Preparation method of ultrahigh modulus silicate

A silicate and silicate solution technology, applied in the direction of silicate, alkali metal silicate, etc., can solve the problems of difficult modulus, low modulus, brittle coating film, etc., and achieve the improvement of salt spray resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

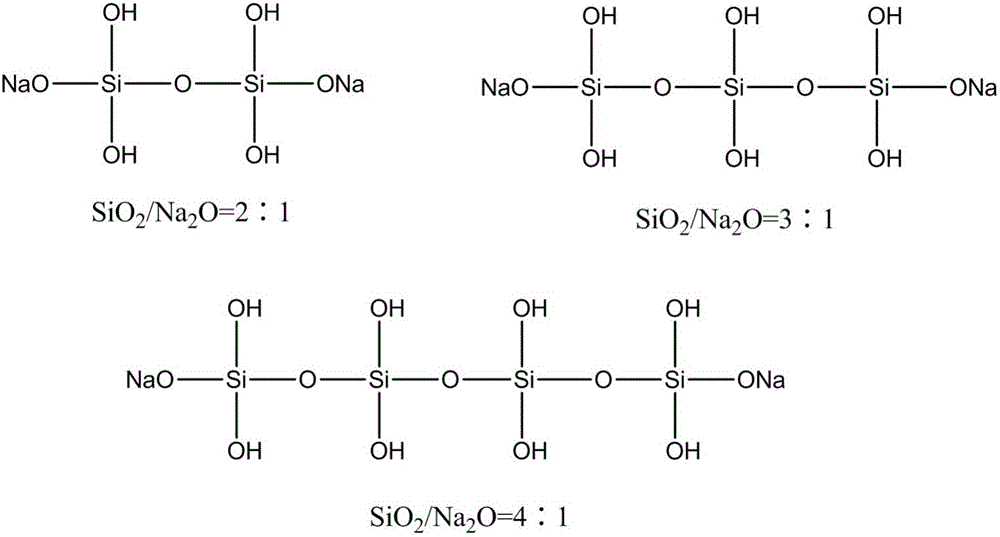

[0027] The modulus of the national standard industrial silicate is generally 2.2-3.6. A single sodium silicate molecule in the sodium silicate aqueous solution should have three situations of 2:1, 3:1 and 4:1 according to the ratio of silicon to sodium, and its molecular structure is :

[0028]

[0029] The modulus M of a silicate is its degree of polymerization. Although it is commonly known as silicate, in essence, silicon atoms and their derived atomic structures do not belong to inorganic acids, but should belong to inorganic alcohols, so silicates can also be named sodium silyl ether alcohols. It has neither the properties of an acid nor the characteristic molecular structure of an acid.

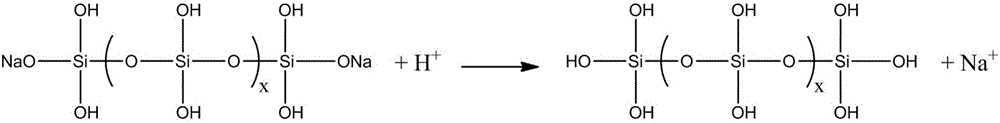

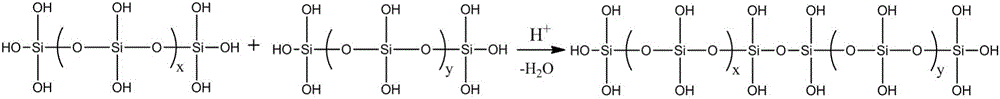

[0030] From the above molecular structure, it can be seen that a typical silicon polyol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com