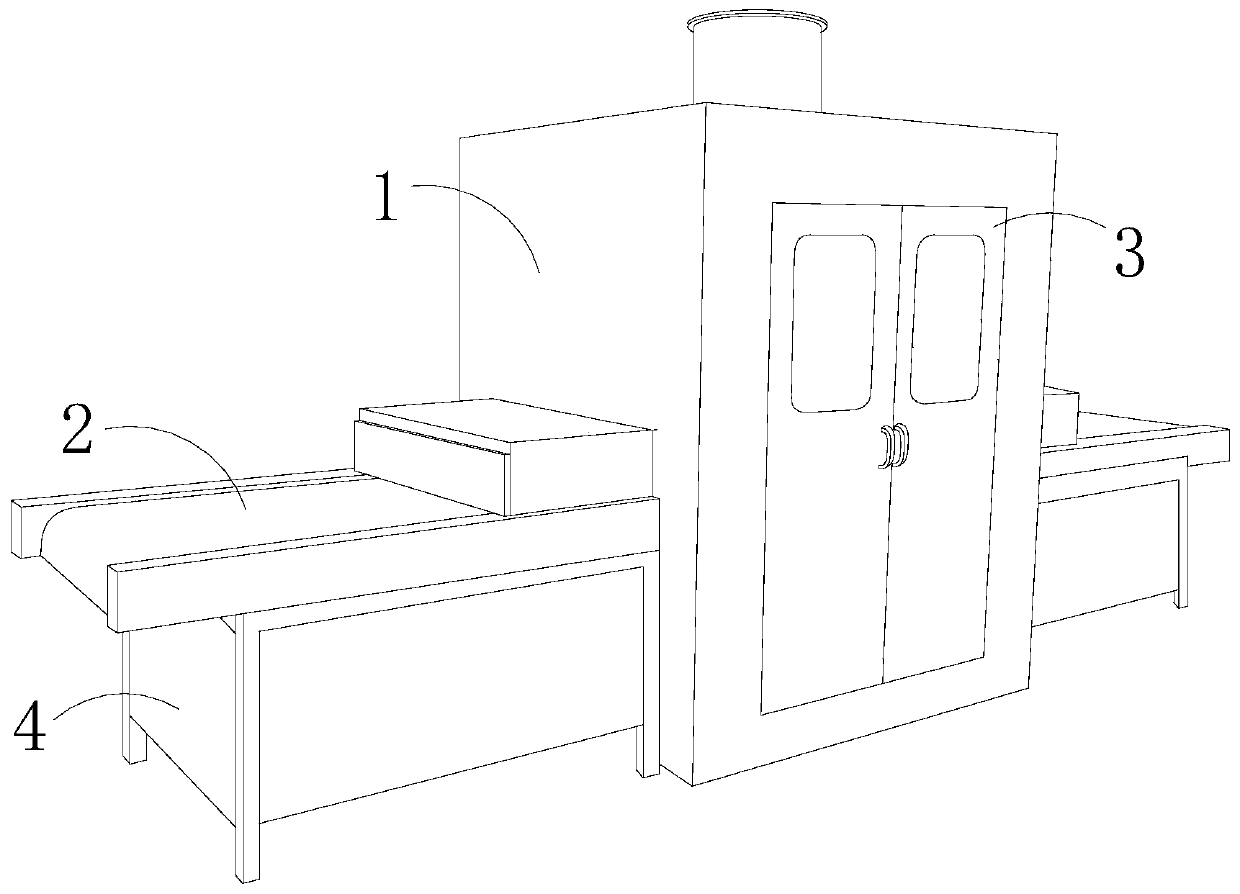

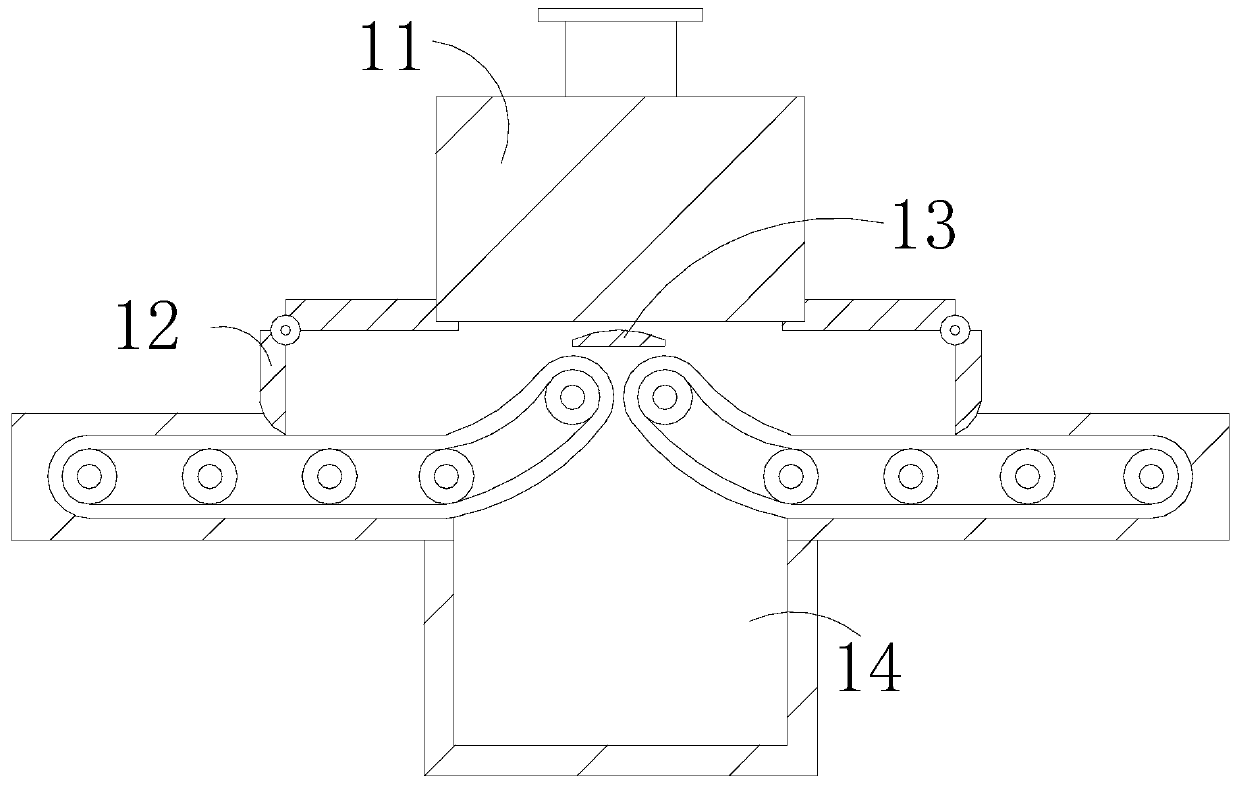

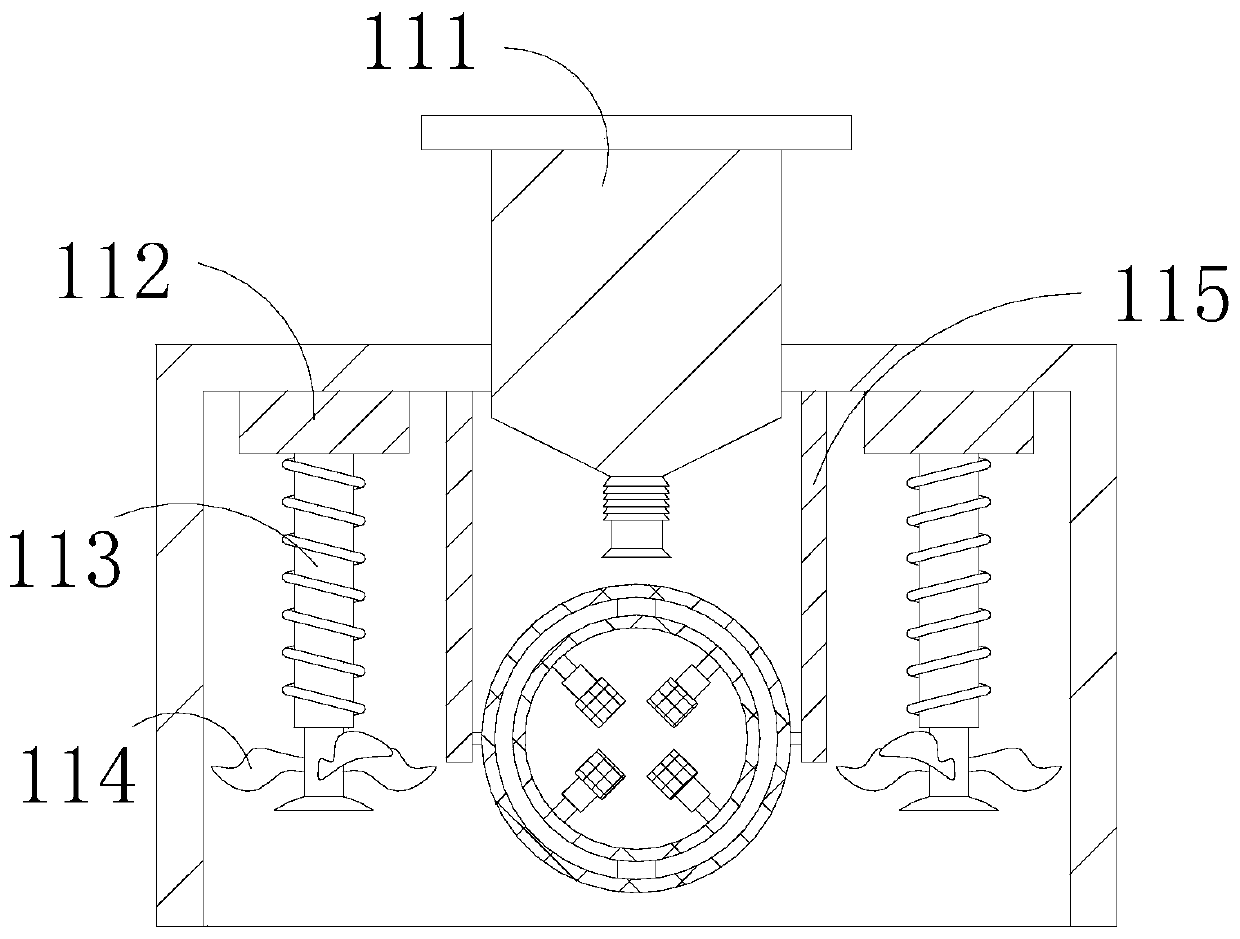

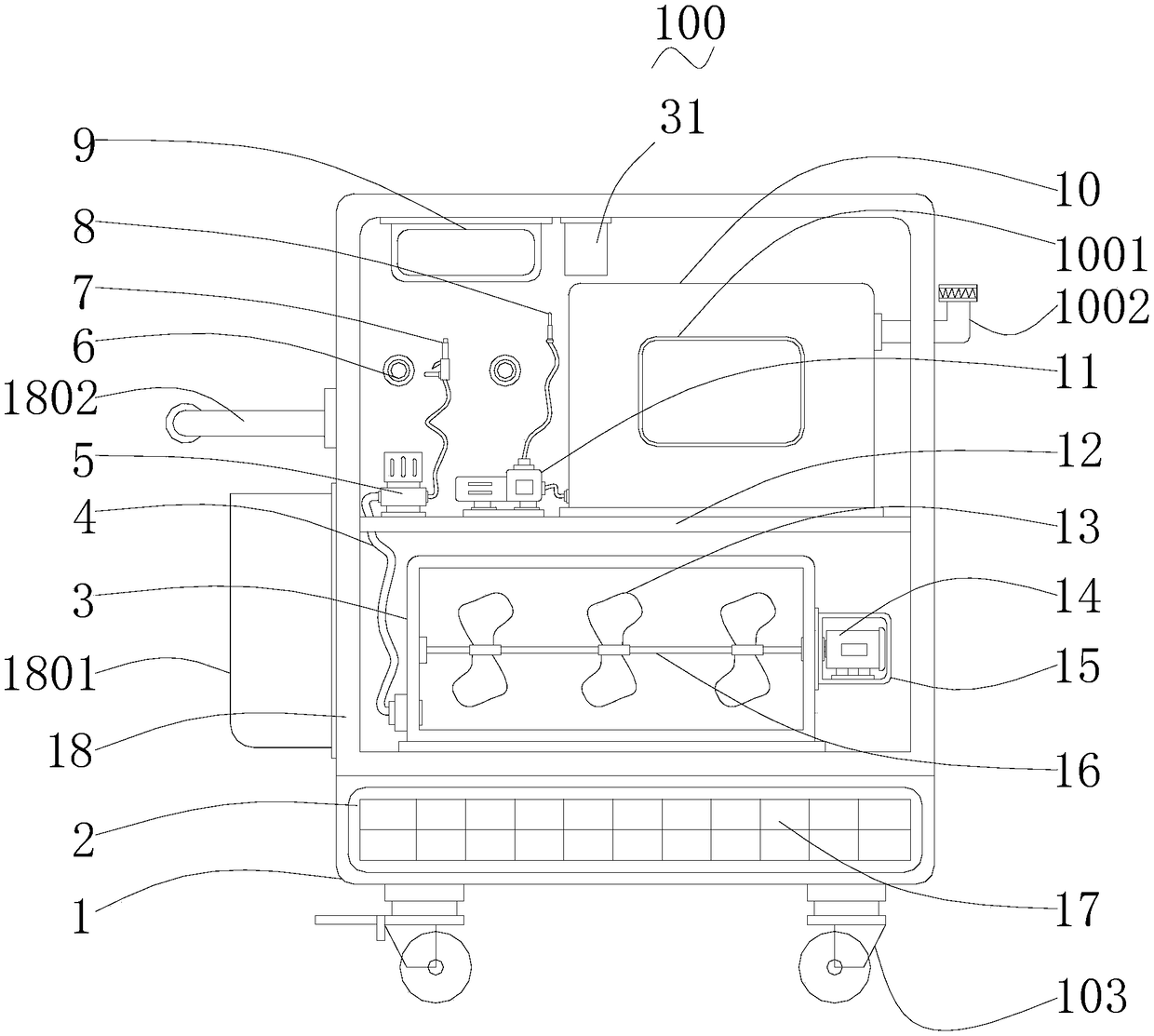

Hardware paint spraying and drying robot

ActiveCN111330796APrevent fallingPrevent oxidation and rustPretreated surfacesCoatingsStructural engineeringSpray painting

The invention discloses a hardware paint spraying and drying robot. The hardware paint spraying and drying robot structurally comprises a machining cabinet, a conveying belt, box doors and a base. Themachining cabinet comprises a paint spraying and drying cavity, valves, a guide plate and an impurity storage cavity. The paint spraying and drying cavity comprises a paint storage barrel, heating plates, heating pipes, drying fans and an object device. The object device comprises a horizontal rotating rod, a locating outer shell, vertical rotating rods, a locating inner shell and clamping blocks. The clamping blocks comprise fixed blocks, rotating wheels, supporting springs and fixed rods. The paint storage barrel comprises an upper cover, a stirring paddle, an adjusting device, a discharging plug and a paint spraying pipe. The adjusting device comprises a concave-convex block, a guide rail, rolling wheels, a supporting block, a limiting plate and a supporting rod. Each rolling wheel comprises a clamp plate, a rubber block and a ball. Hardware needing paint spraying is placed on the object device, under the action of the supporting spring, the hardware is clamped by the clamping blocks, the hardware is prevented from falling off during paint spraying, clamping faces are changed, all the faces of the hardware can be sprayed with paint, and therefore oxidization rusting of the hardware is avoided, and the attractiveness of the hardware is improved.

Owner:义乌市佳倩科技有限公司

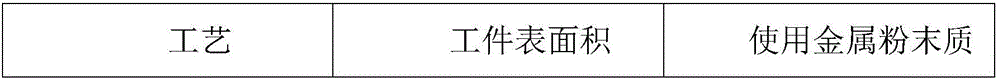

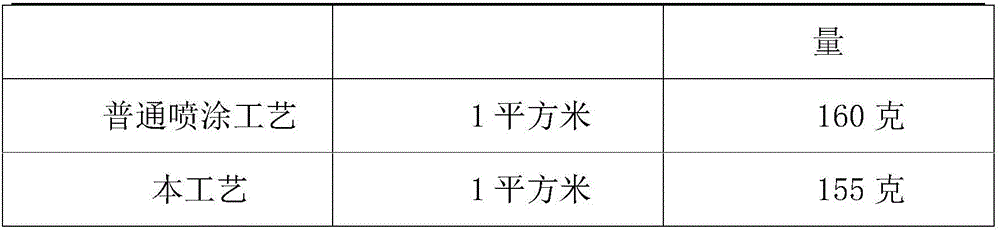

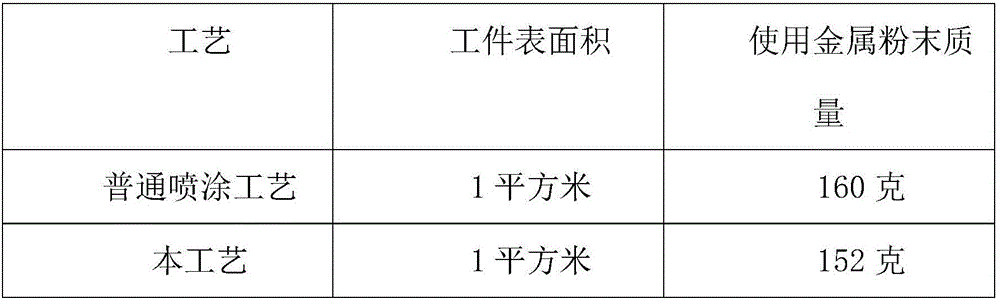

Metal powder spraying process capable of reducing coating particles on surface of workpiece

InactiveCN106824697AEasy to follow upPrevent oxidation and rustPretreated surfacesCoatingsSulfonateThiourea

The invention discloses a metal powder spraying process capable of reducing coating particles on the surface of a workpiece. The process includes the following steps that S1, the workpiece is placed in a pond, the outer wall of the workpiece is washed with hot water with the temperature being 60-80 DEG C, and oil stains and dirt on the outer wall of the workpiece are removed; and S2, whether the rusting phenomenon exists on the surface of the workpiece is observed, if the rusting phenomenon occurs, an acid washing solution is used for cleaning the workpiece at the temperature of 70-80 DEG C, and the acid washing solution is prepared from sulfuric acid, thiourea, alkyl sodium sulfonate and water. According to the metal powder spraying process, oil stains and dirt on the surface of the workpiece is removed, so that subsequent treatment on the workpiece is facilitated; the acid washing solution is used for removing rust, the workpiece can be protected against further oxidation and rusting, and the strength of the workpiece is improved; and the bubble area on the surface of the workpiece is polished and subjected to hole repairing, the actual spraying area of the workpiece is reduced, metal powder is saved, and the cost is lowered.

Owner:滁州市友邦涂装有限公司

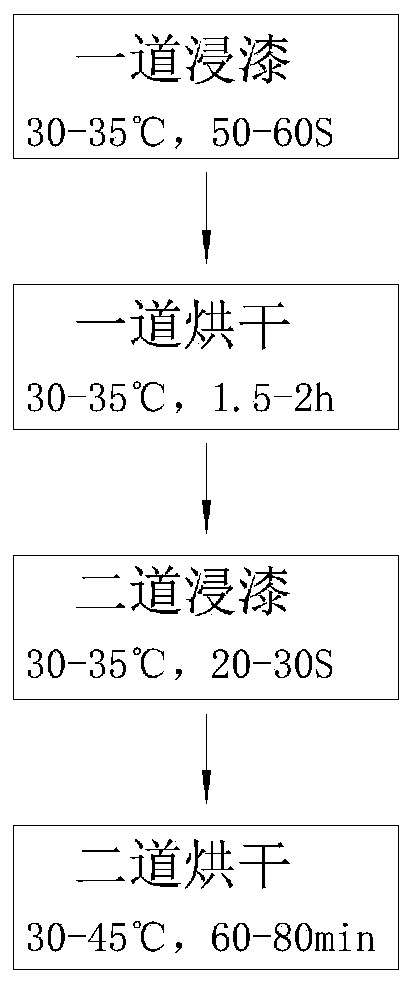

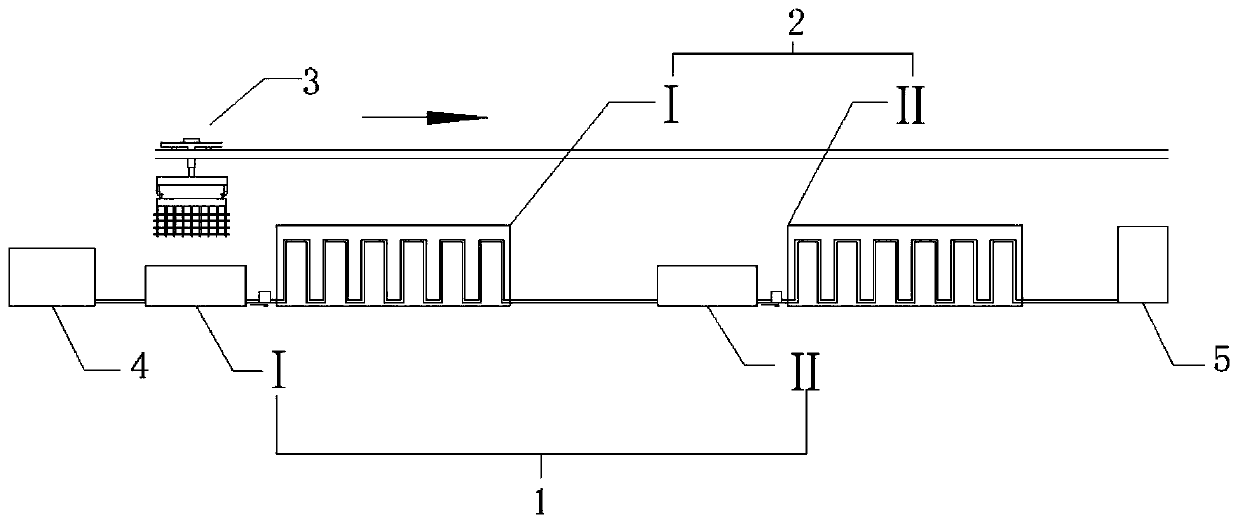

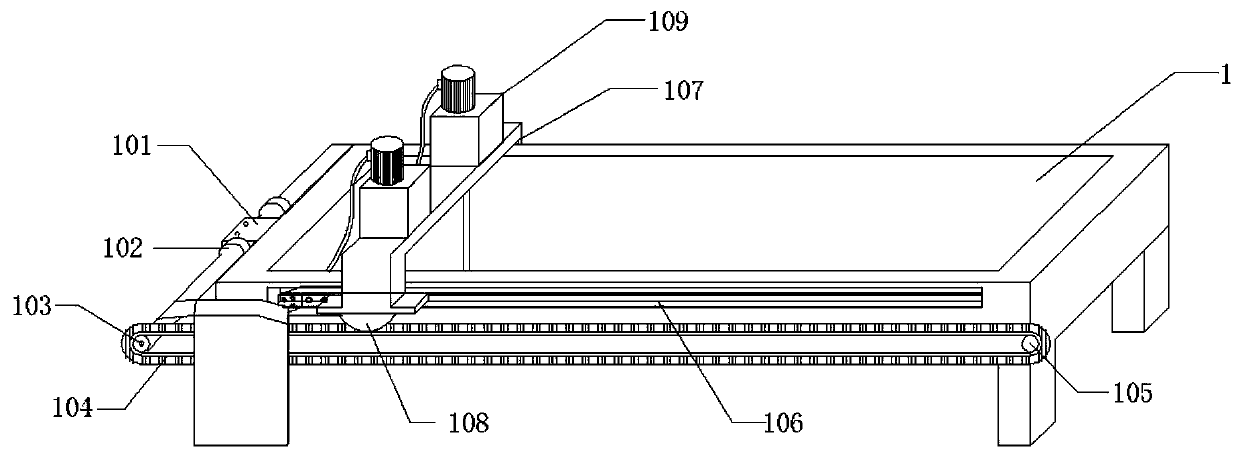

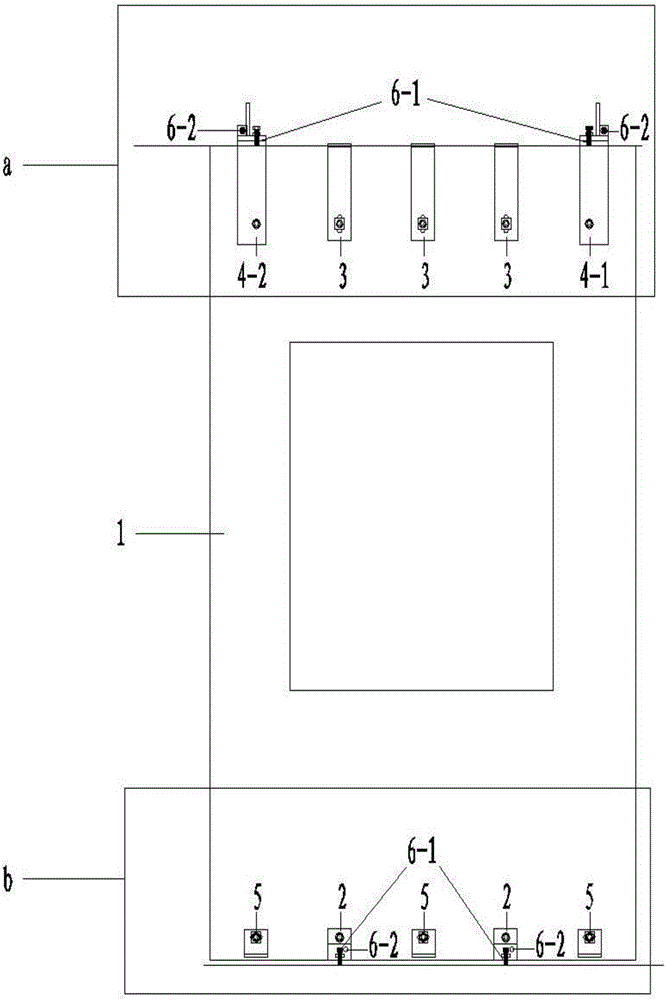

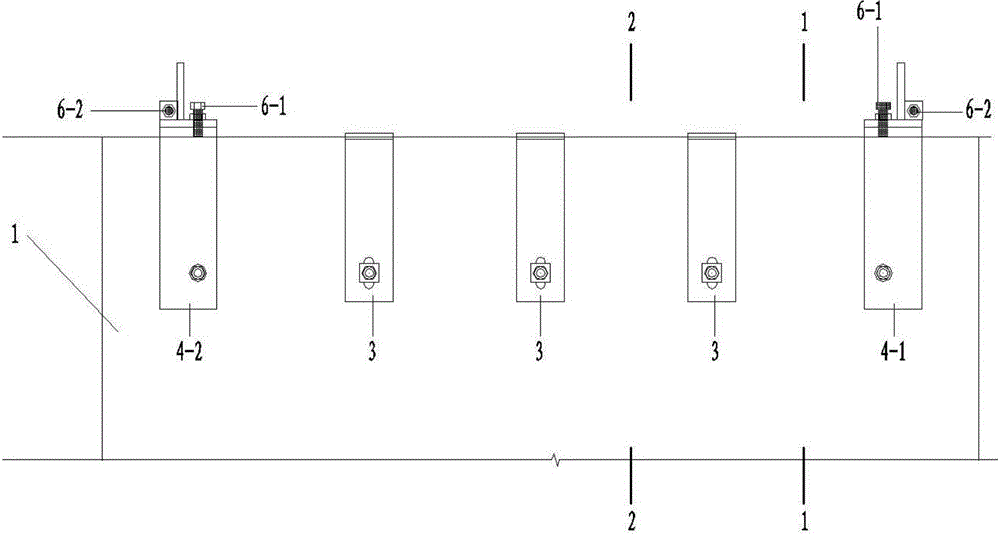

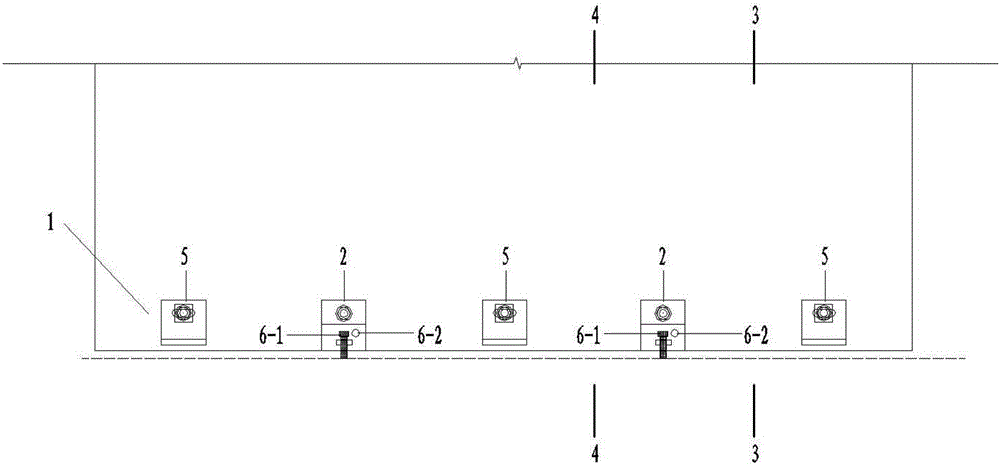

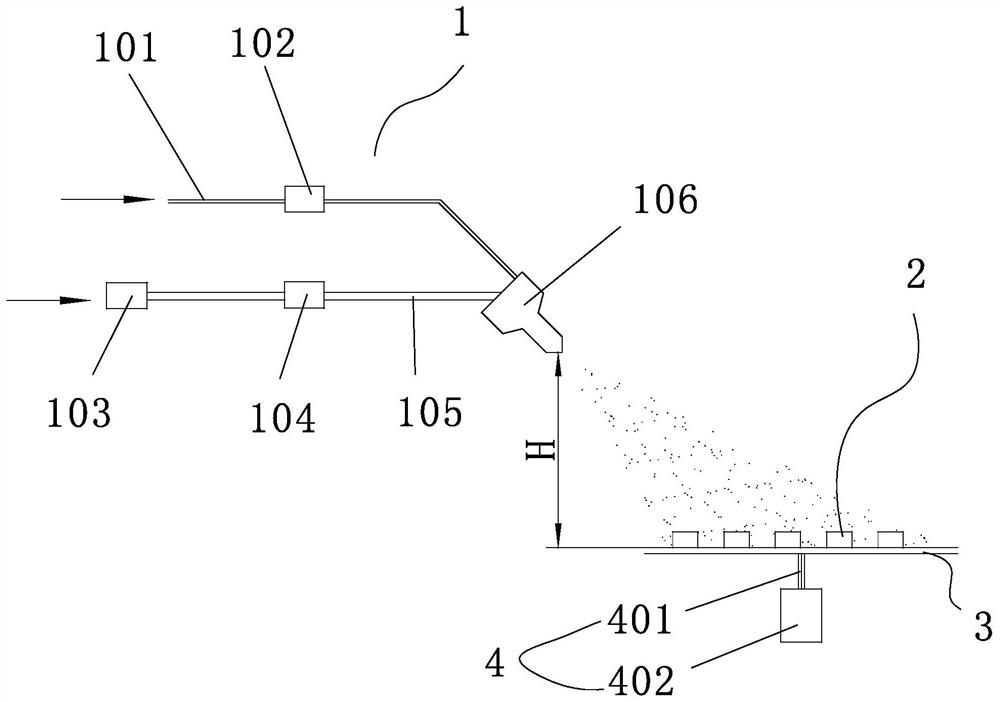

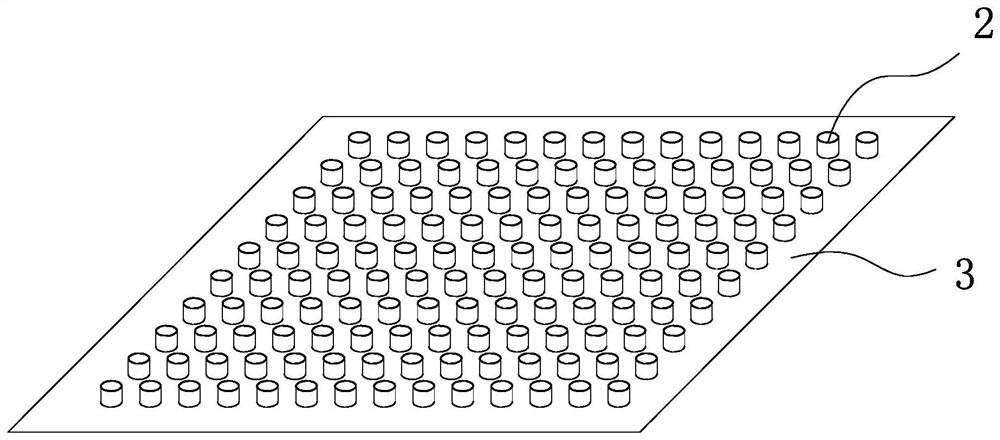

Method and device for improving paint dipping effect of reinforcing mesh

PendingCN111589681AResolve frozen depositsSolve for uniformityConjugated diene hydrocarbon coatingsPretreated surfacesMesh reinforcementCeramic materials

The invention discloses a method for improving the paint dipping effect of a reinforcing mesh. A production process comprises the following steps of S1, placing the reinforcing mesh in a paint dippingtank I for primary paint dipping; S2, moving the reinforcing mesh subjected to the primary paint dipping to a drying room I from the paint dipping tank I, and conducting primary drying in the dryingroom I; S3, entering a paint dipping tank II for secondary paint dipping after the reinforcing mesh being subjected to the primary drying; and S4, entering a drying room II for secondary drying afterthe reinforcing mesh being subjected to the secondary paint dipping; and the production device of the reinforcing mesh comprises the paint dipping tanks and the drying rooms, the paint dipping tanks comprises the paint dipping tank I and the paint dipping tank II, the drying rooms comprises the drying room I and the drying room II, the paint dipping tank I is arranged at the head end, the drying room II is arranged at the tail end, and the drying room I and the paint dipping tank II are arranged between the paint dipping tank I and the drying room II. According to the method for improving thepaint dipping effect of the reinforcing mesh, the reinforcing mesh is subjected to two times of the paint dipping and two times of the drying, the defect of the primary paint dipping is remedied through of the secondary paint dipping, uneven primary paint dipping is avoided, and the problems of paint blistering, cracking and shelling of the reinforcing mesh are solved.

Owner:贵州长通装配式建材有限公司

Construction method for hanging and connecting prefabricated concrete external retaining sandwich type wall panels

ActiveCN106121102AImprove efficiencyHigh precisionWallsBuilding material handlingFloor slabEngineering

The invention discloses a construction method for hanging and connecting prefabricated concrete external retaining sandwich type wall panels. The method includes the steps that the upper portions and the lower portions of the multiple prefabricated concrete sandwich type wall panels to be hung on floor slab edges of a concrete main body structure are connected with connecting parts in the transverse direction correspondingly; as for the two prefabricated concrete sandwich type wall panels adjacently arranged left and right, foamed rubber strips are fixed to two side surfaces of one wall panel correspondingly, and a foamed rubber strip is fixed to one side surface of the other prefabricated concrete sandwich type wall panel; A-level fireproof insulation materials are laid in a set position of a ground beam on the outer side of a main body outer edge beam cornice at the lowest layer in a through mode; and then the connecting parts are used for installing the prefabricated concrete sandwich type wall panels. By the adoption of the method, the installation speed is high, the adjustment precision is high, the appearance effect is good, and the connecting strength is high.

Owner:天津住宅集团建设工程总承包有限公司

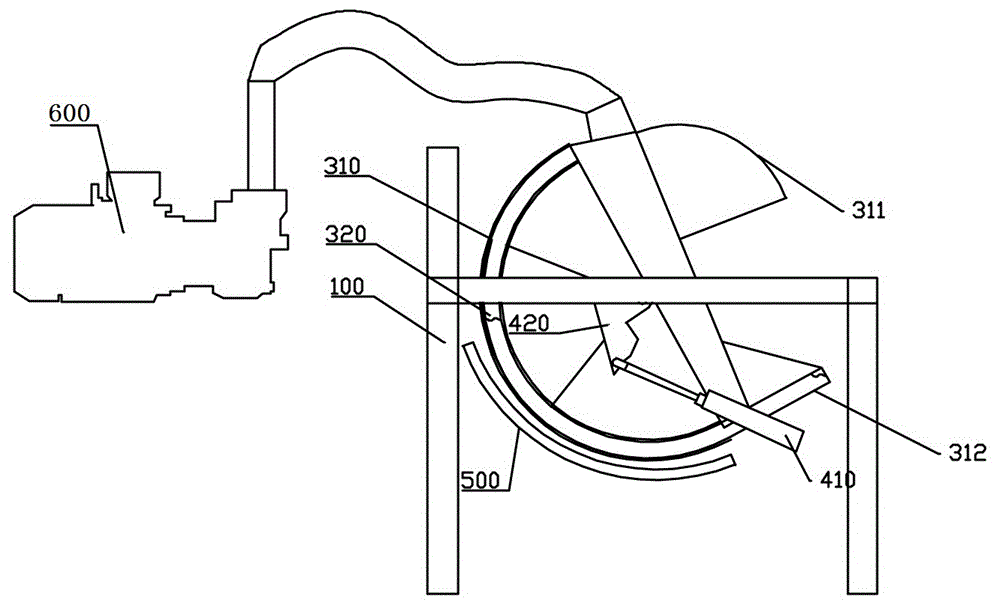

Method and device for spraying surface of bonded neodymium-iron-boron magnet

InactiveCN112076961ASolve the problem of easy oxidation and rustHigh dimensional accuracyLiquid surface applicatorsLiquid spraying apparatusEpoxyCoated membrane

The invention discloses a method and a device for spraying the surface of a bonded neodymium-iron-boron magnet. The method comprises the following steps: 1, placing a plurality of bonded neodymium-iron-boron magnets on a flat plate at equal intervals; 2, preparing spraying liquid, specifically, mixing epoxy resin paint and a diluent in proportion and stirring uniformly to form the spraying liquid;3, pressing the spraying liquid into a spray gun to form uniform spray; 4, controlling the spray gun to uniformly move, and spraying a product above the flat plate; and 5, rotating the flat plate bymultiple times, and repeating the step 4 after each time of rotation till the coating film reaches the needed thickness. A bonded neodymium-iron-boron magnet surface spraying device comprises the spray gun and the flat plate. According to the method and the device for spraying the surface of the bonded neodymium-iron-boron magnet, the problem that the surface of the bonded neodymium-iron-boron magnet is prone to oxidation and rusting is solved. the coating uniformity is ensured, and the size precision is improved; and the loss of the coating is reduced, the cost is reduced, and the coating thickness is convenient to control.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Illuminating, cleaning and curing device

InactiveCN109047096APrevent oxidation and rustAvoid tangled situationsCleaning using liquidsWater storageConductor Coil

The invention designs a mechanical device cleaning and curing device which comprises a base and a box body; a placing groove is formed in the base; a storage battery is fixedly mounted in the placinggroove; the box body is fixedly mounted at the top of the base; a water tank is fixedly mounted at the bottom end in the box body; a mounting chamber is fixedly mounted on one side of the water tank;a servo motor is fixedly mounted in the mounting chamber; a shaft lever extending into the water tank is mounted at the output end of the servo motor; and stirring vanes are uniformly distributed on the shaft lever. The water tank has an effective water storage effect, so that the condition that workers take water from the outside is avoided or reduced; an oil gun is arranged to enable the workerto conveniently perform lubricating care on the mechanical device with a lubricant in an oil pump; and a winding rod is arranged to wind a rubber hose after the operation of the device is completed, so that the condition that the rubber hose is knotted and twined in the device is avoided, the functionality of the device is improved, and the device is worthy of popularization and application.

Owner:东莞市闻誉实业有限公司

Tea processing technology

InactiveCN106798034AStable tea temperatureStable temperaturePre-extraction tea treatmentInlet valveProduct gas

The invention relates to a tea processing technology which comprises the following steps: 1, opening a liquid inlet valve, injecting batching water into a liquid storage cavity, starting a water ring vacuum pump, and exhausting gases in the liquid storage cavity of a pot body, so that the air pressure in the liquid storage cavity of the pot body is maintained to be 0.04-0.06 MPa; 2, starting an arc-shaped electromagnetic heating plate, and heating one side, which is close to the arc-shaped electromagnetic heating plate, of the pot body by the arc-shaped electromagnetic heating plate; 3, controlling start of the water ring vacuum pump by a gas-pressure meter, starting the water ring vacuum pump when the air pressure in the liquid storage cavity is higher than 0.06 MPa, and closing the water ring vacuum pump when the air pressure in the liquid storage cavity is lower than 0.04 MPa. In order to solve the problem that the formed tea is poor in quality because the existing tea forming equipment is non-uniform in heating, the invention aims to provide the tea processing technology which is capable of frying tea leaves at a uniform temperature and is excellent in forming effect.

Owner:遵义茗香康源茶饮发展科技有限公司

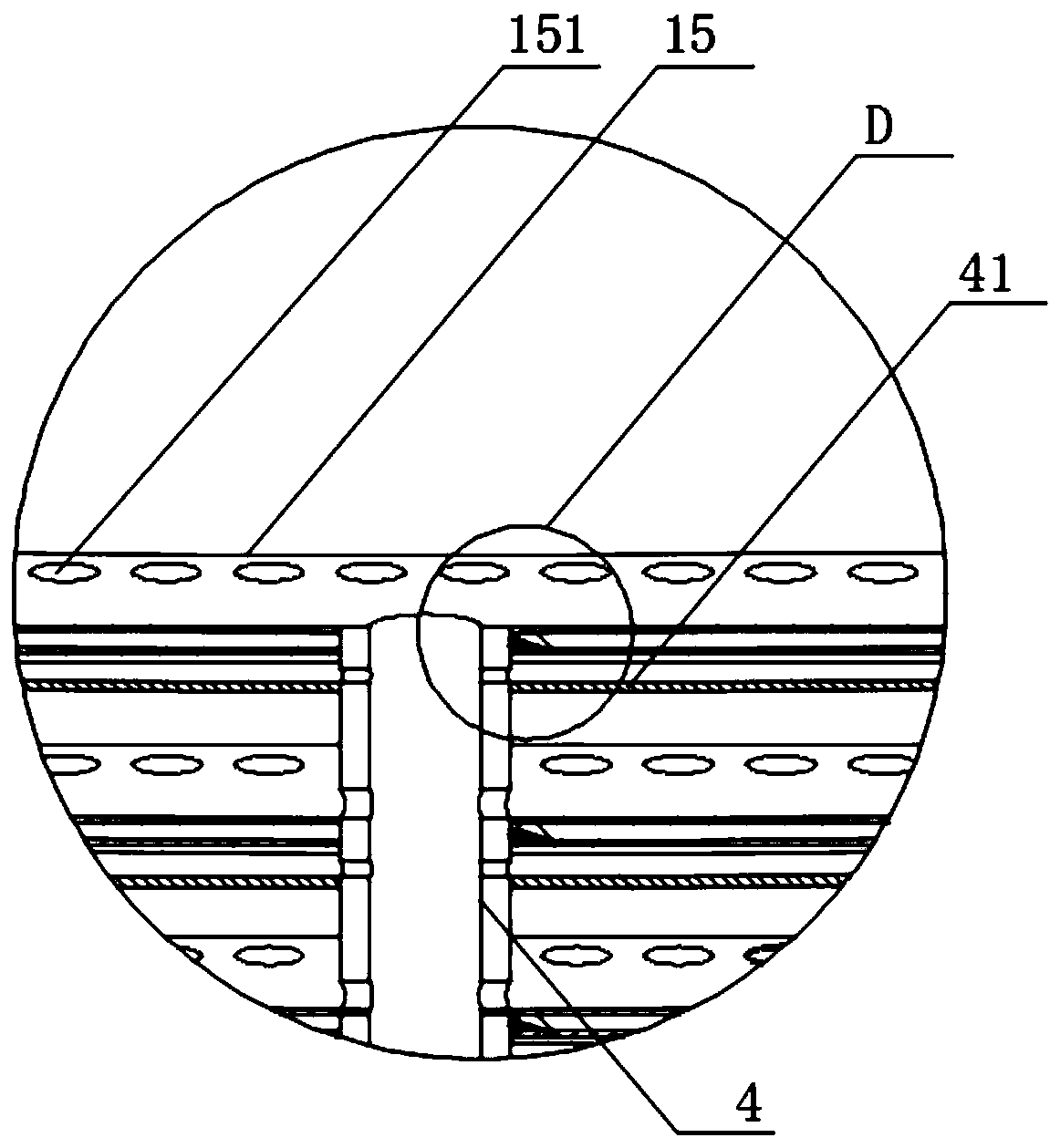

Horizontal-type steam turbine condenser

ActiveCN109883216AReduce dosageAvoid increased oxygen capacitySteam/vapor condensersNon-rotary device cleaningPipingThin walled

The invention discloses a horizontal-type steam turbine condenser. The main viewing shape of each cooling water pipe is an arc which is opened upwards. Each cooling water pipe is of a thin-walled cavity structure. The cross section shape of each cooling water pipe is a major arc which is opened upwards. The lowest point in the horizontal direction of each cooling water pipe vertically communicateswith a condensed water guide pipe. The lowest points of the cooling water pipes are sequentially penetrated by the vertical condensed water guide pipe in the vertical direction, and flow guide holesare formed in the peripheries, corresponding to the lowest points of the cooling water pipes on the lower portion, of the condensed water guide pipe. Water receiving flow guide plates are arranged below the cooling water pipes in parallel, and the cross section shape of each water receiving flow guide plate is an arc which is opened upwards. The lowest point of each water receiving flow guide plate communicates with the condensed water guide pipe. A cooling water inlet chamber communicates with an automatic cleaning device used for cleaning the cooling water pipes. Condensed water condensed byeach cooling water pipe is independently guided to be discharged, supercooling happening due to the fact that the condensed water drips off onto the outer walls of the cooling water pipes on the lower portion is avoided and the blocking phenomenon of a cooling water channel can be effectively prevented.

Owner:大唐东营发电有限公司

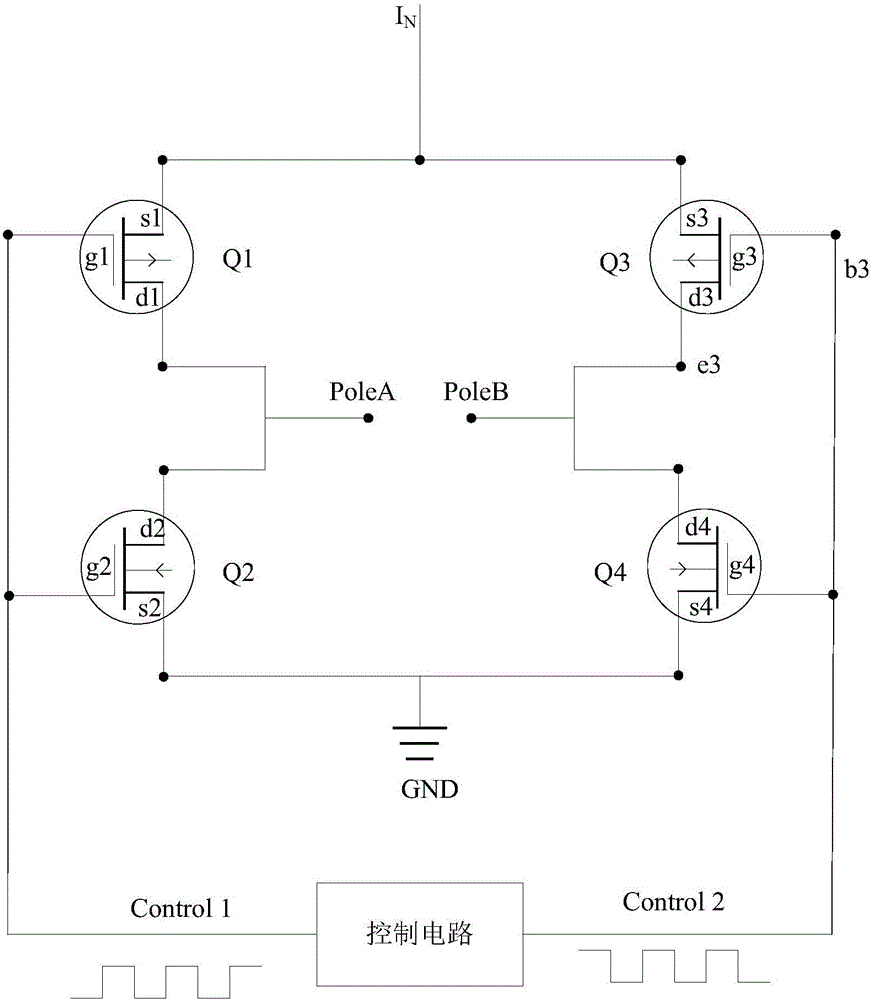

Current control circuit and electrode water level monitoring device

ActiveCN105784056AGuaranteed electrical conductivityReduce misjudgmentMachines/enginesLevel indicatorsPower flowAlternating current

The invention relates to a current control circuit and an electrode water level monitoring device. The current control circuit comprises a triode Q1, a triode Q2, a triode Q3, a triode Q4 and a control circuit. The control circuit outputs a first pulse signal and a second pulse signal opposite in waveform according to the set period. A source electrode s1 of the triode Q1 and a source electrode s2 of the triode Q3 are connected, and work currents are introduced. A grid electrode g1 of the triode Q1 and a grid electrode g2 of the triode Q2 are connected, and the first pulse signal is introduced. A grid electrode g3 of the triode Q3 and a grid electrode g4 of the triode Q4 are connected, and the second pulse signal is introduced. A drain electrode d1 of the triode Q1 and a drain electrode d2 of the triode Q2 are connected, and are connected with a first electrode. A drain electrode d3 of the triode Q3 and a drain electrode d4 of the triode Q4 are connected and are connected with a second electrode. A source electrode s2 of the triode Q2 and a source electrode s4 of the triode Q4 are connected and grounded. According to the technology, electrode oxidizing and rusting or liquid impurity adsorbing caused by long-time alternating-current voltages is avoided, the conductive performance of the electrodes is ensured, wrong judgment on the liquid level is reduced, and the monitoring accuracy is improved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

Novel rust-conversion coating material with rust

InactiveCN103980817AInhibit surface flash rustInhibit the generation of flash rust on the surfaceAnti-corrosive paintsMaleic anhydrideEmulsion

The present invention discloses a novel rust-conversion coating material with rust. According to the coating material, phosphoric acid, a wetting agent, a dispersing agent, an antifoaming agent, an anti-flashrust agent and a thickener are sequentially added to distilled water, uniform stirring is performed to obtain an intermediate material, a pigment filler is added to the intermediate material, high speed stirring is performed to obtain an auxiliary material, linseed oil, maleic anhydride, a modified phenol formaldehyde resin and a styrene-acrylate emulsion are subjected to adduction to obtain an aqueous resin base material, the auxiliary material is added to the resin emulsion, and uniform stirring and filtering are performed to obtain the rust-conversion coating material with rust. The rust-conversion coating material with rust has characteristics of low environmental pollution, strong weathering aging resistance, strong light aging resistance, and strong chemical corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

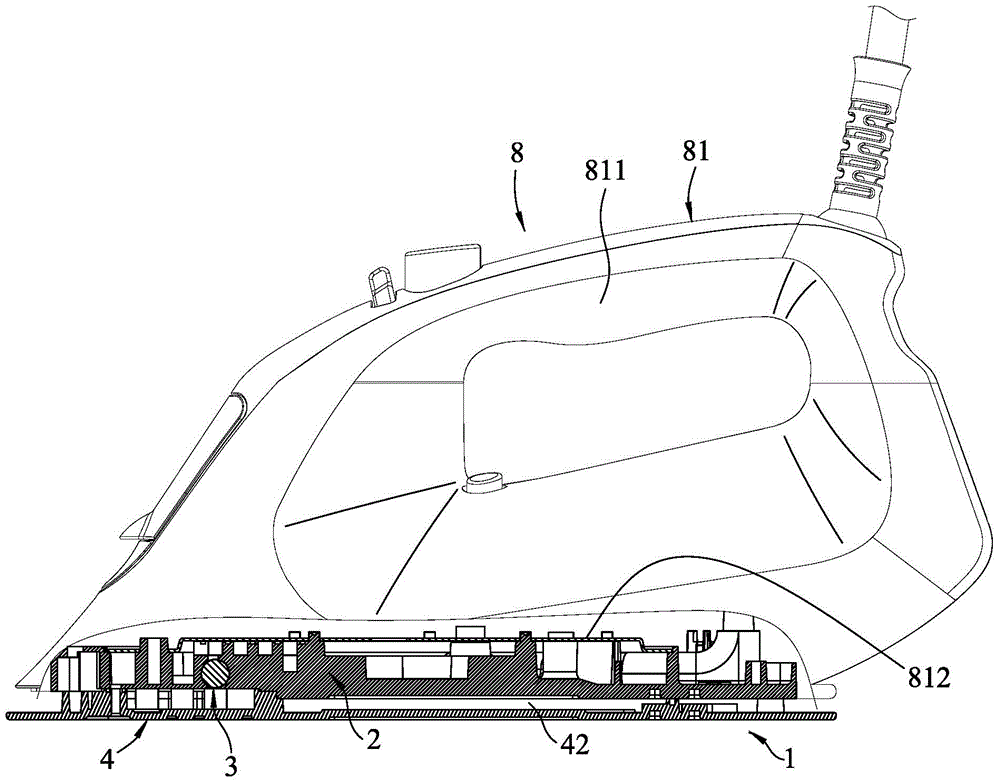

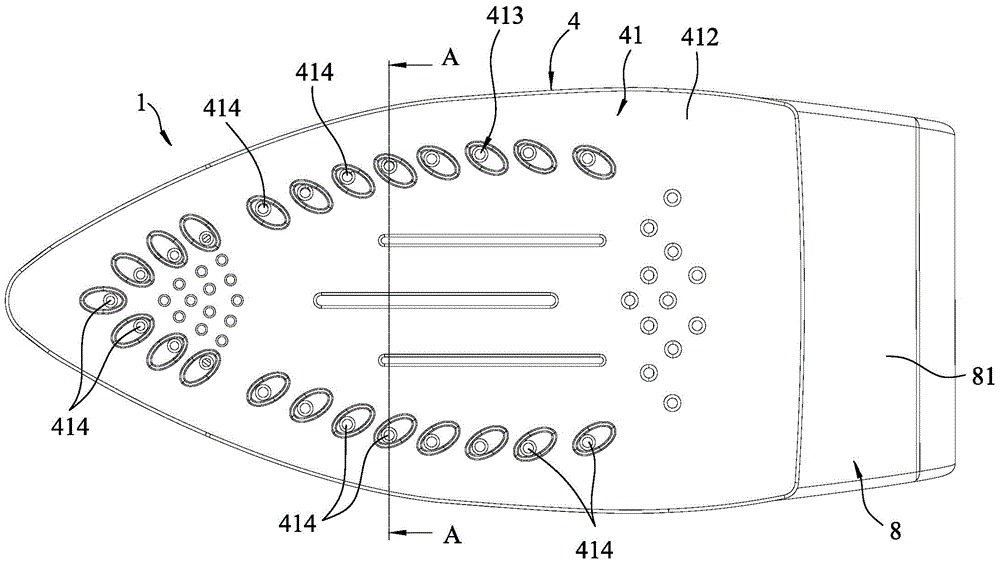

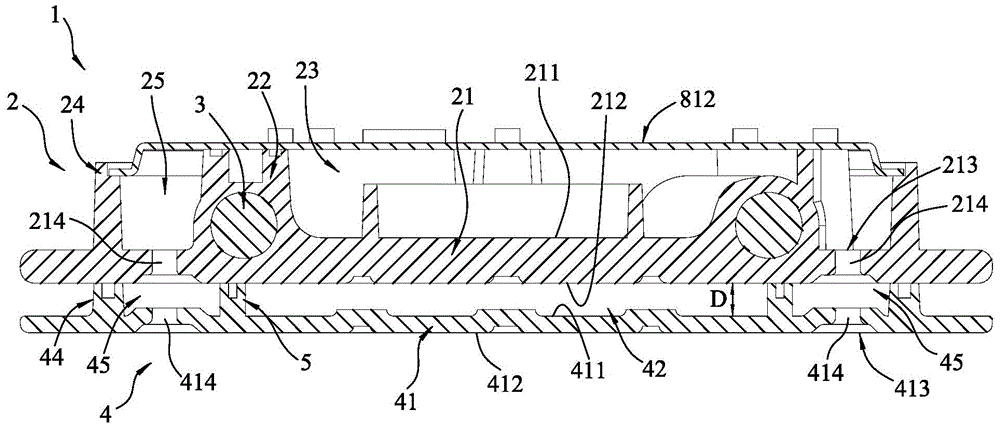

An electric hot tray device of an iron

ActiveCN104894827AAvoid material deterioration or burningReduce the temperatureHand ironTextiles and paperElectric heatingCorrosion

The invention provides an electric hot tray device of an iron. The electric hot tray device is suitable for heating water into steam and comprises a hot tray with a perforation unit, an electric heating member capable of heating the hot tray and an ironing tray. The ironing tray comprises an ironing tray base wall located under the hot tray and a separating space located between the hot tray and the ironing tray base wall. The ironing tray base wall comprises a vent hole unit communicated with the perforation unit. The electric hot tray device also comprises a separator making the separating space and the perforation unit not communicated and separated. The separating space and reduce the temperature of the ironing tray, so that the ironing tray can be used for ironing clothes with lower temperature; the separator separates the separating space from the perforation unit, so that steam can pass through the vent hole unit directly without remaining or condensing on the ironing tray, oxidization and corrosion of the ironing tray can be effectively prevented and the service life of the ironing tray can be increased.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com