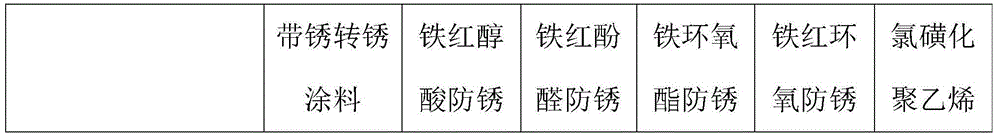

Novel rust-conversion coating material with rust

A rust-to-rust, paint technology, applied in anti-corrosion coatings, coatings and other directions, can solve problems such as restricting the development of anti-rust coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of novel belt rust turning rust coating that the embodiment of the present invention proposes, comprises:

[0026] Weigh 5 parts by weight of phosphoric acid, 0.45 parts of wetting agent, 0.25 parts of dispersant, 0.2 part of defoamer, 0.3 part of anti-flash rust agent and 0.45 part of thickener, in the above sequence Add 650wt% distilled water based on phosphoric acid mass and stir to obtain intermediate material;

[0027] Based on the mass of the intermediate material, add 245wt% of pigments and fillers to the intermediate material and stir at a high speed for 27 minutes to obtain an auxiliary material with a fineness of less than 50 μm, wherein the feeding speed is 18kg / min;

[0028] Based on the mass of the intermediate material, mix 14wt% linseed oil, 6wt% maleic anhydride, 2wt% modified phenolic resin, and 6wt% styrene-acrylic emulsion to obtain a water-based resin base material. The mixing temperature is 65 ° C. The mixing pressure is 2.3MPa;

[0029] Am...

Embodiment 2

[0032] A kind of novel belt rust turning rust coating that the embodiment of the present invention proposes, comprises:

[0033] Weigh 6 parts by weight of phosphoric acid, 0.5 part of wetting agent, 0.25 part of dispersant, 0.2 part of defoamer, 0.3 part of anti-flash rust agent and 0.4 part of thickener, according to the above sequence Add 750wt% distilled water based on phosphoric acid mass and stir to obtain intermediate material;

[0034] Based on the mass of the intermediate material, add 245wt% of pigments and fillers to the intermediate material and stir at a high speed for 25 minutes to obtain an auxiliary material with a fineness of less than 50 μm, wherein the feeding speed is 20kg / min;

[0035] Based on the mass of the intermediate material, mix 17wt% linseed oil, 7wt% maleic anhydride, 2wt% modified phenolic resin, and 6wt% styrene-acrylic emulsion to obtain a water-based resin base material. The mixing temperature is 65 ° C. The mixing pressure is 2.4MPa;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com