An electric hot tray device of an iron

A technology of electric heating plate and heating plate, which is applied in the direction of hand irons, washing devices, textiles and paper making, etc. It can solve the problems of reduced service life, oxidation and corrosion of the plate surface, and achieve the effect of avoiding material deterioration or burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

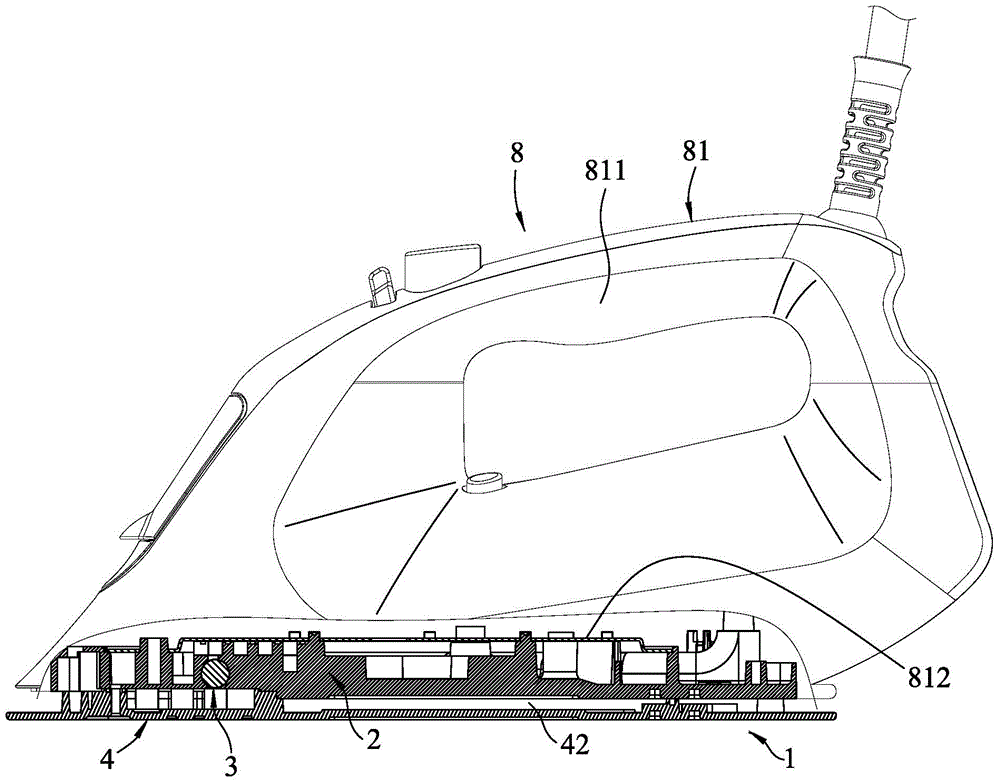

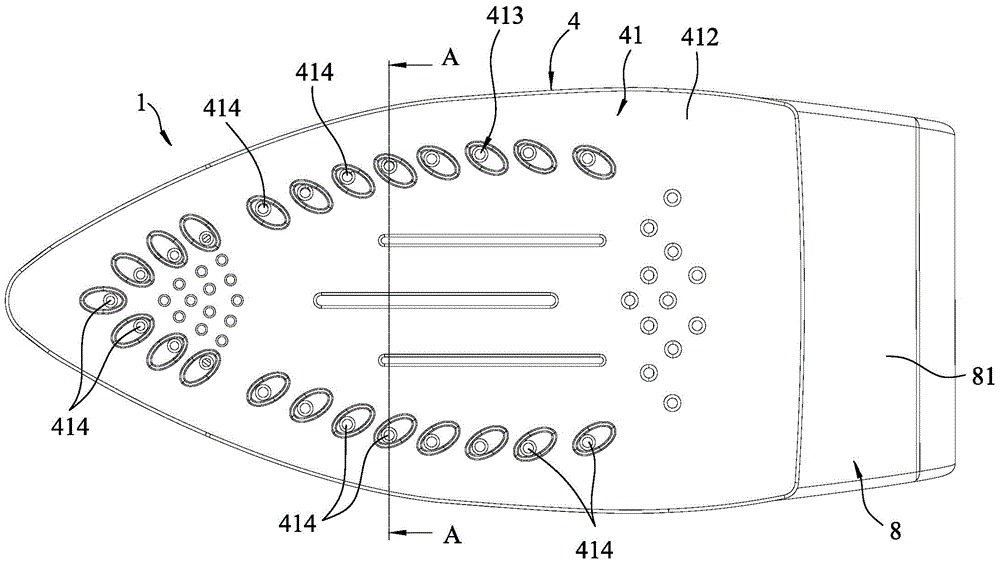

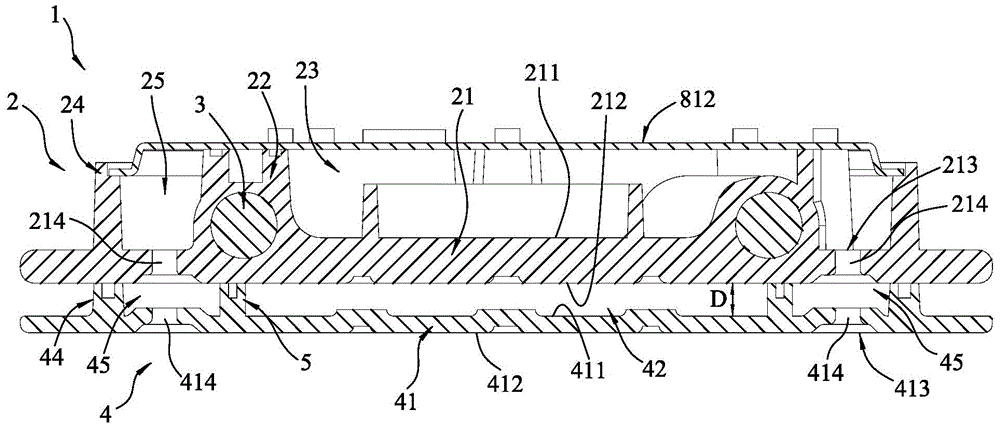

[0020] Refer to figure 1 , 2 3. An embodiment of the heating plate device 1 of the present invention is one of the components of an iron 8. The iron 8 also includes a housing 81 assembled on the heating plate device 1, and a water tank installed in the housing 81 (Picture not shown). The shell 81 includes a shell wall 811 that can be held and a bottom wall 812 assembled below the inner side of the shell wall 811. The water tank can deliver water to the hot plate device 1, and the hot plate device 1 of this embodiment is suitable for heating water into steam for ironing clothes.

[0021] The electric heating plate device 1 includes a heating plate 2 installed under the bottom wall 812 of the housing 81, an electric heating element 3 installed in combination with the heating plate 2 and capable of heating the heating plate 2, and an electric heating element 3 installed on the heating plate 2 The lower ironing tray 4, and a divider 5.

[0022] Refer to figure 1 , 3 4, the hot plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com