Preparation method of highly dispersed micron order flake silver powder with large radius-thickness ratio

A flake silver powder, large diameter-to-thickness ratio technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unfriendly reagent environment, unsuitable application, product agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 2.5g silver nitrate is dissolved in 50mL deionized water to make silver nitrate solution, and in this silver nitrate solution, dripping the concentrated nitric acid that mass fraction is 65% makes its solution pH be 0.5, obtains solution A;

[0031] (2) Dissolving 5.2 g of ascorbic acid in 50 mL of deionized water to prepare an ascorbic acid solution, and adding dropwise concentrated nitric acid with a mass fraction of 65% in the silver nitrate solution to make the pH of the solution 0.5, to obtain a mixed solution B;

[0032] (3) 0.3g Tween-80 is dissolved in 200mL deionized water to make Tween-80 solution, and in this silver nitrate solution, dripping concentrated nitric acid that mass fraction is 65% makes its solution pH be 0.5, obtains mixed Solution C;

[0033] (4) At room temperature, add mixed solution A to mixed solution C while stirring and mix evenly to obtain mixed solution D;

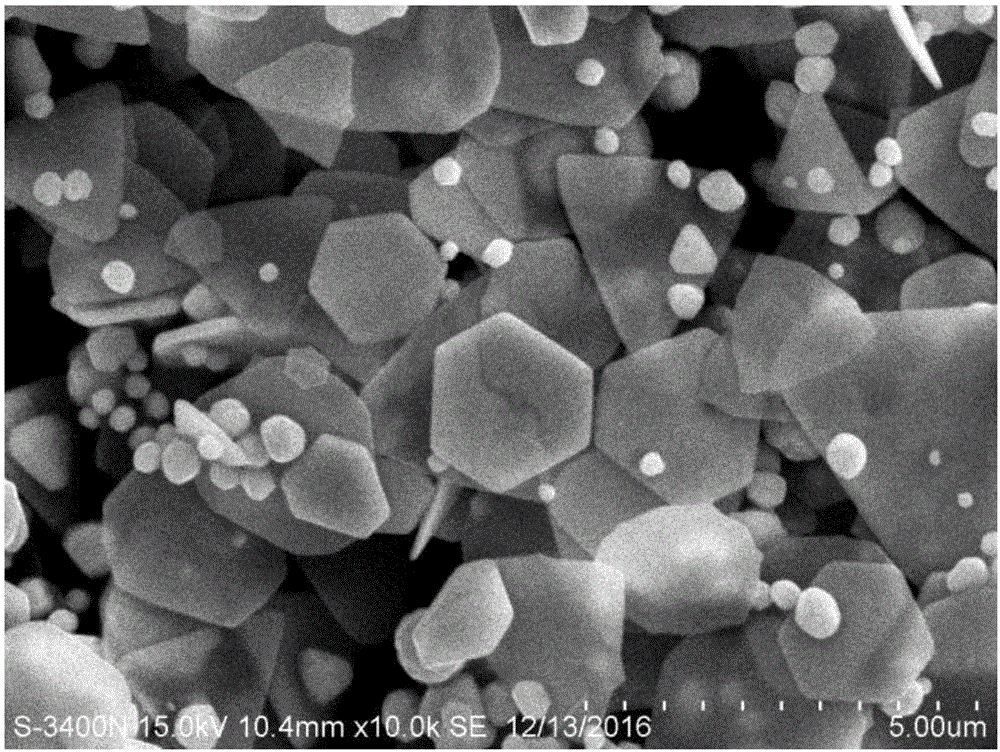

[0034] (5) At room temperature, add mixed solution D to mixed solution B wh...

Embodiment 2

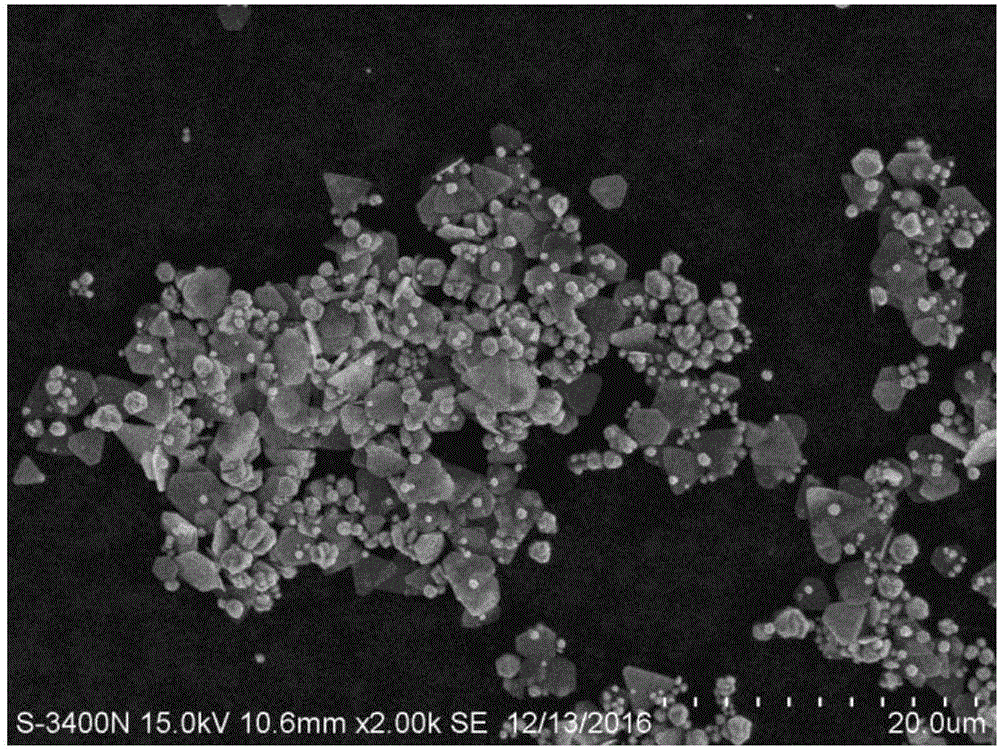

[0038] On the basis of Example 1, only steps (1), (2), and (3) need to be changed to: add acetic acid dropwise to make the pH of the solution 0.5, and the rest of the steps are carried out according to Example 1. products such as figure 2 As shown, the flake silver powder accounts for about 85% of the mixed silver powder, wherein the average flake diameter of the ultrafine flake silver powder is 3.8 μm, and the average flake thickness is 0.08 μm.

Embodiment 3

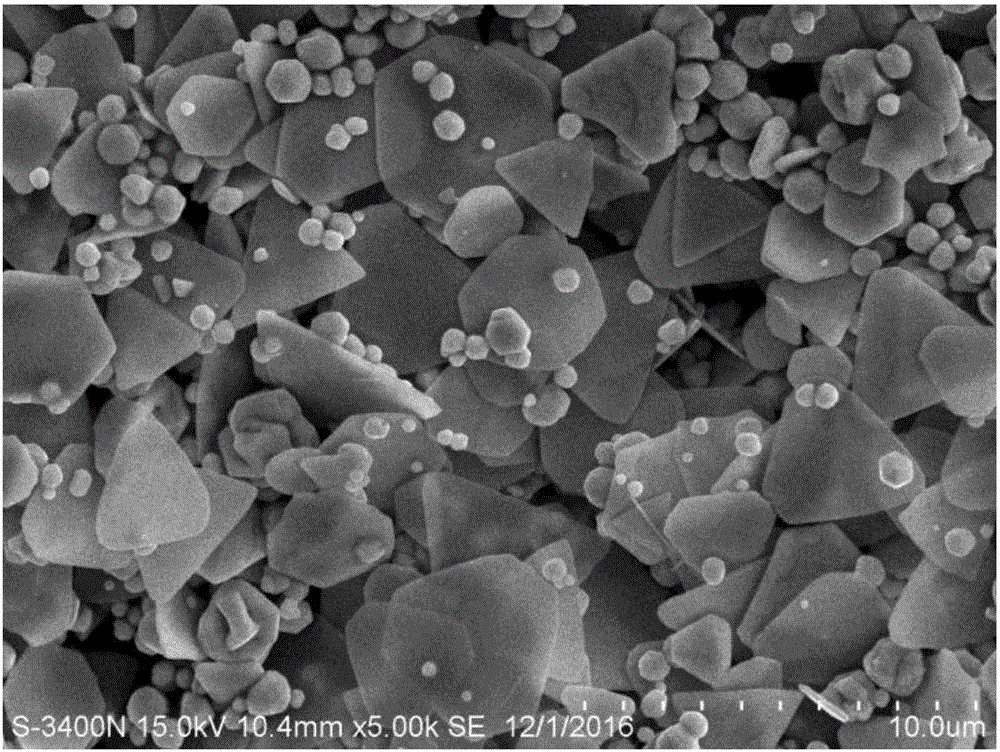

[0040] On the basis of Example 2, it is only necessary to change steps (1), (2), and (3) to: add acetic acid dropwise to make the pH of the solution 4.0, and carry out the remaining steps according to Example 2. products such as image 3 As shown, the flaky silver powder accounts for about 70% of the mixed silver powder, wherein the ultrafine flaky silver powder has an average diameter of 4.2 μm and an average thickness of 0.07 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com