String and preparation method thereof

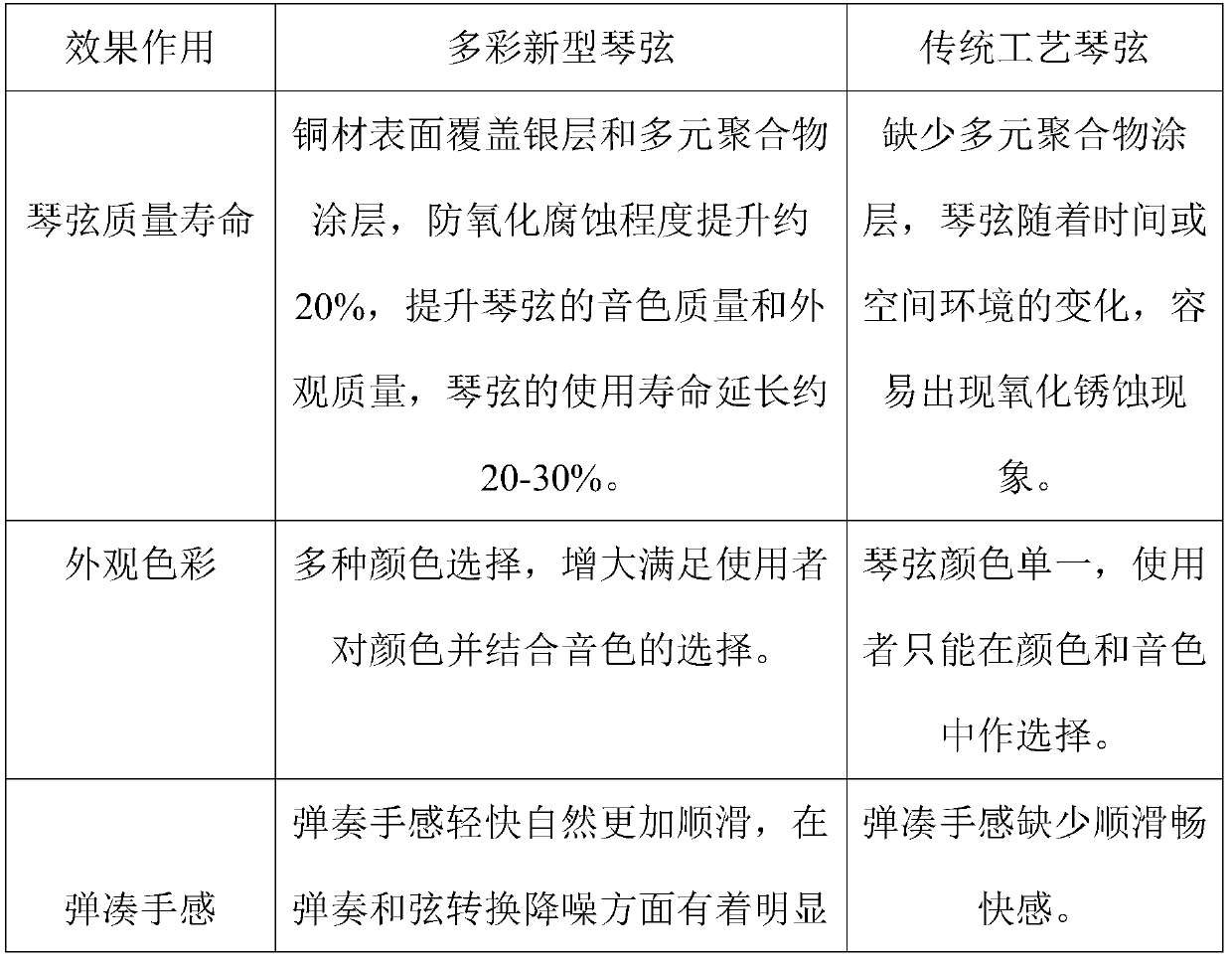

A manufacturing method and technology of strings, applied to stringed instruments, instruments, musical instruments, etc., can solve the problems of affecting the timbre of the strings, the color layer is easy to fall off, the timbre of the strings and multiple colors cannot coexist, and achieve a smooth playing feel. slippery, anti-discoloration improvement, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

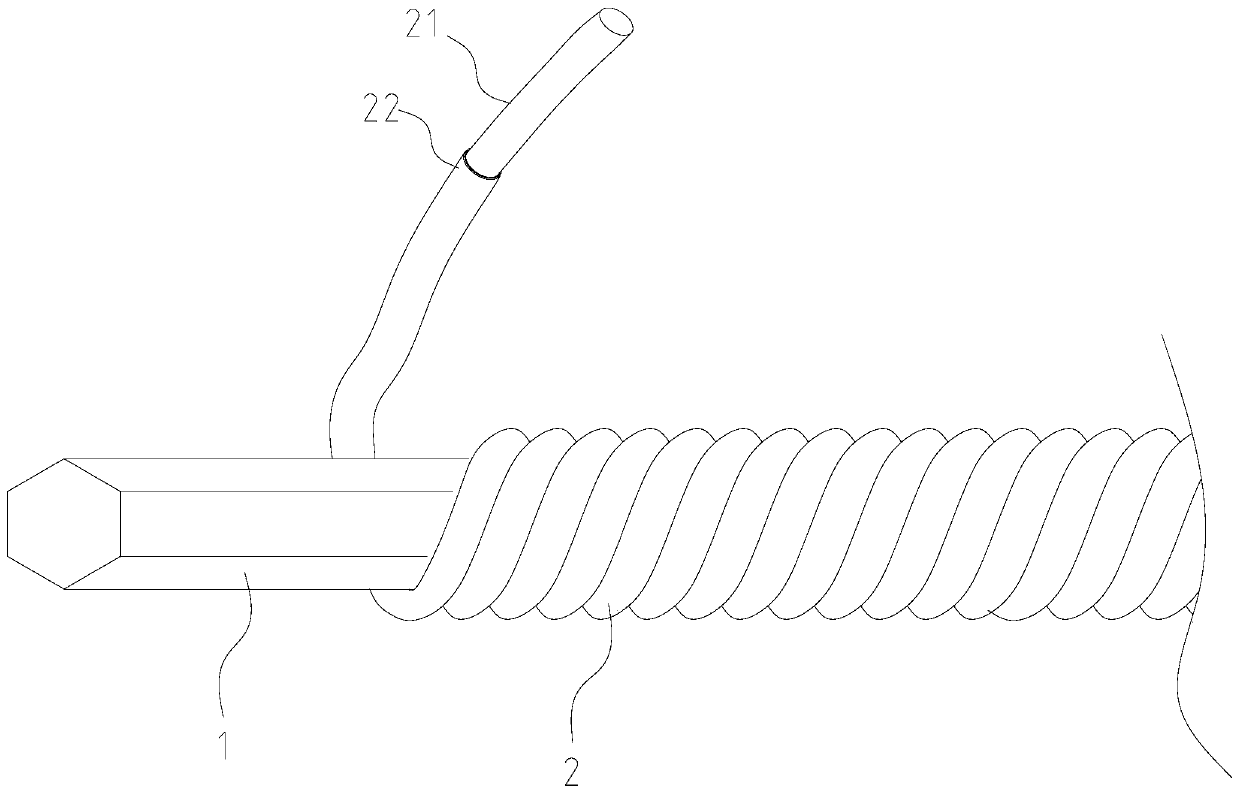

[0026] Such as figure 1 As shown, a string includes a string core 1 and a winding string 2 helically wound on the string core 1 .

[0027] The string core 1 is a hexagonal steel core, a nylon string core 1 or a composite wire string core 1 formed by calendering. In this embodiment, a hexagonal steel core is selected as the string core 1 .

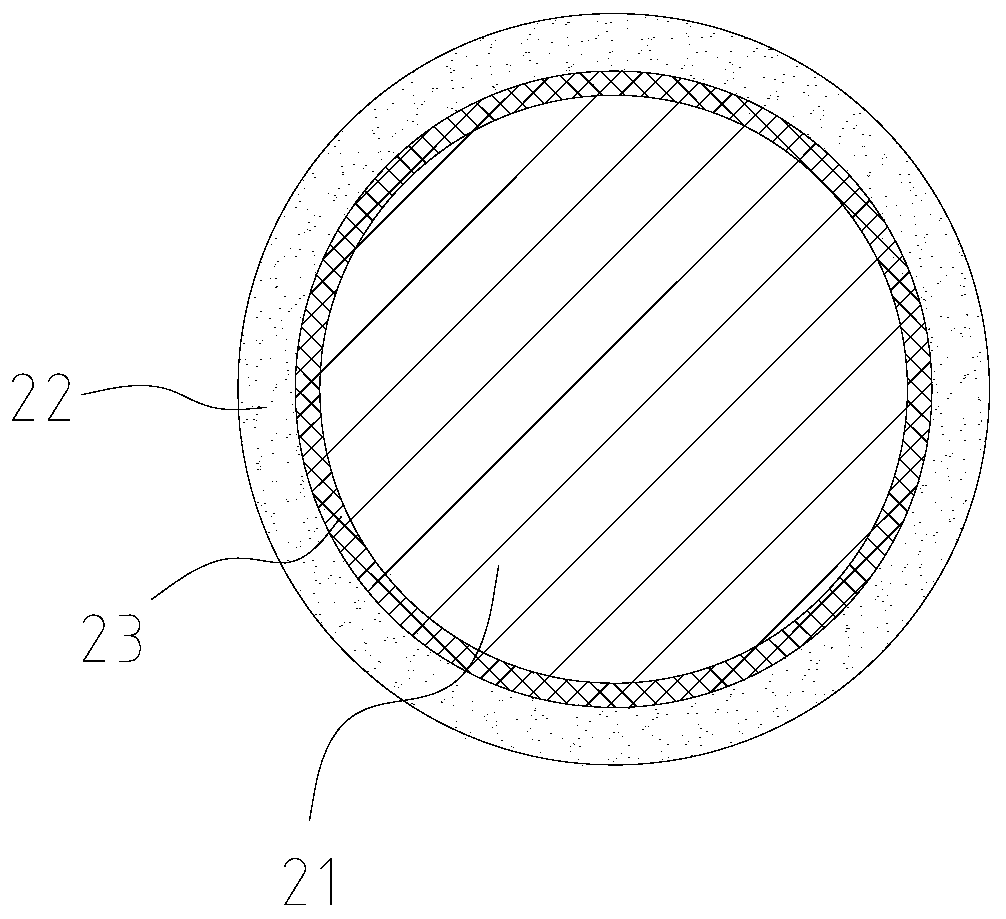

[0028] Such as figure 2 As shown, the winding string 2 includes a copper wire 21, a silver-plated layer 23 covering the surface of the copper wire 21, and a protective layer 22 covered outside the silver-plated layer 23. The total thickness of the silver-plated layer 23 and the protective layer 22 is 0.01~0.1mm. The material of the copper wire 21 is phosphor bronze, red copper, bronze or brass. In this embodiment, based on the standard requirements for the string tone of the folk guitar, it must have thick, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com