Method and device for improving paint dipping effect of reinforcing mesh

A technology of steel mesh and dipping, which is applied to the device, transportation and packaging, charge manipulation and other directions of coating liquid on the surface. It can solve the problems of shelling, bubbles, cracking, etc. The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

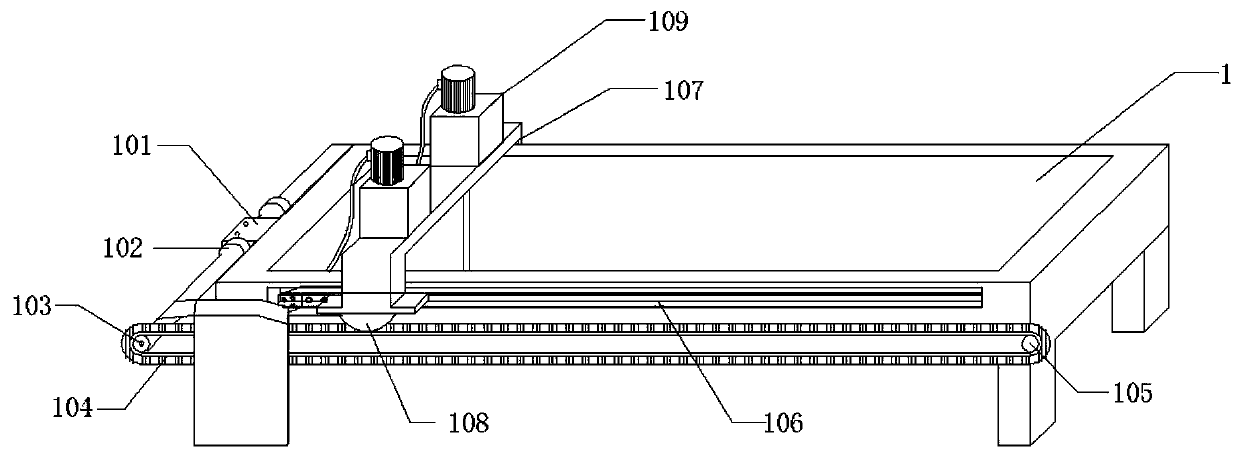

[0034] The concept, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, features and effects of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention.

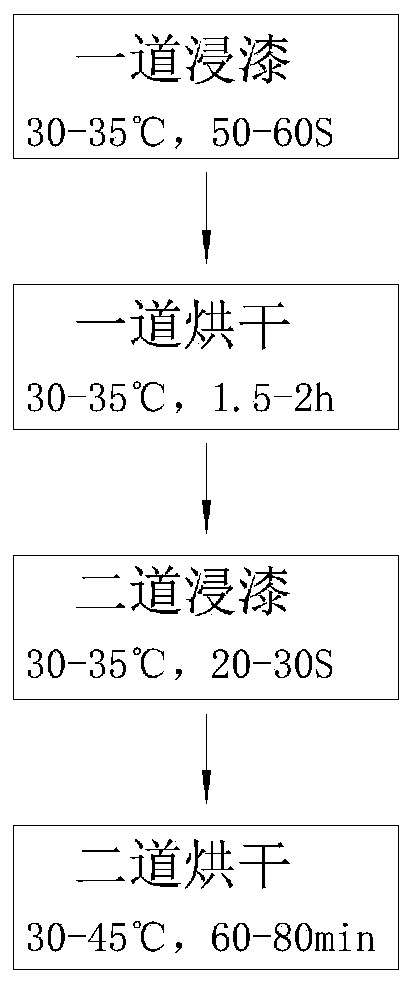

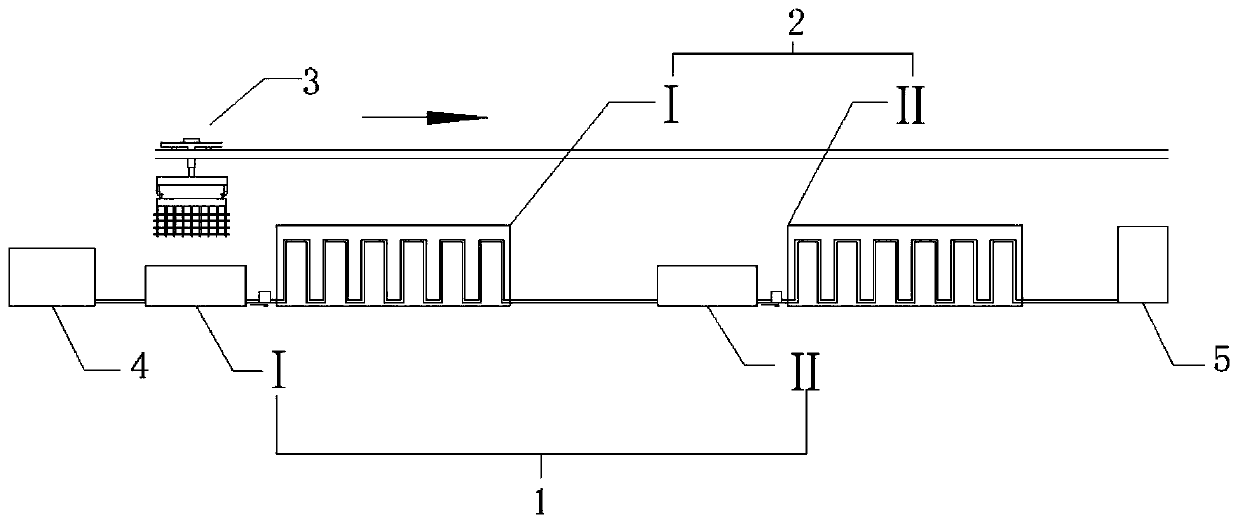

[0035] see figure 1 , a method for improving the dipping effect of steel mesh, comprising the following process:

[0036] S1: First place the steel mesh in the paint dipping tank Ⅰ for a dipping paint. The temperature of the paint is kept at 30-35°C, and the dipping time is 1min;

[0037] S2: Move the impregnated steel mesh from the impregnating tank Ⅰ to the drying room Ⅰ through the crane, and move it along the track in the drying room Ⅰ to perform a drying process. The temperature of the drying room Ⅰ is 30-35°C. Time 1.5-2h, bake the steel mesh paint until 80% dry;

[0038] S3: After one drying, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com