Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

An acrylate and copolymer technology, applied in the field of Ming Dynasty, can solve the problems of water resistance, salt spray resistance, adhesion between paint film and substrate, unreasonable application, etc., to ensure dense and excellent salt spray resistance. , to ensure the effect of hardness and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. prepares acrylate copolymer emulsion

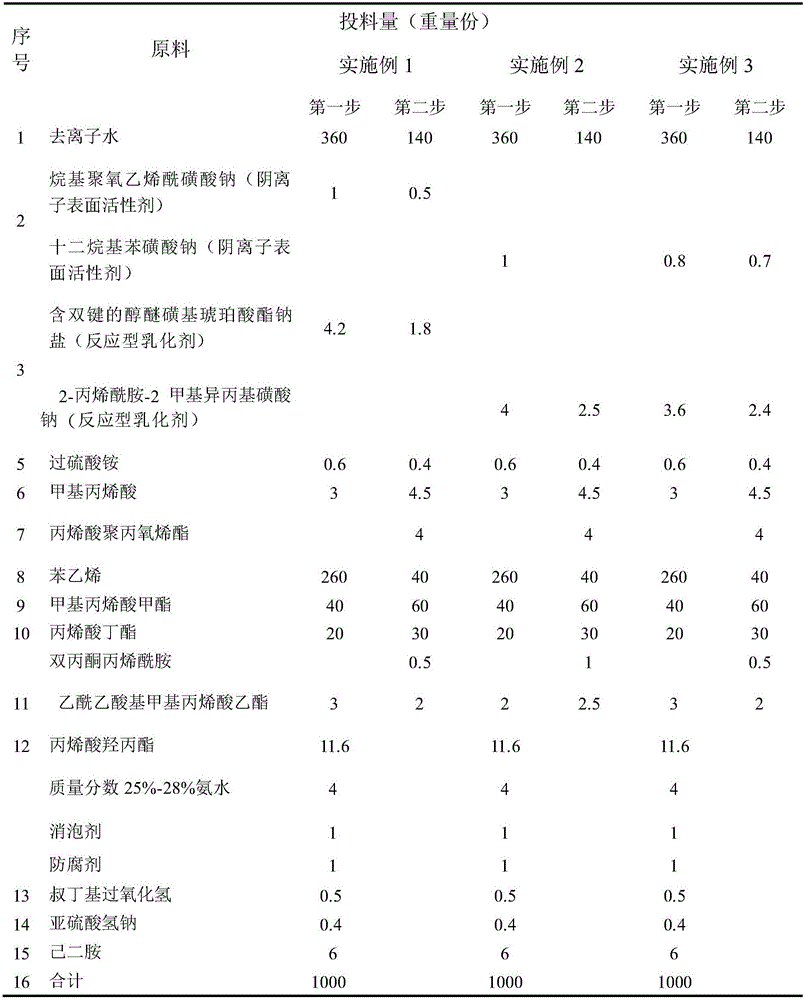

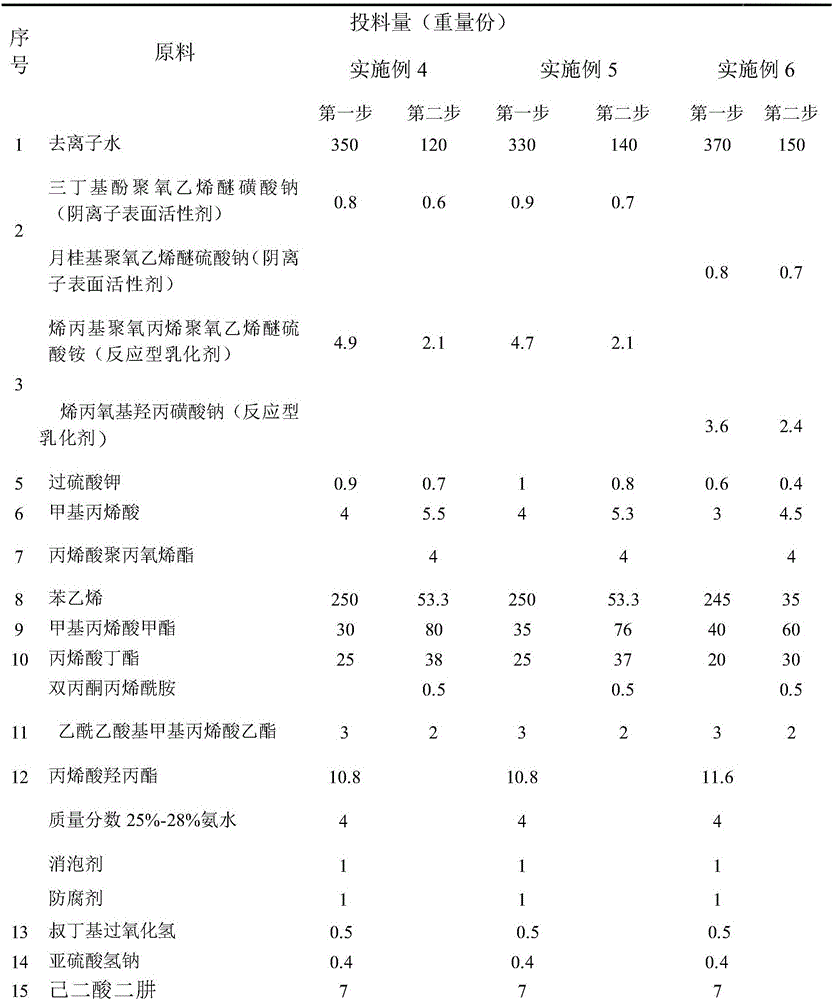

[0031] Table 1 Components and dosage ratio of room temperature crosslinking acrylate copolymer emulsion

[0032]

[0033] The concrete preparation of acrylate copolymer emulsion comprises the following steps:

[0034] (1) Preparation of monomer pre-emulsion: water, anionic surfactant, reactive emulsifier, methacrylic acid, methyl methacrylate, butyl acrylate, styrene and functional The monomers are put into the monomer pre-emulsification tank in turn, and emulsified at a high speed for 0.5-3h (preferably 1h) to form the first step monomer pre-emulsion; the water, anionic surfactant, and reactive emulsifier described in the second step in Table 1 , methacrylic acid, methyl methacrylate, butyl acrylate, styrene and functional monomers are sequentially put into a monomer pre-emulsification tank, and emulsified at a high speed for 0.5-3h (preferably 1h) to form a second-step monomer pre-emulsion;

[0035] (2) Prepara...

Embodiment 4

[0050] Embodiment 4: take the acrylate copolymer emulsion prepared by the foregoing embodiment as the water-based industrial anticorrosion paint of film former

[0051] Table 4 Components and dosage ratio of water-based industrial anticorrosion paint

[0052]

[0053]

[0054] The concrete preparation of this waterborne industrial anticorrosion paint comprises the following steps:

[0055] (1) Take formula quantity water, dispersant, wetting agent, filler, defoamer, pH adjuster, antifreeze in grinding kettle and join in above-mentioned stirring kettle, with rotating speed 2500-3500r / min (preferably 3000r / min) min) Grinding for 80-100 min (preferably 90 min) to obtain slurry.

[0056] (2) Add the slurry to another dispersing tank, take the emulsion, film-forming aid, anti-flash rust agent, leveling agent and thickener of the formula and add it to the dispersing tank at a speed of 300-500r / min (preferably 400r / min) and stirred for 20-40min (preferably 30min), to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com