Anti-aging glass fiber reinforced plastic material and preparation method thereof

A glass fiber reinforced plastic, aging-resistant technology, applied in the field of composite materials, can solve the problems affecting the performance and service life of glass fiber reinforced plastic products, performance defects, easy to appear aging, etc., to achieve the best application effect, less impurities, and improved mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

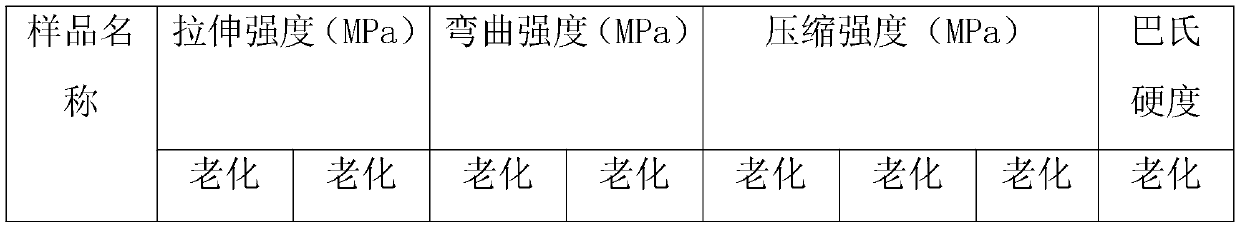

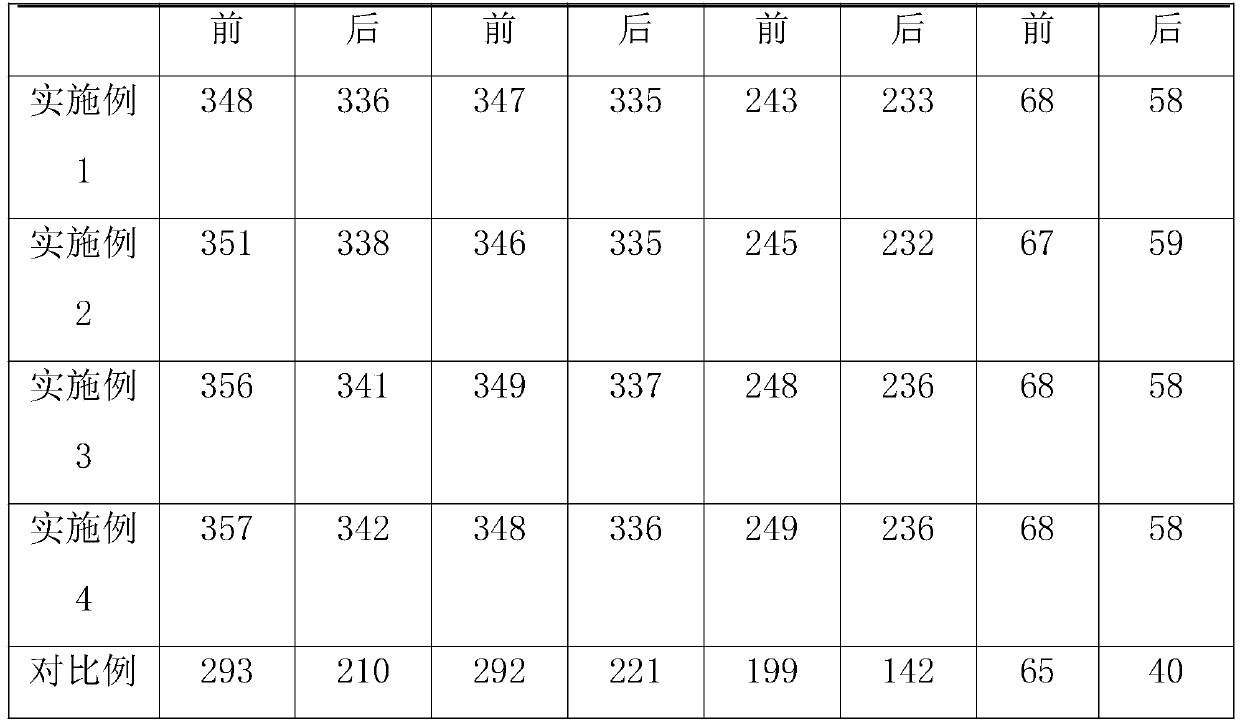

Examples

Embodiment 1

[0041] Preparation of illite functional powder material: 100 grams of illite powder is acid-washed with sulfuric acid and then washed with water to neutrality. The mass fraction of each component of illite powder is: SiO 2 72%, Al 2 o 3 18%, K 2 O 6%, other metal oxides 4%, the particle size of the illite powder is 325 mesh, the amount of acid is 10% of the mass of the illite powder, the pickling temperature is 90°C, the pickling time is 2h, and dried to contain water rate is less than 1%, add silane coupling agent KH550, the amount of silane coupling agent KH550 is 0.5% of the mass of illite powder, the stirring temperature of adding silane coupling agent KH550 is 50°C, and the stirring time is 2h. Obtain illite functional powder material.

[0042] Preparation of aging-resistant FRP material: Weigh 100 grams of isobenzene-type unsaturated polyester resin 199# resin, 2 grams of styrene, 2 grams of methyl ethyl ketone peroxide, 1 gram of cobalt naphthenate, 110 grams of glas...

Embodiment 2

[0045] Preparation of illite functional powder material: pickling illite powder with nitric acid and washing with water until neutral, the mass fraction of each component of illite powder is: SiO 2 75%, Al 2 o 3 14%, K 2 O 9%, other metal oxides 2%, the particle size of the illite powder is 500 mesh, the amount of acid is 20% of the mass of the illite powder, the pickling temperature is 90°C, the pickling time is 2.5h, and dried to The water content is less than 1%, add silane coupling agent KH560, the dosage of silane coupling agent KH560 is 1.0% of the mass of illite powder, the stirring temperature for adding silane coupling agent KH560 is 50°C, the stirring time is 2h, stir Finally, the illite functional powder material is obtained.

[0046] Preparation of aging-resistant FRP material: Weigh 100 grams of bisphenol A type unsaturated polyester resin (197C# resin), 4 grams of styrene, 2 grams of ethylenediamine, 2 grams of N,N-dimethylaniline, and 100 grams of glass fiber...

Embodiment 3

[0049] Preparation of illite functional powder material: pickling illite powder with sulfuric acid, nitric acid, hydrochloric acid and washing with water until neutral, the mass fraction of each component of illite powder is: SiO 2 78%, Al 2 o 3 16%, K 2 O 5.8%, other metal oxides 0.2%, the particle size of the illite powder is 800 mesh, the amount of acid is 30% of the mass of the illite powder, the pickling temperature is 90°C, the pickling time is 3h, and dry to water rate is less than 1%, add silane coupling agent KH792, the amount of silane coupling agent KH792 is 2.0% of the mass of illite powder, the stirring temperature for adding silane coupling agent KH792 is 50°C, the stirring time is 2h, after stirring The illite functional powder material is prepared.

[0050] Preparation of anti-aging FRP material: Weigh 100 grams of vinyl ester type unsaturated polyester resin W2-3# resin, 8 grams of styrene, 3 grams of benzoyl peroxide, 2 grams of N,N-dimethylaniline, glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com