Method for separating and extracting metal element from varadium-titanium magnetite

A vanadium-titanium magnetite and metal element technology, applied in the field of mineral processing, can solve the problems of difficult control of vanadium-titanium flow direction, long reduction time, long production process, etc., achieve significant social and economic benefits, and fast reduction reaction speed , The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

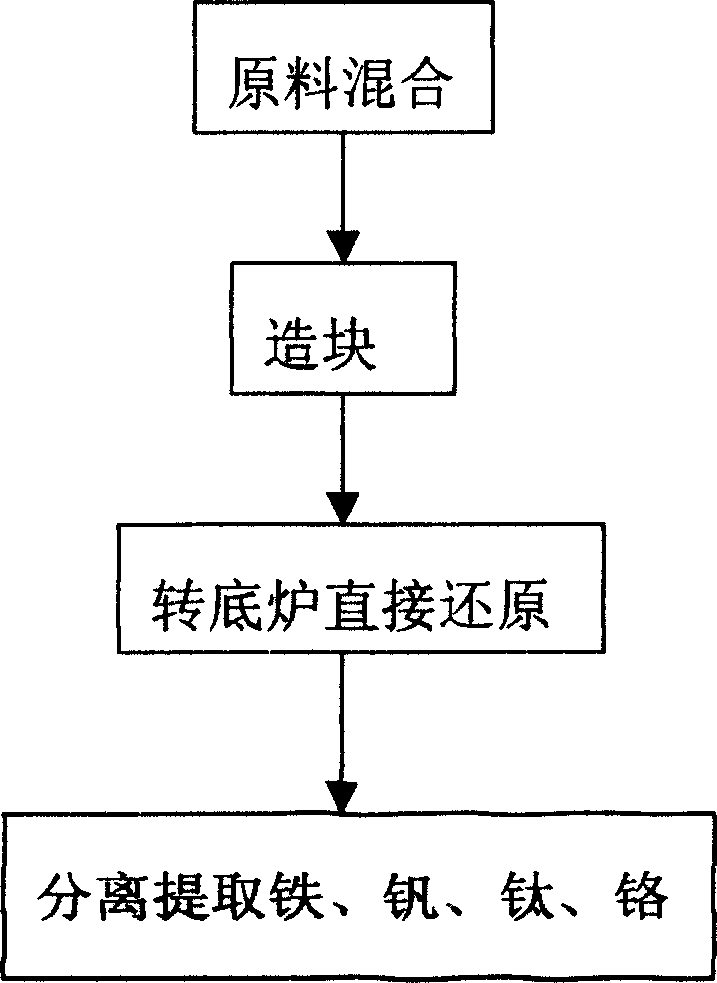

[0021] As shown in Figure 1, the vanadium-titanium magnetite concentrate (composition is: TFe 58.64%, FeO 19.69%, TiO 2 11.06%, V 2 o 5 0.71%, Cr 2 o 3 0.021%, Co 0.010%, Ni 0.0015%, SiO 2 1.68%, Al 2 o 3 3.13%, CaO 0.38%, MgO 1.78%, S 0.093%, P 0.021%. Grinding particle size: -200 mesh size 85%. ), coal powder (composition: ash 9.93%, volatile matter 10.49%, fixed carbon 78.19%, calorific value 30.75MJ / kg; coal powder particle size: -120 mesh accounts for 86%, coal powder dosage: 230kg / t iron concentrate), additives (Na 2 CO 3 , the dosage is 3-5% of the mineral powder), binder (carboxymethyl cellulose, concentration: 0.3-0.5%, the dosage is 0.025-0.03% of the mineral powder) mixed in proportion and pressed into a diameter of 10-15mm spherical shape, dried at 80°C and then loaded into a rotary hearth furnace. The temperature of the furnace is controlled at 1200°C. After 60 minutes of reduction, it is cooled and taken out. The total reduction period is 150 minu...

Embodiment 2

[0023] As shown in Figure 1, the vanadium-titanium magnetite concentrate (composition is: TFe 59.98%, FeO 20.06%, TiO 2 10.97%, V 2 o 5 0.76%, Cr 2 o 3 0.023%, Co 0.012%, Ni 0.011%, SiO 2 1.52%, Al 2 o 3 3.05%, CaO 0.19%, MgO 1.70%, S 0.018%, P 0.024%. The particle size of the iron concentrate is: 84-87% of the particle size of -200 mesh. ), coal powder (composition is: ash content 8.62%, volatile matter 17.73%, fixed carbon 73.47%, S 0.56%, particle size is -200 mesh particle size 70-75%, coal powder dosage is 260kg / t iron concentrate ore), additives (Na 2 CO 3 , the dosage is 4-6% of the mineral powder), binder (carboxymethyl cellulose, the concentration is about 0.5%, the dosage is 0.03-0.035% of the mineral powder) mixed in proportion and pressed into a diameter of 10- 15mm spherical shape, dried at 2 56%±, V 2 o 5 3.89%. It can be used as raw material for extracting vanadium and titanium. After melting, the recovery rate of iron is over 96%, and the re...

Embodiment 3

[0025] As shown in Figure 1, the vanadium-titanium magnetite concentrate (composition is: TFe 56.36%, FeO 23.67%, TiO 2 13.58%, V 2 o 5 0.55%, Cr 2 o 3 0.002%, Co 0.014%, Ni 0.008%, SiO 2 1.17%, Al 2 o 3 3.86%, CaO 0.21%, MgO 3.03%, S 0.24%, grinding particle size: -200 mesh size 85%. ), coal powder (high volatile lignite, composition: C58.20%, V32.63%, A8.44%, S0.83%; coal powder particle size: -120 mesh, accounting for 80% to 85%; coal Powder dosage: 280kg / t iron concentrate), additives (Na 2 CO 3 , the amount is 3-5% of the mineral powder), binder (polyvinyl alcohol, concentration: 1%, the dosage is 0.03-0.035% of the mineral powder) mixed in proportion and pressed into a diameter of 10-15mm Spherical, dried and loaded into a rotary hearth furnace. The temperature of the furnace is controlled at 1400°C. After 35 minutes of reduction, it is cooled and taken out. The total reduction period is 90 minutes, and the metallization rate reaches 93%. Then it is melted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com