Pb-Sn grid alloy and preparation method

An alloy and grid technology is applied in the field of lead-tin grid alloy and its preparation to achieve the effects of improving working performance, improving corrosion resistance and increasing oxygen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

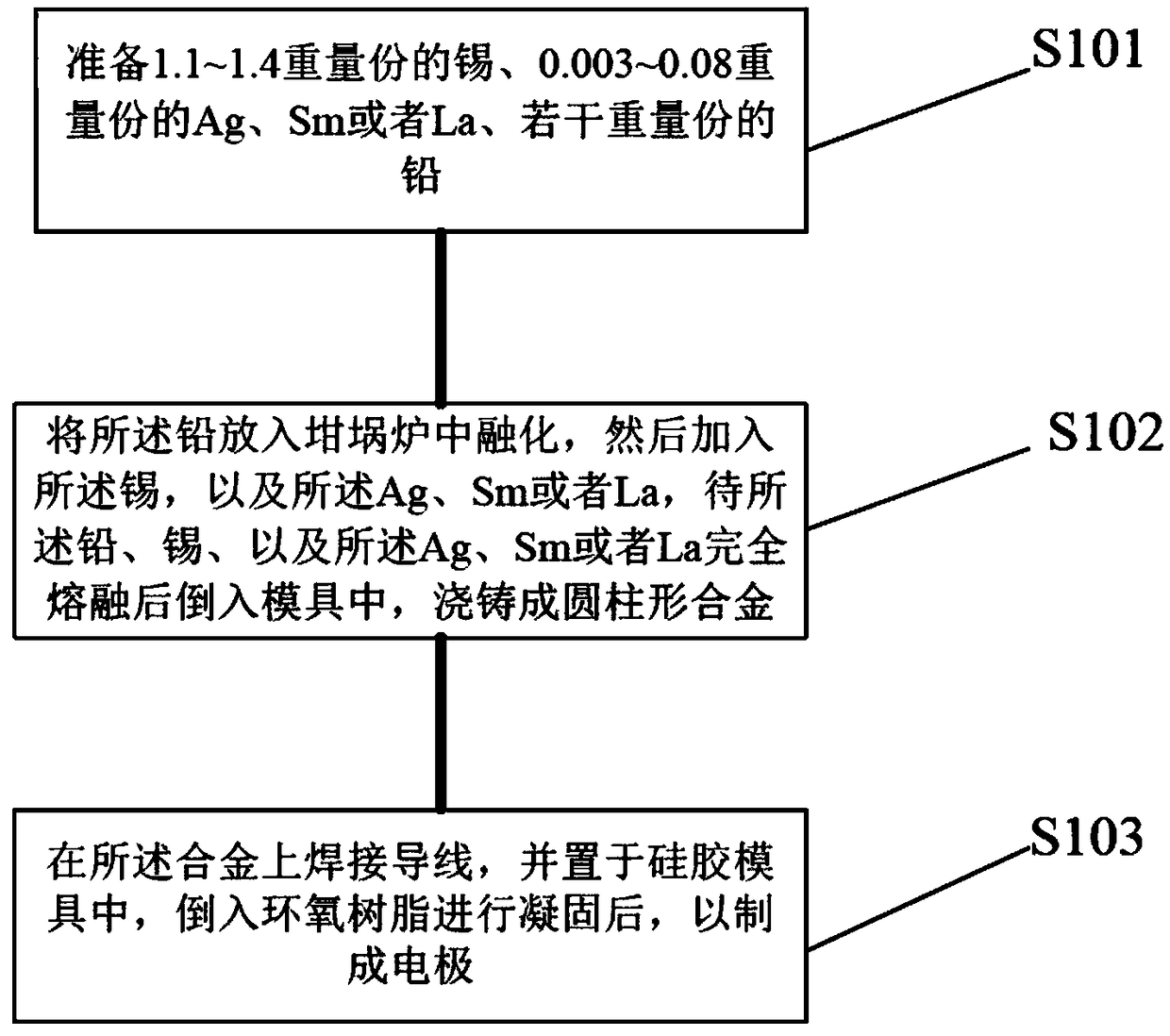

[0019] Based on the above examples, see figure 1 As shown, this embodiment also provides a method for preparing a lead-tin grid alloy, including the following steps:

[0020] Step 1 S101: Prepare 1.1-1.4 parts by weight of tin, 0.003-0.08 parts by weight of Ag, Sm or La, and several parts by weight of lead;

[0021] Step 2 S102: Put the lead into a crucible furnace to melt, then add the tin, and the Ag, Sm or La, and pour the lead, tin, and the Ag, Sm or La into the furnace after they are completely melted In the mold, the alloy is cast into a cylindrical shape.

[0022] Specifically, the above method also includes:

[0023] Step 3 S103: Weld wires on the alloy, place it in a silicone mold, pour epoxy resin into it for solidification, and make electrodes.

[0024] Specifically, the above-mentioned lead may be a lead ingot.

Embodiment 1

[0027] A Pb-Sn grid alloy for lead-acid batteries, comprising the following components by weight:

[0028] Sn 1.3 parts

[0029] 98.7 parts of Pb.

[0030] Put Pb into the crucible furnace to melt, then add the Sn, pour into the mold after Pb and Sn are completely melted, and cast into a cylindrical alloy. Pb may be lead ingots.

[0031] Solder the wires on the alloy, place it in a silicone mold, pour epoxy resin to solidify, and make an electrode for use.

Embodiment 2

[0033] A Pb-Sn grid alloy for lead-acid batteries, comprising the following components by weight:

[0034] Sn 1.1 parts

[0035] Ag 0.003 parts

[0036] 98.897 parts of Pb.

[0037] Put Pb into the crucible furnace to melt, then add the Sn and Ag, pour into the mold after the complete melting of Pb, Sn and Ag, and cast into a cylindrical alloy. Pb may be lead ingots.

[0038] Solder the wires on the alloy, place it in a silicone mold, pour epoxy resin to solidify, and make an electrode for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com