Antirust primer and finishing paint for steel structure and preparation and application of primer and finishing paint

A steel structure and anti-rust paint technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of low adhesion, high cost, and high zinc powder consumption, so as to improve adhesion and avoid coating Porous and guaranteed anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

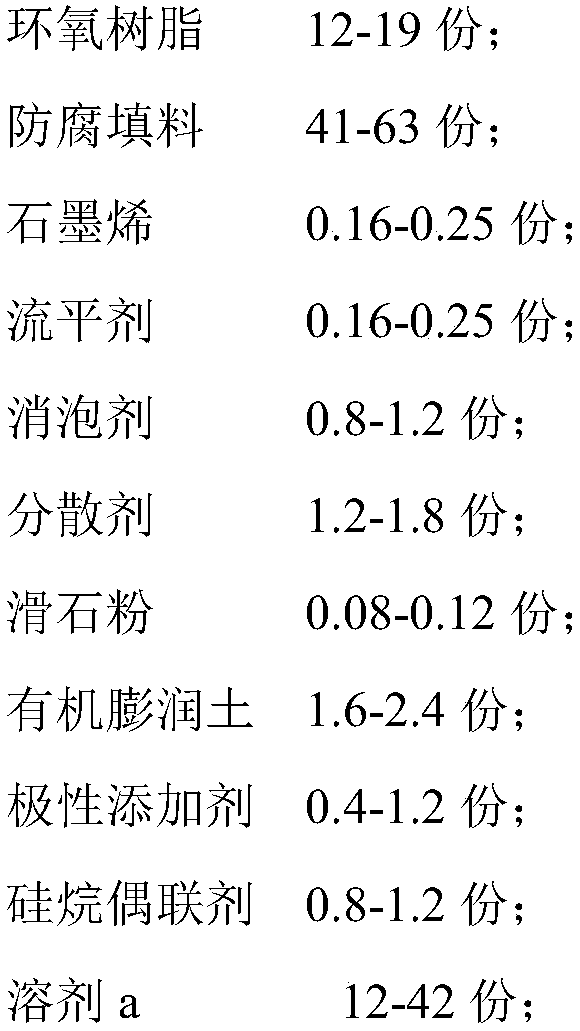

[0132] To prepare 100g of component A coating, get 12g of solvent (formed by methyl isobutyl ketone, xylene and n-butanol in a ratio of 1:2:1), add 2.39g of organobentonite, stir for 10 minutes, add 0.72g of acetone as polar Additives, after stirring for 10 minutes to obtain a dispersion. Add 1.20g of silane coupling agent KH550 and 1.79g of dispersant (BYK-163) to 0.24g of graphene powder, stir for 10 minutes and then add to the resulting dispersion, and add 17.94g of epoxy resin E44 (Sinopec Baling Petrochemical public, epoxy equivalent 210-240), stirred for 10 minutes and ultrasonically dispersed for 12 hours. After the dispersion is complete, add 1.20g of defoamer (BYK-066N), 0.24g of leveling agent (BYK-323), and 0.12g of talc, and stir for 10 minutes. 13.96g flaky zinc powder (800 mesh), 13.96g flaky zinc powder (1000 mesh), 13.96g flaky zinc powder (1200 mesh), 11.96g flaky aluminum powder (1200 mesh), 2.39g rare earth powder ( Lanthanum-cerium composite phosphate par...

Embodiment 2

[0141] Prepare 100g of component A coating, get 18g of solvent (formed by methyl isobutyl ketone, xylene and n-butanol in a ratio of 1:2:1), add 1.8g of organobentonite, stir for 10 minutes, add 0.54g of acetone as electrode Additives, after stirring for 10 minutes to obtain a dispersion. Add 0.9g of silane coupling agent KH550 and 1.35g of dispersant (BYK-163) to 0.18g of graphene powder, stir for 10 minutes and then add to the resulting dispersion, and add 13.5g of epoxy resin E44 (Sinopec Baling Petrochemical Co., Ltd. , epoxy equivalent 210-240) and 15.75g solvent, stirred for 10 minutes and ultrasonically dispersed for 12 hours. After the dispersion is complete, add 0.90g defoamer (BYK-066N), 0.18g leveling agent (BYK-323), 0.09g talcum powder, and stir for 10 minutes. 10.50g flaky zinc powder (800 mesh), 10.50g flaky zinc powder (1000 mesh), 10.50g flaky zinc powder (1200 mesh), 9.00g flaky aluminum powder (1200 mesh), 1.80g rare earth powder ( Lanthanum-cerium composi...

Embodiment 3

[0150] To prepare 100g of component A coating, get 16.2g of solvent (formed by methyl isobutyl ketone, xylene and n-butanol in a ratio of 1:2:1), add 1.62g of organobentonite, stir for 10 minutes, add 0.49g of acetone as Polar additive, a dispersion was obtained after stirring for 10 minutes. Add 0.81g of silane coupling agent KH550 and 1.21g of dispersant (BYK-163) to 0.16g of graphene powder, stir for 10 minutes and then add to the resulting dispersion, and add 12.14g of epoxy resin E44 (Sinopec Baling Petrochemical Public, epoxy equivalent 210-240) and 24.25g solvent, stirred for 10 minutes and ultrasonically dispersed for 12 hours. After the dispersion is complete, add 0.81g defoamer (BYK-066N), 0.16g leveling agent (BYK-323), 0.08g talcum powder, and stir for 10 minutes. 9.44g flaky zinc powder (800 mesh), 9.44g flaky zinc powder (1000 mesh), 9.44g flaky zinc powder (1200 mesh), 8.09g flaky aluminum powder (1200 mesh), 1.62g rare earth powder ( Lanthanum-cerium composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com