Preparation method and application of macropore-mesoporous silicon dioxide hollow micro-sphere

A technology of mesoporous silica and hollow microspheres, applied in the directions of silica, silica, pharmaceutical formulations, etc., can solve the problems of short effective action time, short sustained release period, low drug loading, etc., and achieve excellent The effect of slow release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) 0.3g oil-soluble surfactant sorbitan monooleate is dissolved in 4ml cyclohexane to form the inner oil phase O 1 , wherein the concentration of the oil-soluble surfactant is about 0.075g / ml; 0.5g of the water-soluble surfactant polyoxyethylene sorbitan monolaurate and 0.267g of P123 are dissolved in 10ml of hydrochloric acid with a mass fraction of 8% Prepare water phase W, wherein the concentration of water-soluble surfactant is about 0.05g / ml, and the concentration of polymer P123 is about 0.0267g / ml; another 3g of sorbitan monooleate is dissolved in 10ml of n-decyl alcohol O 2 , wherein the concentration of oil-soluble surfactant is about 0.3g / ml;

[0049] (2) Under strong stirring, add the inner oil phase to the water phase to form O 1 / W single emulsion, wherein the volume ratio of the internal oil phase to the water phase is 1: 2.5;

[0050] (3) Mix 1ml of O prepared in step (2) 1 / W single emulsion is added dropwise in the outer oil phase, the volume ratio...

Embodiment 2

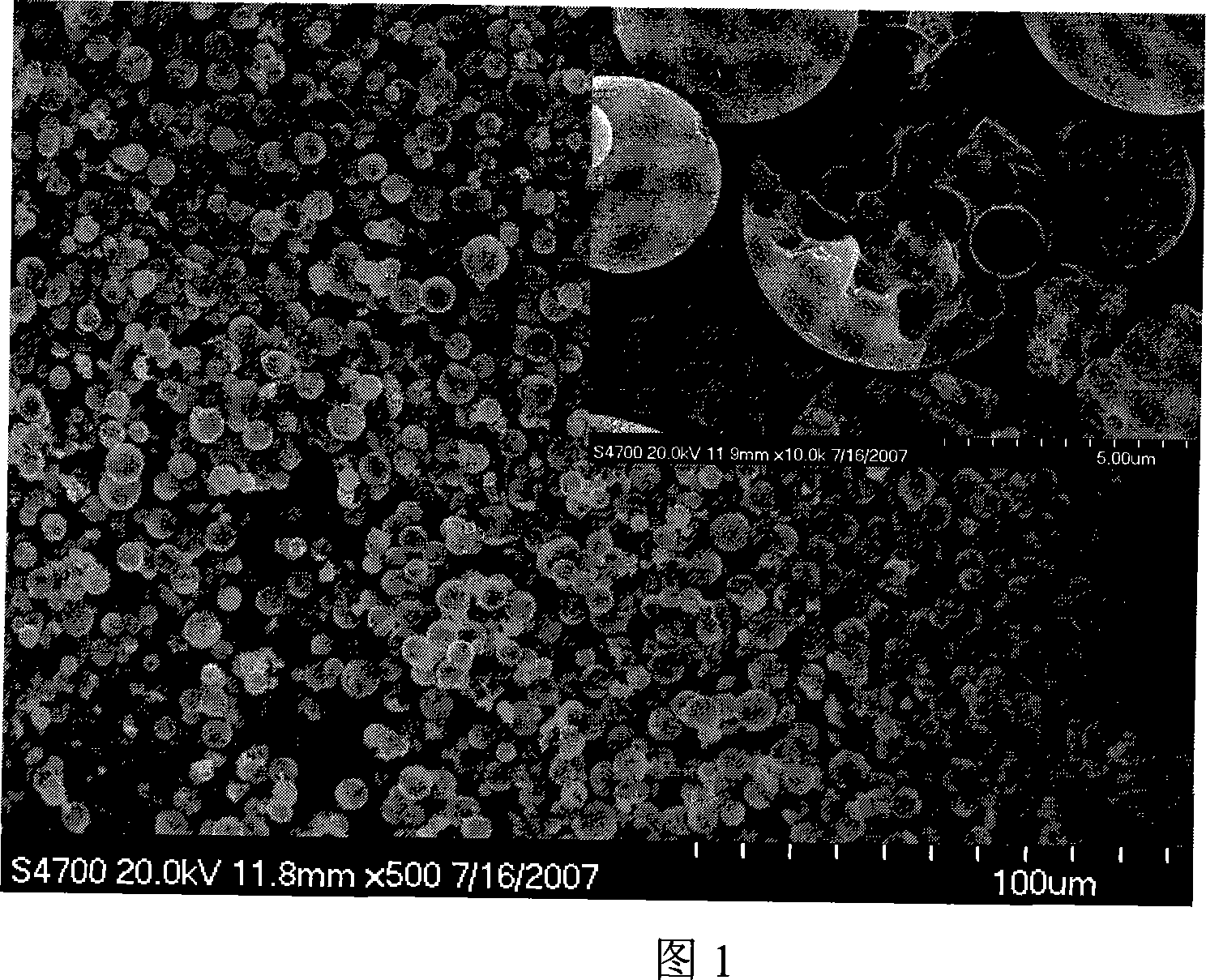

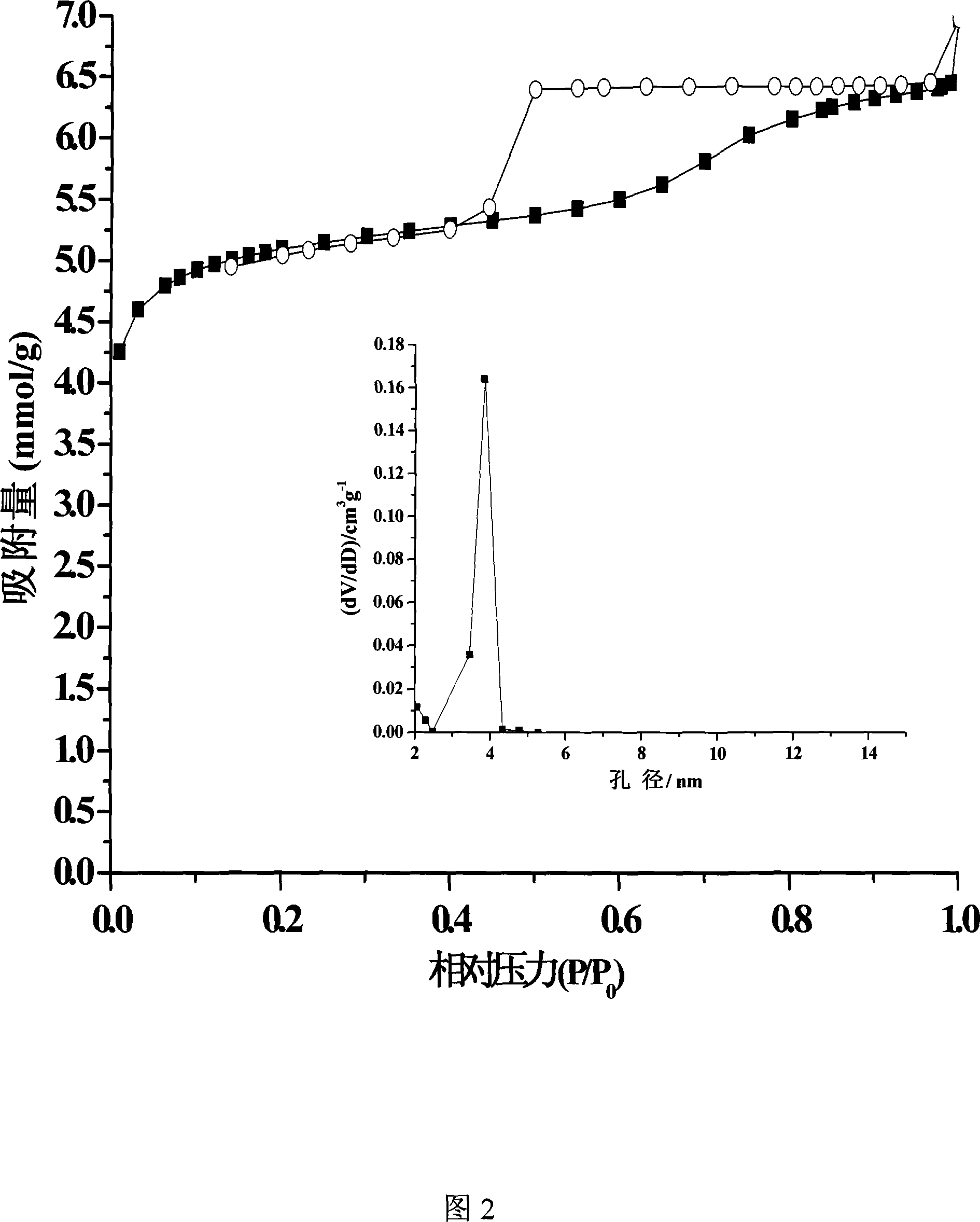

[0055] The operating parameters are similar to Example 1, except that the O in the external oil phase is added 1 The volume of the / W single emulsion is 2ml, the volume ratio of the oil / water single emulsion to the outer oil phase is 1: 5, and the addition of tetraethyl orthosilicate is 1.4ml (according to 25% of the water phase mass), the resulting macropores -Mesoporous silica microspheres have an average diameter of 11.41μm, a mesopore diameter of 4.3nm, and a specific surface area of 352m 2 / g.

Embodiment 3

[0057] (1) Dissolve 0.2g of oil-soluble surfactant sorbitan monooleate in 3ml of n-hexane to form the inner oil phase O 1 , wherein the concentration of oil-soluble surfactant is about 0.067g / ml; 0.5g water-soluble surfactant polyoxyethylene sorbitan monolaurate and 0.4g P123 are dissolved in 10ml mass fraction of 5% hydrochloric acid Prepare water phase W, wherein the concentration of water-soluble surfactant is about 0.05g / ml, and the concentration of polymer P123 is about 0.04g / ml; another 1g of sorbitan monooleate is dissolved in 10ml of n-decyl alcohol O 2 , wherein the concentration of oil-soluble surfactant is about 0.1g / ml;

[0058] (2) Under strong stirring, add the inner oil phase to the water phase to form O 1 / W single emulsion, wherein the volume ratio of the internal oil phase to the water phase is about 1: 3.3;

[0059] (3) Mix 1ml of O prepared in step (2) 1 / W single emulsion is added dropwise in the outer oil phase, the volume ratio of the oil / water singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com