Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

A technology for melting slag and sensible heat recovery, applied in recycling technology, furnace, waste heat treatment, etc., can solve the problems of energy consumption, large system maintenance workload, waste of water resources, etc., to improve the cooling rate and intensity, ensure cooling Heat exchange effect, effect of reducing the amount of cooling air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

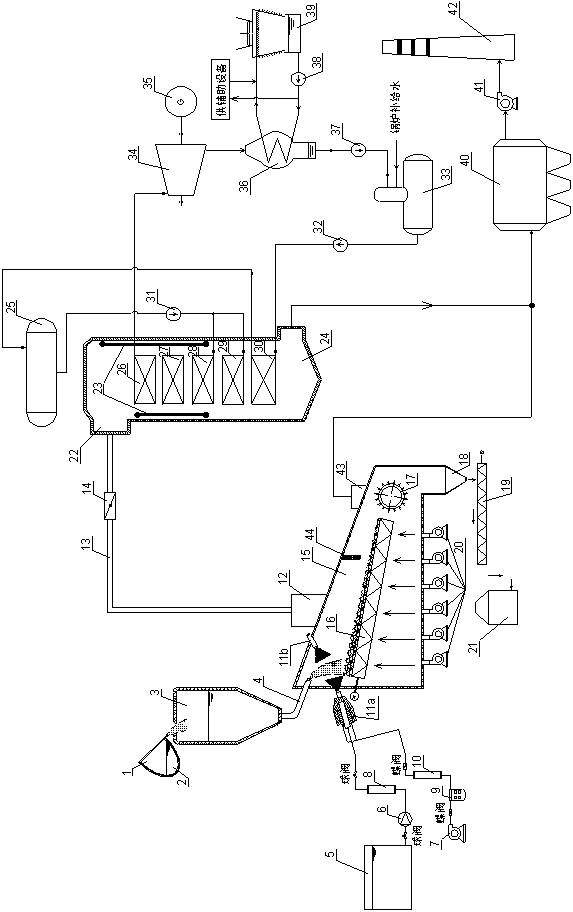

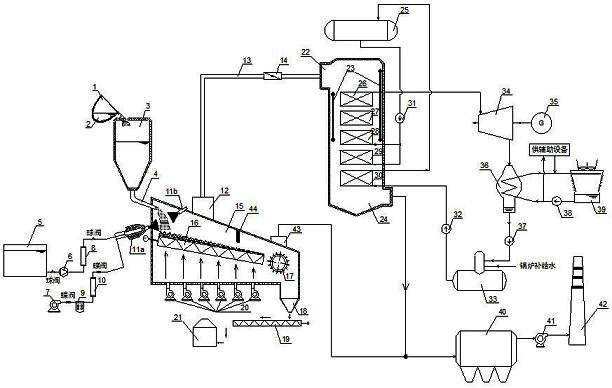

[0025]The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] According to the requirements of molten slag quenching and dry granulation and the characteristics of slag, the present invention proposes a high-pressure water-air atomization quenching granulation device and a water-cooled vibrating grate bed sensible heat recovery method, referred to as high-pressure water-air atomization method.

[0027] The invention mainly solves three key technologies of rapid cooling of molten slag and recovery of sensible heat: 1) granulation technology of molten slag; 2) rapid cooling technology of slag; 3) efficient recovery technology of sensible heat of slag.

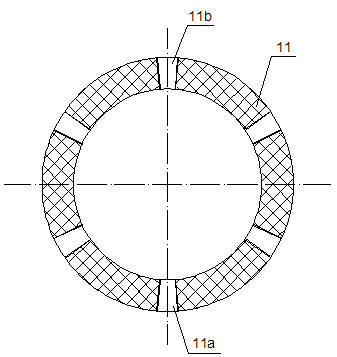

[0028] Such as figure 1 As shown, the structure of molten slag high-pressure water-air atomization quenching dry granulation and sensible heat recovery power generation system, including slag receiving device, high-pressure water-air atomization slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com