Graphene/acrylic acid static-conducting paint and preparation method thereof

A graphene and electrostatic conductive technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor compatibility between conductive pigments and fillers and resin matrix, shortened service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

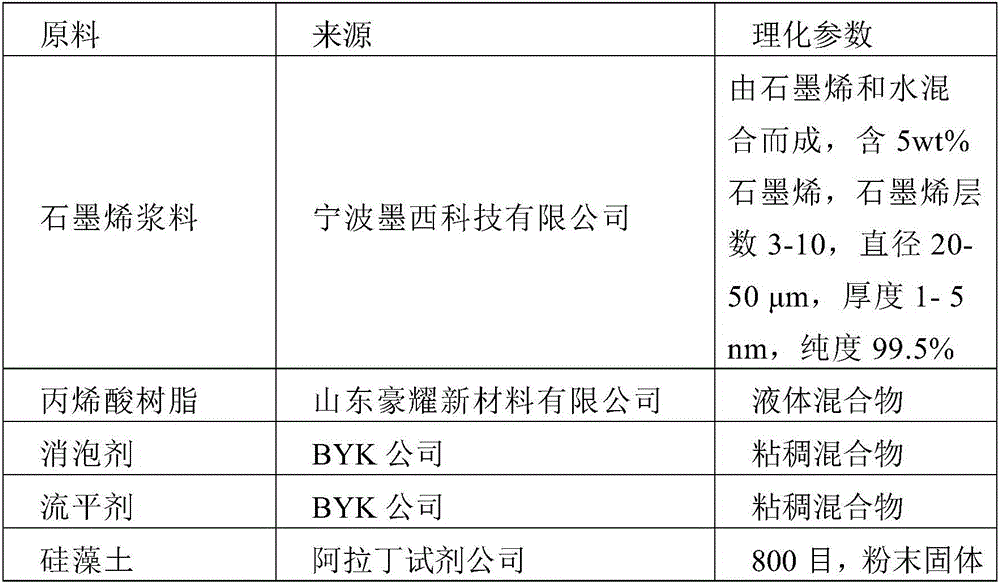

[0071] Example 1 - Coating 1

[0072] Disperse 0.01 g of benzyl alcohol, 0.01 g of pyrogallol, and 2.0 g of graphene slurry in 0.6 L of acetone, and sonicate for 1 hour. Add the obtained dispersion slurry to 50 g of acrylic resin, then add 20 mL of xylene, 0.1 g of BYK348, 0.1 g of BYK085, and 0.3 g of diatomaceous earth in sequence, and stir at 1500 r / min for 30 min to obtain Coating 1. Coating 1 is sprayed onto the PP board for its comprehensive physical properties and surface morphology see figure 2 .

[0073] result:

[0074] According to GB / T 16906, GB / T 1720 and GB / T 1771, the results are shown in Table 1 below. The surface resistivity, salt spray resistance and adhesion of coating 1 all meet the requirements.

Embodiment 2-

[0075] Example 2 - Coating 2

[0076] Disperse 0.01g of Triton X-100, 0.01g of pyrogallol, and 4.0g of graphene slurry in 1.0L of acetone, and ultrasonically disperse for 1 hour. Add the obtained dispersion slurry to 70g of acrylic resin, then sequentially add 28mL of xylene, 0.2g of BYK351, 0.1g of BYK085, 0.5g of diatomaceous earth, and stir at 1500r / min for 30min to obtain coating 2.

[0077] result:

[0078] The inspection was conducted according to GB / T 16906, GB / T 1720, and GB / T 1771. The results are shown in Table 1 below. The surface resistivity, salt spray resistance, and adhesion of coating 2 all meet the requirements.

Embodiment 3-

[0079] Example 3 - Coating 3

[0080] Disperse 0.01g of Triton X-100, 0.01g of pyrogallol, and 2.0g of graphene slurry in 0.6L of acetone, and ultrasonically disperse for 1 hour. Add the obtained dispersion slurry to 60g of acrylic resin, then add 15mL of xylene and 10mL of absolute ethanol, 0.1g of leveling agent (BYK348), 0.1g of defoamer (BYK085), 0.3g of diatomaceous earth, 1500r / min and stirred for 30 min to obtain coating 3.

[0081] result:

[0082] The inspection was conducted according to GB / T 16906, GB / T 1720, and GB / T 1771. The results are shown in Table 1 below. The surface resistivity, salt spray resistance, and adhesion of coating 3 all meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com