Metallurgical molten slag dry granulating and heat recovering system

A dry granulation and heat energy recovery technology, applied in the field of machinery and equipment, can solve the problems of energy consumption and unrecovered heat energy, and achieve the effect of avoiding waste, saving energy consumption and ensuring continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] see Attachment

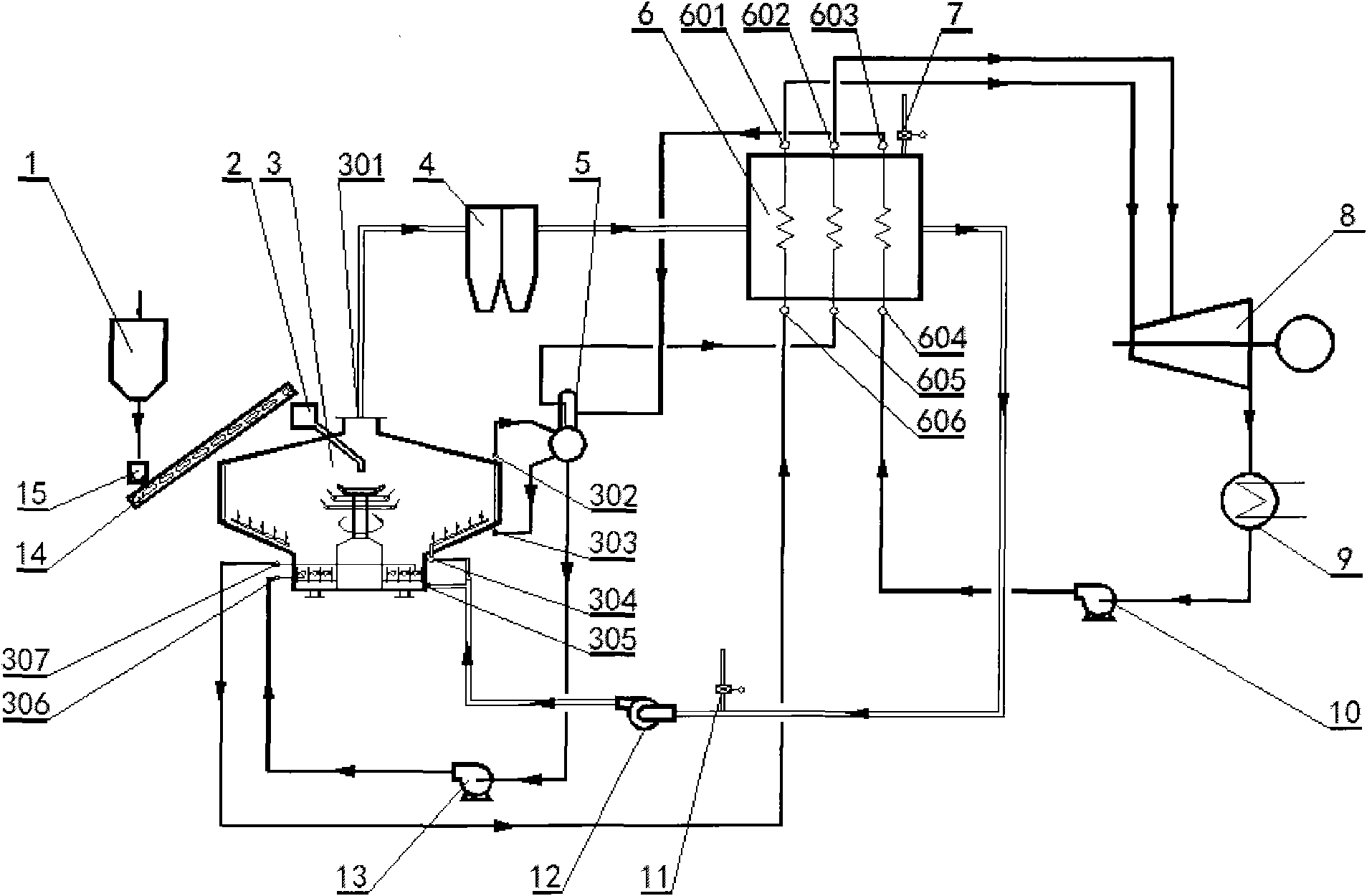

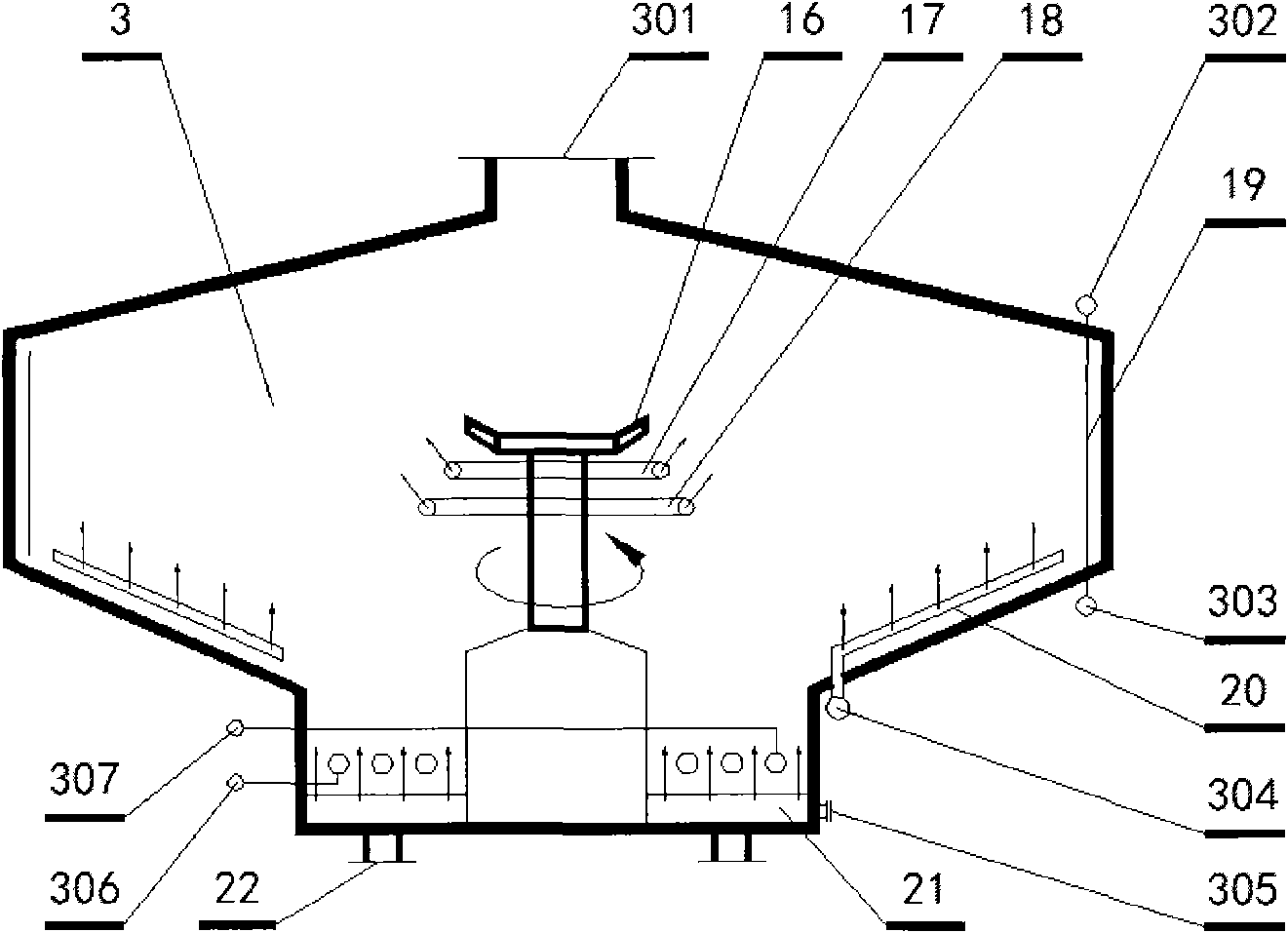

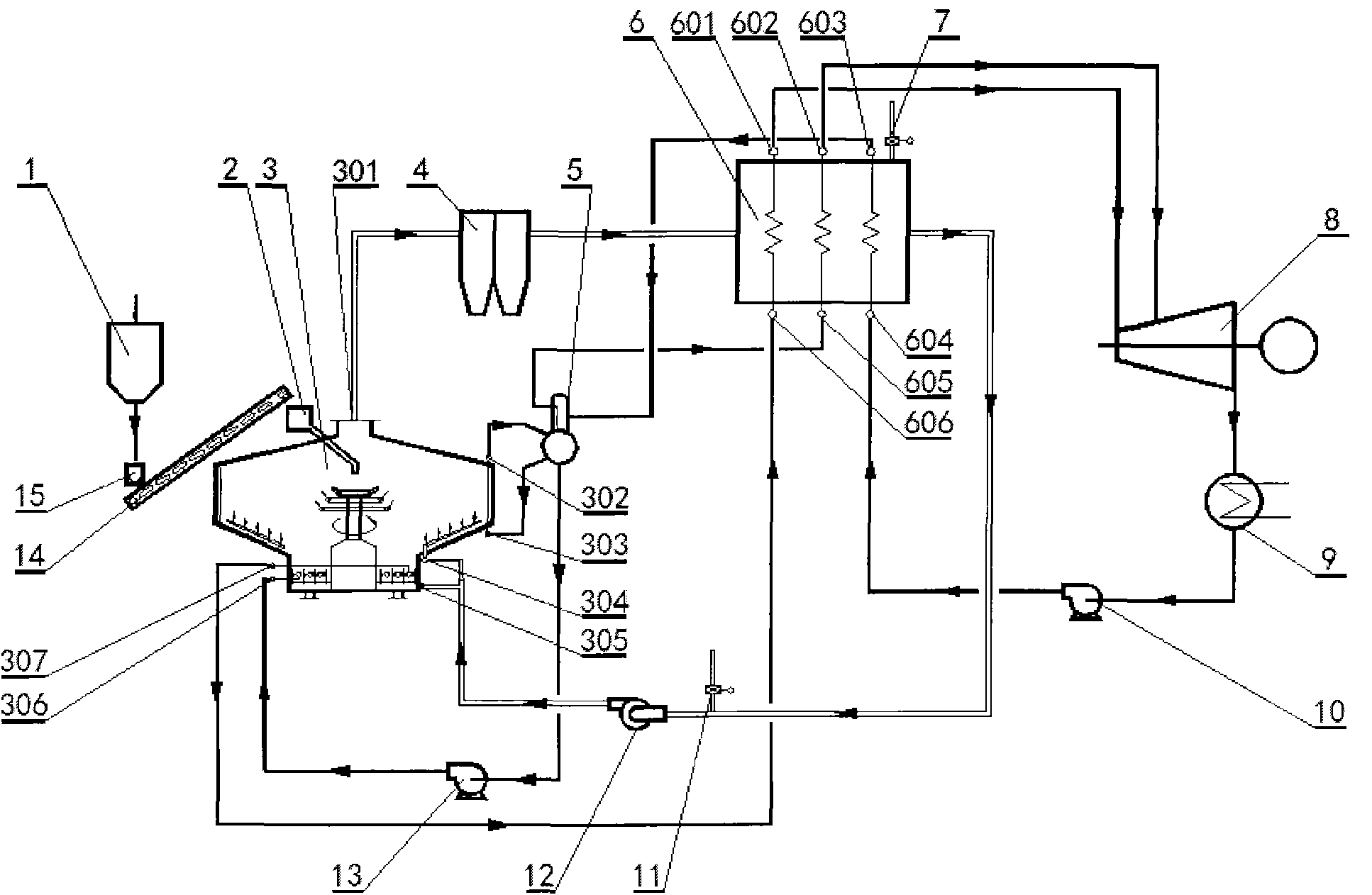

[0022] The metallurgical slag dry granulation and heat recovery system consists of a feeding system, a dry granulation device 3 and a heat recovery system. The slag feeding device 2 is composed. The metallurgical slag received by the slow storage tank 1 is transported to the slag feeding device 2 through the slag bag 15 and the guide rail elevator 14, and then falls into the dry granulation device 3 from the discharge port of the slag feeding device 2 On the centrifugal rotating disk 16 in the middle, the liquid slag is granulated into particles due to the centrifugal force and the pulse action of the airflow nozzle 17 under the centrifugal rotating disk 16 during the process of being thrown out by the centrifugal rotating disk 16, and is forced to cool at the same time, and the granular The molten slag hits the water wall 19 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com