Multi-iron composite material and method for preparing flexible multi-iron composite material

A composite material and adhesive technology, which is applied in the field of multiferroic composite materials and the preparation of flexible multiferroic composite materials, can solve the problems that natural multiferroic materials are not widely used, and achieve the effect of improving magnetic properties and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

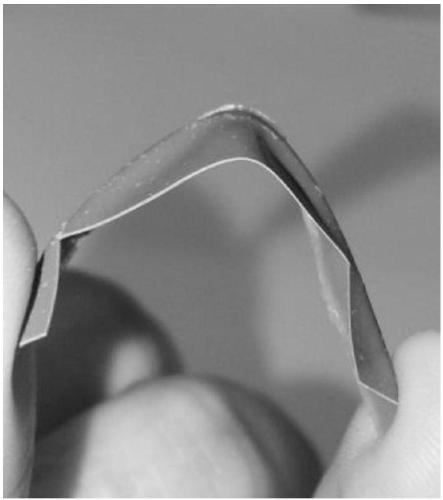

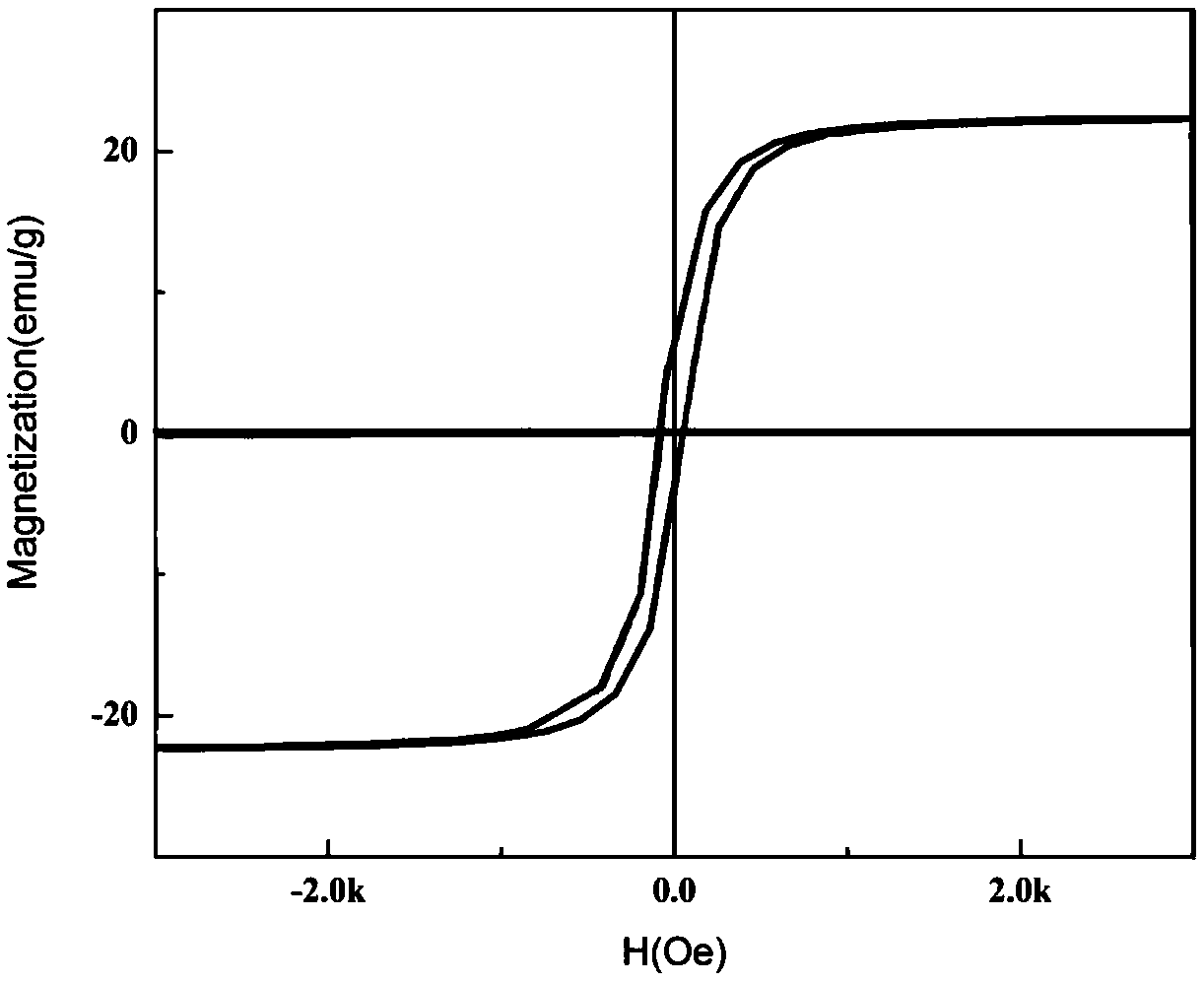

Image

Examples

Embodiment 1

[0027] Embodiment 1 steps are as follows:

[0028] 1. La 0.5 Y 0.5 FeO 3 Preparation of oxide powder and bulk materials:

[0029] (1) Take out an appropriate amount of lanthanum trioxide (La 2 o 3 ), Yttrium trioxide (Y 2 o 3 ), ferric oxide (Fe 2 o 3 ), and pre-fired them at 900°C, 650°C, and 400°C for 12 hours to remove moisture and impurities in the raw materials. After the pre-burning is completed, quickly weigh lanthanum trioxide (La 2 o 3 ), this is mainly because lanthanum trioxide is easy to absorb water and thus affects its purity and quality. Then according to the molar ratio of 1:1:2, according to the weighed lanthanum trioxide (La2 o 3 ) to weigh diyttrium trioxide (Y 2 o 3 ) and ferric oxide (Fe 2 o 3 );

[0030] (2) Mix the oxide raw materials weighed in the first step and put them into the agate jar. According to the ratio of powder, ethanol and agate beads 1:1.5:6, add an appropriate amount of ethanol, and then put them in different sizes. Aga...

Embodiment 2

[0035] Embodiment 2 steps are as follows:

[0036] 1. La 0.5 Y 0.5 FeO 3 Preparation of oxide powder and bulk materials:

[0037] (1) Take out an appropriate amount of lanthanum trioxide (La 2 o 3 ), Yttrium trioxide (Y 2 o 3 ), ferric oxide (Fe 2 o 3 ), and pre-fired them at 1000°C, 700°C, and 500°C for 12 hours to remove moisture and impurities in the raw materials. After the pre-burning is completed, quickly weigh lanthanum trioxide (La 2 o 3 ), this is mainly because lanthanum trioxide is easy to absorb water and thus affects its purity and quality. Then according to the molar ratio of 1:1:2, according to the weighed lanthanum trioxide (La 2 o 3 ) to weigh diyttrium trioxide (Y 2 o 3 ) and ferric oxide (Fe 2 o 3 );

[0038] (2) Mix the oxide raw materials weighed in the first step and put them into the agate jar. According to the ratio of powder, ethanol and agate beads 1:1.5:6, add an appropriate amount of ethanol, and then put them in different sizes. ...

Embodiment 3

[0043] Embodiment 3 steps are as follows:

[0044] 1. La 0.5 Y 0.5 FeO 3 Preparation of oxide powder and bulk materials:

[0045] (1) Take out an appropriate amount of lanthanum trioxide (La 2 o 3 ), Yttrium trioxide (Y 2 o 3 ), ferric oxide (Fe 2 o 3 ), and pre-fired them at 950°C, 700°C, and 450°C for 12 hours to remove moisture and impurities in the raw materials. After the pre-burning is completed, quickly weigh lanthanum trioxide (La 2 o 3 ), this is mainly because lanthanum trioxide is easy to absorb water and thus affects its purity and quality. Then according to the molar ratio of 1:1:2, according to the weighed lanthanum trioxide (La 2 o 3 ) to weigh diyttrium trioxide (Y 2 o 3 ) and ferric oxide (Fe 2 o 3 );

[0046] (2) Mix the oxide raw materials weighed in the first step and put them into the agate jar. According to the ratio of powder, ethanol and agate beads 1:1.5:6, add an appropriate amount of ethanol, and then put them in different sizes. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com