High performance water-based industrial anti-corrosion coating and preparation method thereof

A kind of anti-corrosion coating, high-performance technology, applied in the field of coatings, can solve the problems of slow drying of the paint film, easy to bite the bottom, pollute the environment, etc., achieve good water resistance and salt spray resistance, high chemical resistance, and excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

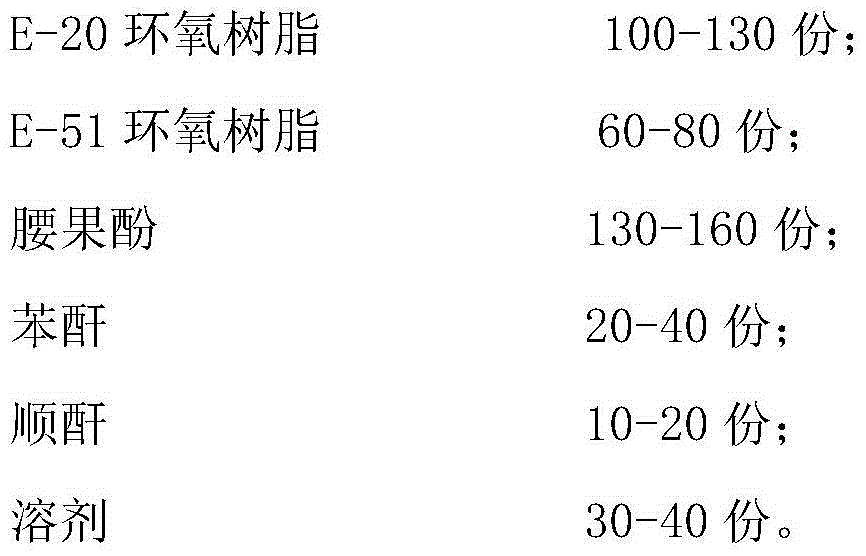

[0032] High-performance water-based industrial anticorrosion coatings, comprising the following components by weight:

[0033]

[0034] Wherein, the mass solid concentration of waterborne epoxy ester resin is 65%, and it is made up of the component of following parts by weight:

[0035]

[0036] Its preparation method comprises the following steps:

[0037] (1) Add the water-based epoxy ester resin of 65% formula quantity into the batching tank, add deionized water with 50% formula quantity under stirring and stir evenly, then add water-based anti-sedimentation agent, and disperse for 10 minutes at a speed of 1000 rpm;

[0038] (2) Add dispersant, defoamer, pigments and fillers, chrome-free antirust pigment, and disperse for 20 minutes at a speed of 1000 rpm to obtain a slurry;

[0039] (3) The slurry is sent into a sand mill for grinding, and after the fineness reaches 35 microns, it is poured into a paint tank, and the water-based epoxy ester resin of a surplus is ad...

Embodiment 2

[0047] High-performance water-based industrial anticorrosion coatings, comprising the following components by weight:

[0048]

[0049] Wherein, the mass solid concentration of waterborne epoxy ester resin is 65%, and it is made up of the component of following parts by weight:

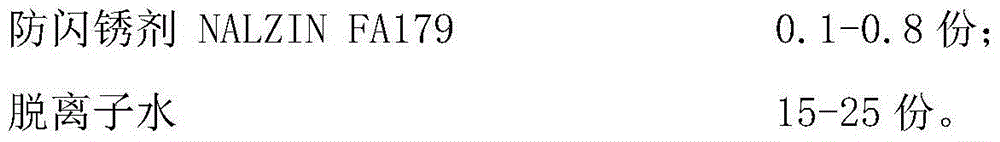

[0050]

[0051] Its preparation method comprises the following steps:

[0052] (1) Add 60% of the water-based epoxy ester resin in the formulation amount into the batching tank, add 40% of the deionized water in the formulation amount under stirring and stir evenly, then add the water-based anti-sedimentation agent, and disperse for 15 minutes at a speed of 800 rpm;

[0053] (2) Add dispersant, defoamer, pigments and fillers, chrome-free antirust pigment, and disperse for 15 minutes at a speed of 800 rpm to obtain a slurry;

[0054] (3) The slurry is sent into a sand mill for grinding, and after the fineness reaches 35 microns, it is poured into a paint tank, and the water-based epoxy ester re...

Embodiment 3

[0062] High-performance water-based industrial anticorrosion coatings, comprising the following components by weight:

[0063]

[0064] Wherein, the mass solid concentration of waterborne epoxy ester resin is 65%, and it is made up of the component of following parts by weight:

[0065]

[0066] Its preparation method comprises the following steps:

[0067] (1) Add 70% of the water-based epoxy ester resin in the formulation amount into the batching tank, add 60% of the deionized water in the formulation amount under stirring and stir evenly, then add the water-based anti-sedimentation agent, and disperse for 5 minutes at a speed of 1200 rpm;

[0068] (2) Add dispersant, defoamer, pigment and filler, chrome-free antirust pigment, and disperse for 25 minutes with a rotating speed of 1200 rpm to obtain a slurry;

[0069] (3) The slurry is sent into a sand mill for grinding, and after the fineness reaches 35 microns, it is poured into a paint tank, and the water-based epox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com