Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237results about How to "High resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile metal sparkling paint and preparation method thereof

ActiveCN101077954ANo condensationImprove stabilityLiquid surface applicatorsCoatingsFiberWater dispersible

The water-thinned flash paint consists of water dispersible acrylic resin, deionized water, water-thinned curing cross-linking agent, water dispersible aluminum powder, dispersant, carboxymethyl butyl acetate resin fiber and water thinned assistant. The water dispersible acrylic resin is prepared with monomer mixture of methyl methacrylate, styrene, butyl acrylate, methacrylic acid, ethoxy methacrylate and acetyl acetoxy methacrylate, and through free radical polymerization. The water-thinned flash paint has regularly arranged water dispersible aluminum powder, and can form paint film with high flash number, great adhesion of metal grain, high water tolerance, etc.

Owner:GUANGDONG YATU CHEM +1

Antirust emulsion of self-crosslinked interpenetrating net polymer and its production

InactiveCN101029115AImprove stabilityExcellent calcium ion stabilityAnti-corrosive paintsCross-linkEpoxy

A self-cross-linked interpenetrating network polymer antirust emulsion and its production are disclosed. The emulsion consists of epoxy resin 2-50 proportion, unsaturated hydrocarbon monomer mixture 20-80 proportion, olefine hydroxyl-acid 0.5-8 proportion, functional organic silane 0.5-25 proportion, functional organic fluoride monomer 0.5-20 proportion, cross-linking agent 0.1-1.2 proportion, neutralizing agent 0.5-1.5 proportion, emulsifying agent 1-8 proportion, chain transfer agent 0.05-0.6 proportion, pH regulator 0.2-0.6 proportion, initiating agent 0.3-0.8 proportion, softened water 90-150 proportion and cross-linking curing agent 0.2-5 proportion. The process is carried out by dosing in the first, second and third reactors, mixing in the third reactor and discharging to obtain final product. It has excellent weather and water resistances, better anti-corrosive performance and storage stability.

Owner:HARBIN INST OF TECH

Salt-spray-resistant and anti-aging water-based paint and preparation method thereof

ActiveCN107286798AGood storage stabilityImprove water resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

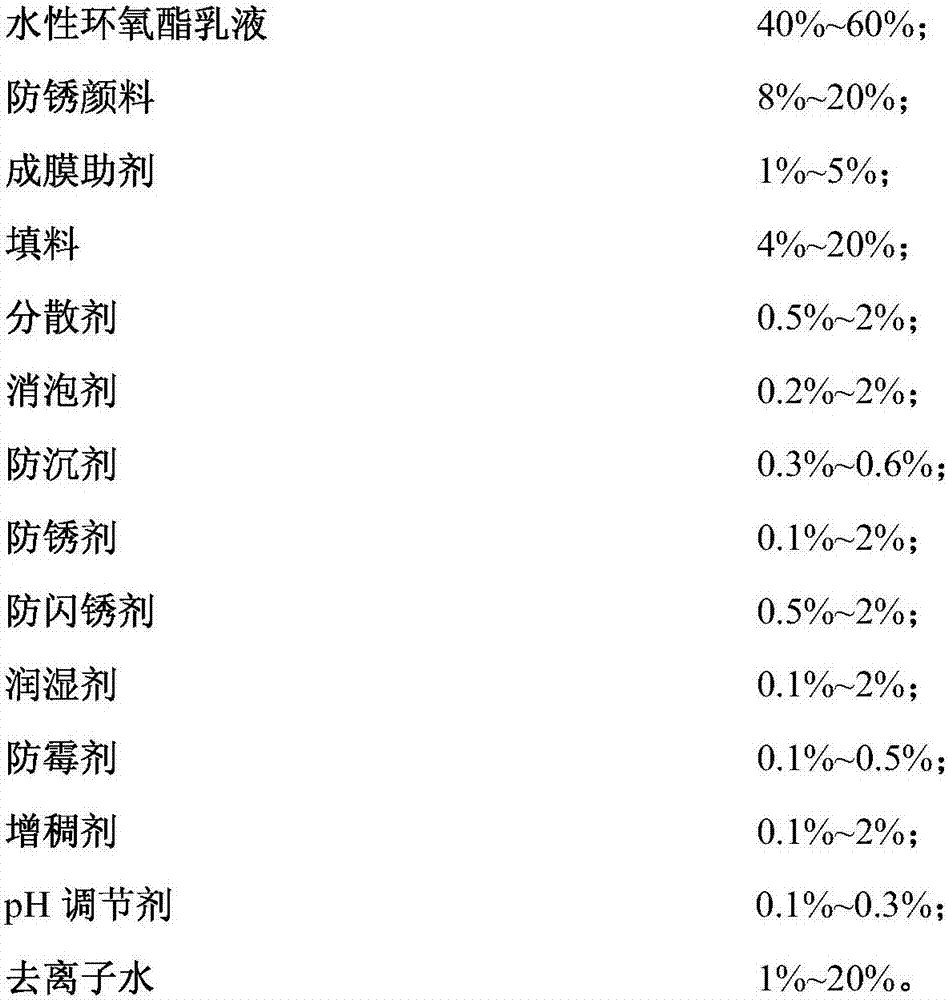

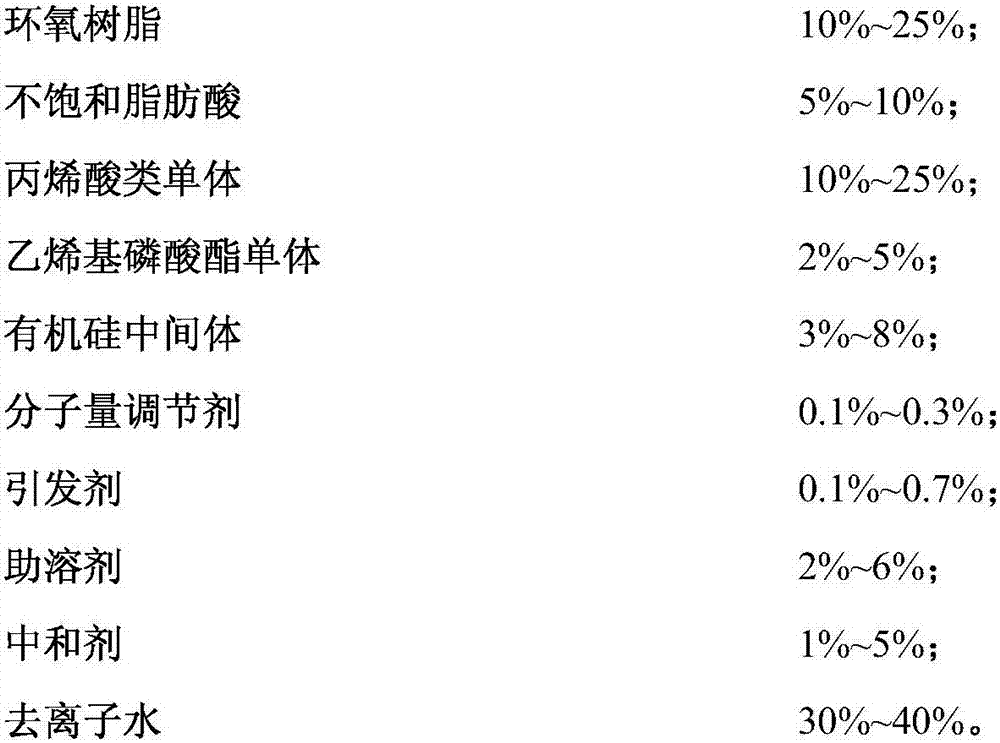

The invention discloses salt-spray-resistant and anti-aging water-based paint and a preparation method thereof. The salt-spray-resistant and anti-aging water-based paint is prepared from components in percentage by weight as follows: 40%-60% of a water-based epoxy ester emulsion, 8%-20% of an anti-rust pigment, 1%-5% of a coalescing agent, 4%-20% of filler, 0.5%-2% of a dispersant, 0.5%-2% of a defoaming agent, 0.3%-0.6% of an anti-settling agent, 0.1%-2% of an anti-rust agent, 0.5%-2% of a flash-rust inhibitor, 0.1%-2% of a wetting agent, 0.1%-0.5% of a mildew preventive, 0.1%-2% of a thickening agent, 0.1%-0.3% of a pH conditioning agent and 1%-20% of deionized water. The water-based paint can resist neutral salt spray for 550 H and resist QUV aging for 600 H, has the advantages of high water resistance, good storage stability, contamination resistance, fast drying, safety, environment-friendliness, simple preparation process and the like, is environment-friendly, accords with the environmental protection development trend and is suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

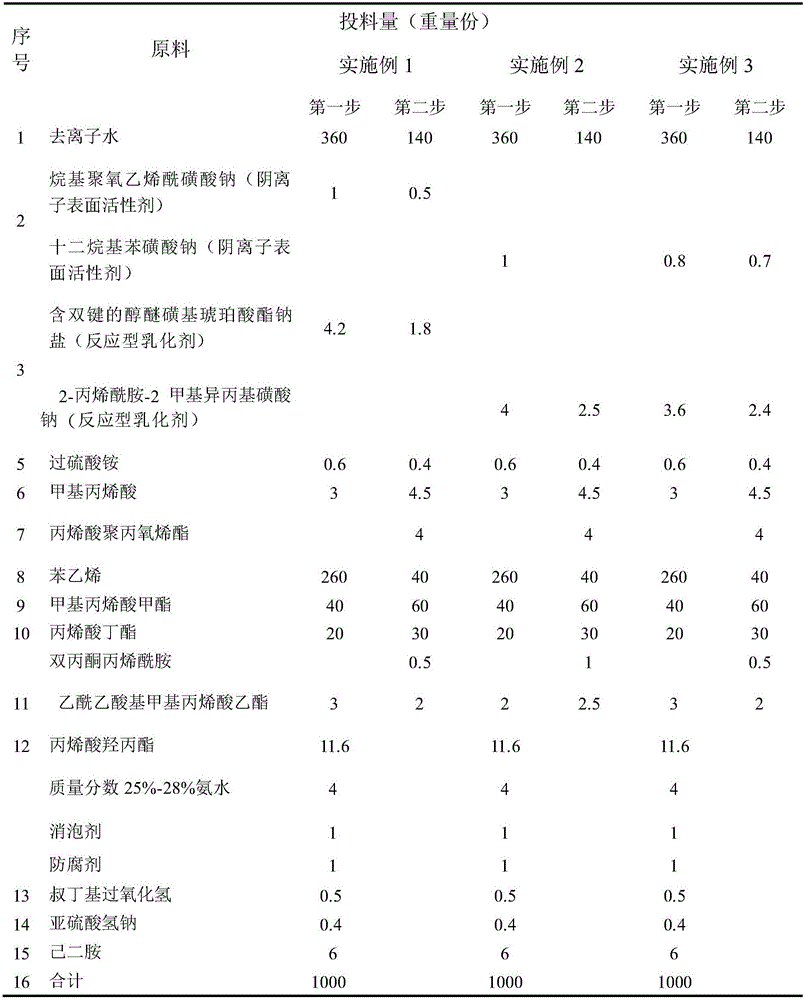

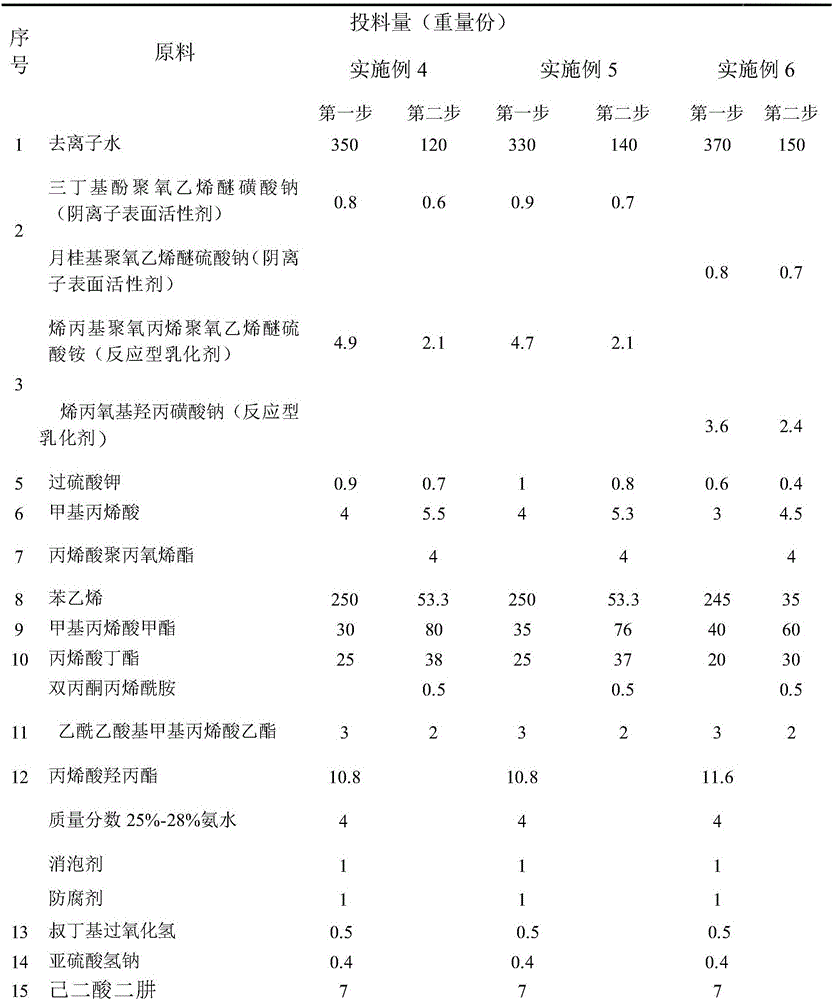

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Anticorrosion epoxy primer and preparation method thereof

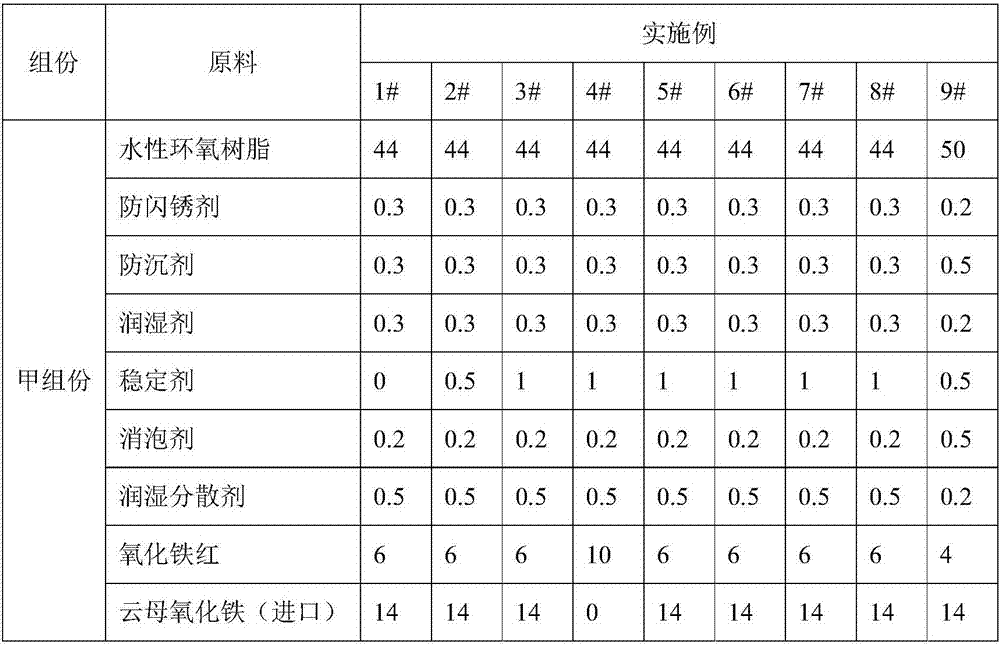

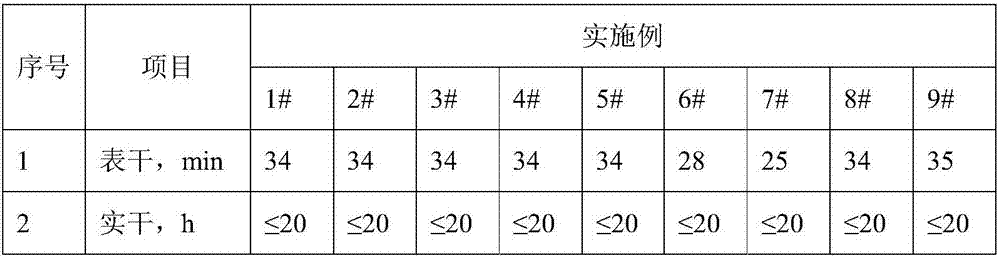

The invention discloses a water-borne anticorrosion epoxy primer and a preparation method thereof. The water-borne anticorrosion epoxy primer comprises a component A and a component B, wherein the component A comprises the following subcomponents in parts by weight: 34-50 parts of water-borne epoxy resin, 0.2-0.5 part of a flash rust preventer, 0.2-0.5 part of an anti-settling agent, 0.2-0.5 part of a wetting agent, 0.5-1.5 parts of a stabilizer, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of a wetting dispersant, 4-9 parts of iron oxide red, 12-19 parts of micaceous iron oxide, 4-9 parts of composite phosphate, 7-12 parts of talcum powder, 8-15 parts of distilled water and 0.5-2 parts of a nano-sized inorganic filler; the component B comprises the following subcomponents in parts by weight: 43-59 parts of a water-borne epoxy curing agent, 1.5-3 parts of a flash rust preventer and 39-54 parts of distilled water; the component A and the component B are blended according to a weight ratio of (3-7): 1. The water-borne anticorrosion epoxy primer adopts a unique formula and a proportion design; compared with the prior art, the water-borne anticorrosion epoxy primer has the advantage as follows: the overall performance, especially the salt spray resistance, of the water-borne anticorrosion epoxy primer is effectively improved.

Owner:SICHUAN OLIN PAINT IND

Spray polyurea elastomer applied to marine drilling platform corrosion prevention as well as preparation method and construction method thereof

ActiveCN103740247ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsAnti-corrosive paintsElastomerSalt resistance

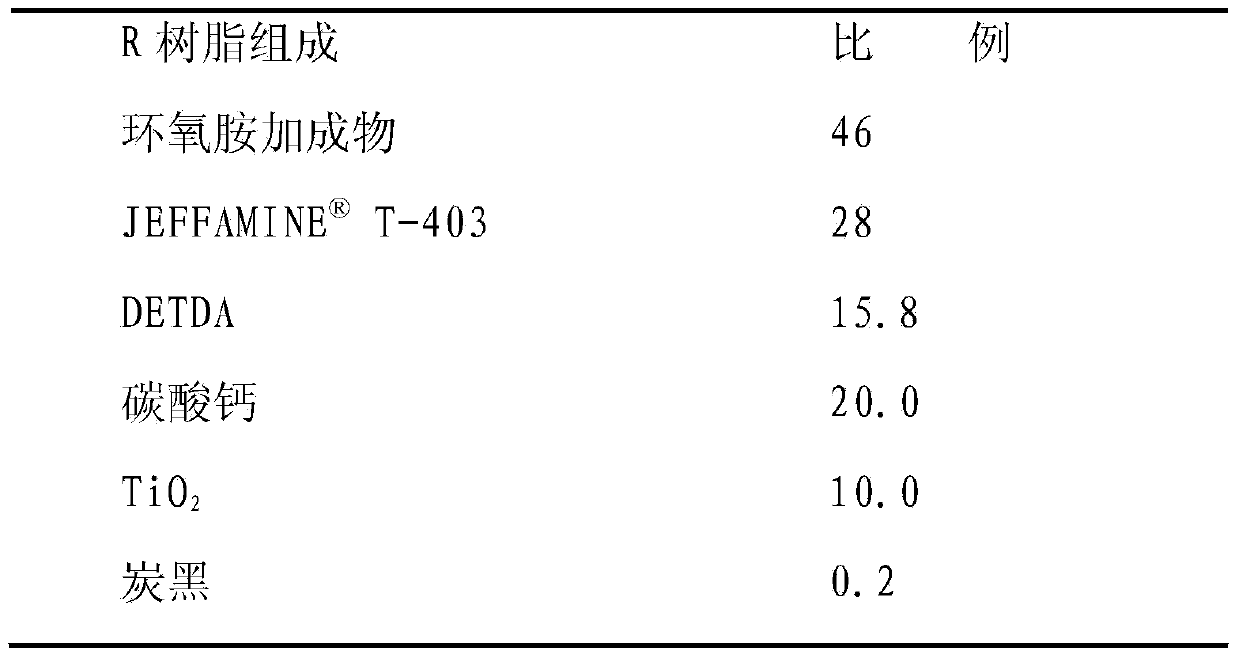

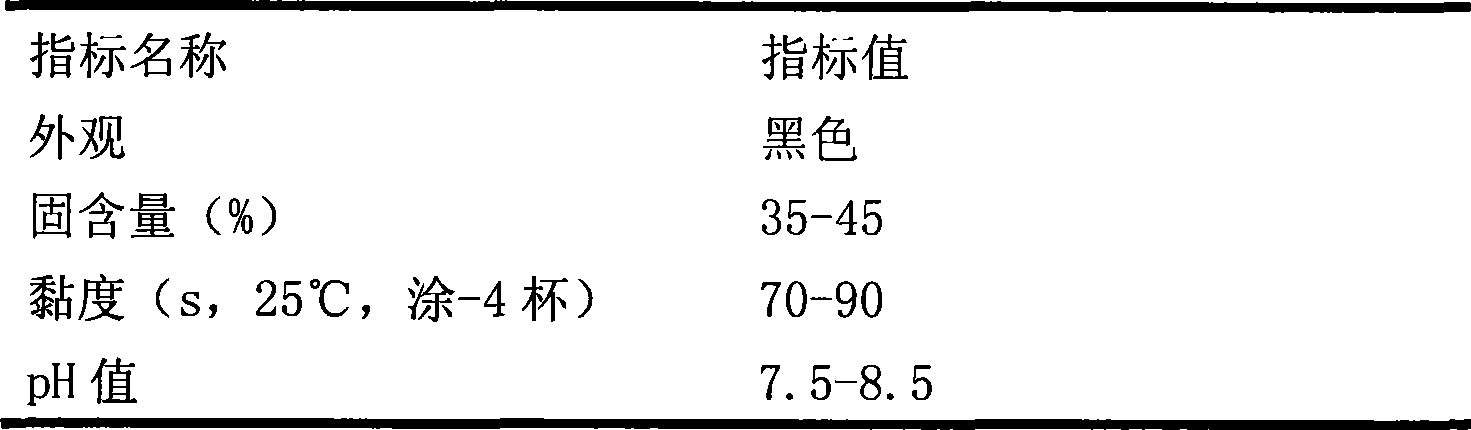

The invention provides a spray polyurea elastomer applied to marine drilling platforms as well as a preparation method and construction method thereof. The problems of poor adhesion and poor corrosion resistance in the marine environments in the prior art can be solved. The spray polyurea elastomer comprises components A and R and is characterized in that the component A is a semi-prepolymer synthesized by 10-40 parts of polyisocyanates, 20-90 parts of epoxy modified polyether polyol and 0-50 parts of polyether polyol by weight; the component R comprises 15-60 parts of epoxy amine adduct, 0-30 parts of amine-terminated polyether resin, 15-40 parts of chain extender and 5-25 parts of filler by weight. The spray polyurea elastomer material has good physical properties and high adhesion, simultaneously has excellent oil resistance, salt mist resistance, bacterium resistance, aging resistance and construction properties, can be shaped randomly, and can be widely applied to the parts with relatively high corrosion prevention requirements, such as platform decks, pile legs and the like of the marine drilling platforms.

Owner:MARINE CHEM RES INST

Heavy-duty graphene primer for ocean ships and preparation method thereof

InactiveCN108997889AStrong adhesionWide applicabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The present invention provides a heavy-duty graphene primer for ocean ships and a preparation method thereof. The primer is prepared by mixing a plurality of antirust pigments, fillers and solvents, such as modified epoxide resin, additives, nanoscale graphene, zinc powder and diphenyl guanidine chromate, with a modified amine and a polyamide, and has long-term corrosion resistance and also advantages unmatched by other graphene primers, including wide scope of application, convenience in construction, excellent electrical conductivity, and good self-repair performance and hydrophobic and oleophobic properties of the coating. In addition, the primer is air-dried at normal temperature, thereby saving energy and facilitating industrialization thereof.

Owner:HUNAN JINHAI SCI & TECH

Water-soluble baking finish special for compressor and preparation method thereof

InactiveCN101381577AIncrease the degree of cross-linkingHigh resistance to salt sprayAnti-corrosive paintsEpoxyAcrylic resin

The invention provides water-soluble baking paint special for a compressor. The paint comprises the following compositions in weight percentage: 30 to 40 percent of epoxy phosphate modified acrylic resin, 5 to 10 percent of methyl-etherified melamine resin, 10 to 20 percent of an antirust filler, 2 to 3 percent of black carbon, 0.1 to 0.5 percent of a defoaming agent, 0.1 to 1.5 percent of a dispersion wetting agent, 10 to 15 percent of a cosolvent and 30 to 40 percent of water; and the water-soluble epoxy phosphate modified acrylic resin is obtained by utilizing epoxy phosphate to modify acrylic resin. The paint has the advantages of nonflammability, nonexplosiveness, low toxicity, low pollution, low cost and the like, is suitable for the application condition and the baking condition of surface coating of the prior refrigerator and the prior air compressor; and the water resistance and the salt spray resistance of a formed paint film can reach or even excess the requirements of the prior solvent-type paint.

Owner:GUANGZHOU UNIVERSITY

High performance water-based industrial anti-corrosion coating and preparation method thereof

ActiveCN104371507AGood chemical resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

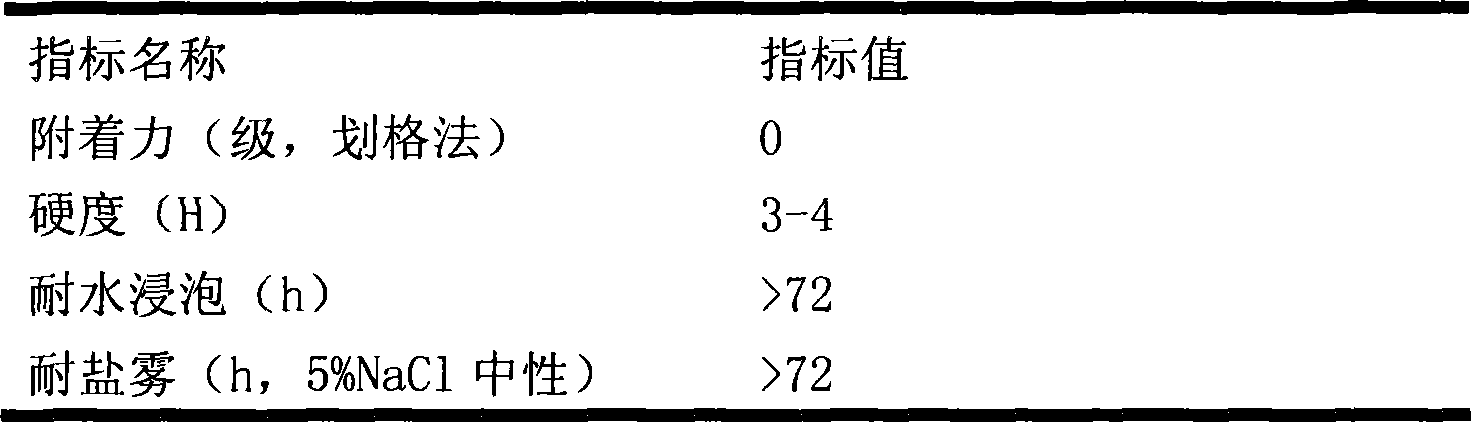

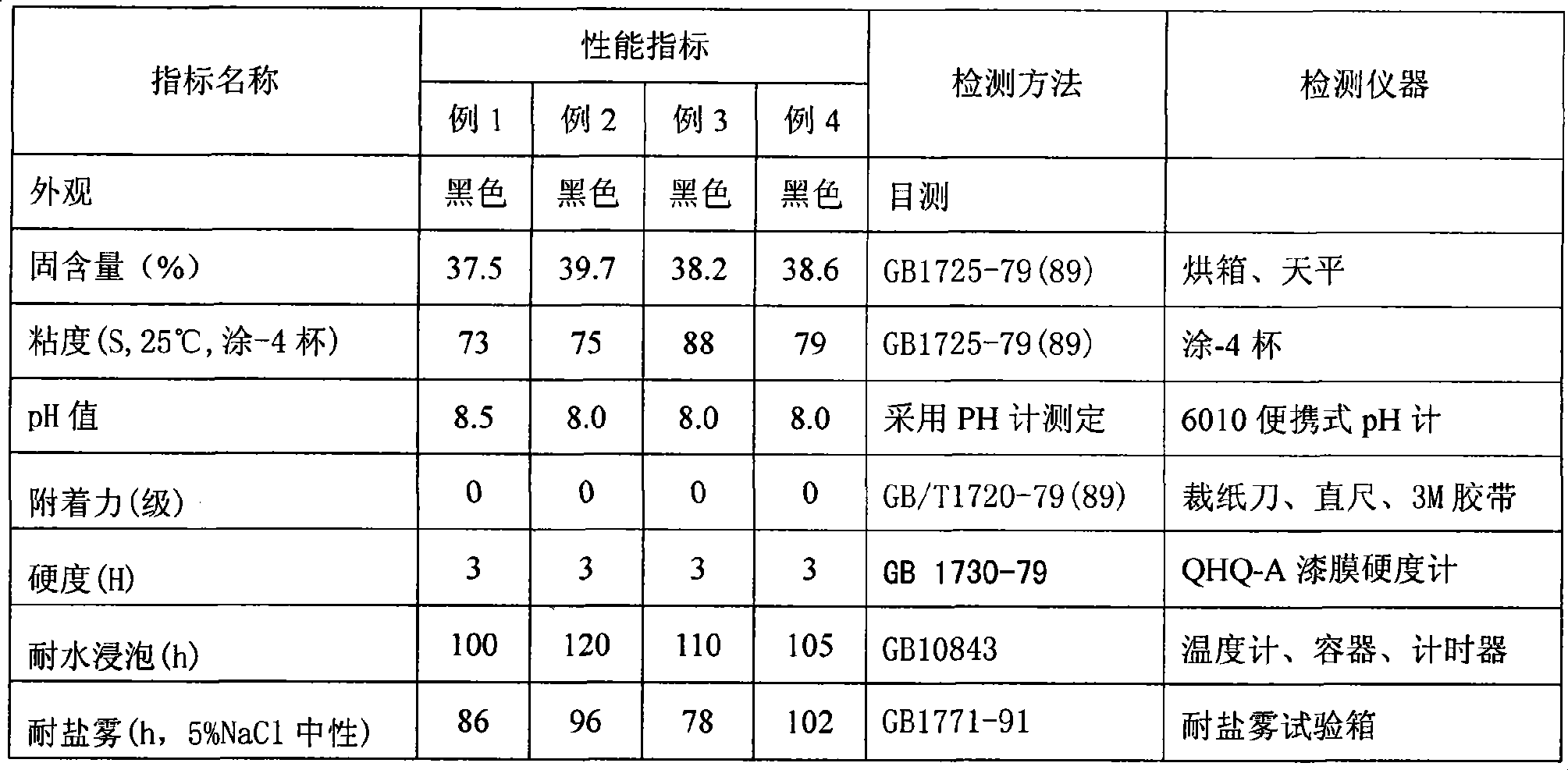

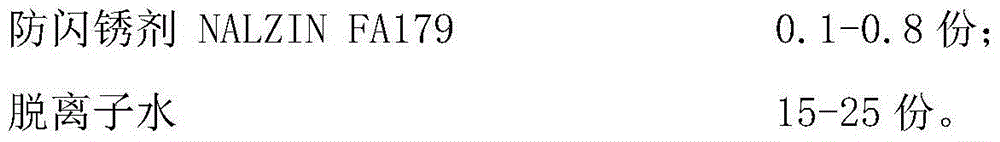

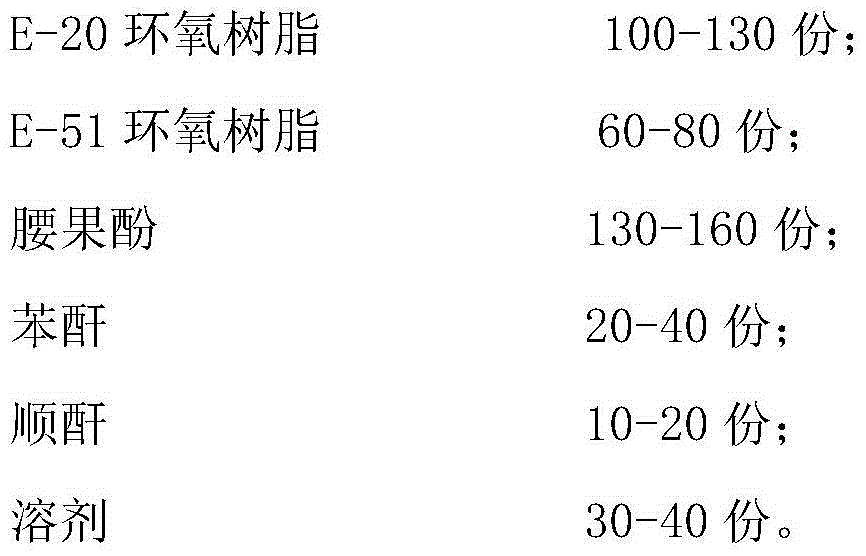

The invention provides a high performance water-based industrial anti-corrosion coating which comprises the following components by weight: 30-45 parts of water-based epoxy ester resin; 10-25 parts of pigments and fillers; 10-25 parts of a non-chromium antirust pigment; 0.5-1 part of water-based anti-settling agent BENTONE DE; 0.5-1.5 parts of dispersing agent NUOSPERSE FX 365; 0.3-1 part of defoaming agent DAPR0DF 1181; 1-2 parts of a water-based drier; 0.5-2.5 parts of water-based wax slurry DeuWax W-2340; 0.3-0.5 parts of leveling agent RHEOLATE FX1070; 0.1-0.8 part of anti flash rust agent NALZIN FA179; and 15-25 parts of deionized water. The high performance water-based industrial anti-corrosion coating has good chemical resistance, water resistance and salt fog resistance, and wide application range.

Owner:山东奔腾漆业股份有限公司

Process for preparing low temperature baking silver mirror back lacquer

InactiveCN1900189ALow baking temperatureShort baking timeInstrumentsPolyester coatingsOrganic solventLacquer

The lower temperature baked silver mirror back lacquer consists of priming lacquer and finishing paint. The priming lacquer consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, and organic solvent in certain weight proportion. The finishing paint consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, leveling agent and organic solvent in certain weight proportion. The present invention has silver mirror back lacquer with baking temperature lowered to 100 deg.c, raised adhesion, high wet head resistance, high temperature change tolerance, high salt fog resistance, high salt water resistance, high corrosion resistance and good post finishing property.

Owner:SHANGHAI JIAO TONG UNIV

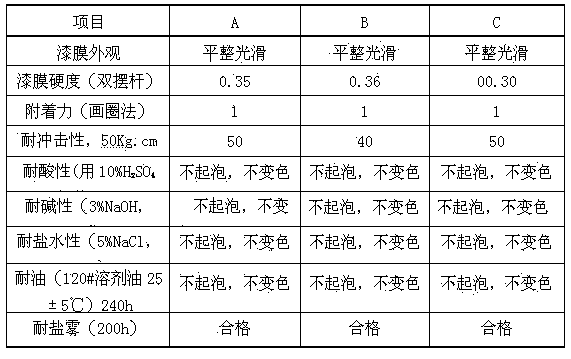

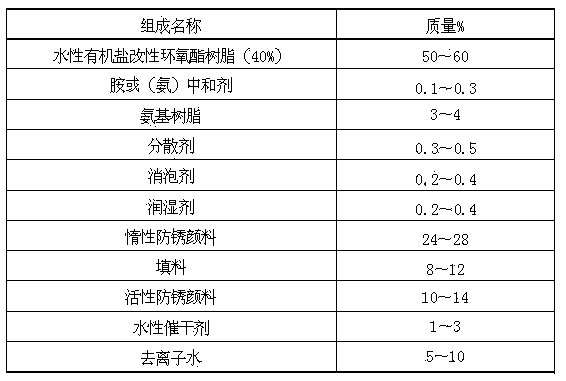

Aqueous organic salt modified epoxy ester resin, and preparation method and application thereof

InactiveCN103360575ANot easy to break by hydrolysisGood water resistance and stabilityAnti-corrosive paintsEpoxy resin coatingsSolventWater soluble

The invention relates to an aqueous organic salt modified epoxy ester resin, and a preparation method and an application thereof. The modified epoxy ester resin is prepared by using the following raw materials, by mass, 7-9% of an epoxy resin, 26-34% of vegetable oil fatty acid, 3-5% of organic sulfonate, 9-16% of diol, 5-10% of polyol, 17-21% of diacid, 1.5-3.0% of polyacid, 0.06-0.08% of an esterification catalyst, 16-18% of a cosolvent and 0.3-0.5% of amine or ammonia. The invention also relates to the preparation method of the aqueous organic salt modified epoxy ester resin, and the application of the aqueous organic salt modified epoxy ester resin. The aqueous organic salt modified epoxy ester resin has a good water soluble stability and a good salt spray resistance.

Owner:CHANGSHA UNIVERSITY

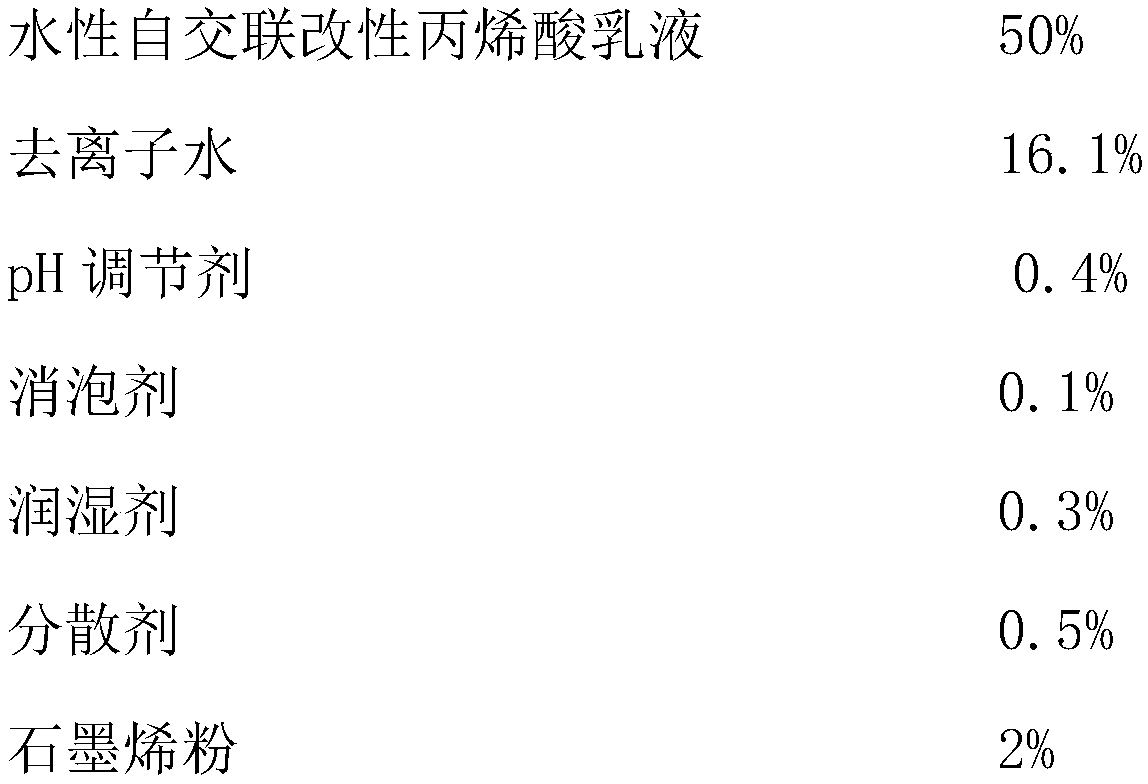

Water-based acrylic anti-corrosion coating and preparing method thereof

InactiveCN109627880AReduce air bubblesReduce the use of defoamersAnti-corrosive paintsEmulsionCorrosion inhibitor

The invention relates to a water-based acrylic anti-corrosion coating and a preparing method thereof, and belongs to the technical field of anti-corrosion coatings. The water-based acrylic anti-corrosion coating is prepared from, by mass, 50-70% of a water-based acrylic emulsion, 0.2-0.4% of a pH modifier, 0.1-0.2% of a defoaming agent, 0.3-0.6% of a wetting agent, 0.5-1.5% of a dispersing agent,1-2% of graphene powder, 12-18% of inorganic toner, 2-4% of a corrosion inhibitor, 2-4% of a cosolvent, 2-5% of a rust converting agent, 1-3% of a flash-rust resistor, 0.3-0.6% of a thickening agent and the balance deionized water. The water-based acrylic anti-corrosion coating is good in stability, high in drying speed, solid content, hardness and adhesive force, good in salt fog resistance and water resistance, and environmentally friendly.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water-based anticorrosive paint

InactiveCN104987831AImprove anti-corrosion performancePerfect anti-corrosion mechanismFireproof paintsAnti-corrosive paintsWater basedPhosphoric acid

The invention provides water-based anticorrosive paint. The water-based anticorrosive paint comprises, by weight, 82-95 parts of phenyl glycidyl ether modified polyaniline, 60-80 parts of epoxy resin, 30-60 parts of alkyd resin, 20-40 parts of modified polyurethane, 10-15 parts of modified nanometer titania, 5-12 parts of zinc phosphate, 6-18 parts of aluminum phosphate, 5-12 parts of imvite, 3-8 parts of mica powder, 2-9 parts of talcum powder, 4-14 parts of quartz powder, 8-18 parts of pigment, 2-8 parts of defoaming agents, 3-6 parts of dispersing agent, 1-5 parts of flatting agents, 4-9 parts of coalescing agents and 60-83 parts of water. The water-based anticorrosive paint is good in antiseptic property, excellent in waterproofness, long in service life and low in cost.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Graphene/acrylic acid static-conducting paint and preparation method thereof

InactiveCN106009984AImprove conductivityHigh resistance to salt sprayAnti-corrosive paintsElectrically-conductive paintsAcrylic resinGraphene

The present invention provides a kind of graphene / acrylic acid conductive electrostatic coating and preparation method thereof, described coating comprises: graphene, dispersant, acrylic resin, auxiliary agent, wherein, the mass ratio of described graphene and dispersant is 20:1 -1:1, and the mass ratio of the graphene to the acrylic resin is 1:20-1:1000, based on the total weight of the coating. The coating of the invention has excellent static electricity conductivity and salt spray resistance, simple process and low cost. The prepared graphene / acrylic conductive coating can be applied to automotive protective primers and topcoats.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

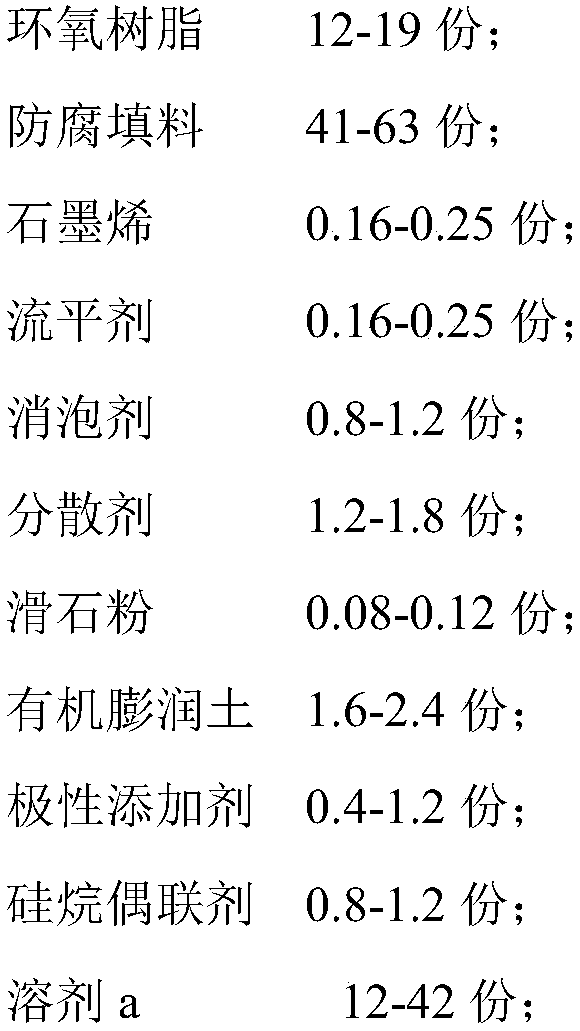

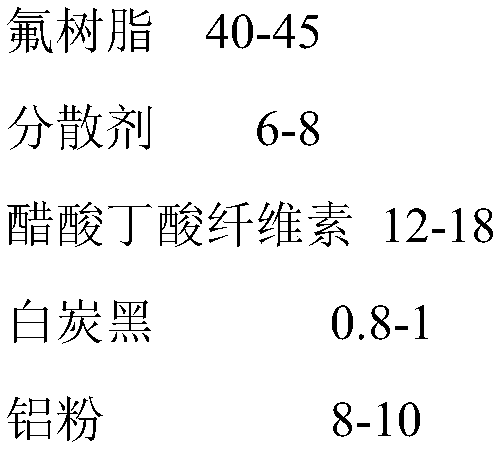

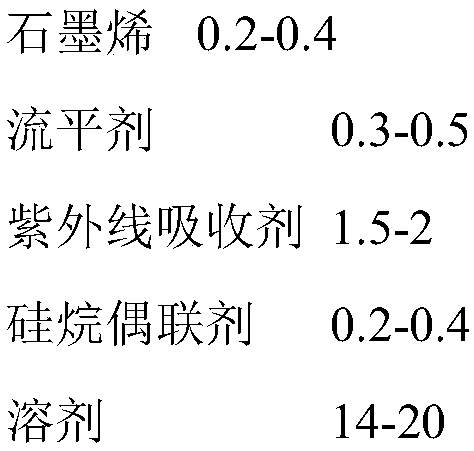

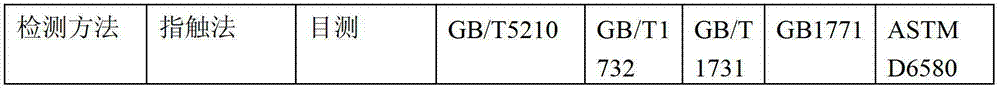

Antirust primer and finishing paint for steel structure and preparation and application of primer and finishing paint

ActiveCN108641548AReduce dosageReduce generationAnti-corrosive paintsEpoxy resin coatingsRare earthCombined use

The invention relates to the technical field of antirust paint for steel structures and particularly discloses antirust primer and finishing paint for a steel structure. The primer comprises a component A and a component B, the component A contains epoxy resin, anticorrosive filler and graphene; the component B contains an epoxy curing agent; the anticorrosive filler comprises a mixture of a rareearth material, composite iron titanium powder, zinc powder and aluminum powder, wherein the particle size of the composite iron titanium powder is greater than or equal to that of the zinc powder, the particle size of the zinc powder is greater than or equal to that of the aluminum powder, and the particle size of the aluminum powder is greater than that of the rare earth material. The finishingpaint contains materials such as fluororesin. Through combined use of the primer and the finishing paint, not only are good anti-corrosion performance and good anti-aging performance achieved, but also a high adhesion force is achieved.

Owner:CENT SOUTH UNIV +1

Quick-drying type organic zinc-rich coating and preparation method thereof

InactiveCN103205179AIncrease productivityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsManufacturing technologyNitrocellulose

The invention relates to a quick-drying type organic zinc-rich coating and a preparation method thereof, and belongs to the technical field of coating preparation. The quick-drying type organic zinc-rich coating comprises independently packaged zinc powder, an organic zinc-rich coating liquid and an organic zinc-rich coating curing agent; when the coating is used, the three components are mixed together and is uniformly stirred by using a stirrer. The coating liquid comprises the following components of various auxiliaries such as a medium molecular weight solid bisphenol A epoxy resin of which the molecular weight is 500 to 2,000, a poly-vinyl butyral resin of which the acetal degree is 44% to 50%, low-viscosity nitrocellulose, a plasticizer, a flexibilizer and the like and high-class solvents; and the curing agent is prepared from polyamide with low molecular weight in a modification mode. The quick-drying type organic zinc-rich coating has the advantages of high solid content, low viscosity and good engineering property, is dried quickly at a low temperature, has high impact resistance and has excellent corrosion resistance and chemical resistance.

Owner:无锡市太湖防腐材料有限公司

Coating as well as preparation method and application thereof

ActiveCN107987677AHigh resistance to salt sprayStrong acid and alkali stabilityAnti-corrosive paintsEpoxy resin coatingsWrinkle skinEpoxy

The invention relates to coating. The coating is prepared from a component A and a component B according to the mass ratio of (4 to 10) to 1, wherein the component A is prepared from 0.5 to 3 weight percent of a graphene material, 20 to 40 weight percent of zinc powder, 20 to 30 weight percent of epoxy resin, 0.5 to 3 weight percent of a dispersant, 3 to 6 weight percent of an anti-sedimentation agent, 10 to 30 weight percent of filler and 20 to 30 weight percent of an organic solvent; the component B is prepared from 40 to 60 weight percent of polyamide, 2 to 6 weight percent of a curing accelerant, 25 to 38 weight percent of epoxy resin and 14 to 26 weight percent of an organic solvent. According to the coating provided by the invention, the epoxy resin is introduced into the component Bin traditional double-component corrosion-resisting coating, and a corresponding component ratio and a grain diameter ratio of the graphene material to the zinc powder are preferred so that the prepared coating has a smooth coating layer surface and does not have phenomena of wrinkles, cracks, air bubbles and the like; the adhesive power of a coated surface is remarkably improved to grade 0 and the salt spray resistance can be further improved to be 3000h or more; the coating has relatively high impact strength and strong acid-alkali stability and is very suitable for being used as a corrosion-resisting coating layer on the surface of a metal material.

Owner:广东好邦石墨烯新材料科技有限公司

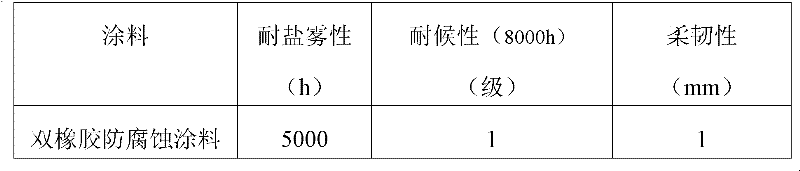

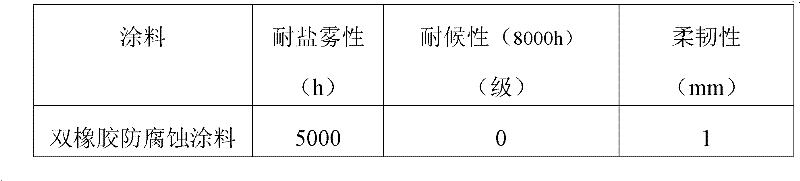

Double-rubber anti-corrosion coating and preparation method thereof

InactiveCN102250518AImprove adhesionGood flexibilityRubber derivative coatingsAnti-corrosive paintsAcrylic resinSolvent

The invention relates to a double-rubber anti-corrosion coating and a preparation method thereof. The double-rubber anti-corrosion coating is composed of the following components in parts by weight: 1 part of chlorinated rubber, 0.5-0.8 part of vinyl chloride vinyl acetate copolymer, 3.1-3.7 parts of dimethylbenzene, 0.1-0.15 part of n-butyl alcohol, 0.1-0.2 part of acrylic resin, 0.2-0.35 part of rutile type titanium white, 0.05-0.1 part of talc powder, 0.05-0.1 part of mica powder, 0.01-0.02 part of dispersing agent, 0.005-0.02 part of titanate coupling agent, 0.0005-0.02 part of organic silicon defoamer and 0.005-0.02 part of flatting agent. The double-rubber anti-corrosion coating is prepared by mixing, dispersing at a high speed and grinding. When in use, the double-rubber anti-corrosion coating forms a coating film along with the volatilization of the solvent. The double-rubber anti-corrosion coating is used for the corrosion resistance of steel structures, such as platforms, ships, bridges, buildings and the like, has the advantages of good adhesive force and flexibility, good water vapor permeability resistance, resistance against corrosion of various chemical mediators and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Modified chlorosulphonated polyethylene rubber paint for steel storage tank and preparation method thereof

InactiveCN101294016AImprove dispersion efficiencyHigh viscosityLarge containersEpoxy resin coatingsSodium BentoniteN-Butanol

The invention relates to a modified chlorosulfonated polyethylene rubber coating used for steel storage tanks and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A is composed of chlorosulfonated polyethylene rubber, dimethylbenzene, trimethylbenzene, titanium white powder, talc powder, fluorocarbon-modified polyacrylamide and organic bentonite; and the component B is composed of bisphenol-A epoxy resin, dimethylbenzene, n-butanol, diphenyl guanidine (manufactured by Dongbei Auxiliary general factory, Shenyang) and ethylenethiourea. The component A and the component B are mixed and cured to form a coating film before application. The coating is excellent in physical property, chemical resistance, salt spray resistance and light fastness, and can be used for the surface protection and coating of steel storage tanks in various corrosive environments.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

High-corrosion resistance acrylate resin and preparation method thereof

ActiveCN106749852AGood weather resistancePrevent infiltrationAnti-corrosive paintsCoating systemPhosphate

The invention provides a high-corrosion resistance acrylate resin. A macromolecular tert-carbonyldioxy group, a phosphate-containing group, long-straight chain (meth)acrylate and a long-side chain carboxyl group are uniformly distributed in the molecule chain segment of the high-corrosion resistance acrylate resin, and the acrylate resin comprises, by mass, 40-60% of a solvent, 2.5-10% of a tert-carbonic acid-containing monomer, 0.1-% of a phosphate ester-containing monomer, 2-12% of a long-straight chain (meth)acrylate monomer, 0.2-1.5% of a long-side chain carboxyl monomer, 15-45% of a non-long-straight chain (meth)acrylate monomer, 0-25% of a vinyl monomer and 0.2-1.2% of an initiator. The invention also provides a preparation method of the acrylate resin and a single-component acryalte coating prepared from the acrylate resin. The acrylate resin has excellent weather resistasnce, excellent chemical resistance and good corrosion resistance, and the single-component acryalte coating prepared in the invention has strong adhesion to a substrate, so the single-component acryalte coating can be widely applied to anticorrosive coating systems as a bottom and surface integrated coating.

Owner:上海华谊涂料有限公司

Preparation method of self-repairing fluorocarbon coating for ships

InactiveCN108102478AReduce releaseImprove liquidityMicroballoon preparationEpoxy resin coatingsSiphonCarbon nanotube

The invention relates to the technical field of coating preparation and in particular relates to a preparation method of self-repairing fluorocarbon coating for ships. The self-repairing fluorocarboncoating for the ships is prepared by taking a self-made oil-soluble capsule core and a sodium dodecyl benzene sulfonate solution as raw materials, emulsifying and dispersing to obtain oil-in-water emulsion, doping a self-made urea formaldehyde pre-polymer into the oil-in-water emulsion, treating to obtain a microcapsule, mixing and stirring a self-made co-solvent, PVDF (Polyvinylidene Fluoride) fluorocarbon resin and titanium white powder to obtain a pre-dispersed raw material and finally, stirring the pre-dispersed material, a self-made carbon nanotube dispersion solution and the microcapsuleat a high speed, and stirring and curing at a low speed; tourmaline powder is adsorbed on a rough surface of the microcapsule and can be used for preventing marine organisms, such as shells and alga,from being attached on ship bodies to grow; meanwhile, the salt spray resistance performance of the fluorocarbon coating is improved; carbon nanotubes are doped so that the siphon action generated bycracks can be enhanced; the capsule core in the microcapsule is slowly released so that the cracks of a coating layer are completely repaired at a relatively rapid speed and the self-repairing fluorocarbon coating has a wide application prospect.

Owner:常州万博金属构件厂

Nanometer modified rust-proof top-coat for metal

InactiveCN1876742AImprove qualityImprove adhesionLiquid surface applicatorsAnti-corrosive paintsFirming agent2-Butanol

The invention relates the nanometer modified metallic anti-corrosive paint, comprising 50-70wt% host crystal, 20-40wt% curing agent and 1-10wt% oxide addition. The host crystal comprises compound resin, color paste and auxiliary agent, and the curing agent comprises 75% aromatic isocyanate, 75% aliphatic isocyanate, dimethylbenzene, butyl acetate optal and 2-butanol. The invention adds nanometer oxidate to improve the quality of anti-corrosive paint, and adds alcohols solvent in host crystal to reduce noxious constituents in solvent. The invention doesn't use the compounds which contain lead and chromium.

Owner:彭志伟

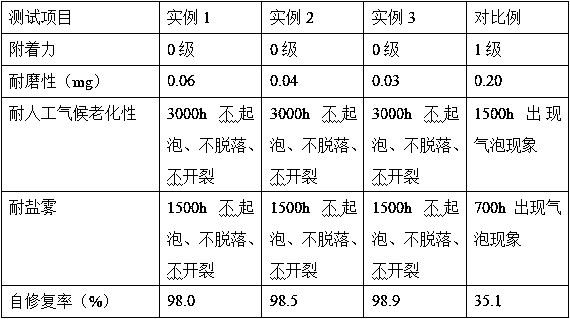

Thin-coating heavy-duty anticorrosive coating and preparation method thereof

InactiveCN110643267AImprove corrosion resistanceHigh glass transition temperatureAnti-corrosive paintsEpoxy resin coatingsFirming agentResin-Based Composite

The invention relates to the technical field of anticorrosive coatings, and in particular, relates to a thin-coating heavy-duty anticorrosive coating and a preparation method thereof. The thin-coatingheavy-duty anticorrosive coating comprises the following raw materials in parts by mass: composite resin, a dispersing agent, a defoaming agent, a thixotropic agent, glass flakes, modified graphene slurry, a special functional filler, a filler, a solvent and a composite curing agent. With adopting of the thin-coating type heavy-duty anticorrosive coating provided by the invention, the problems ofslow paint film drying time, long construction period, insufficient flexibility, coating layer failure such as easiness in cracking and peeling and like due to the high-film-thickness design of a conventional heavy-duty anticorrosive coating are solved, the coating is applied to long-acting heavy-duty corrosion prevention of steel structures and concrete engineering in a marine environment, improves the paint film defect of high-film-thickness design of the conventional heavy-duty anticorrosive coating, greatly reduces the construction cost and the construction progress, reduces the use amount of the coating and reduces the emission of volatile organic compounds. The production process is simple, the processing cost is low, and large-scale commercial production is easy.

Owner:XIAMEN SUNRUI SHIP COATING

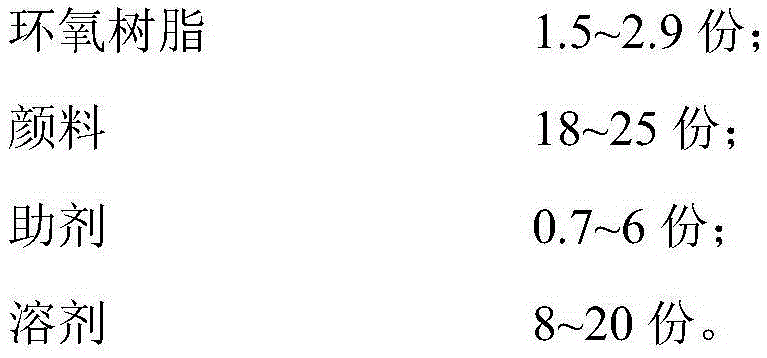

Thick plate polyurethane primer and preparation method thereof

InactiveCN105602435AGood flexibilityHigh resistance to salt sprayAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyester

The invention discloses a thick plate polyurethane primer which comprises the following ingredients in parts by weight: 17-35 parts of polyester resin, 2-6 parts of amino resin, 2-6 parts of isocyanate, 1.5-2.9 parts of epoxy resin, 18-25 parts of pigment, 0.7-6 parts of an auxiliary agent and 8-20 parts of a solvent. The invention also discloses a preparation method of the thick plate polyurethane primer. The T bend of the thick plate polyurethane primer provided by the invention can reach 0T without cracks, the flexibility is good, and a paint peeling phenomenon is avoided in a processing process; the salt spray resistance is high; by virtue of cooperation of the thick plate polyurethane primer and a polyester topcoat with common performances, the salt spray test achieves grade 1 within 1000 hours; the adhesive force with a substrate and the adhesive force with the topcoat are superior to those of traditional epoxy primer and polyester primer. Compared with the traditional primer, the thick plate polyurethane primer provided by the invention has relatively excellent adhesive force, flexibility and chemical corrosion resistance.

Owner:NIPPON PAINT TIANJIN

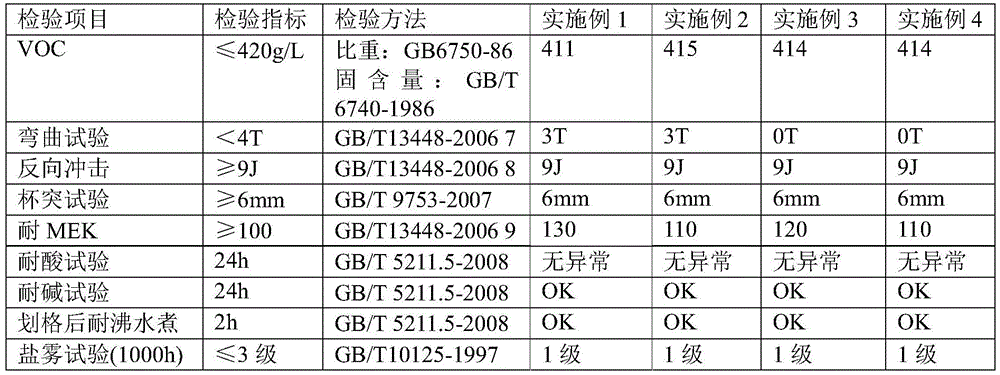

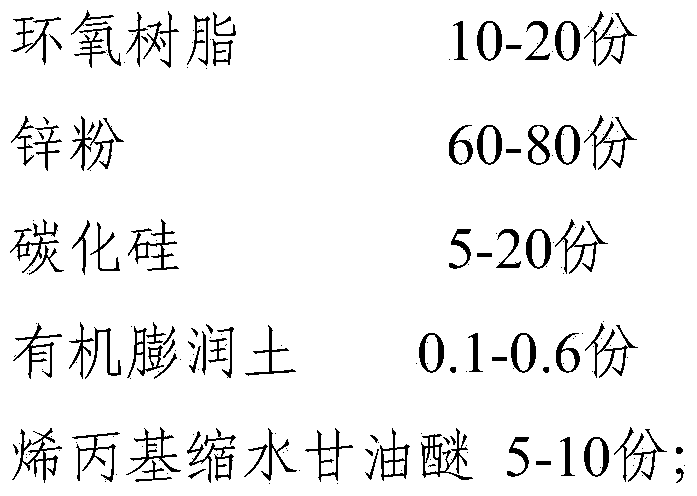

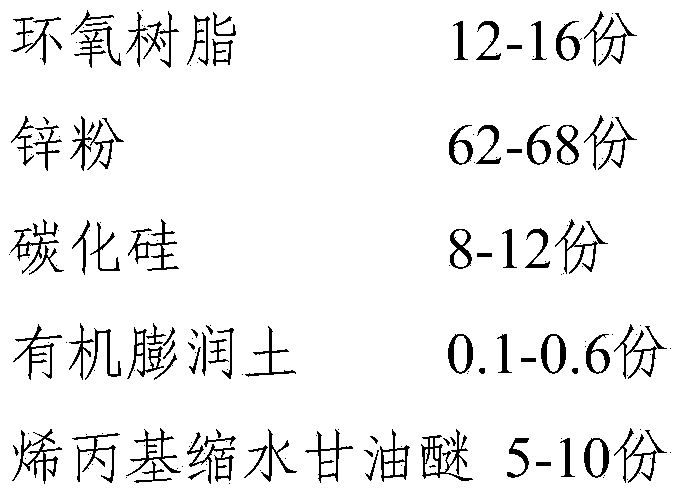

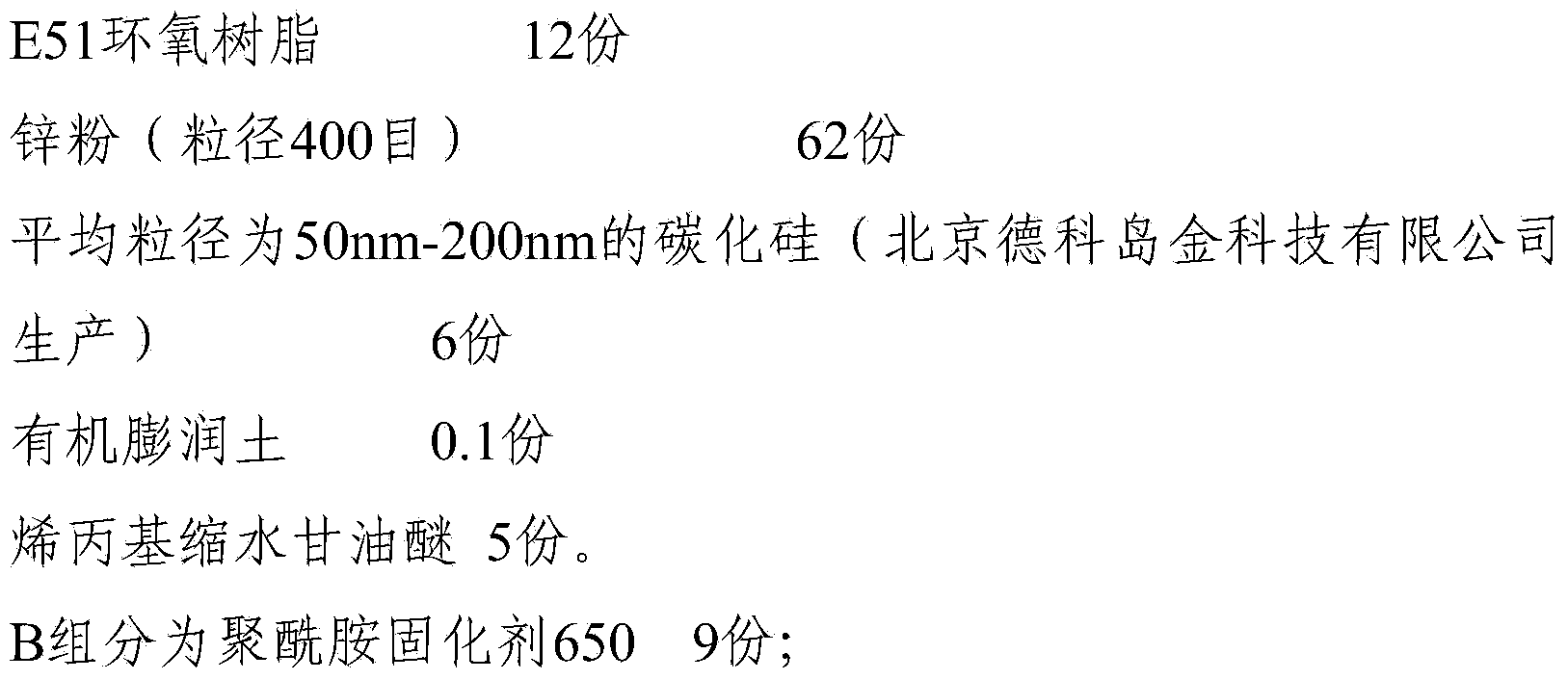

Zinc-rich primer and preparation method thereof

ActiveCN103805027ADense paint filmImprove anti-corrosion performanceEpoxy resin coatingsPolyamideCorrosion

The invention belongs to the field of coatings and provides a zinc-rich primer. The zinc-rich primer is composed of a component A and a component B, wherein the component A comprises the following components in parts by weight: 10-20 parts of epoxy resin, 60-80 parts of zinc powder, 5-20 parts of silicon carbide, 0.1-0.6 part of organic bentonite and 5-10 parts of allyl glycidyl ether; the component B comprises 5-30 parts of a polyamide curing agent or cashew nut shell oil by weight. According to the technical scheme, nano-grade fillers are added into an epoxy zinc-rich paint; the fillers can sufficiently fill up a gap formed between large spherical zinc grains so that a paint film of the epoxy zinc-rich paint is dense and the permeation of a corrosion medium is blocked, and furthermore, the anticorrosion property of the zinc-rich primer is greatly improved. Furthermore, the epoxy zinc-rich paint has no organic emissions and is an environment-friendly material.

Owner:XIAN HIGHWAY INST +1

High-performance water-based heavy anti-corrosion paint and preparation method thereof

InactiveCN108690465AEasy to prepareRaw materials are easy to getAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEpoxy

The invention relates to high-performance water-based heavy anti-corrosion paint and a preparation method thereof, and belongs to the technical field of water-based anti-corrosion paint. The water-based heavy anti-corrosion paint comprises water-based epoxy zinc rich primer, water-based epoxy graphene-modified intermediate paint and water-based polyurethane finishing paint, wherein an intermediatecoating uses the water-based epoxy graphene-modified intermediate paint; properties, such as an extra-large specific surface area, good barrier property, high chemical stability and good electrical conductivity, of graphene are utilized, so the overall performance of the anti-corrosion compound coating is greatly improved, for example, an adhesive force of the coating to a base material is reinforced, the abrasive resistance and the anti-corrosion property of the paint are improved, and the coating has the characteristics of environmental protection and safety, and no secondary pollution andthe like. Three types of the paint are compounded for using, a thickness of a paint film can be greatly reduced under the precondition without affecting the anti-corrosion property, and the requirements of lightweight coating are satisfied. The preparation method of the water-based heavy anti-corrosion paint is simple, and suitable for industrial production, and raw materials are easily obtained.

Owner:重庆绿涂腾科技有限公司

Preparation method of waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating

InactiveCN110698951AReduce reunionImprove reflectivityAnti-corrosive paintsEpoxy resin coatingsZinc phosphateFirming agent

The invention discloses a preparation method of a waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating. The preparation method comprises the following steps: adding water, a substrate wetting agent, a defoaming agent, an anti-flash-rust agent and a coalescing agent into a paint mixing tank and carrying out dispersing; adding waterborne bisphenol A epoxy resinand performing dispersing; adding a pH regulator to regulate a pH value and carrying out dispersing; adding anionic emulsified asphalt and carrying out dispersing; adding an inorganic bentonite thickener to regulate viscosity; and carrying out dispersing to obtain a component A of the coating; adding water, a defoaming agent, a dispersing agent and an anti-settling agent into another paint mixingtank and carrying out dispersing; adding dry-process modified sericite powder and zinc phosphate, and carrying out sanding and dispersing; adding a waterborne modified amine curing agent and carryingout dispersing to obtain a component B; and mixing inorganically coated rutile titanium dioxide, precipitated phase silicon dioxide, hollow microspheres, a dispersing agent, a waterborne epoxy curingagent and a waterborne epoxy emulsion, carrying out grinding and dispersing, and mixing the formed mixture with the component A of the coating, the component B and chemically surface-modified shell powder to obtain the waterborne coating.

Owner:萧县金虹新型防水建材有限公司

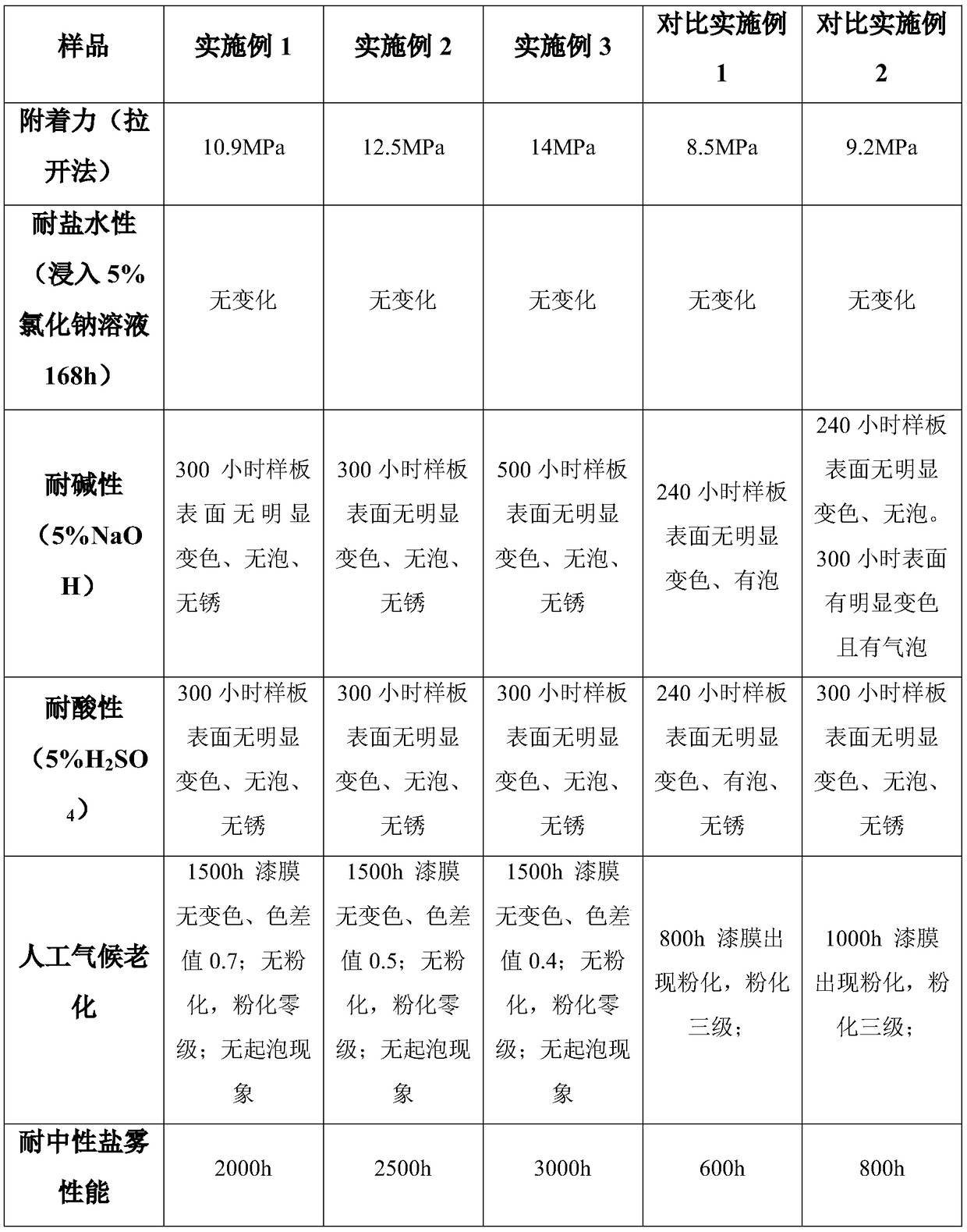

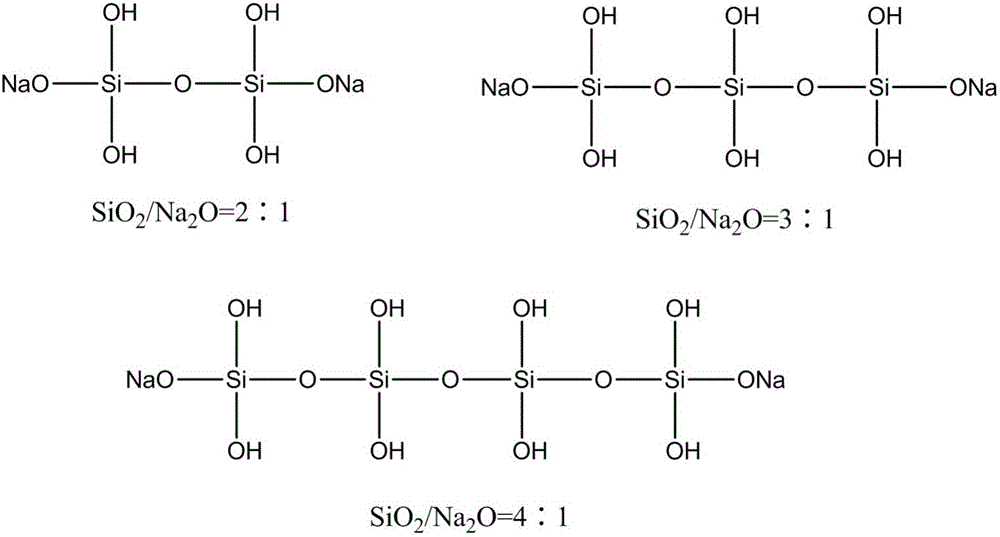

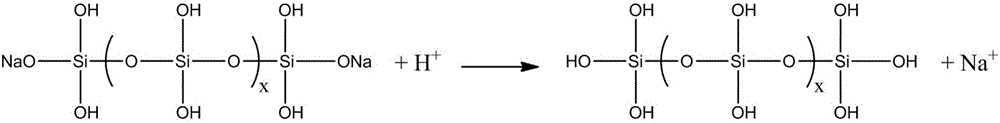

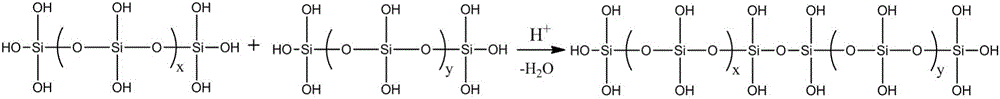

Preparation method of ultrahigh modulus silicate

The invention discloses a preparation method of ultrahigh modulus silicate. The preparation method successively comprises the following steps: dilution, activated carbon absorption treatment, cation exchange resin exchange, conversion to organic phase, removal of solvent water, etherification polymerization, neutralization, alkalization reaction, removal of organic solvent, and water addition for regulating solid content. By the preparation method of the scheme, ultrahigh modulus sodium silicate, potassium silicate or lithium silicate with high added value can be prepared. The product can be applied to a waterborne inorganic zinc-rich anticorrosive paint and other fields. Flexibility of the waterborne inorganic zinc-rich anticorrosive paint with the application of the ultrahigh modulus silicate can pass a 2mm bend axis test, shock resistance can reach 50 Kg.cm, and salt spray resistance can be effectively raised.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Nano silicon dioxide/graphene/epoxy resin composite anticorrosive coating as well as preparation and application

PendingCN108384389AImprove corrosion resistanceImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention belongs to the technical field of anticorrosive coating and discloses nano silicon dioxide / graphene / epoxy resin composite anticorrosive coating as well as preparation and application. The composite anticorrosive coating is prepared from the following components in parts by weight: 40 to 60 parts of epoxy resin, 0.1 to 2 parts of graphene, 5 to 10 parts of nano silicon dioxide, 5 to 10 parts of acetylene carbon black, 10 to 30 parts of curing agent, 1 to 5 parts of antirust additive, 1 to 5 parts of de-foaming agent, 1 to 5 parts of flatting agent, 2 to 10 parts of dispersant and80 to 160 parts of organic solvent. The composite anticorrosive coating disclosed by the invention has a very good anticorrosive effect and excellent comprehensive performance, is environmentally friendly and has high attachment; a preparation method is simple and industrialization is easy to realize; meanwhile, the nano silicon dioxide / graphene / epoxy resin composite anticorrosive coating has a relatively good application prospect in the field of ocean corrosion prevention.

Owner:SOUTH CHINA UNIV OF TECH

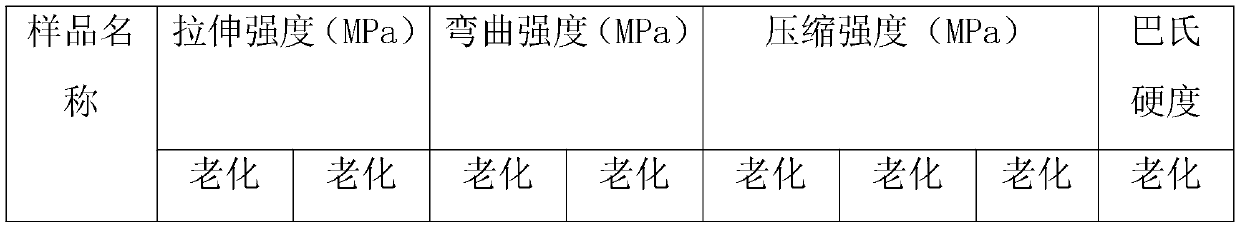

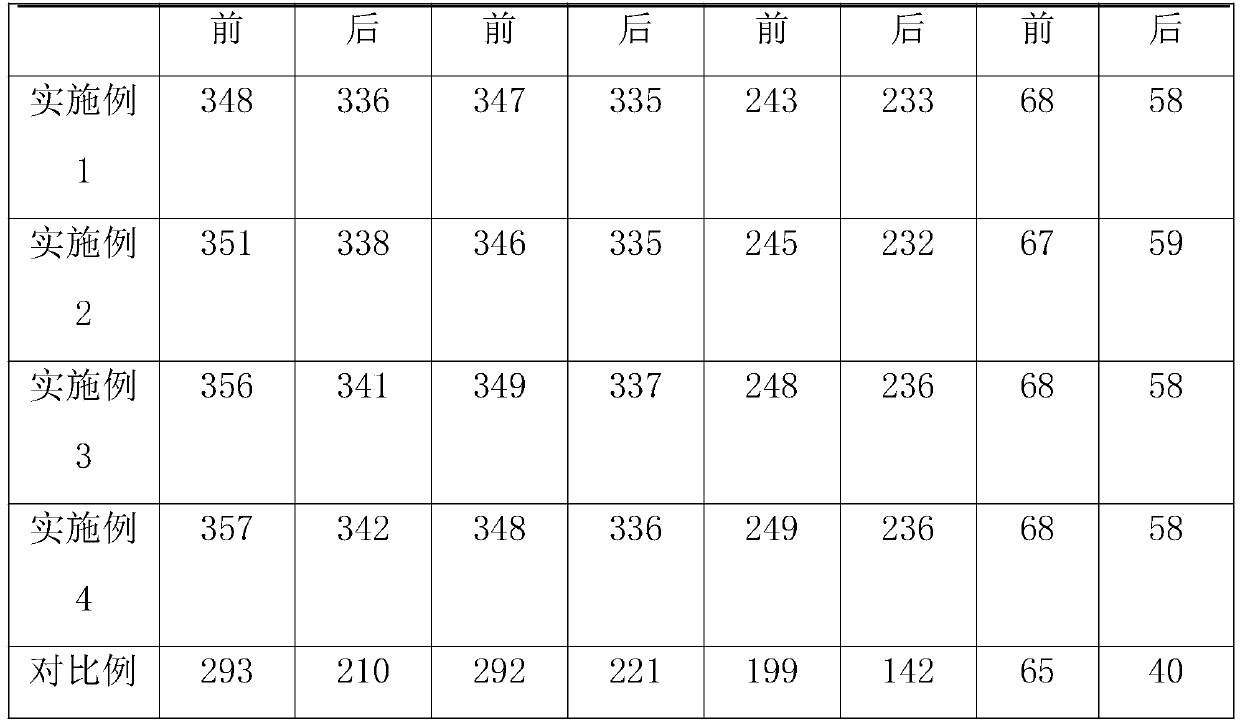

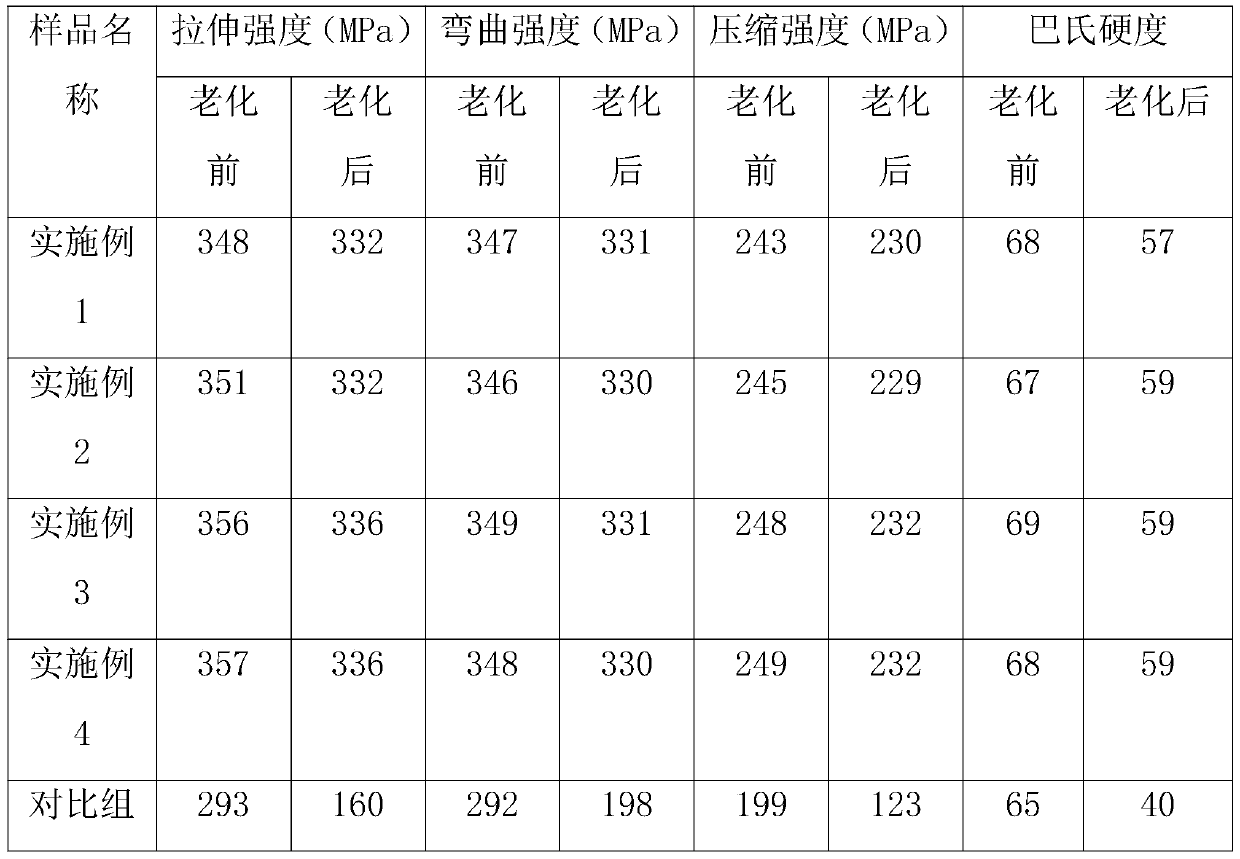

Anti-aging glass fiber reinforced plastic material and preparation method thereof

The invention provides an anti-aging glass fiber reinforced plastic material. The anti-aging glass fiber reinforced plastic material is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyester resin, 2-8 parts of styrene, 1-3 parts of a curing agent, 1-3 parts of an accelerant, 80-120 parts of glass fibers, 10-40 parts of an illite functional powder material, 1-3 parts of a coupling agent I, 1-2 parts of zinc oxide and 5-6 parts of graphene. The preparation method comprises the following steps: pickling illite powder, washing with water to be neutral, drying, and modifying with a coupling agent II to obtain the illite functional powder material. The illite functional powder material is added and compounded with other raw materials, so that the crosslinking degree between macromolecular chains can be increased; the anti-aging glass fiber reinforced plastic material is particularly suitable for marine environments such as ships, and the salt fog resistance, the aging resistance and the strength of the anti-aging glass fiber reinforced plastic material are remarkably improved compared with those of a common glass fiber reinforced plastic material.

Owner:CHENGDE RENHE MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com