Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

A technology of glass-ceramics frit and glass-ceramics, which is applied in the fields of comprehensive utilization of resources and material preparation, high value-added utilization of metallurgical slag and preparation of glass-ceramics, and can solve the problems of no iron recovery and coarse adjustment and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition of the converter slag discharged from the front of a steel plant is 12.92% SiO 2 , 0.79% Al 2 o 3 , 29.18% CaO, 3.58% MgO, 42.29% TFe, 26.35% MFe, 13.25% FeO, 8.03% Fe 2 o 3 , 2.46% MnO, 1.80% P 2 o 5 , 0.15% R 2 O (R is a monovalent metal ion). This steel slag is remelted to form ferrous industrial slag.

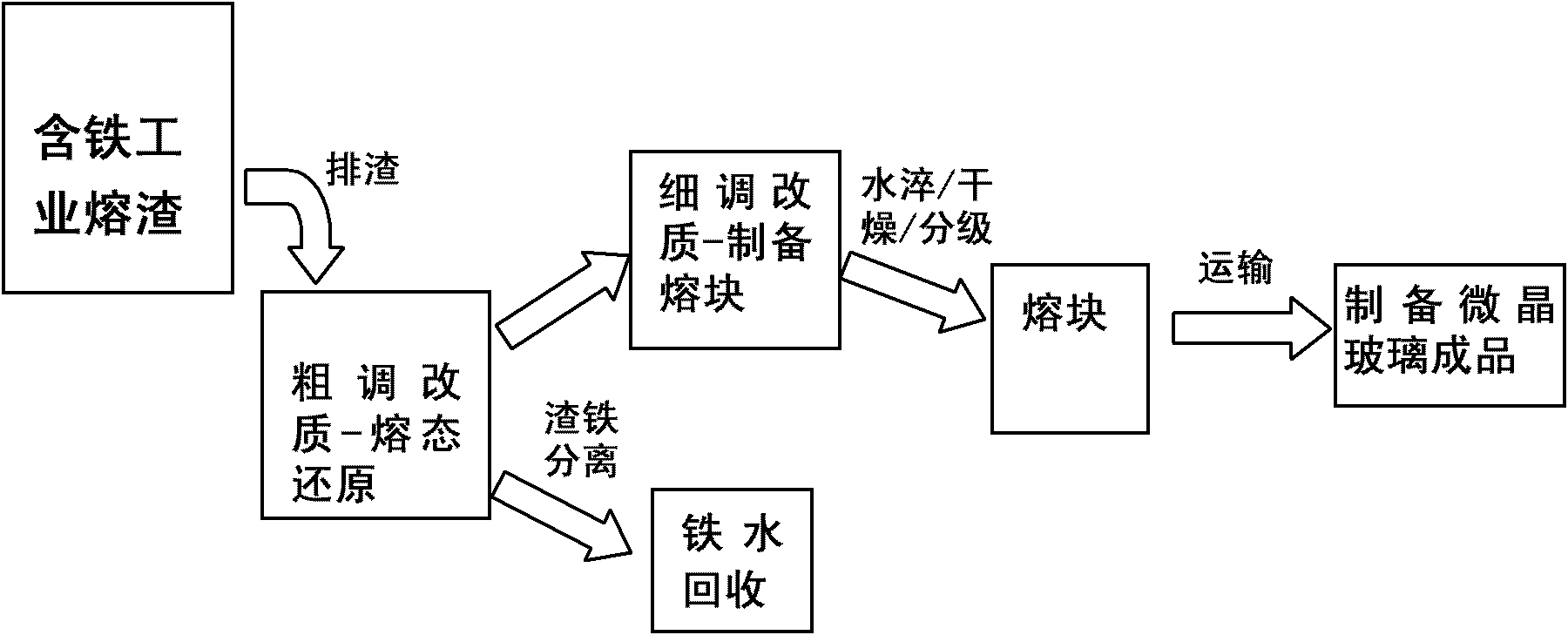

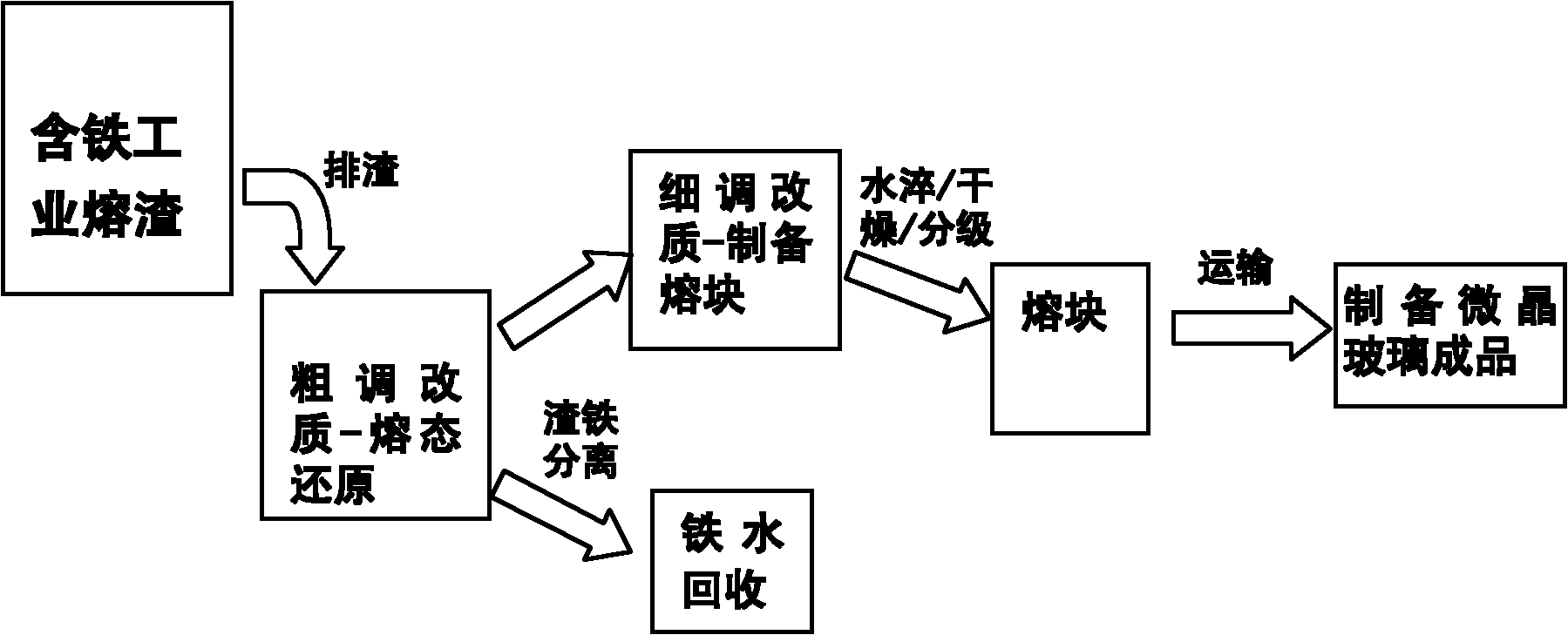

[0030] according to figure 1 In the process shown, in the rough adjustment and upgrading, a modifier consisting of 34% fly ash, 5% quartz sand, and 10% waste refractories by the weight of steel slag, and a reducing agent consisting of 13% coal powder by weight of steel slag were added In the high-temperature slag, and stir evenly, so that the basicity of the slag reaches 1.1; after holding at 1550°C for 20 minutes, pour the slag into the fine-tuning reaction bag, and the remaining molten iron is recovered. The recovery rate of iron in steel slag reaches 95%.

[0031] In fine-tuning and upgrading, in order to make the slag composition meet the ...

Embodiment 2

[0033] The chemical composition of converter steel slag discharged from a steel plant is 20.23% SiO 2 , 1.36% Al 2 o 3 , 38.58% CaO, 4.63% MgO, 26.8% Fe 2 o 3 , 3.46% MnO, 2.9% P 2 o 5 , 0.96% TiO 2 , 0.5 % TiO 2 . This steel slag is remelted to form ferrous industrial slag.

[0034] according to figure 1 In the process shown, in the rough adjustment and upgrading, the modifier consisting of 36% fly ash, 15% tailings sand, and 5% converter dust and sludge equivalent to the weight of steel slag, and the reducing agent consisting of 15% coal powder by weight of steel slag were added In the high-temperature slag, and stir evenly, so that the basicity of the slag reaches 1.05; after holding at 1550°C for 20 minutes, pour the slag into the fine-tuning reaction bag, and the remaining molten iron is recovered. The recovery rate of iron in steel slag reaches 96%.

[0035] In fine-tuning and upgrading, in order to make the slag composition meet the requirements of slag glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com