Metal powder spraying process capable of reducing coating particles on surface of workpiece

A technology of workpiece surface and metal powder, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of high amount of metal powder, achieve the effect of reducing the actual area, reducing the cost, and facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

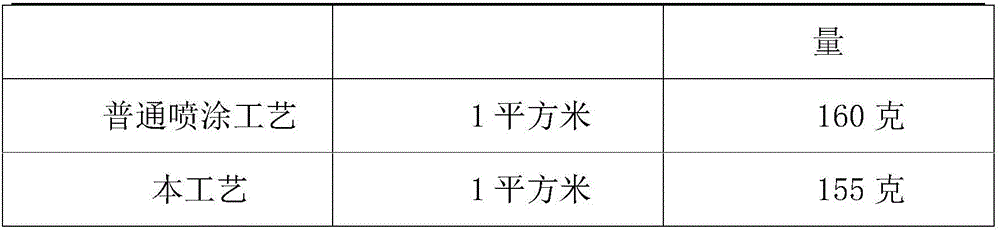

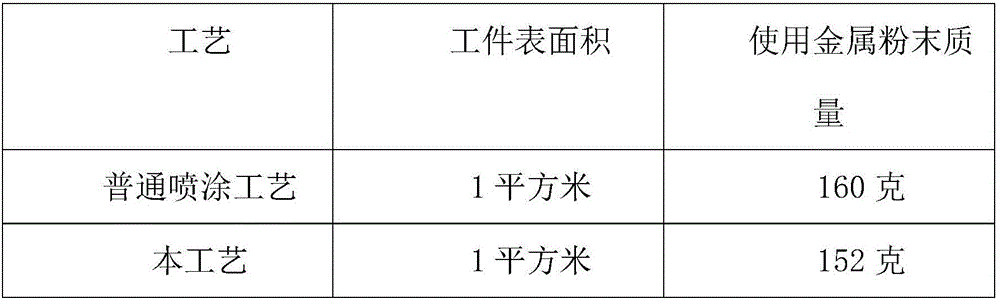

Embodiment 1

[0018] Embodiment one, a kind of metal powder spraying process that reduces workpiece surface coating particle, comprises the following steps:

[0019] S1: Place the workpiece in the pool, use 60 to 80 degrees Celsius hot water to clean the outer wall of the workpiece, and clean the oil and dirt on the outer wall of the workpiece;

[0020] S2: Observe whether there is corrosion on the surface of the workpiece. If there is corrosion and the corrosion is relatively light, use an acidic lotion to clean the workpiece at 70 degrees Celsius. Each liter of the acidic lotion contains 50 milliliters of sulfuric acid, 5 mL thiourea and 20 mL sodium alkylsulfonate;

[0021] S3: Use sodium bicarbonate solution to clean the workpiece after pickling, and rinse it with clean water three to five times to observe whether there are bubbles and cavities in the galvanized layer on the surface of the workpiece. If the galvanized layer has voids, repair the voids on the surface of the workpiece by...

Embodiment 2

[0028] Embodiment two, a kind of metal powder spraying process that reduces workpiece surface coating particle, comprises the following steps:

[0029] S1: Place the workpiece in the pool, use 60 to 80 degrees Celsius hot water to clean the outer wall of the workpiece, and clean the oil and dirt on the outer wall of the workpiece;

[0030] S2: Observe whether there is corrosion on the surface of the workpiece. If there is corrosion and the corrosion is serious, use an acidic lotion to clean the workpiece at 80 degrees Celsius. The acidic lotion contains 70 milliliters of sulfuric acid and 10 milliliters of sulfur per liter of solution. Urea and 40 ml of sodium alkylsulfonate;

[0031] S3: Use sodium bicarbonate solution to clean the workpiece after pickling, and rinse it with clean water three to five times to observe whether there are bubbles and cavities in the galvanized layer on the surface of the workpiece. If the galvanized layer has voids, repair the voids on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com