Double-rubber anti-corrosion coating and preparation method thereof

A technology for anti-corrosion coatings and rubber, applied in the direction of anti-corrosion coatings, rubber derivative coatings, coatings, etc., can solve the problems of poor adhesion and flexibility of coatings, unsatisfactory corrosion resistance, and high brittleness of chlorinated rubber. Achieve good water vapor permeability resistance, long salt spray resistance, good adhesion and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The double-rubber anti-corrosion coating used for the outer wall of a steel structure of the present invention and a manufacturing method thereof.

[0019] In a stainless steel tank, first add 3.2 parts by weight of xylene, add 1 part by weight of chlorinated rubber and 0.6 parts by weight of chlorinated ethylene vinyl acetate copolymer under stirring conditions, and then disperse at high speed until a uniform rubber solution is formed. Then add 0.1 parts by weight of n-butanol, 0.15 parts by weight of acrylic resin, 0.25 parts by weight of rutile titanium dioxide, 0.07 parts by weight of talc, 0.07 parts by weight of mica powder, 0.015 parts by weight of 110 dispersant, 0.011 parts by weight of NDZ201 coupling agent, 0.01 parts by weight 141, 0.009 parts by weight Disperse 358N leveling agent at high speed for 30 minutes, and then grind it with a sand mill for 0.5 to 1 hour to obtain a finished product.

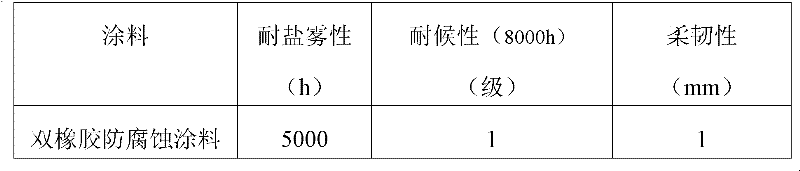

[0020] The main results of the experiment are shown in the table be...

Embodiment 2

[0023] The double-rubber anti-corrosion coating used for the outer wall of a steel structure of the present invention and a manufacturing method thereof.

[0024] In a stainless steel tank, first add 3.2 parts by weight of xylene, add 1 part by weight of chlorinated rubber and 0.6 parts by weight of chlorinated ethylene vinyl acetate copolymer under stirring conditions, and then disperse at high speed until a uniform rubber solution is formed. Then add 0.1 parts by weight of n-butanol, 0.15 parts by weight of acrylic resin, 0.25 parts by weight of rutile titanium dioxide, 0.07 parts by weight of talc, 0.07 parts by weight of mica powder, 0.015 parts by weight of 5010 dispersant, 0.011 parts by weight of NDZ201 coupling agent, 0.01 parts by weight 2035, 0.009 parts by weight Disperse 3777 leveling agent at high speed for 30 minutes, and then grind it with a sand mill for 0.5 to 1 hour to obtain a finished product.

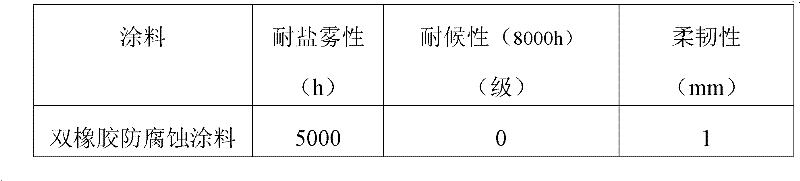

[0025] The main results of the experiment are shown in the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com