Waste-heat pressure closed-loop thermal treatment method for molten steel slag

A treatment method and technology for steel slag, applied in the field of solid waste treatment and hot stuffy treatment of molten steel slag, can solve the problem of high power consumption of steel slag grinding, and achieve the effects of small footprint, high crushing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

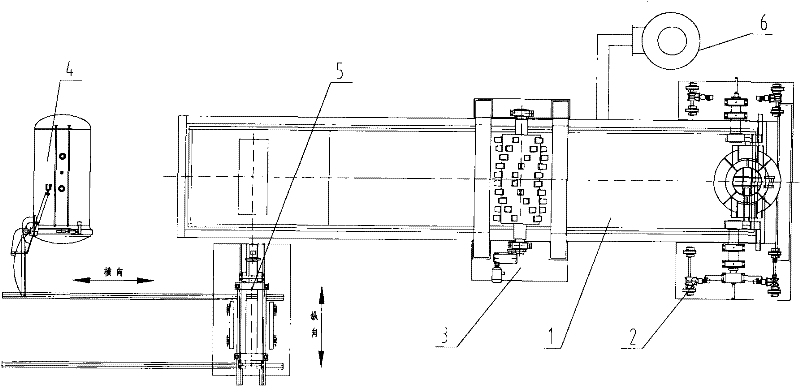

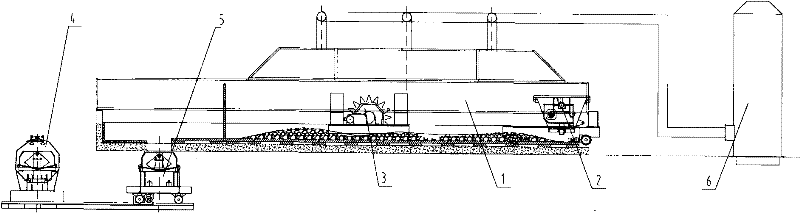

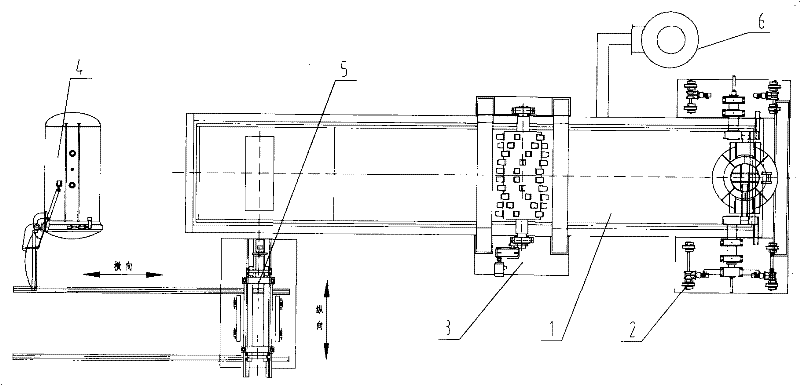

[0020] Embodiment 1 (steel slag temperature is 1600 ℃)

[0021] 1) Start the slag tank tipping device 3 to send the slag tank filled with molten steel slag into the steel slag pretreatment chamber 1, and exit after dumping the molten steel slag. At this time, the temperature of the steel slag is 1600°C, and the steel slag is in a molten liquid state;

[0022] 2) The molten liquid steel slag is cooled by pumping water, the surface of the liquid steel slag is quickly crusted, and the cooling water is vaporized and discharged through the steam exhaust and dust removal system 6;

[0023] 3) Stop spraying water and start the roller crushing device 3 to crush the hard shell on the surface of the steel slag for the first time;

[0024] 4) After the primary crushing is completed, the liquid steel slag under the hard shell is exposed again, the rolling crushing is stopped, and water is fetched for the second time to make the liquid steel slag crust again;

[0025] 5) Start the roller ...

Embodiment 2

[0029] Embodiment 2 (steel slag temperature is 1100 ℃)

[0030] 1) Start the slag tank tipping device 2 to put the slag tank filled with molten steel slag into the steel slag pretreatment chamber 1, dump the molten steel slag and then exit. At this time, the temperature of the steel slag is 1100°C, and the steel slag is in a solid-liquid mixed state;

[0031] 2) The molten liquid steel slag is cooled by pumping water, the surface of the liquid steel slag is quickly crusted, and the cooling water is vaporized and discharged through the steam exhaust and dust removal system 6;

[0032] 3) Stop spraying water and start the roller crushing device 3 to crush the hard shell on the surface of the steel slag for the first time;

[0033] 4) After the primary crushing is completed, the liquid steel slag under the hard shell is exposed again, and the water is pumped for the second time to make the liquid steel slag crust again;

[0034] 5) Start the roller crushing device 3 for secondar...

Embodiment 3

[0038] Embodiment 3 (steel slag temperature is 850 ℃)

[0039] 1) Start the slag tank tipping device 2 to send the slag tank filled with molten steel slag into the steel slag pretreatment chamber 1, and exit after dumping the molten steel slag. At this time, the temperature of the steel slag is 850°C;

[0040] 2) The molten steel slag is cooled by pumping water and crushed by roll pressing at the same time, and the cooling water is vaporized and discharged through the steam exhaust and dust removal system 6;

[0041] 3) After 10 minutes of water spraying and rolling crushing, stop the pretreatment. At this time, the temperature of the steel slag is 300°C, and the particle size is less than 250mm;

[0042] 4) Start the roller crushing device 3 again to push the crushed solid steel slag into the waste heat pressurized stuffy tank 4;

[0043] 5) Residue heat stuffy tank with autoclaving 4. The high-temperature solid steel slag is subjected to autoclavable stuffy treatment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com