Tea processing technology

A processing technology and tea technology, which is applied in the field of tea shape making technology, can solve the problems of poor quality of tea, uneven heating, etc., and achieve the effect of reducing power and stabilizing water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

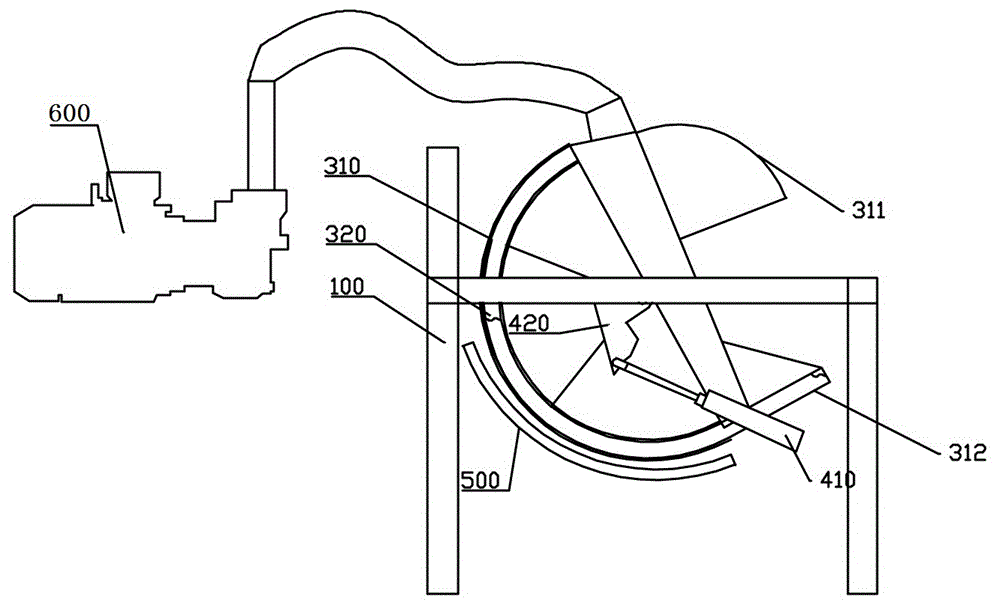

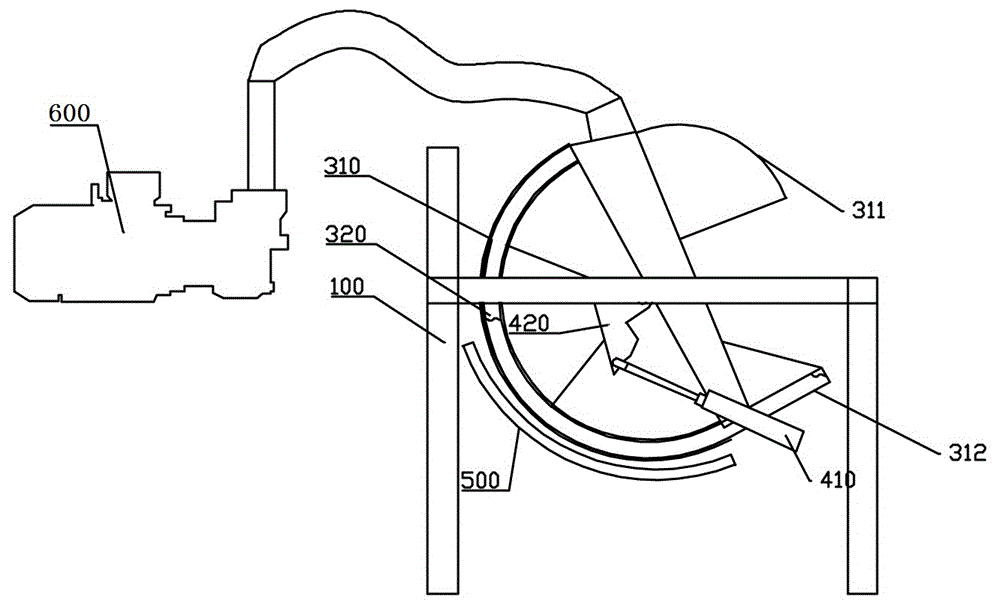

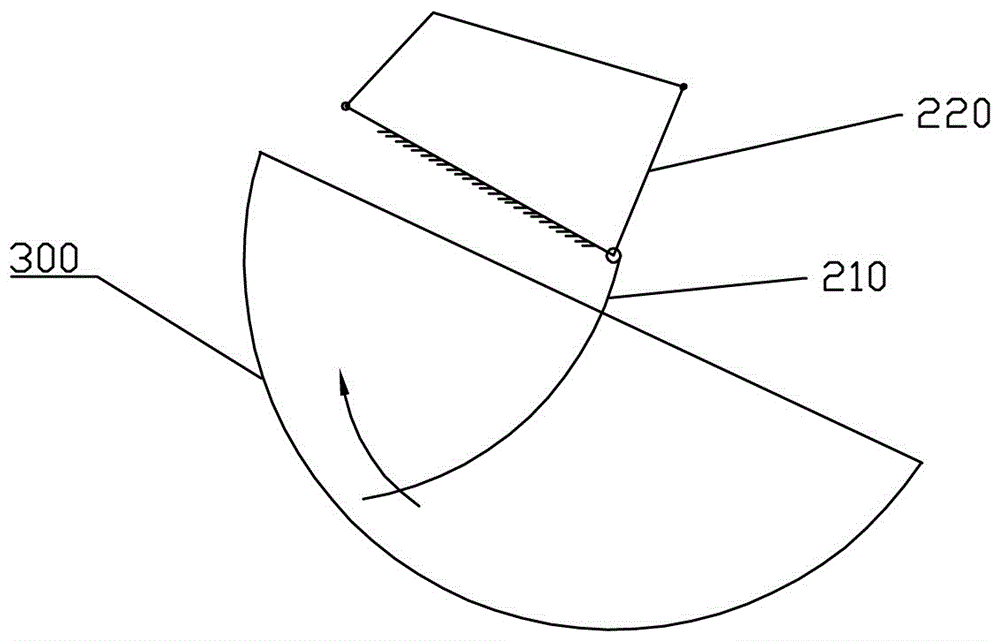

[0029] The reference signs in the drawings of the description include: frame 100, frying plate 210, crank rocker mechanism 220, frying pan 300, pot body 310, turning plate 311, recovery plate 312, liquid storage chamber 320, cylinder 410, turning seat 420 , arc-shaped electromagnetic heating plate 500 , and water ring vacuum pump 600 .

[0030] tea processing techniques such as figure 1 and figure 2The shown equipment used for tea processing includes a frame 100, a wok 300, a power part, a heating mechanism, a frying plate assembly and a wok driving mechanism, and a wok 300, a power part, a heating mechanism, a frying plate assembly and a wok driving mechanism Mechanisms are all installed on the frame 100, and the frying plate assembly includes an arc-shaped frying plate 210 and a crank and rocker mechanism 220, the crank of the crank and rocker mechanism 220 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com