Spring

A technology of elastic material and liquid damping, which is applied in springs, springs/shock absorbers, and spring components composed of several springs, etc., can solve the problems of insufficient damping ratio and complex structure, and achieve the purpose of preventing spring oxidation and corrosion and simplifying the structure , The effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

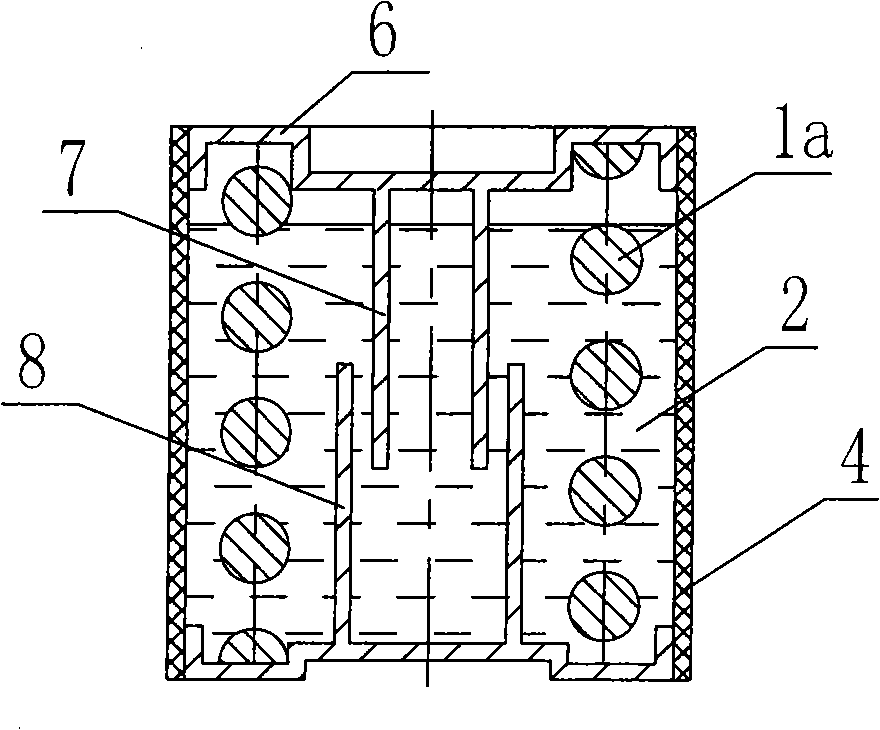

Embodiment 1

[0034] The overall structure of Embodiment 1 of the present invention is as follows figure 1 As shown, it comprises a helical spring 1a and a damping material 2, the helical spring 1a being partly immersed in the liquid damping material 2. The liquid damping material 2 is provided with a tubular sealing protection layer 4 and upper and lower end plates 6 which simultaneously function as sealing and centering. In order to increase the damping shear area, the inner and outer damping cylinders 7 and 8 extending into the liquid are respectively arranged on the upper and lower end plates 6. When the coil spring 1a is deformed under force, the spring body and the inner and outer damping cylinders 7 and 8 will make the liquid The damping material 2 generates relative shearing motion and rubs against the coil spring 1a and the sealing protection layer 4. Since the liquid damping material 2 has a large internal friction, it will generate a damping force that is always opposite to the d...

Embodiment 2

[0037] Such as figure 2 As shown, the spring wire of the coil spring 1a is partially immersed in the liquid damping material 2, and the liquid damping material 2 is located in the interlayer between two large and small sealing protection layers 4, and the upper and lower ends of the interlayer are sealed and centered with a metal ring 6

Embodiment 3

[0039] Such as image 3 As shown, the spring wire part of the coil spring 1a is immersed in the liquid damping material 2, and the liquid damping material 2 is located in the interlayer between the outer peripheral sealing protection layer 4 and the central high damping rubber column 5, and the upper and lower ends of the interlayer are sealed with metal rings 6. middle. This embodiment has greater damping due to the additional damping provided by the high damping rubber post in the center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com