Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Incinerator bottom ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Incinerator bottom ash (IBA) is a form of ash produced in incineration facilities. This material is discharged from the moving grate of municipal solid waste incinerators. Following combustion the ash typically has a small amount of ferrous metals contained within it. This ash can be processed to standardize the material and remove contaminants in order for it to be used as an aggregate. Following processing the material can be termed IBA aggregate or processed IBA. The aggregate uses for the material include...

Method for using double-layer continuous casting pouring box covering agent

The invention relates to an application method of a double-layer continuous casting tundish covering agent, which belongs to the technical field of the continuous casting. The invention relates to a comprehensive using method of two covering agents when the low carbon and ultra-low carbon steel grades which have high requirements on the steel cleanliness are casted, bottom slag begins to be added after a large ladle is casted and is sufficiently added after the liquid lever of molten steel is positioned, and five minutes later, top slag is added at the temperature measuring and sampling location according to proportions; the percentages by weight between the bottom slag and the top slag are that: the top slag is 75-85 percent and the bottom slag is 15-25 percent. The invention has the advantages that the bottom slag keeps the characteristic that the high-basicity covering agent has strong absorbing and intermingling capability, at the same time, the second oxidation of the molten steel can be prevented and the carbolic content in the molten steel can be reduced; the top slag can cover the molten steel by taking a loose and porous shape, the incrusting phenomenon of the covering agent at the temperature measuring and sampling location can be improved obviously, the normal temperature measuring and sampling can be carried out and the invalidation loss caused by the incrusting of a temperature measuring head and a sampler can be reduced; the operation is simple, the covering agent of the common steel grades can be used as the bottom slag and the shell-broken operation is not carried out any more; the operational condition pollution caused by carbonizing rice huskes can be avoided.

Owner:SHOUGANG CORPORATION

Pyroprocessed aggregates comprising IBA and PFA and methods for producing such aggregates

InactiveUS20060162618A1Low melting pointPyroprocessing behavior unpredictablePigmenting treatmentSolid waste managementPorosityPulverized fuel ash

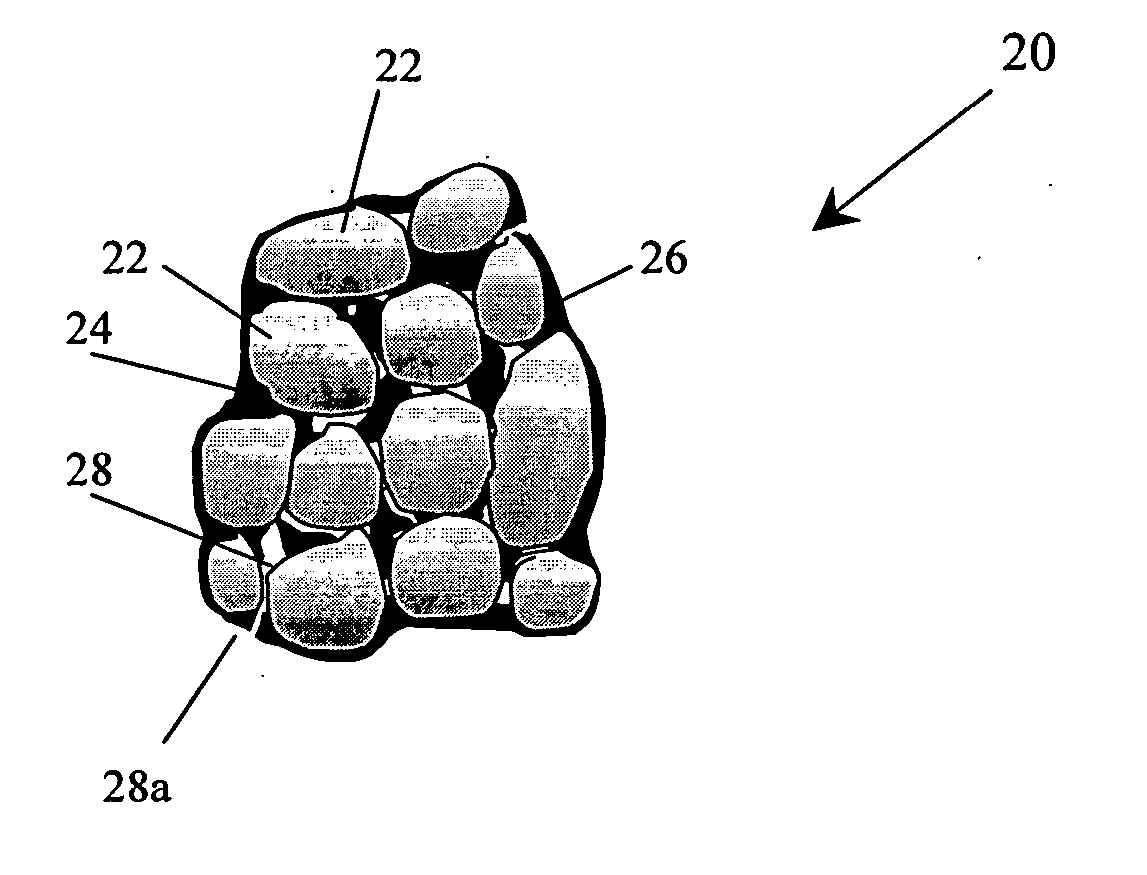

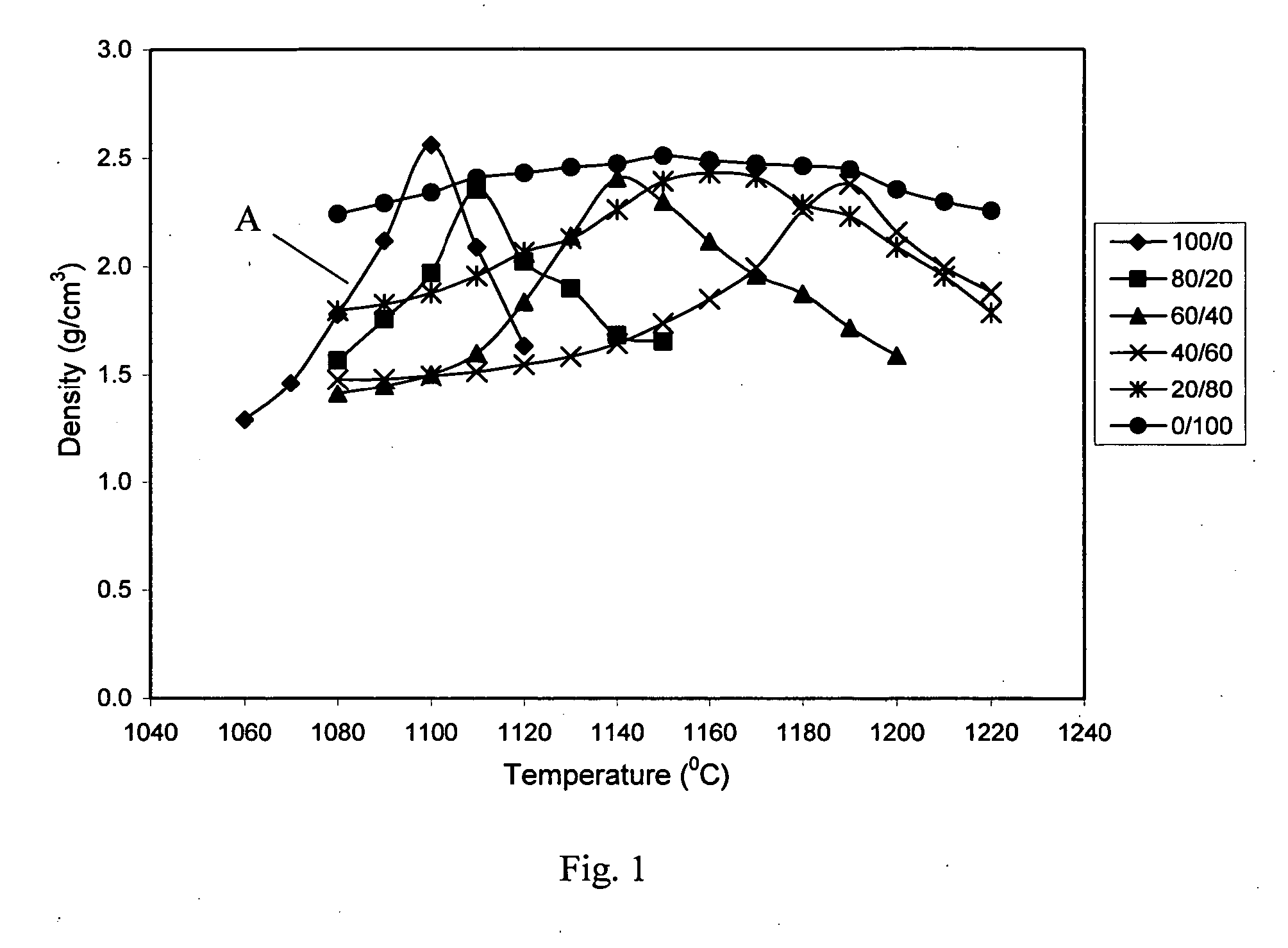

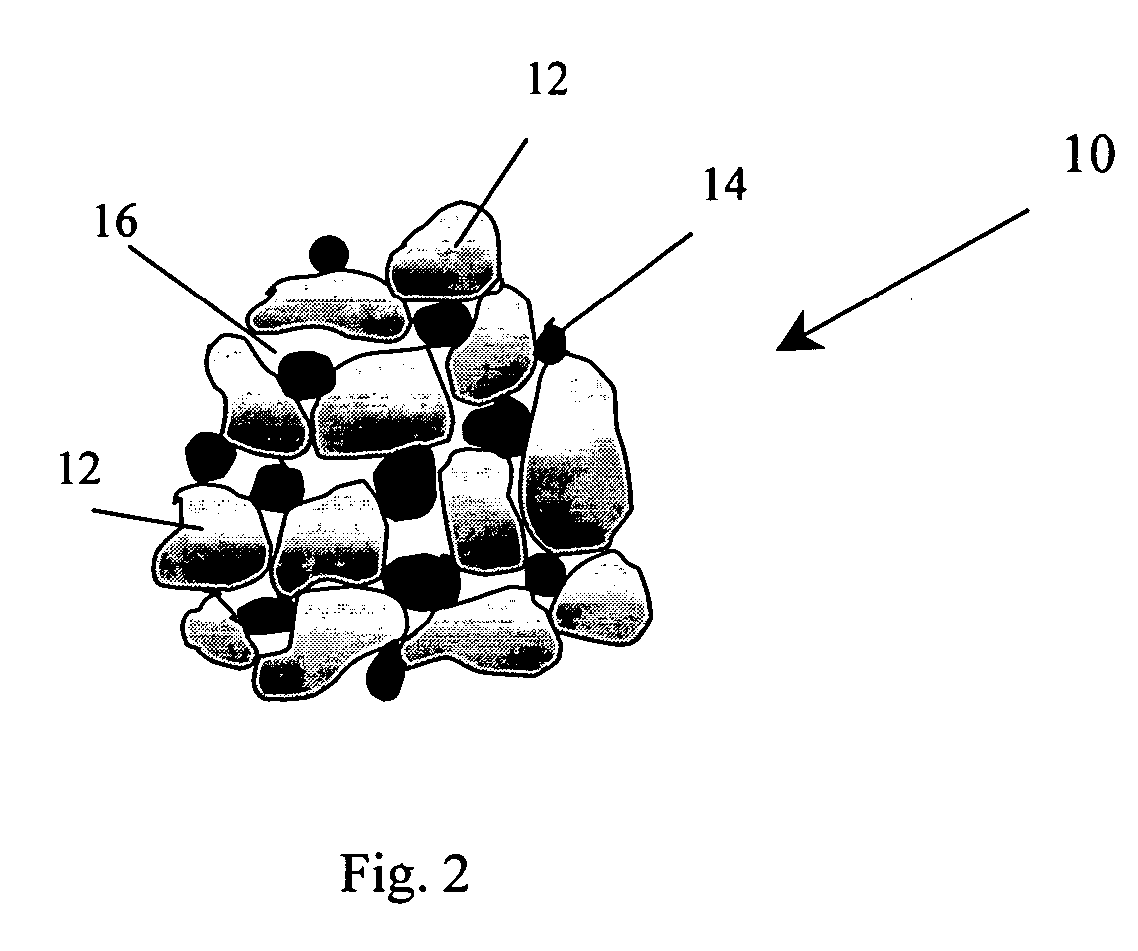

In accordance with an embodiment, a method for producing an aggregate is disclosed comprising mixing incinerator bottom ash (“IBA”) from a municipal solid waste incinerator and pulverized fuel ash (“PFA”) from coal combustion. The method further comprises agglomerating the mixture, such as by pelletizing, and pyroprocessing the agglomerates, such as by sintering or vitrification, to form the aggregate. The addition of PFA to IBA has been found to facilitate production of lightweight and normal weight aggregates. Preferably, the IBA or the mixture of IBA and PFA is wet milled prior to agglomerating. A preferred proportion of IBA to PFA is 40% / 60%. The agglomerates may be coated with an inorganic material to create a surface layer on the aggregate. Organic material may be included in the mixture to increase the porosity of the aggregate. A lightweight sintered aggregate comprising IBA and PFA and an aggregate comprising IBA and PFA are also disclosed.

Owner:ALKEMY

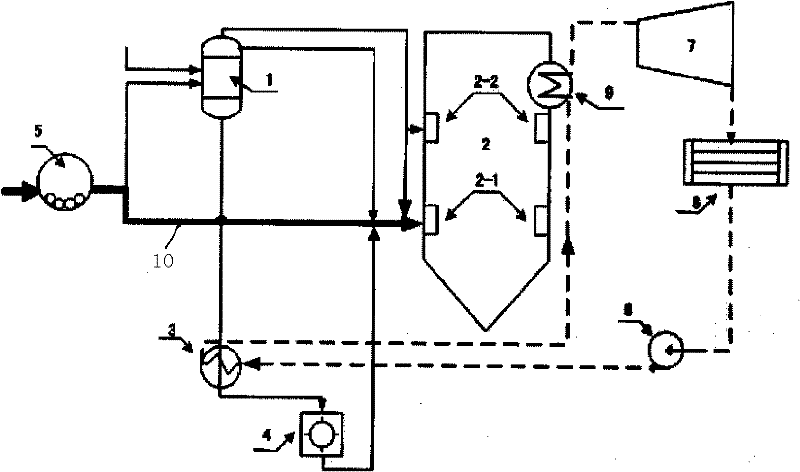

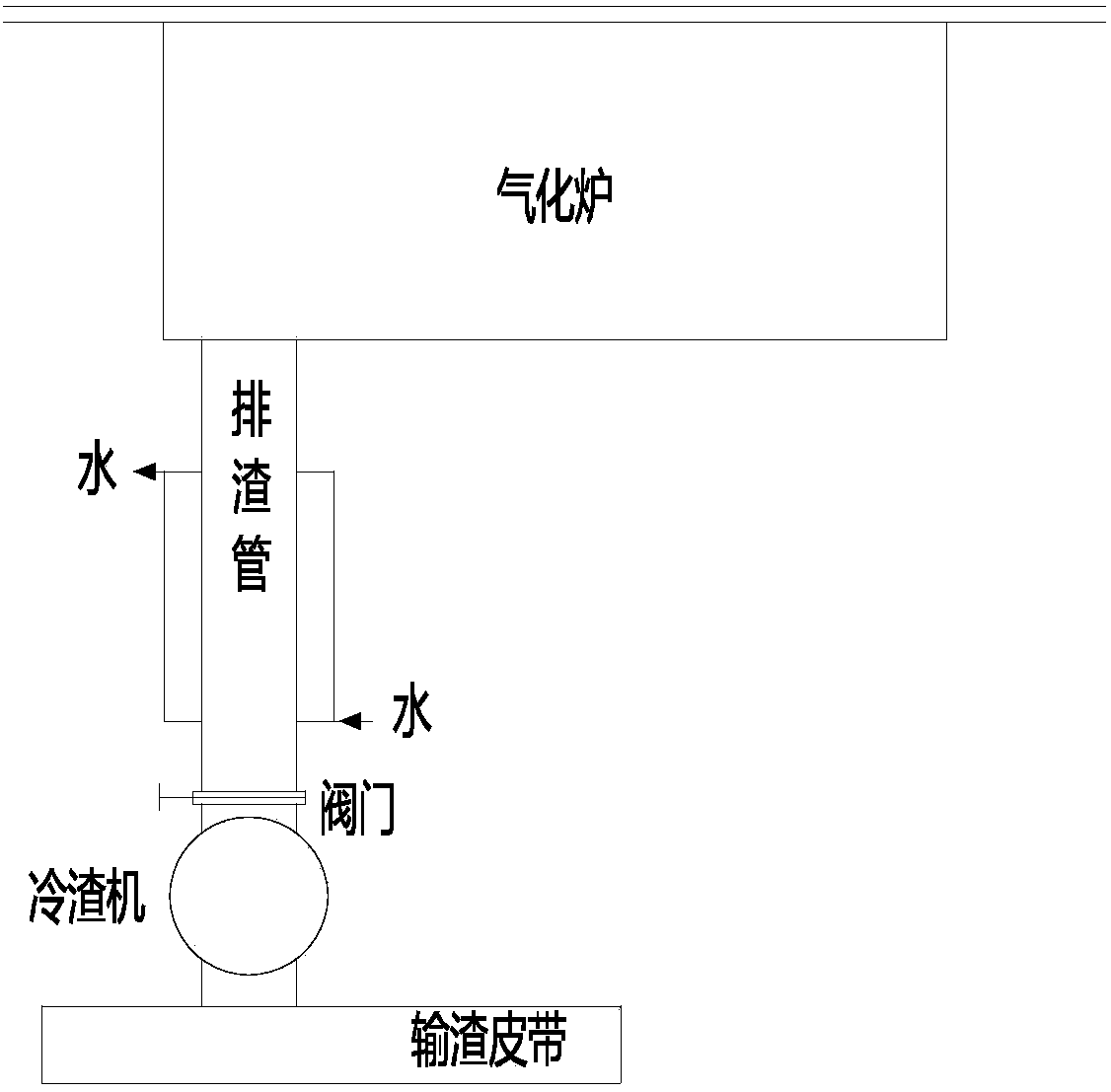

Circulating fluidized bed boiler bottom slag cooling system

ActiveCN101949537AImprove running stabilityReduce running power consumptionFluidized bed combustionApparatus for fluidised bed combustionAir preheaterFluidized bed

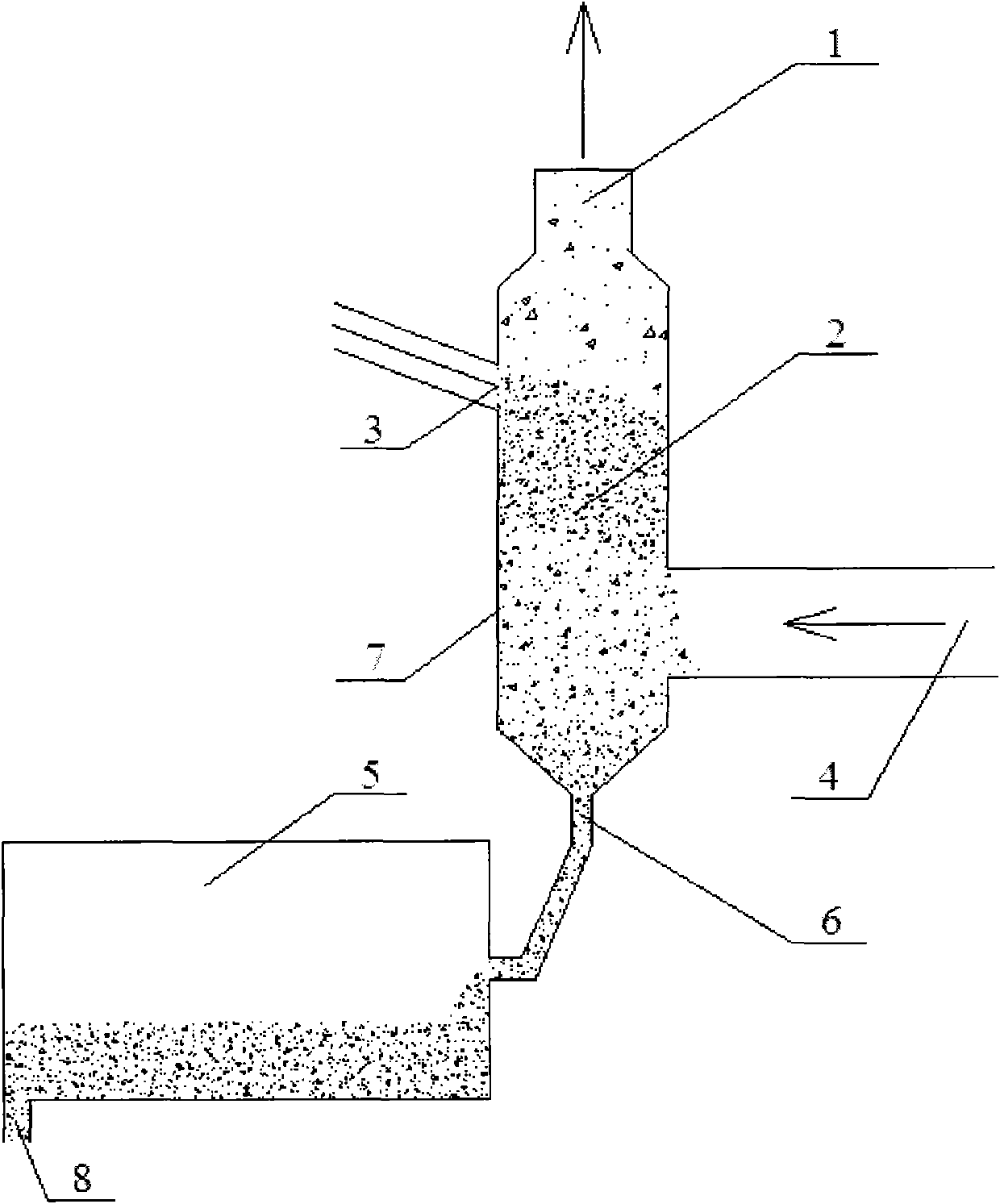

The invention discloses a circulating fluidized bed boiler bottom slag cooling system, and relates to combustion equipment bottom slag cooling technology. The system mainly comprises a slag cooler and a bottom slag thickness separator. The bottom slag thickness separator comprises a barrel, a bottom slag inlet, an air inlet, an air outlet and a bottom slag outlet. The bottom slag inlet is connected with a slag discharge port at the bottom of the circulating fluidized bed boiler through a boiler slag conveying pipe; the bottom slag outlet is connected with the inlet of the slag cooler; and the air inlet is connected with a secondary air pipe of the circulating fluidized bed boiler. Secondary air from an air pre-heater enters the bottom slag thickness separator through the air inlet to exchange heat with bottom slag before entering the hearth of the boiler and takes away fine granule materials in the bottom slag, finally the fine granule materials are returned to the hearth of the boiler through the air outlet to participate in material circulation, and the coarse granular slag falls to the slag cooler on the lower part for further cooling. The system can realize selective slag discharge, and solves the problems of local coking of the fluidized bed slag cooler and the like so as to further improve the running stability of the boiler.

Owner:TAIYUAN BOILER GROUP +1

No-baking bearing brick of hydraulic steel slag and its production process

The present invention discloses one kind one no-baking bearing brick of hydraulic steel slag and its production process. The no-baking bearing brick is produced with blast furnace slag 20-35 wt%, converter slag 10-15 wt%, bottom slag 15- 20 wt%, flyash 4-8 wt%, crushed stone 5-10 wt% and clay 5-12 wt%, and through separate crushing, rolling and sieving to form granular aggregate of certain granularity, mixing, adding cementing material to modify the characteristic of slag, adding water and stirring in semi-drying mode, forming via vibration, naturally curing, hot water curing and stacking. The no-baking bearing brick may be used to replace sintered solid clay brick and is environment friendly.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD +1

Pyroprocessed aggregates comprising IBA and PFA and methods for producing such aggregates

InactiveUS7704317B2Low melting pointPyroprocessing behavior unpredictablePigmenting treatmentOther chemical processesPorosityPulverized fuel ash

Owner:ALKEMY

Method for stabilization heavy metal in fly-ash, bottom slag and soil

The invention relates to a method for stabilizing heavy metals in flying ash, bottom slag or in soil of refuse incineration. The function of the method is that: with silicate as a stabilizing agent and by using a spraying mode or a directly adding mode, the flying ash and bottom slag of refuse incineration or the soil is added with the stabilizing agent, and a stable substance is formed by the silicate or resolvable silicate ions in the stabilizing agent and the heavy metals in flying ash and bottom slag of refuse incineration or in soil so that the heavy metals (especially lead) in flying ash and bottom slag of refuse incineration or in soil are not easy to dissolve out or can be reduced under the erosion of natural environment, meets relevant standards on dissolution and recycling.

Owner:陈鸿亮

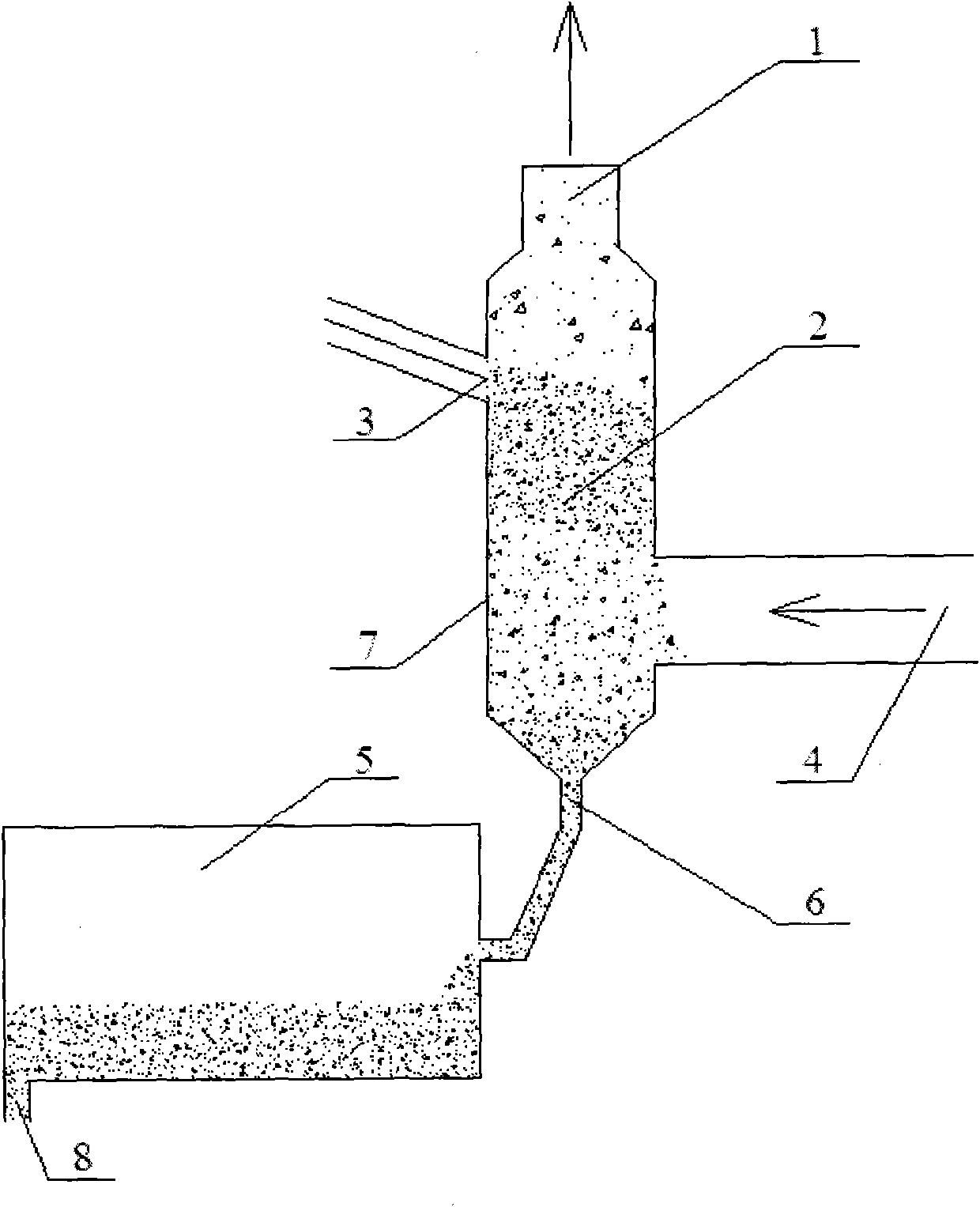

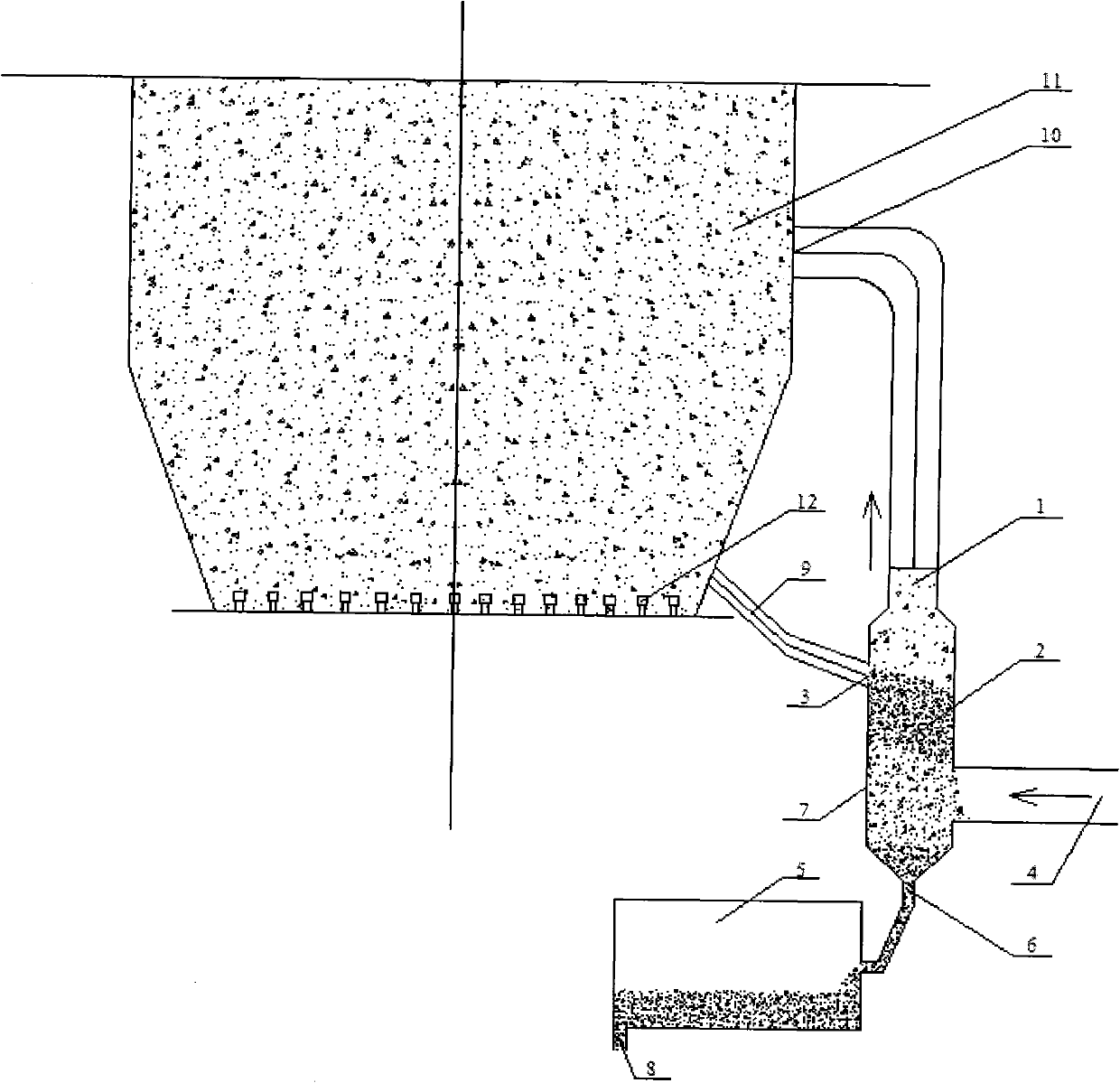

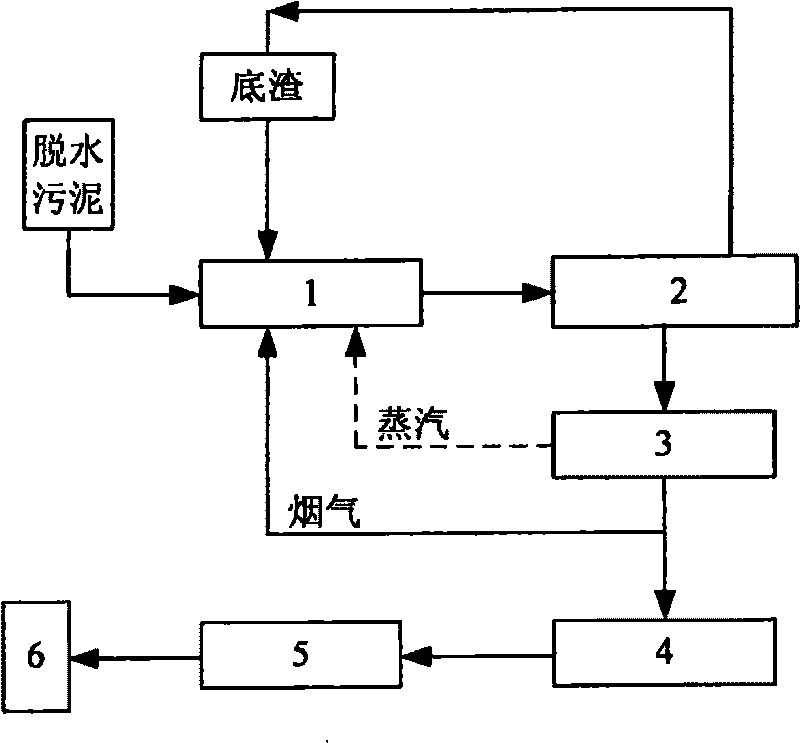

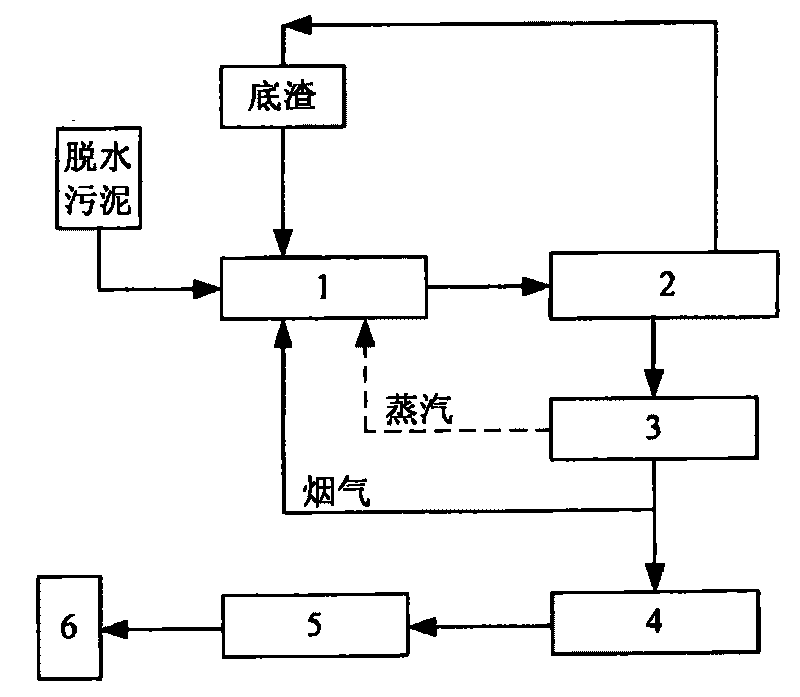

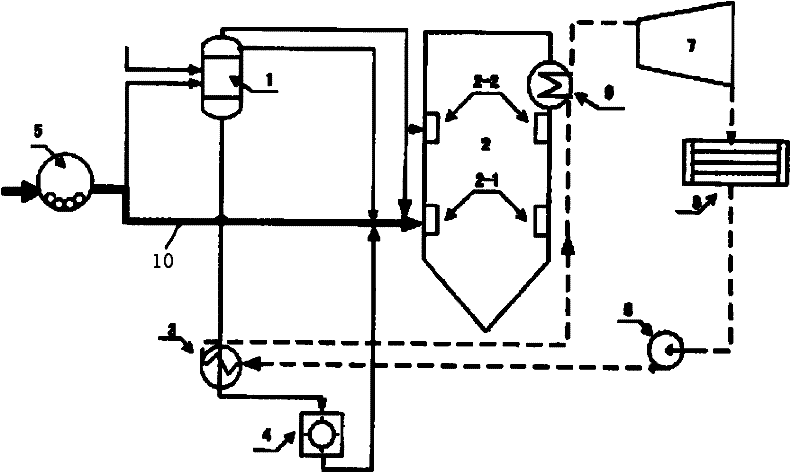

Sludge drying incineration processing system utilizing system residual heat

ActiveCN101708939AReduce loadReduce consumptionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSlagEngineering

The invention relates to a sludge drying incineration system utilizing system residual heat, comprising a sludge semidrying device, a sludge incineration device and a smoke residual heat utilizing device, wherein the sludge semidrying device is provided with a sludge receiving part and a discharge part; the sludge incineration device is provided with a semidrying sludge receiving part, a bottom slag discharge part and a smoke discharge part; the smoke residual heat utilizing device is provided with a smoke receiving part and a smoke discharge part; the discharge part of the sludge semidrying device is connected with the semidrying sludge receiving part of the sludge incineration device; and the smoke discharge part of the sludge incineration device is connected with the smoke receiving part of the smoke residual heat utilizing device. The sludge drying incineration system utilizing system residual heat is characterized in that the sludge semidrying device is also provided with a bottom slag receiving part and a smoke receiving part, wherein the bottom slag receiving part of the sludge semidrying device is connected with the bottom slag discharge part of the sludge incineration device, and the smoke receiving part of the sludge semidrying device is connected with the smoke discharge part of the smoke residual heat utilizing device.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

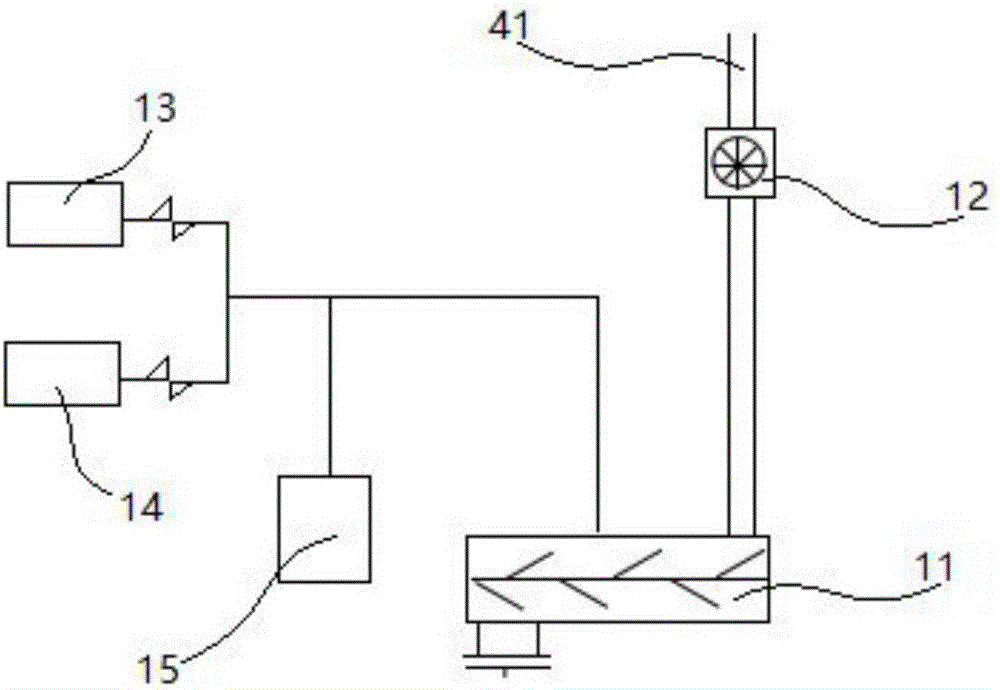

Afterheat recycling device for bottom slag of circulating fluidized bed boiler

ActiveCN107013906AHigh final temperatureIncrease contact timeFluidized bed combustionApparatus for fluidised bed combustionSlagFlue gas

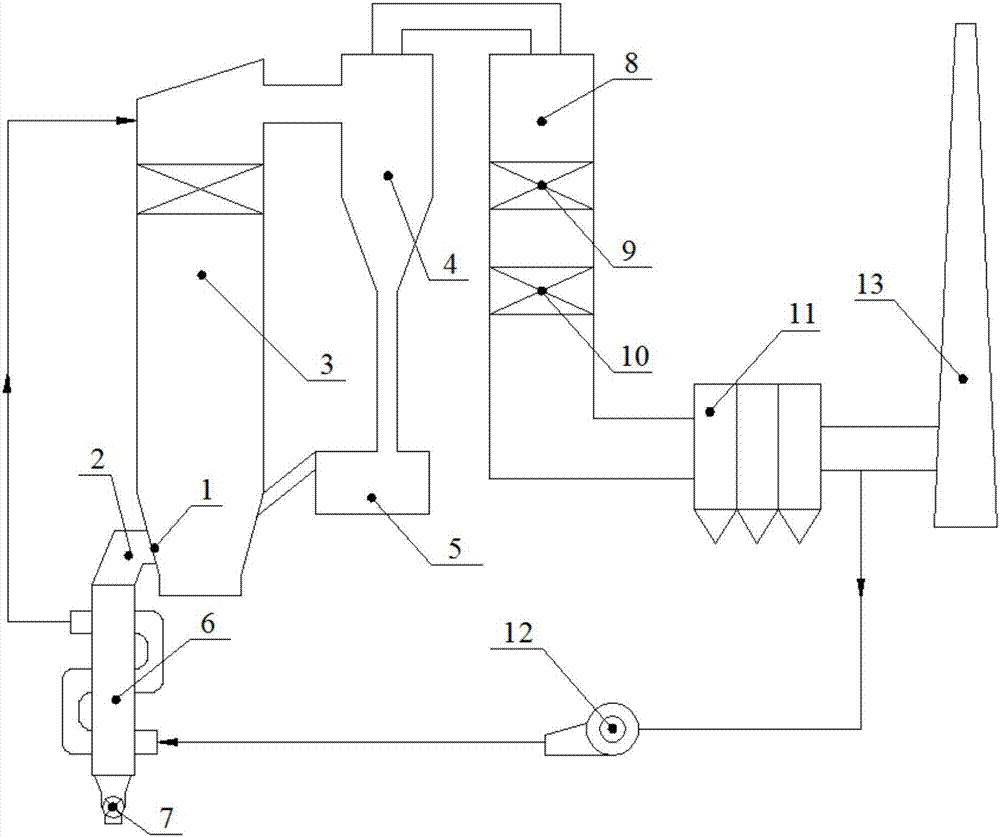

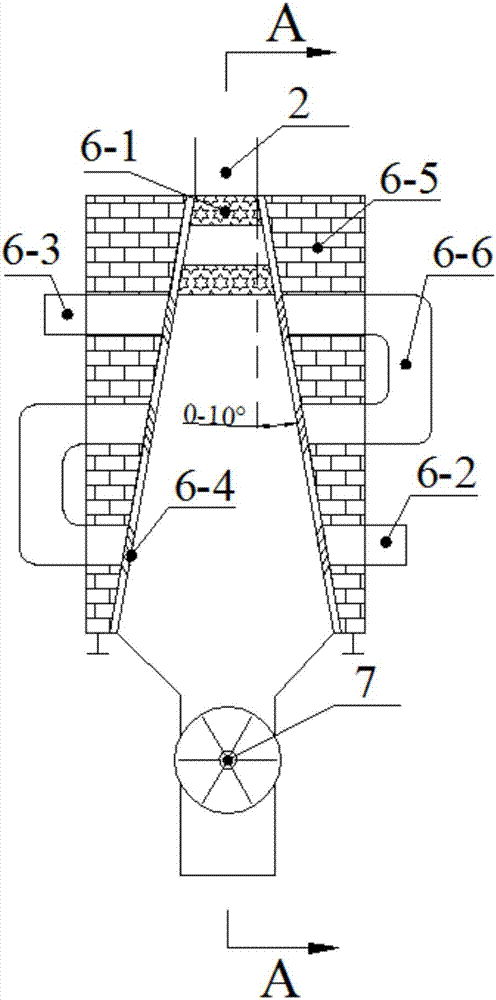

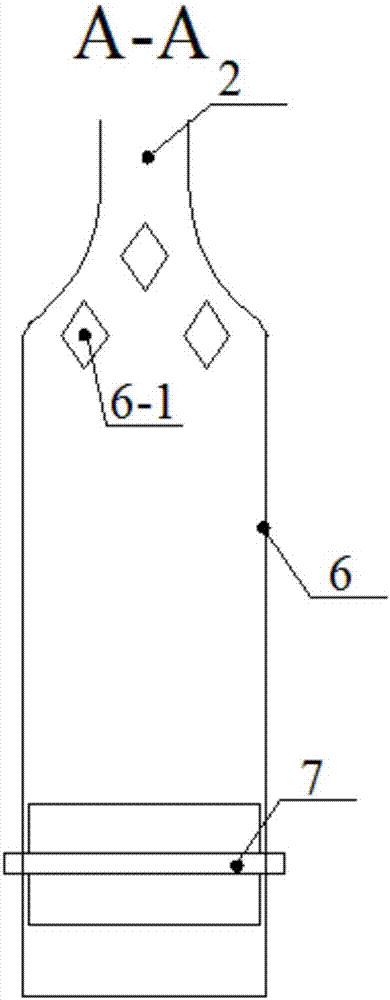

The invention discloses an afterheat recycling device for bottom slag of a circulating fluidized bed boiler. The afterheat recycling device comprises a slag inlet pipe (2), a mobile bed heat exchanger (6) and a rotary slag discharging valve (7), and is characterized in that a bottom slag channel of the mobile bed heat exchanger (6) adopts a streamlined expanding-gradually structure; a bottom slag flow equalization device (6-1) is arranged at an inlet of the mobile bed heat exchanger (6); diversion plates (6-4) which are inclined downwards to the inner side are arranged at each layer of flue gas inlets and flue gas outlets of a cooling flue (6-6); high-temperature bottom slag flows from top to bottom in the mobile bed heat exchanger (6); low-temperature flue gas which is pressurized by a re-recycling flue gas blower (12) does reciprocating direct contact by multi-loop along the diversion plate (6-4) and is subjected to heat adsorption, and then returns to a furnace hearth (3) or a boiler tail flue (8), and the cooled bottom slag is discharged by the rotary slag discharging valve (7). By utilizing re-recycling flue gas as a cooling medium of the bottom slag of the circulating fluidized bed boiler, a large majority of heat energy caused by bringing the bottom slag out of the furnace hearth is recycled into the boiler, so that the physical heat loss of ash slag is reduced, and the heat efficiency of the boiler is improved.

Owner:CHONGQING UNIV

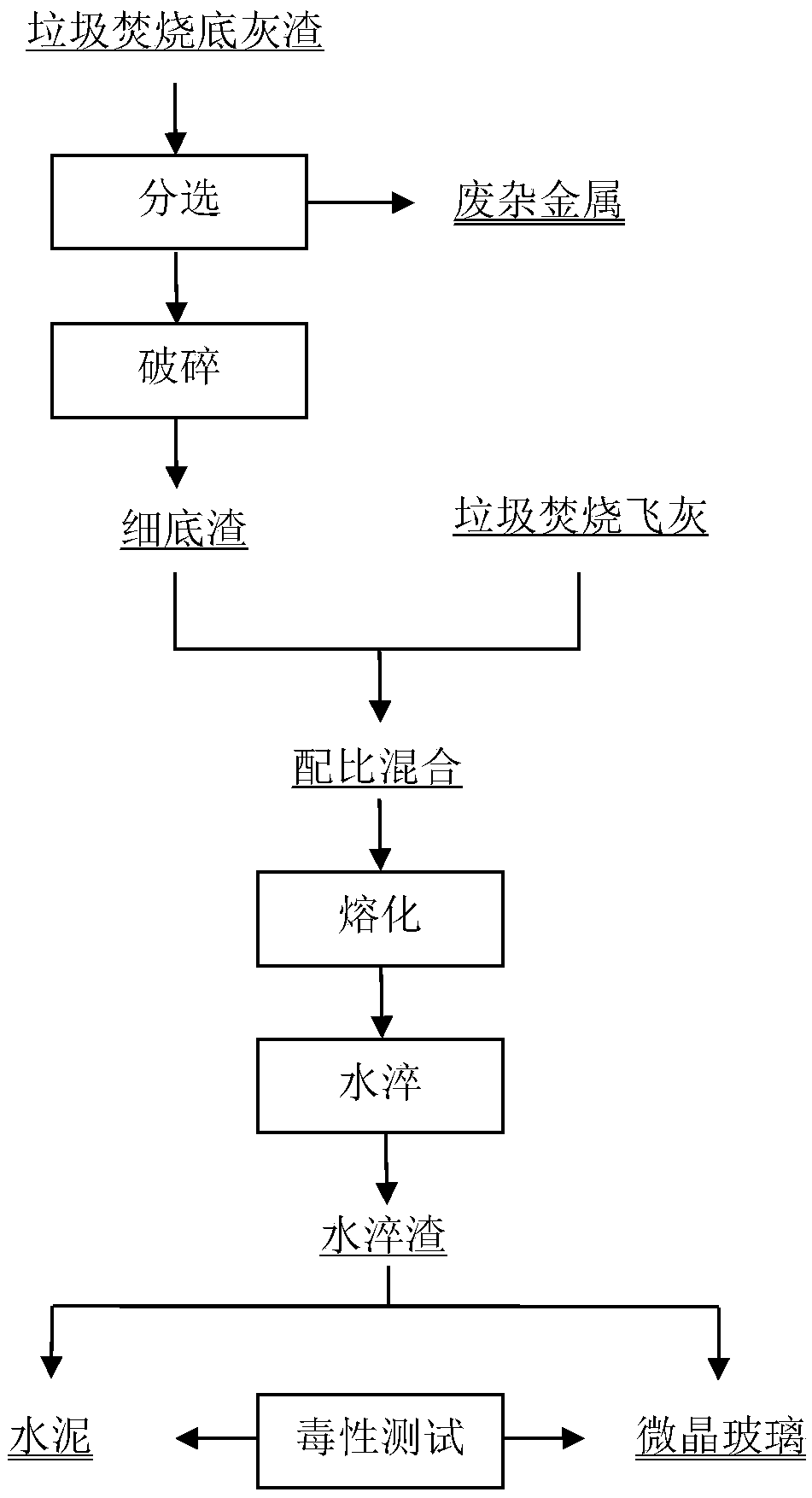

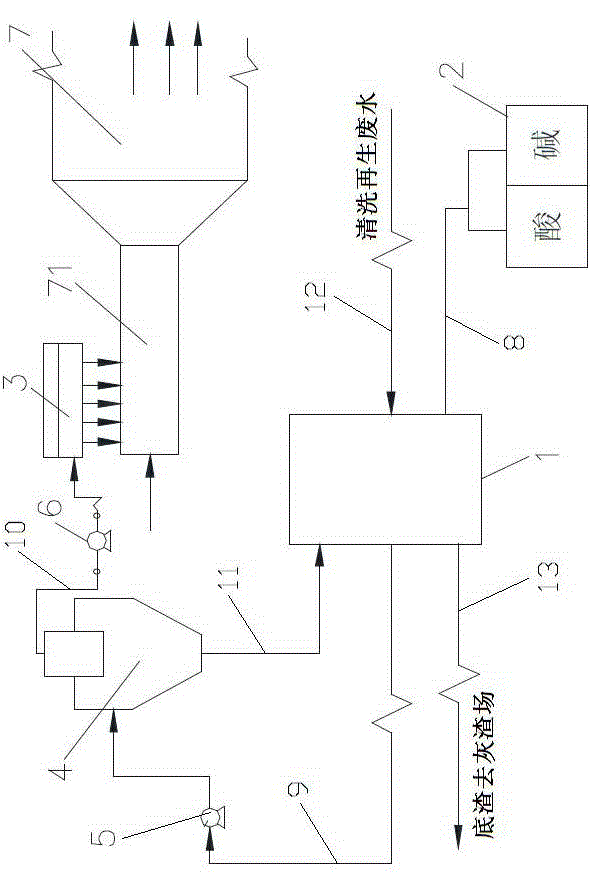

Garbage incineration ash slag heavy metal solidifying method

ActiveCN109516700AEnable co-processingReduce material consumptionCement productionProcess efficiency improvementResource utilizationSlag

The invention discloses a garbage incineration ash slag heavy metal solidifying method, and belongs to the field of solid waste disposal and resource utilization. The method comprises the following steps of obtaining waste sundry metal and fine bottom slag after sorting and crushing of the garbage incineration ash slag; using the waste sundry metal for metal regeneration; performing mixing, fusingand water quenching on the bottom fine slag with the garbage incineration ash slag; using the water quenching slag for cement and crystallized glass, wherein the heavy metal in the product is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The method provided by the invention has the advantages that the process is simple; the industrialization is easy; the goals of safely solidifying garbage incineration ash slag heavy metal and recycling the garbage incineration ash slag heavy metal for cement and crystallized glass can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

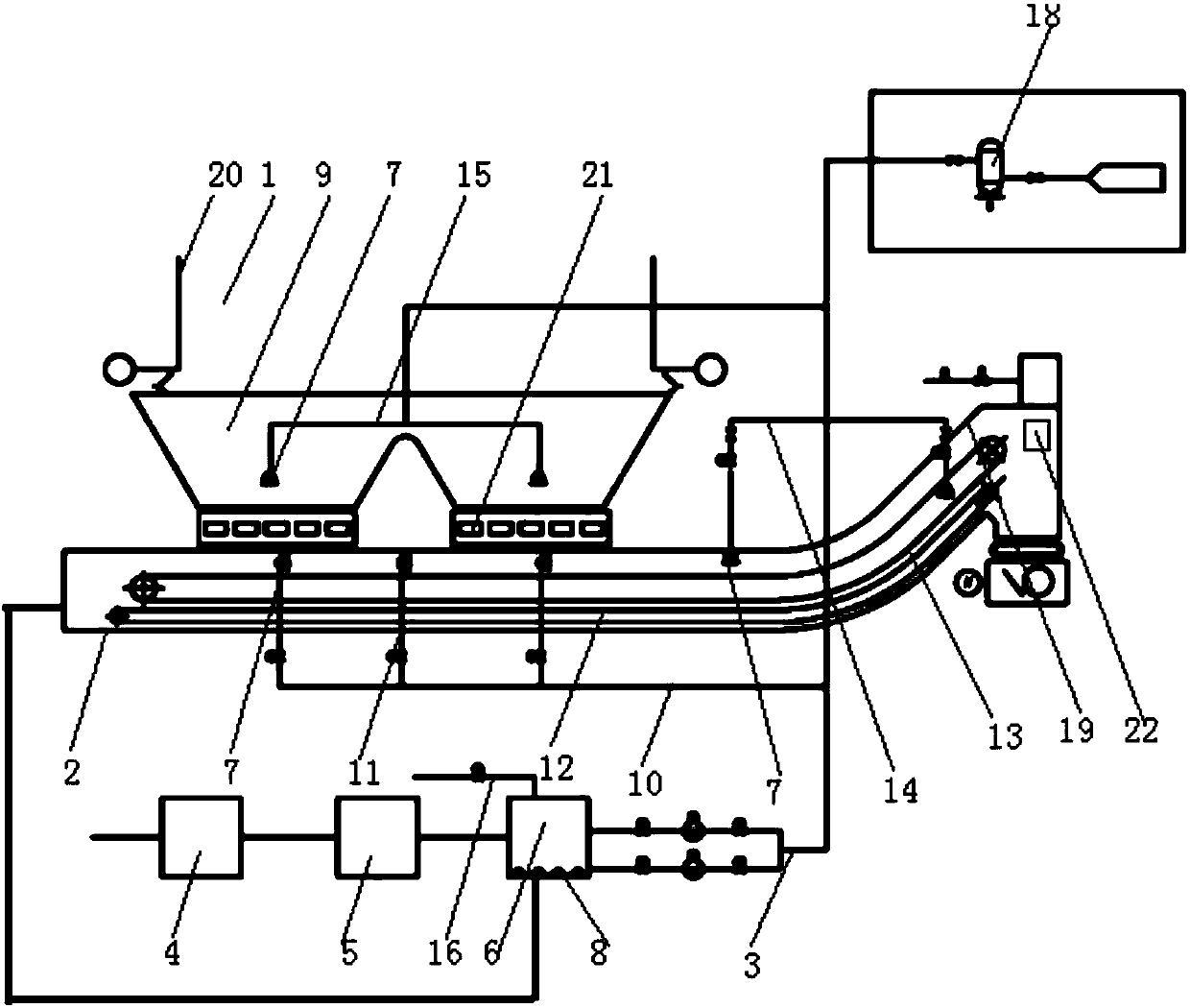

A method and system for reducing NOx emissions and stabilizing combustion of utility boilers

ActiveCN102269402AEmission reductionLow running costCombustion using gaseous and pulverulent fuelSyngasFluidized bed gasifier

The invention discloses a method and a system for realizing NOx discharge reduction and stable combustion of a power station boiler, which belongs to the technical scope of coal powder power station environmental protection. In the system, a coal mill is connected to a fluidized bed gasifier and a boiler respectively, and a top syngas outlet of the fluidized bed gasifier is connected to a boiler combustor. The method particularly comprises the following steps: performing fluidized bed gasification of fire coal which is 5-20% of the boiler load, delivering the syngas generated in the fluidized bed to a boiler reburning combustor for reburning so as to reduce NOx discharge, or delivering the syngas to a boiler main fuel combustor so as to allow the syngas to be used as auxiliary fuel and to combust stably when the boiler combusts inferior coal of has a low load; after treatment, delivering the gasified top ash and bottom slag in the fluidized bed to a primary air channel of a boiler coal powder combustor, mixing with coal powder so as to combust the uncombusted components. During the cooling process, the heat of high-temperature bottom slag is taken away by supplying water into the boiler, and the bottom slag is delivered to a heating surface of the boiler for heating. The invention realizes the effect of NOx discharge reduction and stable combustion of a power station boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Treatment device and treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue

ActiveCN104591460AAchieve reuseImprove applicabilityUsing liquid separation agentMultistage water/sewage treatmentHigh energyWastewater

The invention relates to a treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue. A treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue, which have high energy utilization rate and can realize recycling of the denitration catalyst cleaning regeneration wastewater, are unavailable now. The treatment device is characterized by comprising a wastewater buffer sedimentation tank, an acid-base dosing box, an ultrasonic atomizing nozzle, a wastewater hydrocyclone, a liquid conveying pump, a deduster, an acid-base supply pipe and an underflow return pipe, wherein a cleaning regeneration wastewater conveying pipe and a bottom residue conveying pipe are both connected to the wastewater buffer sedimentation tank; and the acid-base dosing box is connected to the wastewater buffer sedimentation tank through the acid-base supply pipe. The treatment technology comprises the following steps: conveying the denitration catalyst cleaning regeneration wastewater into the wastewater buffer sedimentation tank; adjusting the pH value; standing for sedimentation; performing solid-liquid separation of the supernate; and atomizing the overflow filtrate and spraying into the deduster. The treatment device and treatment technology provided by the invention can be used for realizing recycling of the denitration catalyst cleaning regeneration wastewater.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

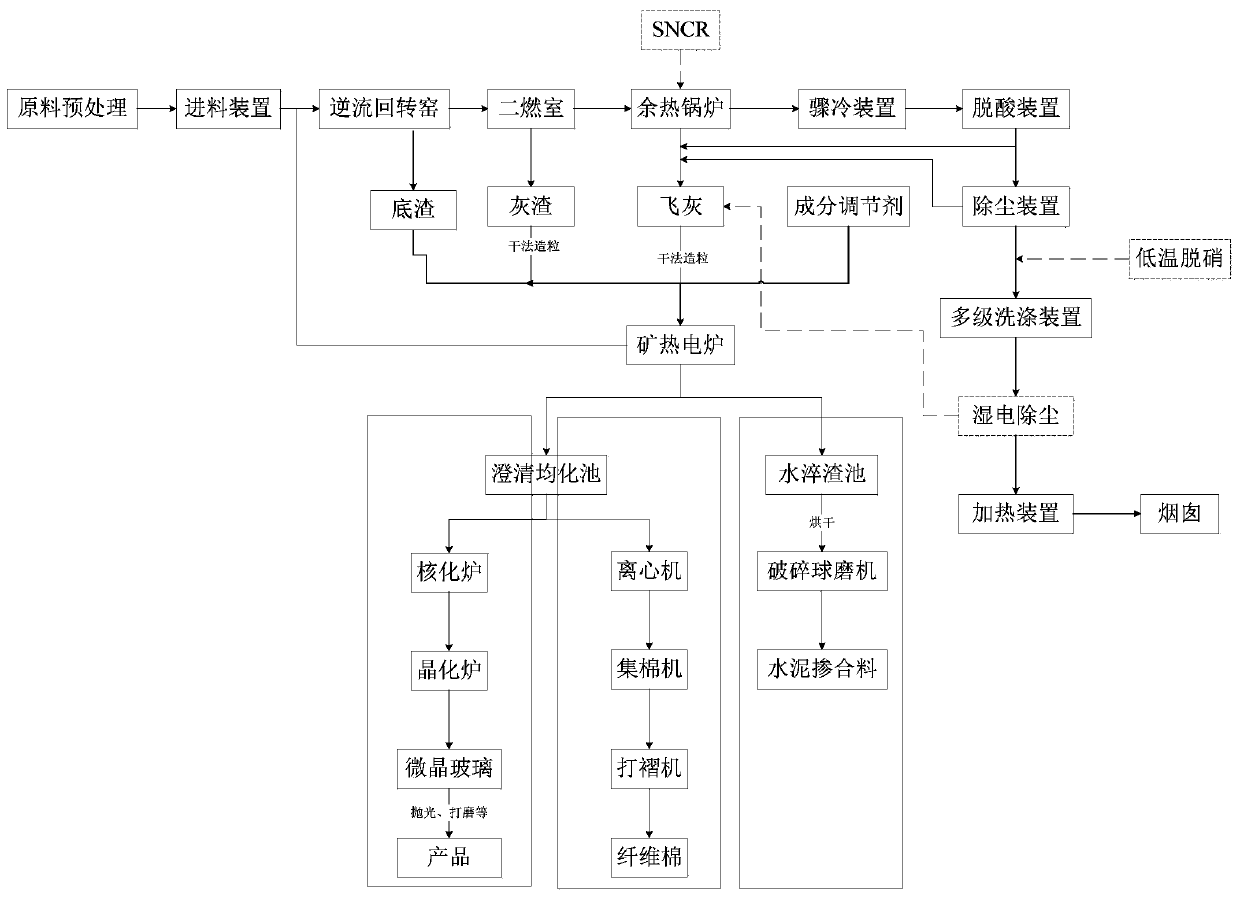

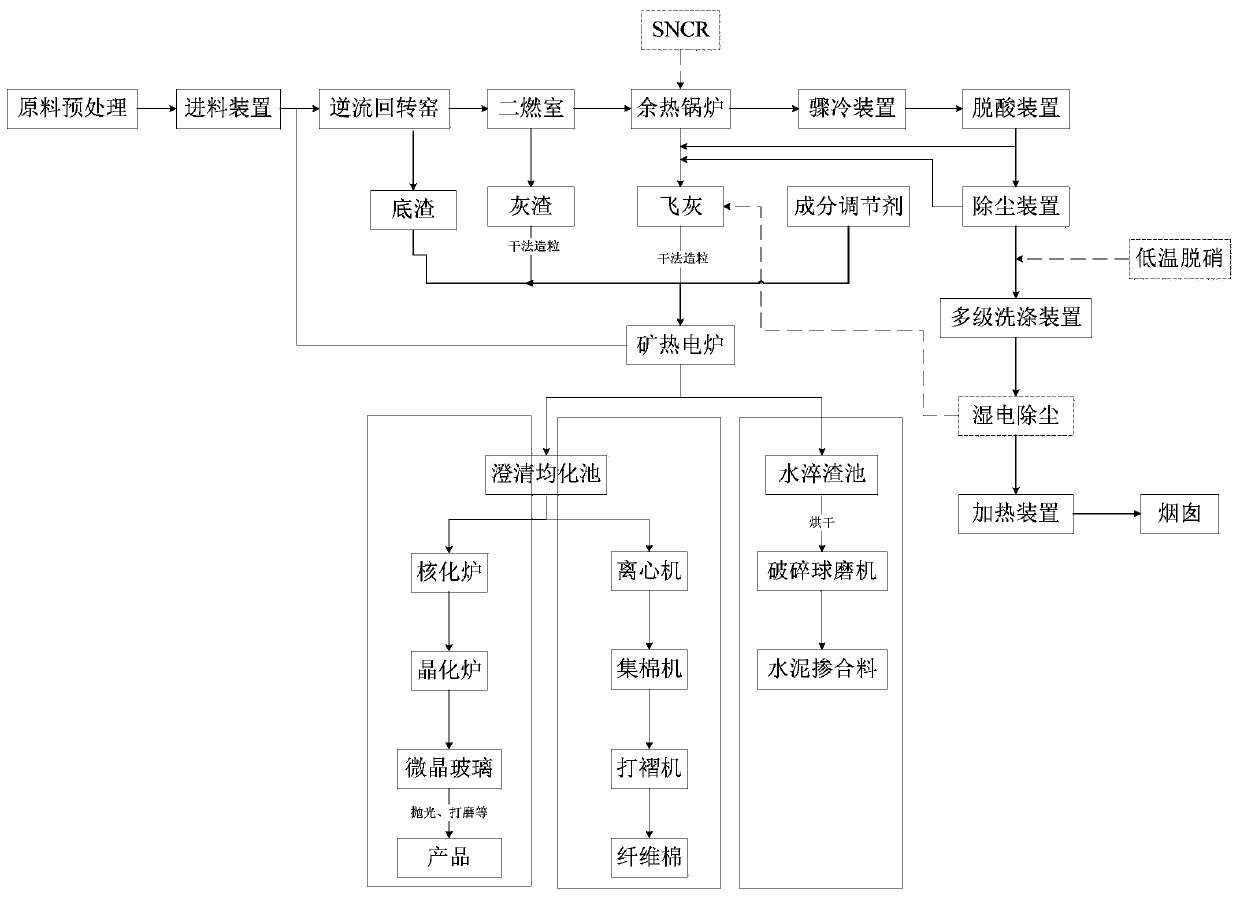

Hazardous waste disposal method

InactiveCN110030560ARealize resource utilizationFlue gas up to standardTransportation and packagingSolid waste disposalFiberFlue gas

The invention provides a hazardous waste disposal method which comprises the following steps: carrying out primary incineration disposal on a hazardous waste to obtain bottom dreg and first flue gas;carrying out secondary incineration disposal on the first flue gas to obtain first fly ash and second flue gas; and melting a melted raw material to prepare one or more of microcrystal glass, fiber cotton and a cement admixture, wherein the melted raw material comprises the bottom dreg and the first fly ash. According to the hazardous waste disposal method provided by the invention, the emitted flue gas reaches the standard and the hazardous waste can be recycled.

Owner:CHINA ENFI ENGINEERING CORPORATION

Bottom slag cooling method of circulating fluidized bed

ActiveCN101598334AHigh thermal efficiencyEasy insulation designFluidized bed combustionApparatus for fluidised bed combustionCombustionSlag

The invention provides a bottom slag cooling method of a circulating fluidized bed, which comprises the specific steps of mounting a slag cooler cavity at the outer side of a conical part at the lower side of a hearth of a circulating fluidized bed boiler; mounting a serpentine heat exchanger at the part between a slag inlet and a slag outlet in the slag cooler cavity, wherein, one end of the serpentine heat exchanger is extended into a primary air chamber and the other end thereof is exposed outside the cavity; putting the bottom slag generated by combustion into the slag cooler cavity through the slag inlet, making the fluidized air of the slag cooler enter the slag cooler cavity from the air chamber of the slag cooler through an air distributor of the slag cooler, and carry fine particles and the desulfurizing agent of the circulating fluidized bed to return to the hearth through a backwind tube, and discharging the cooled bottom slag through the slag outlet. By adopting high-pressure feed water or boiler water of the boiler, the invention cools the bottom slag, realizes heat recovery of the bottom slag, and reduces the floor area of the slag cooler.

Owner:SHANGHAI BOILER WORKS

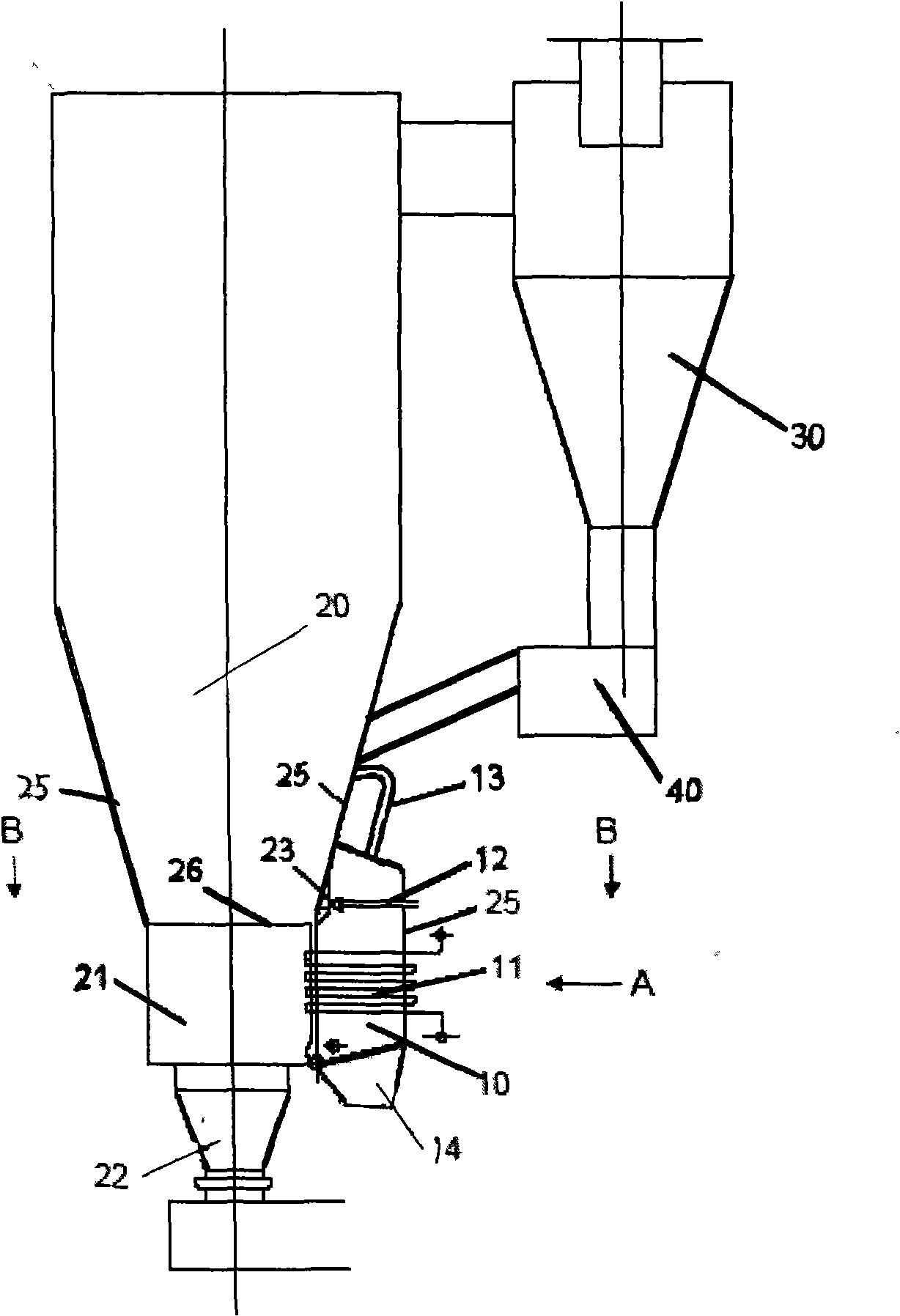

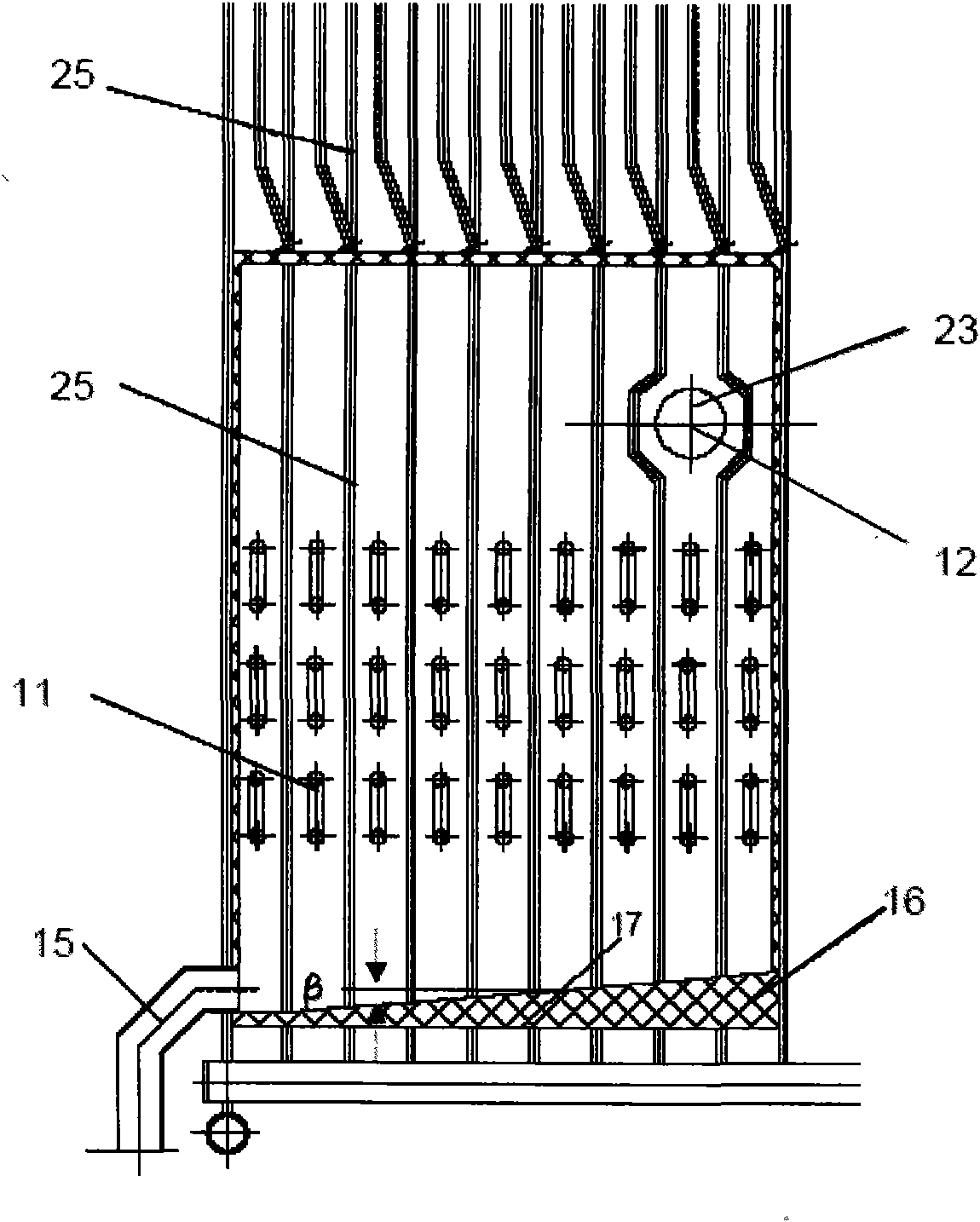

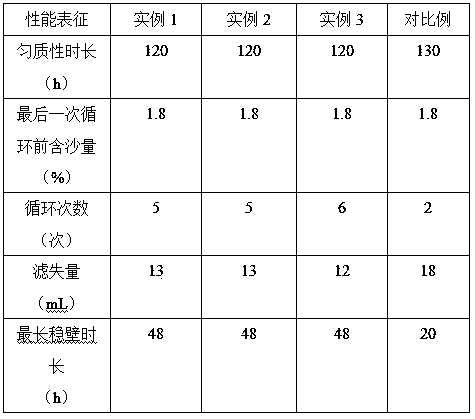

Environment-friendly wall-protecting slurry and preparation method thereof

InactiveCN109180090AIncrease the number ofImprove densification performanceCross-linkInterface layer

The invention relates to environment-friendly wall-protecting slurry and a preparation method thereof and belongs to the technical field of environmental protection. By utilizing mutual adhesion between incinerator bottom ash and clay particles, the frictional resistance in the friction process is enhanced, polymerization and thickening reactions are gradually carried out between the incinerator bottom ash and vegetable gelatin and starch, mutually cross-linked mesh polymer chains are formed among high polymeric substances for coating and bonding the clay particles, and the particle voids arefilled until the whole clay system is solidified to become gel and cured, so that the physical anchoring effect between the incinerator bottom ash and the matrix can be enhanced, the load transfer efficiency of the interface layer of the composite material is improved, the effective contact area between the surface of the wall-protecting slurry and the matrix is enlarged, the cohesion force of thewall-protecting slurry is enhanced, and the problems that the traditional slurry is poor in homogeneity, wall stabilizing time of the deep pile foundation is short, the construction cost is high, thecyclic utilization rate is low and the environment is polluted are effectively solved.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

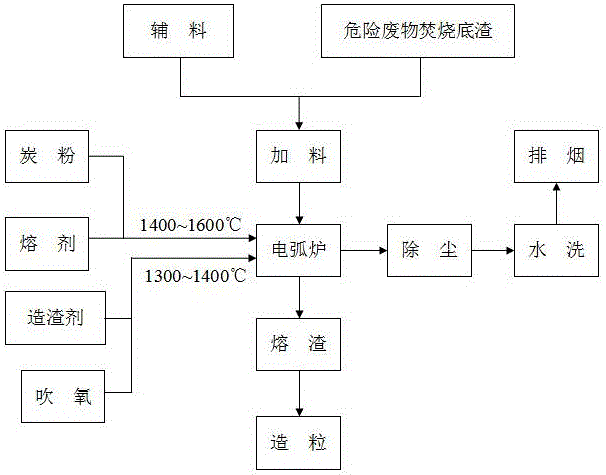

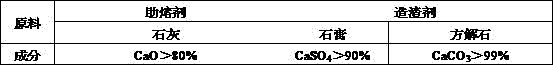

Method for resource utilization of hazardous waste incineration bottom slag

ActiveCN106224979ARealize resource utilizationSignificant volume reductionIncinerator apparatusCeramic materials productionElectric arc furnaceResource utilization

The invention provides a method for resource utilization of hazardous waste incineration bottom slag. In order to solve the disposal problem of the hazardous waste incineration bottom slag, the common organic hazardous waste incineration bottom slag is used as a raw material, clay, coal ash, zeolite, shale, coal gangue and the like with SiO2 and Al2O3 as main ingredients are properly proportioned to serve as an auxiliary material, and a mixed material is formed; and an electric-arc furnace is adopted as a main reacting device for carrying out melting treatment on the mixed material, and finally-formed molten slag has high inertness and can be directly used as a firing raw material of multiple building materials. Poisonous and harmful substances, treated through the method, in the hazardous waste incineration bottom slag are further cured, environmental harm is reduced, the disposal problem of the hazardous waste incineration bottom slag is solved, resource utilization of the hazardous waste incineration bottom slag is achieved, and good environmental and social benefits are achieved.

Owner:南京天地环境污染防治研究院

Method for stabilization of heavy metals in incinerator bottom ash and odor control with dicalcium phosphate dihydrate powder

This invention provides a method for stabilization and treatment of heavy metal bearing materials and wastes subject to acid leaching tests or leach conditions and odor limits by addition of acid semi-soluble DiCalcium Phosphate DiHydrate such that the leaching potential is inhibited to desired levels and odors are reduced to desired levels and the material or waste is free flowing, more permeable, less weight and permits immediate handling and disposal or reuse. The resultant material or waste after stabilization is deemed suitable for on-site reuse, off-site reuse or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH E

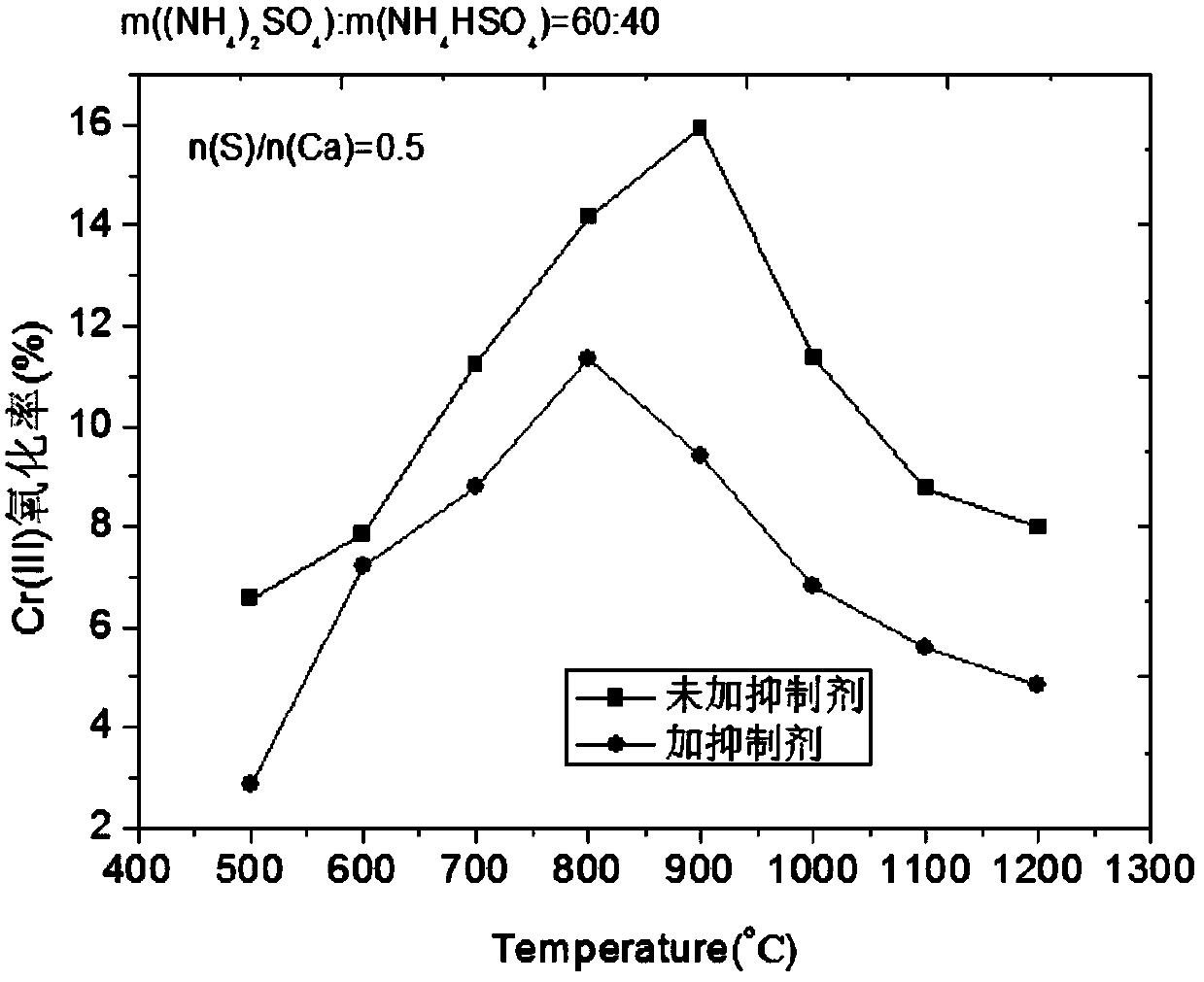

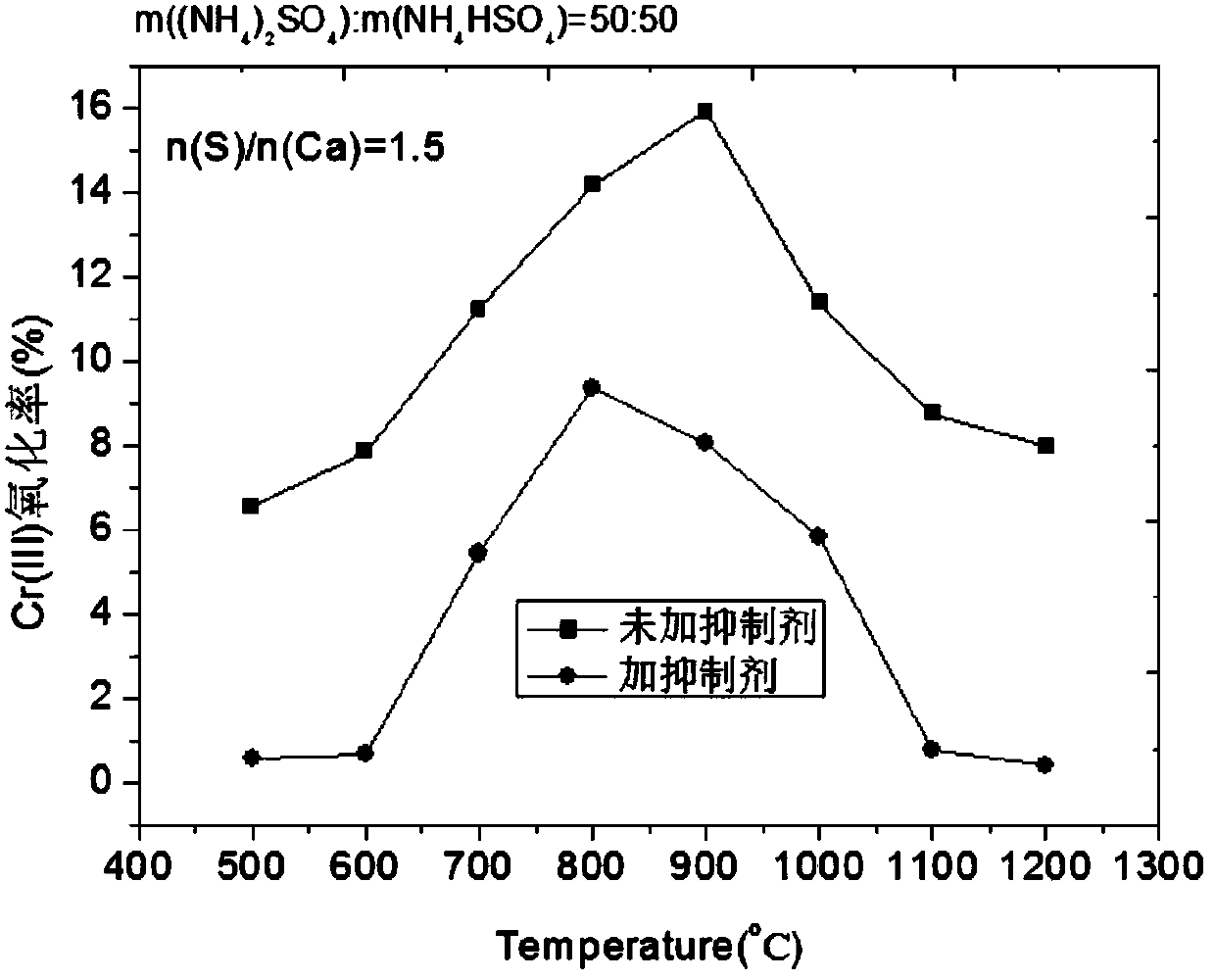

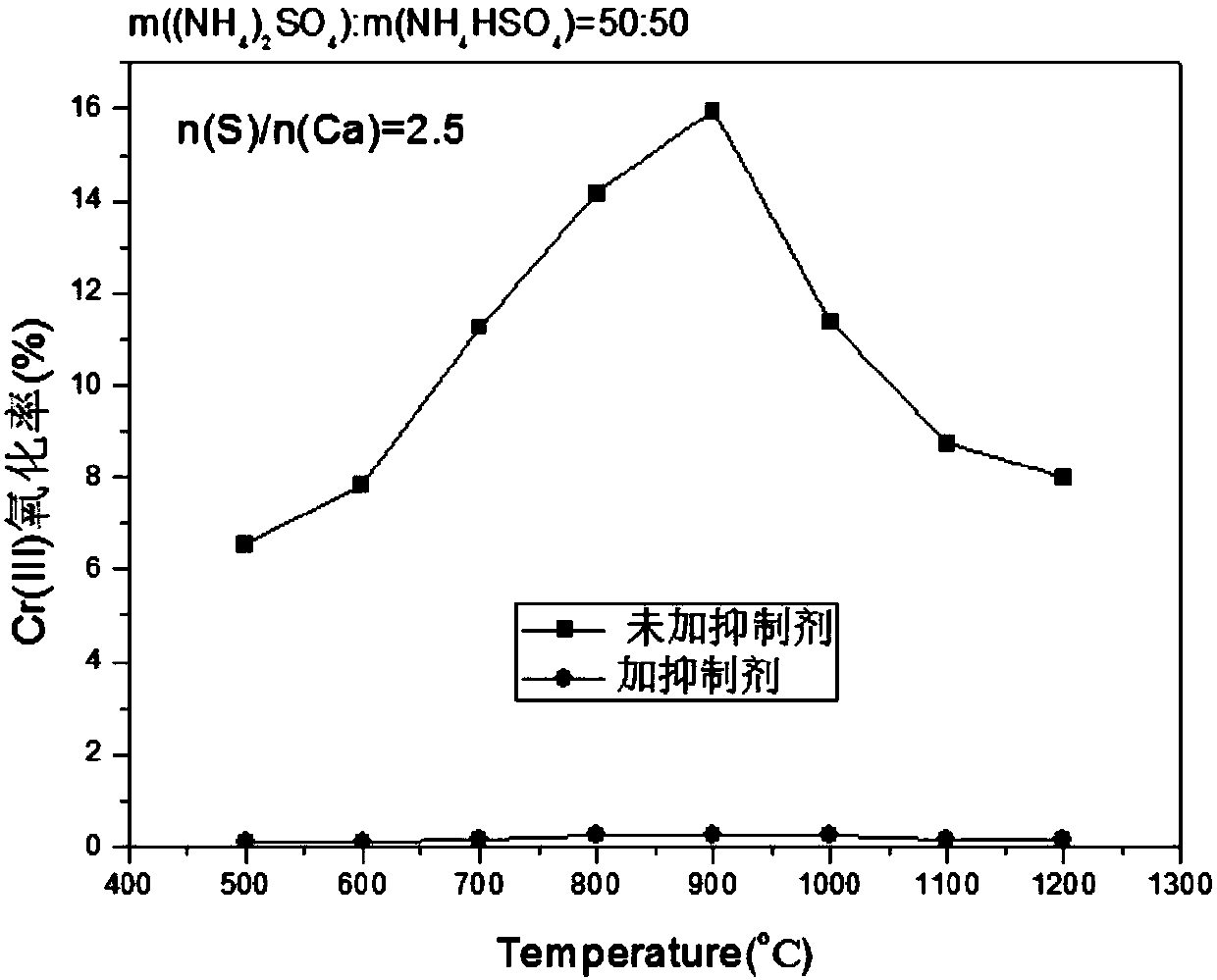

Method for restraining Cr(III) oxidization in tanning sludge incineration process

The invention relates to a method for restraining Cr(III) oxidization in the tanning sludge incineration process, and particularly provides a Cr(III) oxidization restraining inhibitor and matching thereof. The inhibitor is composed of (NH4)2SO4 and NH4HSO4, wherein the mass percent of the (NH4)2SO4 ranges from 40% to 70%, and the mass percent of the NH4HSO4 ranges from 30% to 50%. An application method of the inhibitor comprises the steps that sludge is directly mixed for neutralizing, and a water solution is prepared. According to the optima usage concentration of the inhibitor, it is guaranteed that the substance amount ratio of the S content in an additive in an incinerator to the content of alkali metal and alkali earth metal in slurry is 2-2.5. According to the Cr(III) inhibitor, Cr(III) oxidization generated in the chromium containing sludge heat treatment process can be greatly reduced, and forming of Cr(VI) is obviously restrained. Through usage of the inhibitor, fly ash and bottom slag generated in the sludge incineration process can meet or basically meets the national hazardous waste Cr(VI) safety requirement, and the problem of Cr(VI) forming in the heat treatment process can be well solved. Meanwhile, the inhibitor has the beneficial effects that the reaction speed is high, and reaction is sufficient.

Owner:CHANGZHOU UNIV

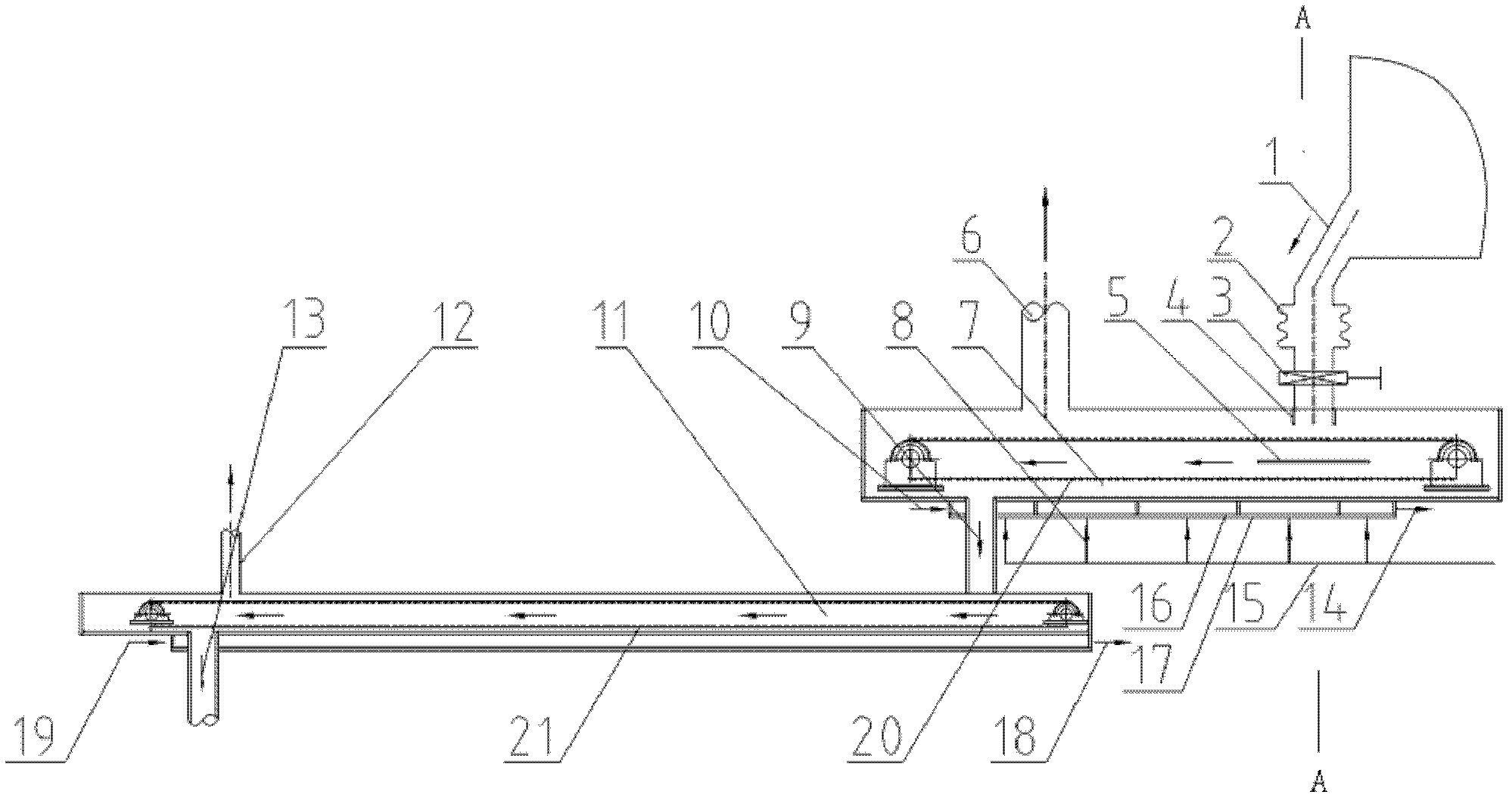

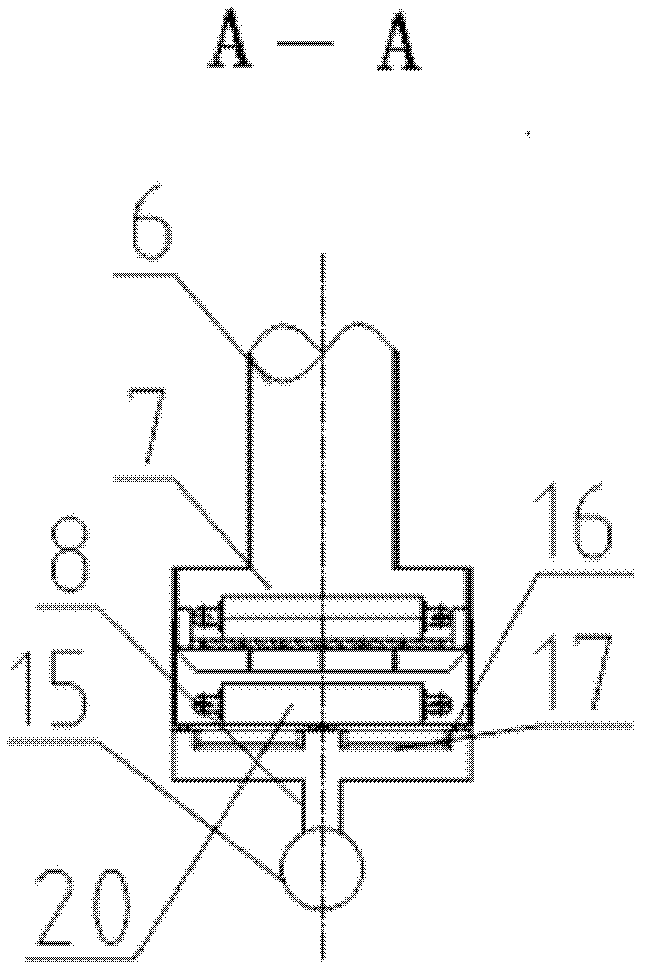

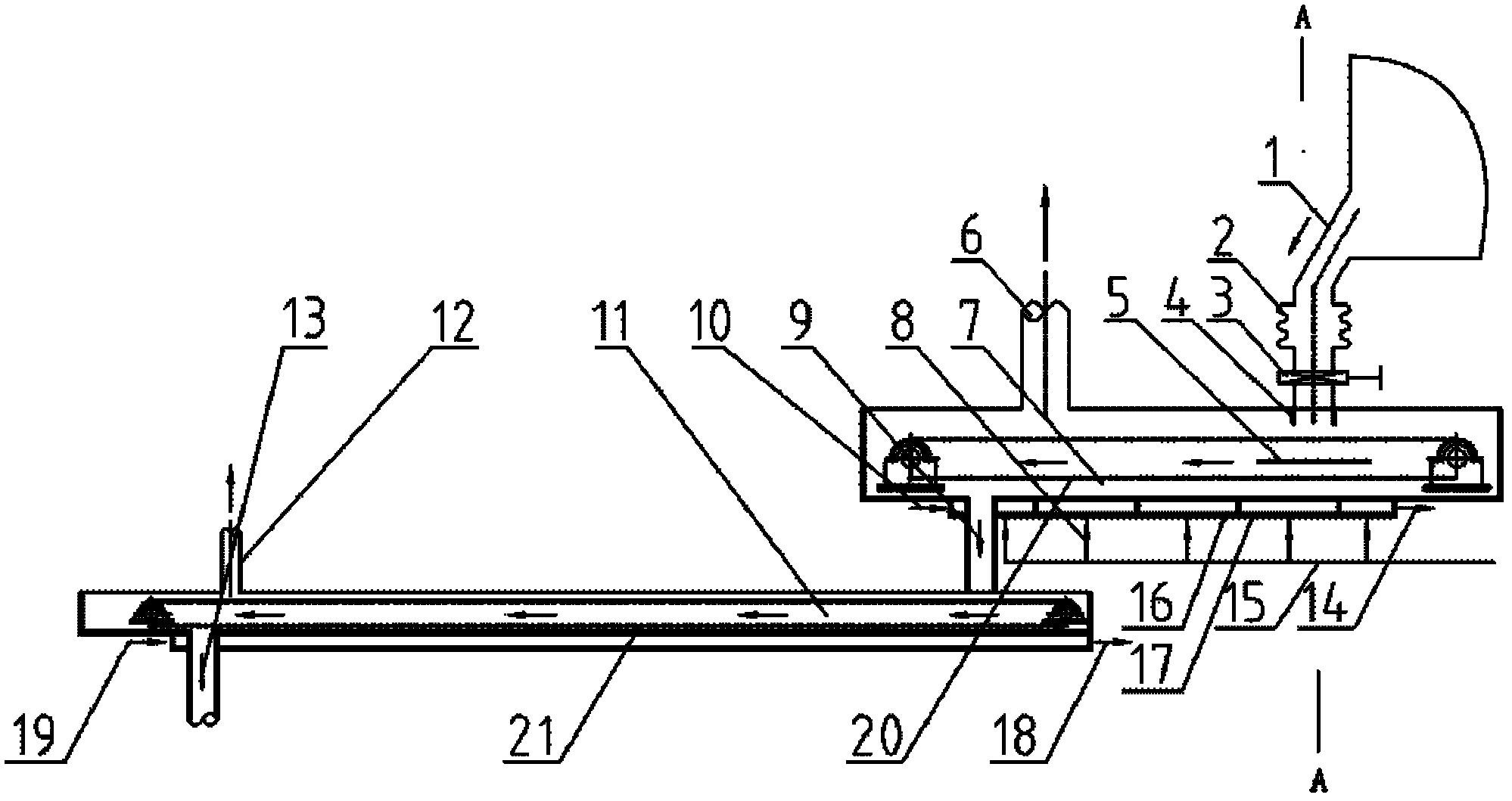

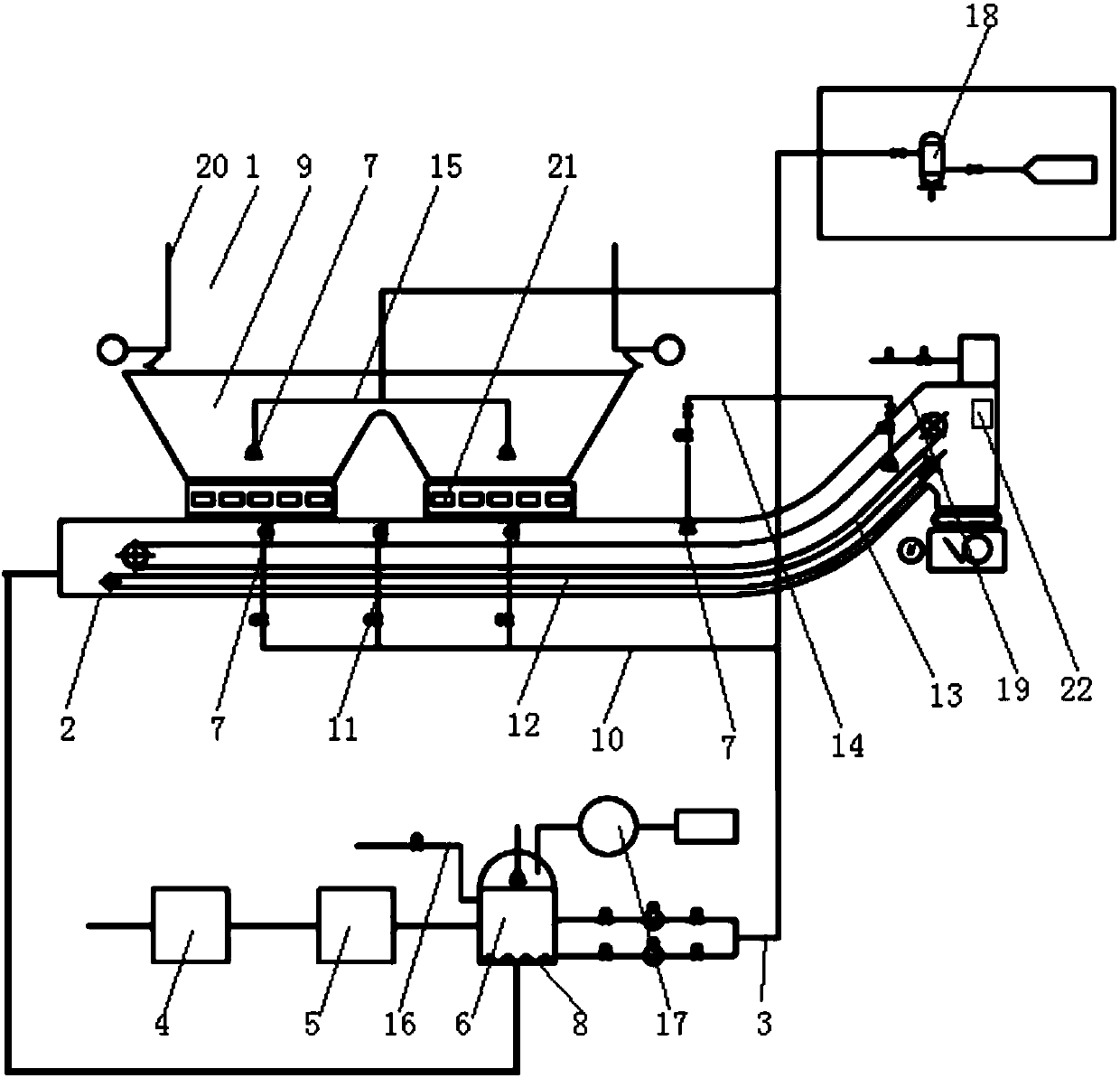

A two-stage air-water combined cooling scraper type cold slag conveyor

ActiveCN102287814AImprove heat transfer effectImprove cooling effectFluidized bed combustionApparatus for fluidised bed combustionSlagCooling effect

The invention relates to a two-stage wind-water joint cooling scraper-type cold slag conveyer which comprises a primary slag cooler; an inlet of the primary slag cooler is communicated with an outlet of a circulating fluidized bed boiler slag discharge pipe; a primary slag cooler scraper is arranged at the middle lower part in the primary slag cooler; the cold slag conveyer also comprises a secondary slag cooler; the inlet of the secondary slag cooler is communicated with the outlet of the primary slag cooler; a secondary slag cooler scraper is arranged at the middle lower part in the secondary slag cooler, a cooling water heating surface is arranged below the secondary slag cooler, and a secondary slag cooler discharge pipe is arranged below the rear part of the secondary slag cooler; bottom flag enters a wind-water joint cooling primary slag cooler; when being cooled, the bottom slag is conveyed by the primary slag cooler scraper; hot air after heat exchange returns to a hearth through an air return pipe; the primarily cooled bottom slag enters the secondary slag cooler; a cooling water jacket further cools the bottom slag and sends the bottom slag to follow-up slag conveying equipment; and the cold slag conveyer has a good slag cooling effect, is not restricted by the grain size of the bottom slag, integrates slag cooling and slag conveying, so that the system is simpler and more reliable.

Owner:HUANENG CLEAN ENERGY RES INST

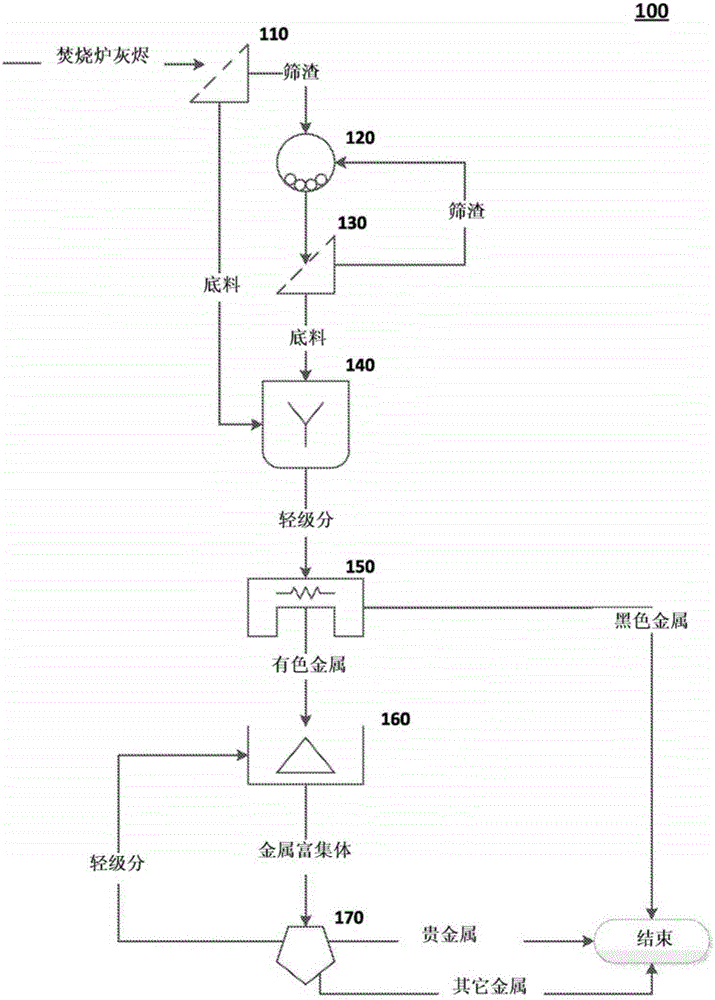

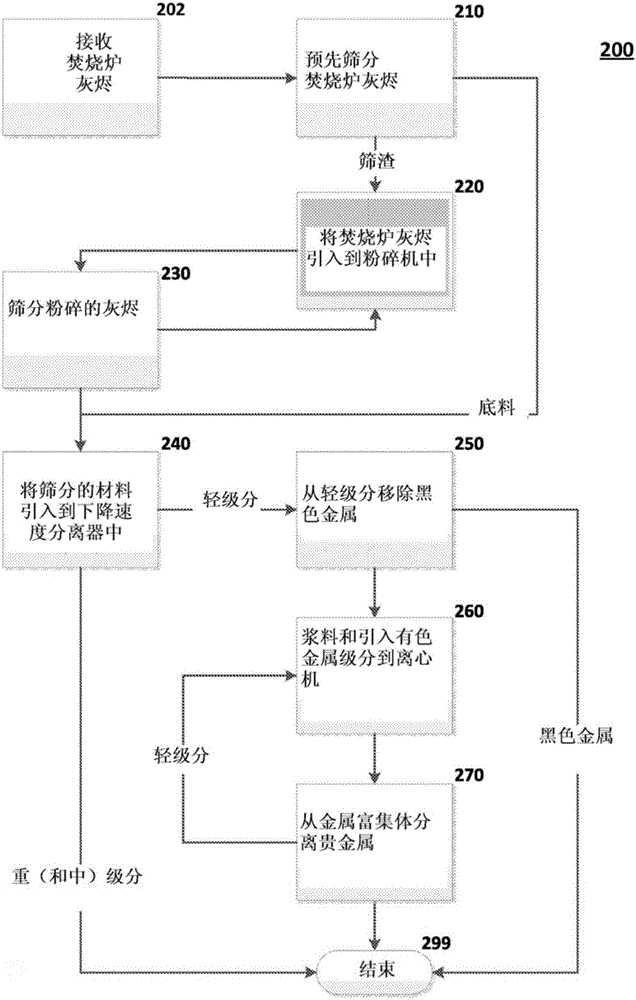

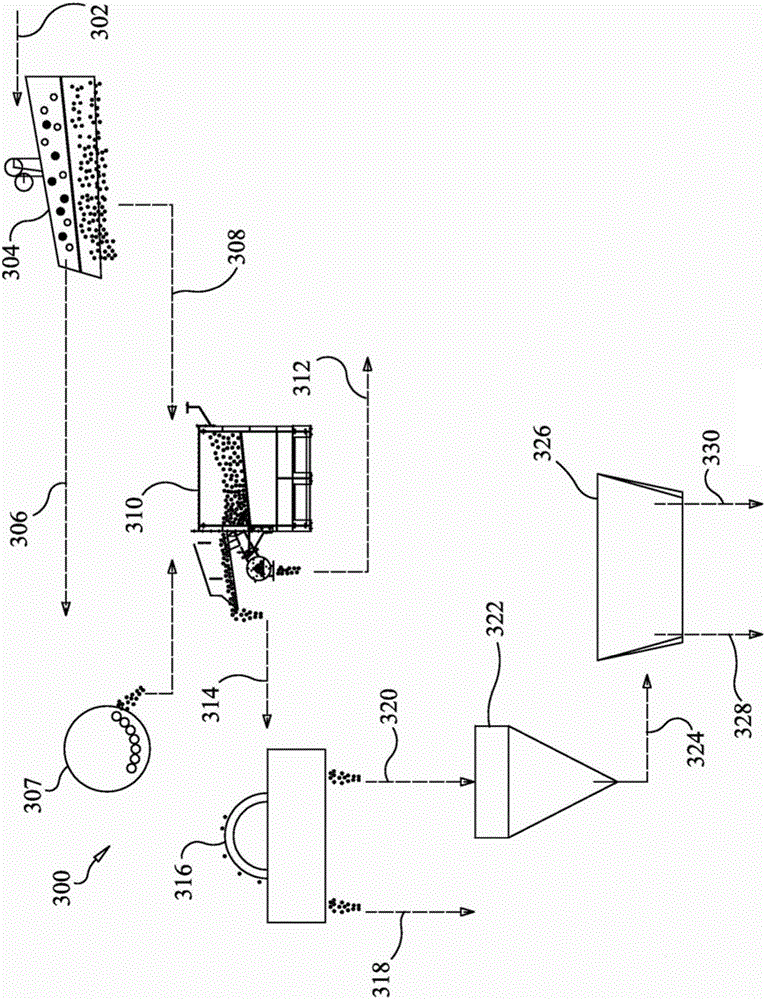

System and method for recovering metals from a waste stream

Devices, systems, and methods for recovering metal constituents from a waste stream containing metals (e.g., incinerator ash) are described. The waste stream may include incinerator bottom ash, fly ash, or a combination thereof. A falling velocity separator is employed in combination with a centrifuge to separate and collect metals from the waste stream. The falling velocity separator uses a liquid to separate particles within incinerator ash according to the particles settling velocities. The centrifuge further separates particles from the incinerator ash according to density of the particles.

Owner:TAV HLDG +1

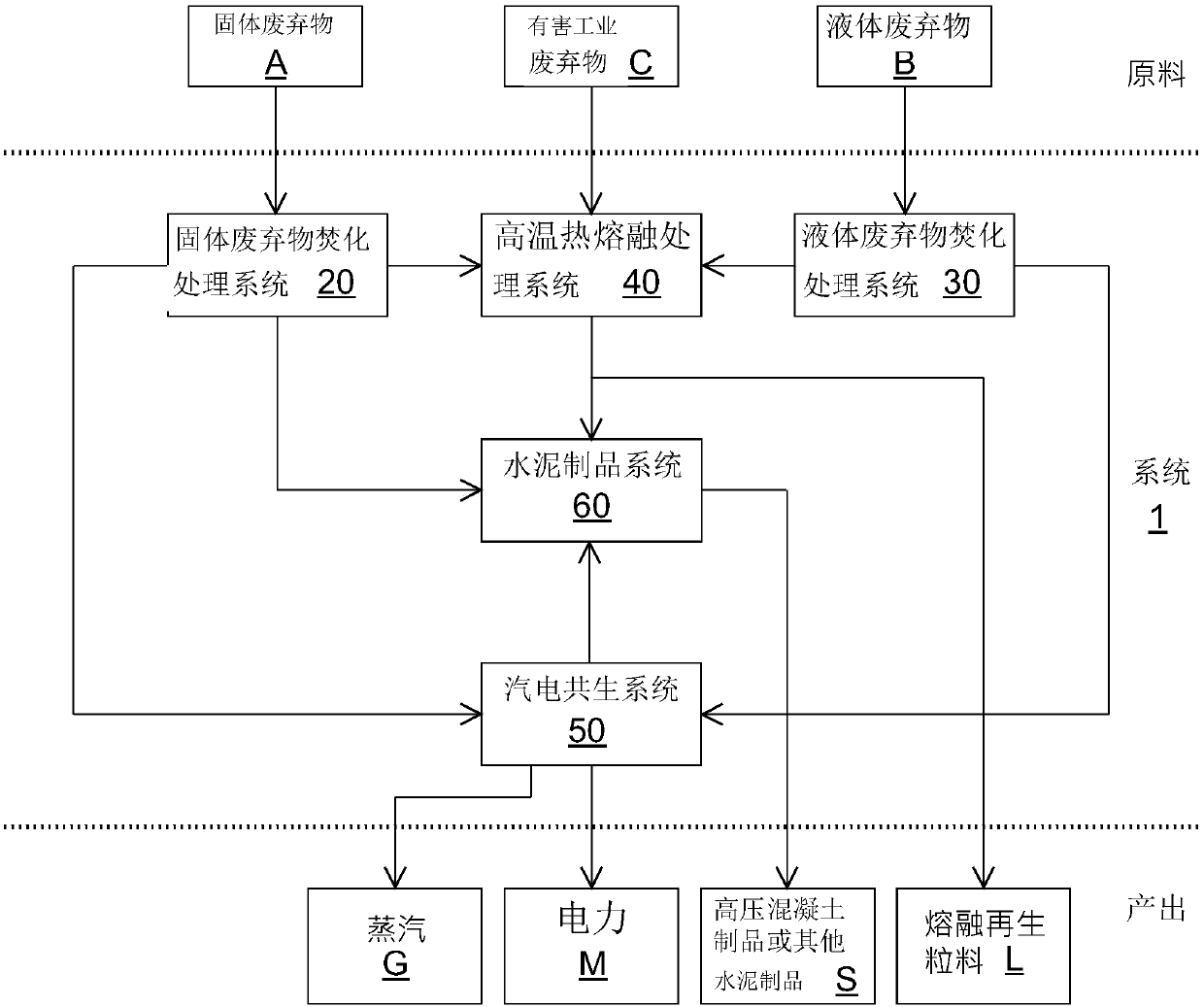

Waste treatment and recycle system

The invention discloses a waste treatment and recycle system, which is characterized in that solid wastes and liquid wastes are treated through a solid and liquid waste incineration treatment system;harmful collected dust and bottom slags produced by incineration are treated through a high-temperature hot melting treatment system so as to produce melting-regenerated aggregates; harmless collecteddust and bottom slags produced by incineration and the melting-regenerated aggregates are processed through a cement product system so as to produce a high-pressure concrete product or other cement products; and waste heat produced by the waste incineration treatment system can be connected to a cogeneration System so as to produce steam and electric power, so that the enterprise waste treatmentproblem is solved, meanwhile, the steam, the electric power, the melting-regenerated aggregates, and the high-pressure concrete product or other cement products are produced, and the effect on waste resource recovery is further achieved.

Owner:TAIWAN ENVIRONMENTAL SUSTAINABLE GROWTH CO LTD

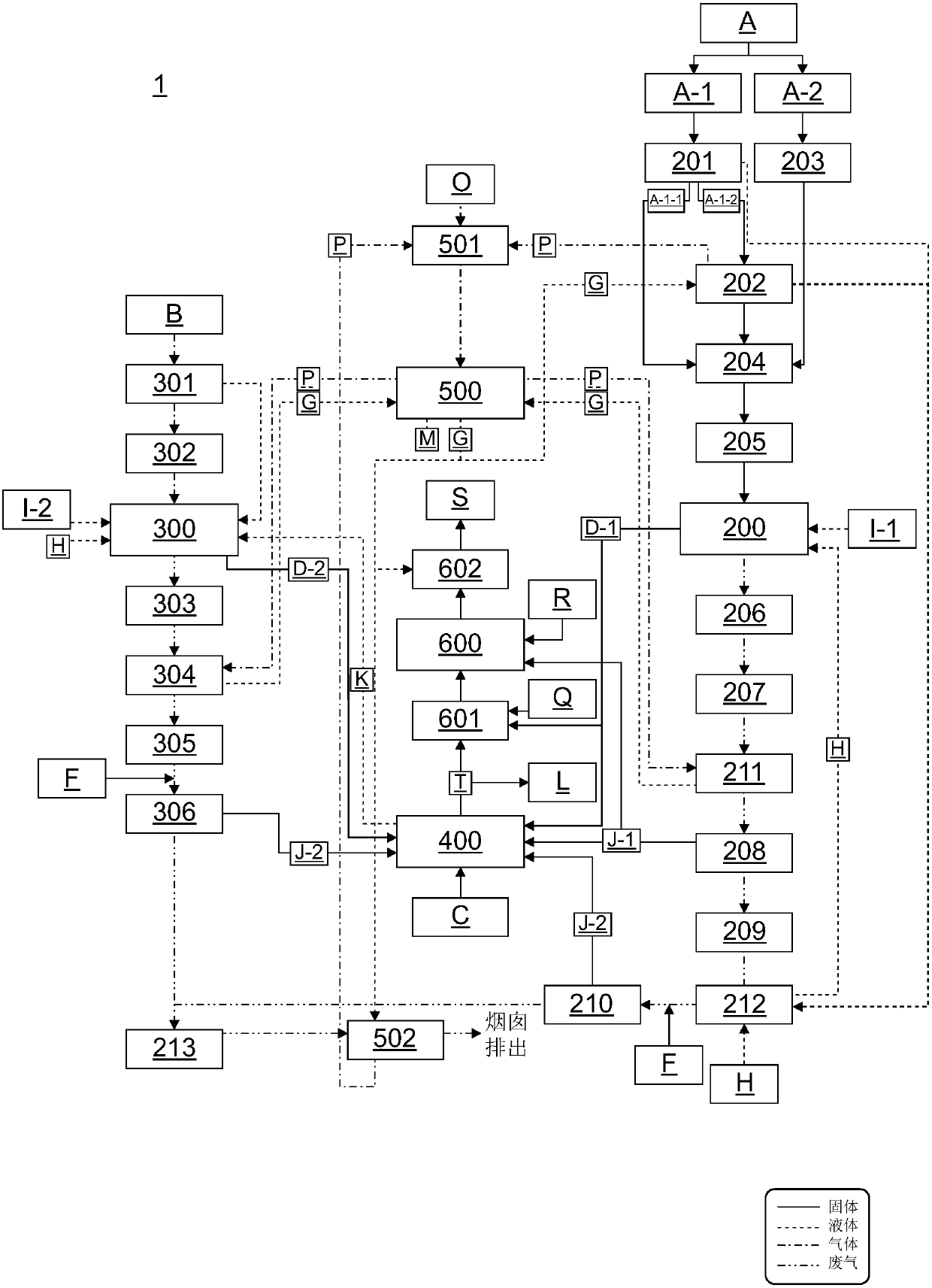

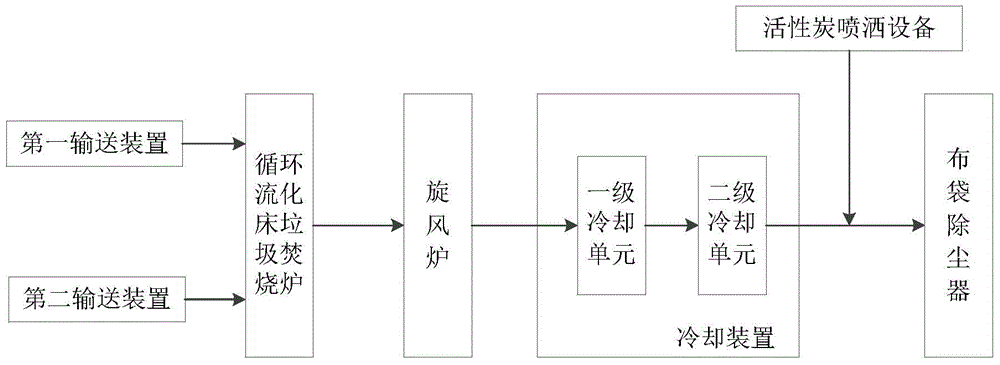

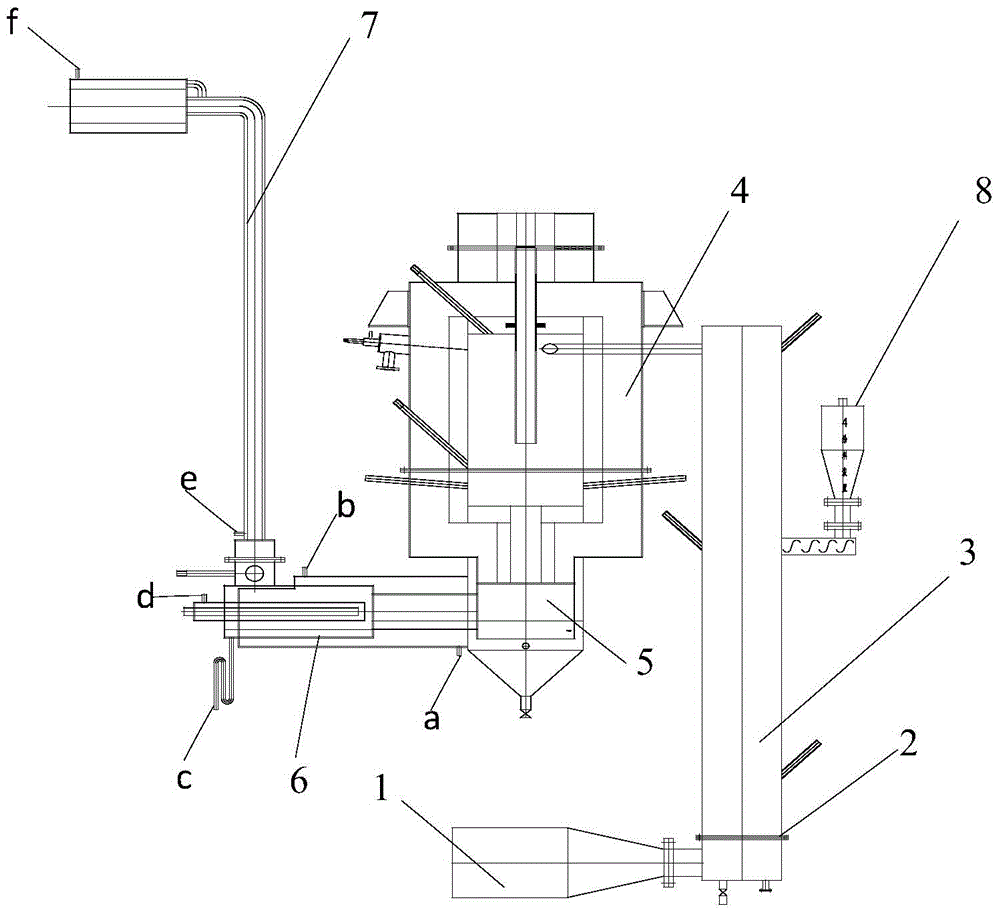

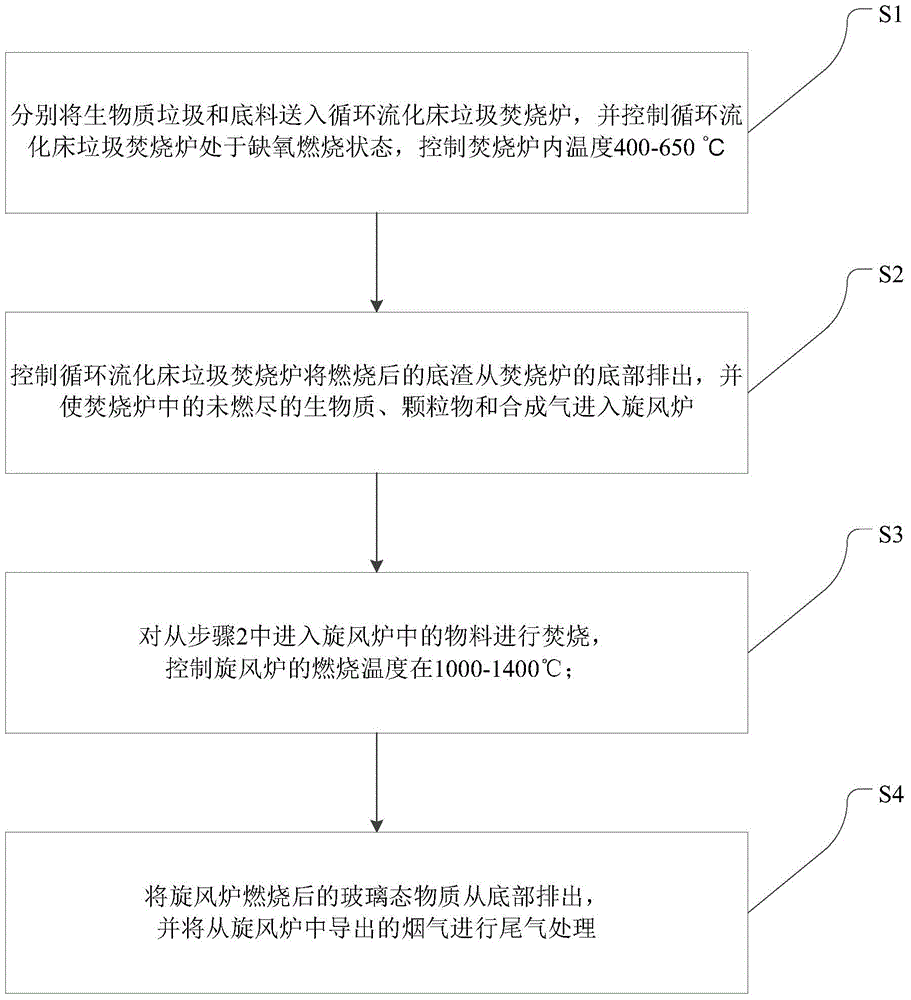

Biomass garbage combustion system and method

InactiveCN104949131ASolve slaggingSolve dust accumulationEmission preventionIncinerator apparatusCombustion systemHigh probability

The invention provides a biomass garbage combustion system and method. The garbage combustion system comprises a first conveying device, a second conveying device, a circulating fluidized bed garbage incinerator and a cyclone furnace, wherein the first conveying device and the second conveying device are communicated with a feeding port of the circulating fluidized bed garbage incinerator respectively; the circulating fluidized bed garbage incinerator is used for combusting biomass garbage primarily and is provided with a bottom slag discharging port and a smoke outlet, the bottom slag discharging port is used for discharging bottom slag after combustion in the circulating fluidized bed garbage incinerator, and the smoke outlet is communicated with the cyclone furnace and used for guiding unburnt biomass and fly ash in the circulating fluidized bed garbage incinerator into the cyclone furnace for combustion; the cyclone furnace is used for combusting materials entering the cyclone furnace secondarily, so that the biomass and the fly ash are molten into glass materials and discharged from the bottom, and produced smoke is guided out for follow-up treatment. The biomass garbage combustion system and method can effectively solve the problems of high probability of coking and ash accumulation, lower incineration temperature and the like caused by high content of alkali metal in the biomass.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

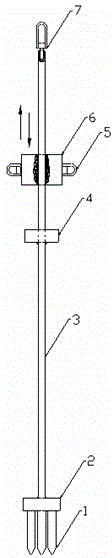

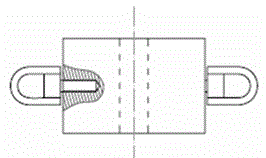

Clearing device and method used for aluminum-zinc pot molten pool bottom slag

The invention discloses a clearing device and a method used for aluminum-zinc pot molten pool bottom slag. The clearing device comprises puncher pins, a connecting base, a supporting bar, a bearing base, and an impact body. The method comprises following steps: determination of original thickness distribution of aluminum-zinc pot molten pool bottom slag, pre-clearing and slag removing of aluminum-zinc pot molten pool bottom slag, and smashing and slag removing of aluminum-zinc pot molten pool bottom slag. The clearing device and the method are capable of completing bottom slag removing in a short time based on bottom slag height distribution, and controlling molten pool bottom slag height in a certain range.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

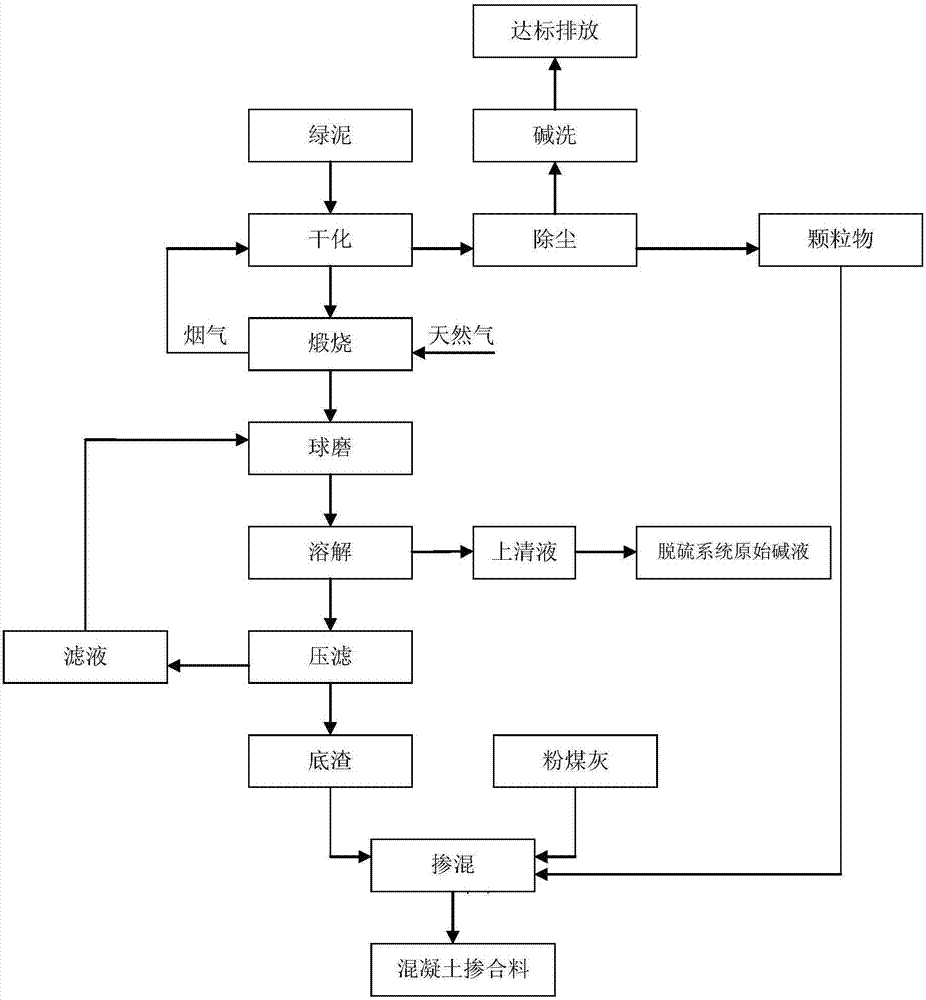

Method for preparation of concrete admixture from papermaking green mud alkali recovery bottom slag

The invention discloses a method for preparation of a concrete admixture from papermaking green mud alkali recovery bottom slag, green mud ash powder is obtained by drying, calcining and ball milling of papermaking green mud, supernatant and bottom slag can be obtained by mixing, dissolving and standing of the green mud ash powder, and the bottom slag is filtered by pressing and mixed with fly ash to obtain the concrete admixture. On the one hand, papermaking green mud burying is avoided, on the other hand, a large amount of waste residue generated after green mud alkali recovery is effectively utilized; meanwhile, the supernatant of the green mud ash solution can be used in a coal fired boiler desulfurization system of a paper making plant.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

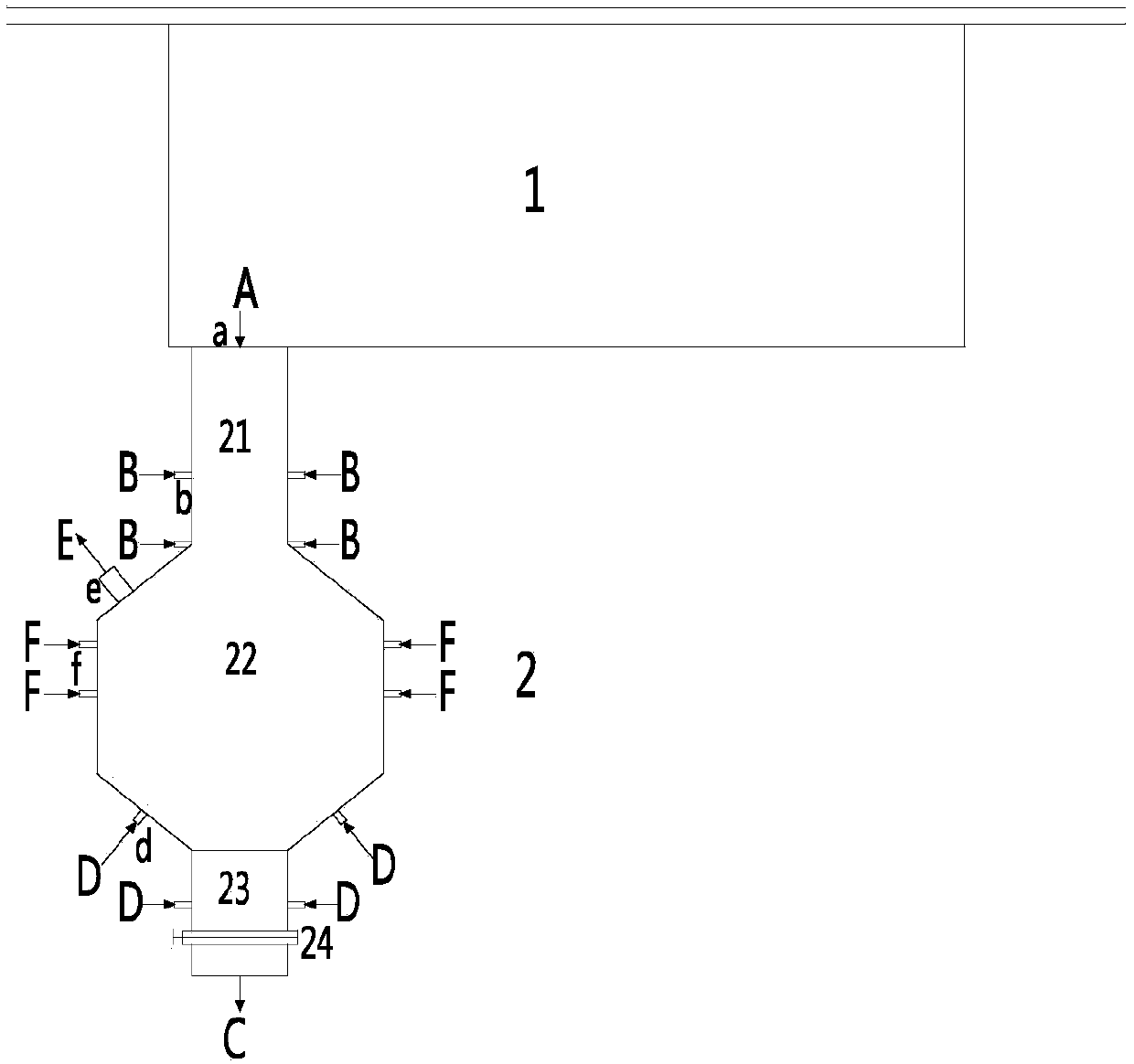

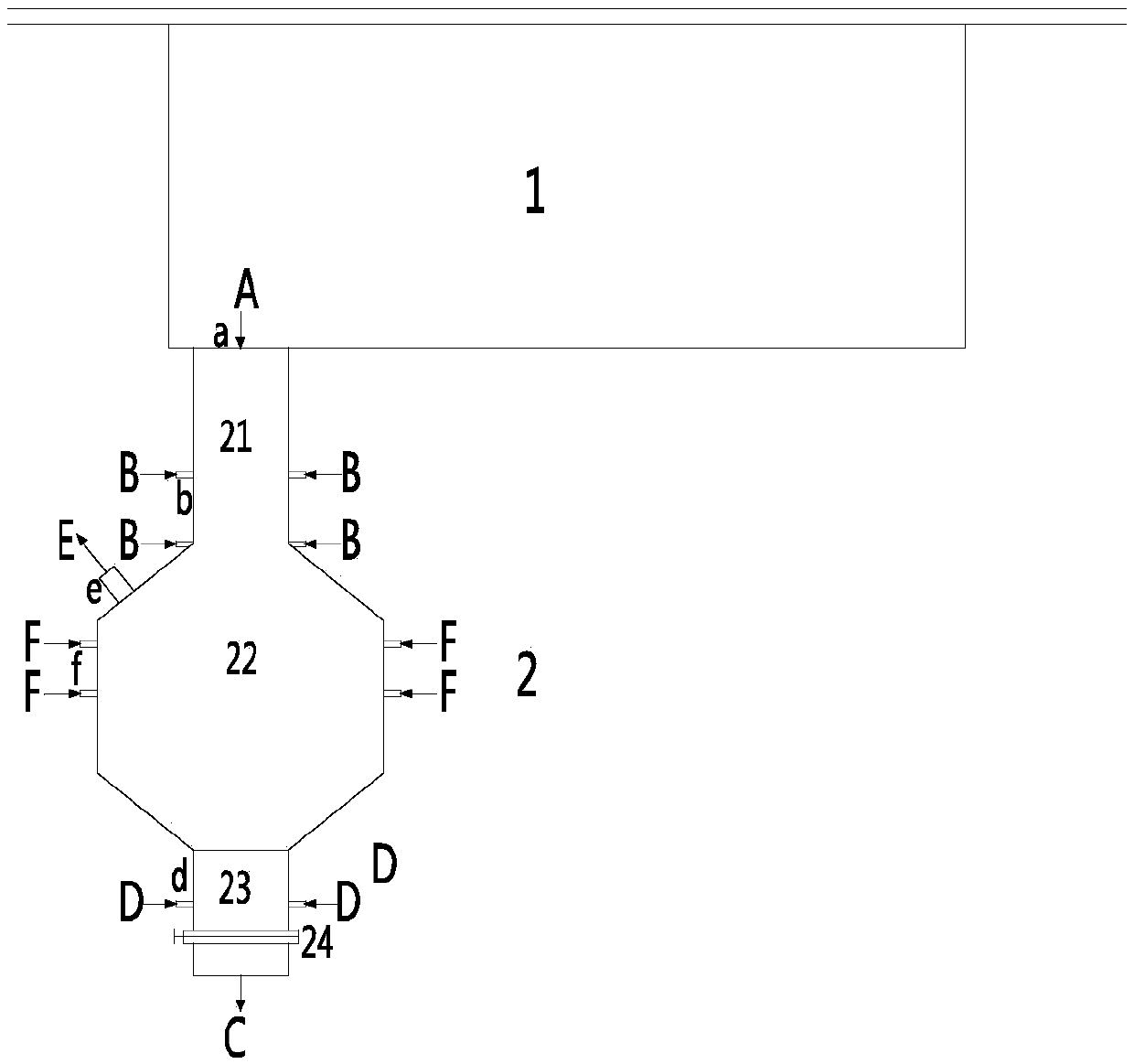

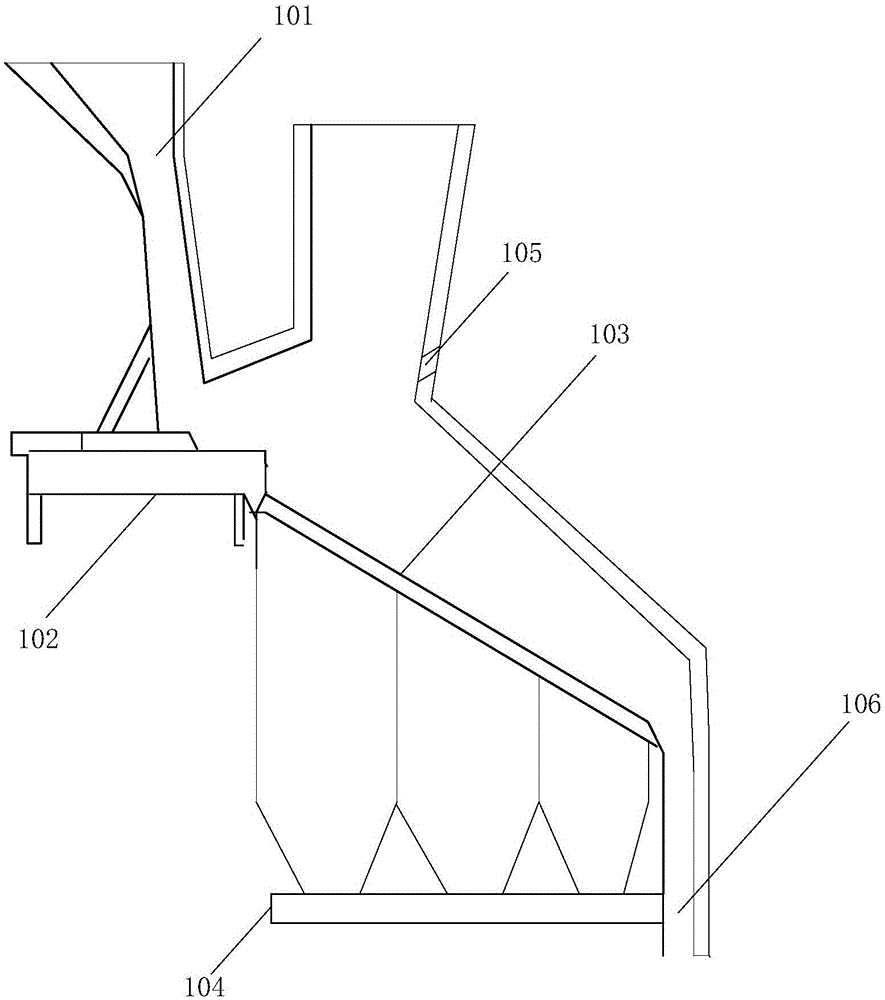

Slagging device and method for fluidized bed gasification furnace

PendingCN110387268APrevent carry-onAvoid enteringChemical industryGasification processes detailsFluidized bed gasifierSlag

The invention provides a slagging device (2) for a fluidized bed gasification furnace, and further provides a slagging method for the fluidized bed gasification furnace. The slagging device (2) is provided with a bottom slag inlet (a) and a bottom slag outlet, and the slagging device (2) is configured to gasify and cool bottom slag (A). According to the slagging device and method for the fluidizedbed gasification furnace, smooth slagging of the fluidized bed gasification furnace can be ensured, potential safety hazards are reduced, energy conservation and consumption reduction are achieved, the carbon content of the bottom slag is reduced, and cold gas efficiency is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

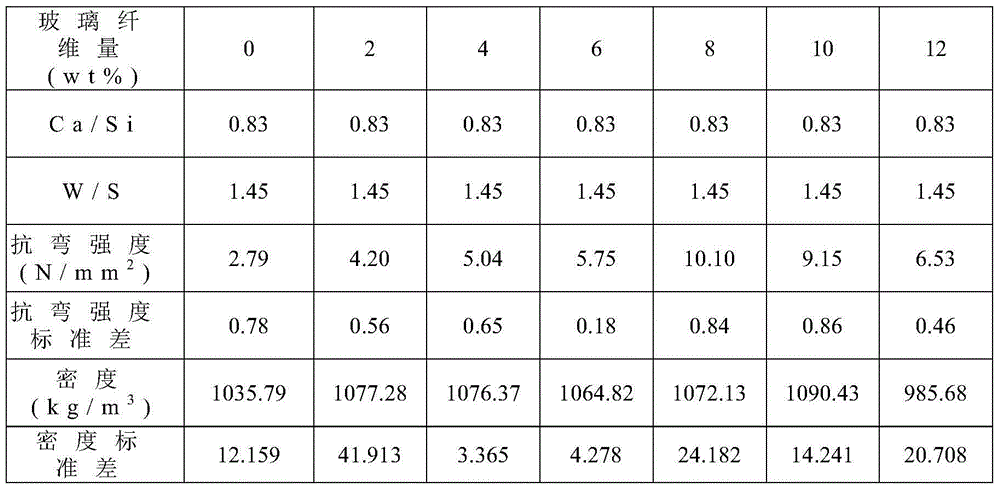

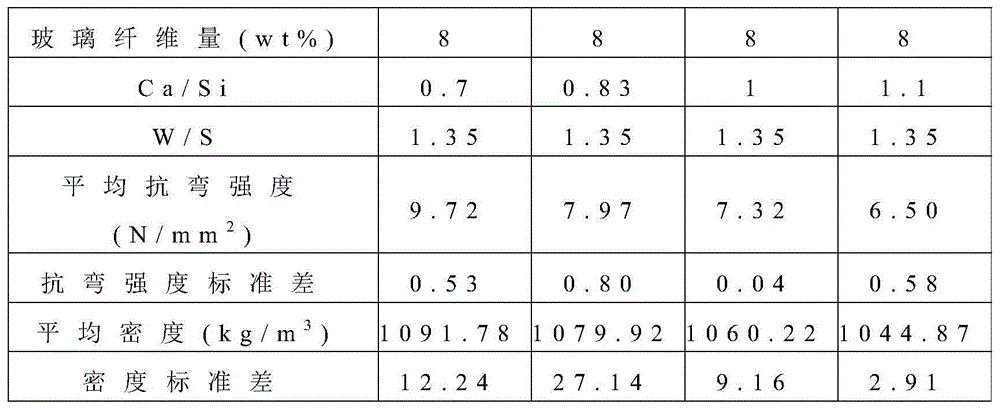

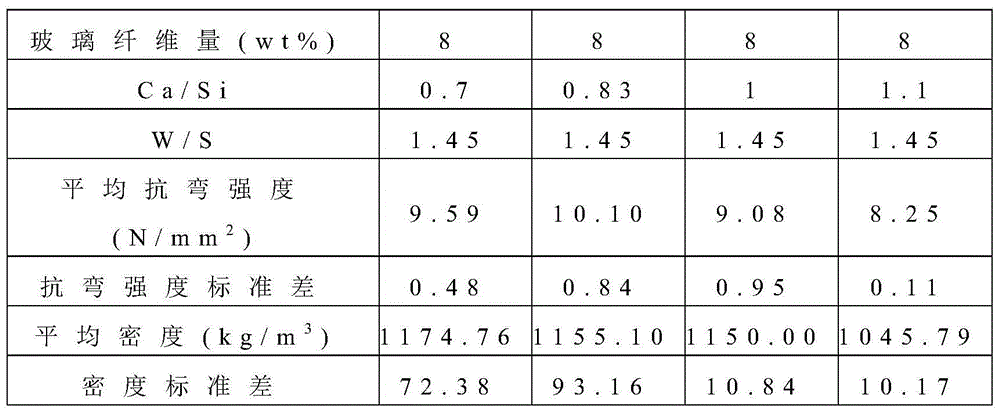

Method for manufacturing regenerated construction material by means of fine aggregate

A method for manufacturing a regenerated construction material by means of fine aggregate comprises the following steps of performing slag collection on an incinerator, performing wet-type screening, magnetic selection, eddy current sorting and sand separator, and collecting fine aggregate of which the diameters of particles of the slag are smaller than 1mm; performing tempering on the fine aggregate, glass fibers and calcium / silicon additive, wherein the weight percent of the fine aggregate is 10-40%, the weight percent of glass fiber is 2-15% and the weight percent of the calcium / silicon additive is 50-80%; mixing the tempered fine aggregate with water for forming a mixture, and controlling ratio between water and solid within 1.35-1.55; and performing pressurizing on the mixture for forming a board, and performing high-pressure steam curing on the board. According to the method of the invention, the fine aggregate which is originally discarded after slag treatment is sufficiently utilized, and the regenerated construction material which accords with a standard is formed after tempering.

Owner:YING CHENG ENVIRONMENTAL TECH

Circulating fluidized bed boiler bottom slag waste heat recovery device

ActiveCN108800118ALow flow resistanceImprove heat transfer coefficientFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

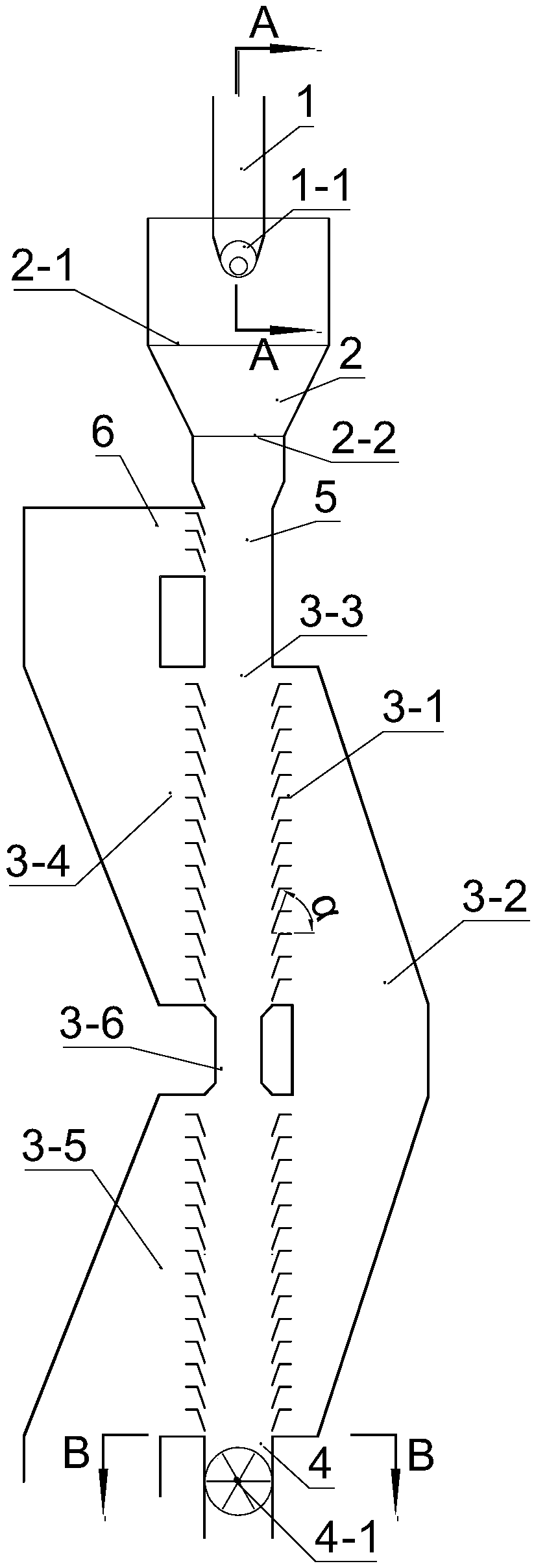

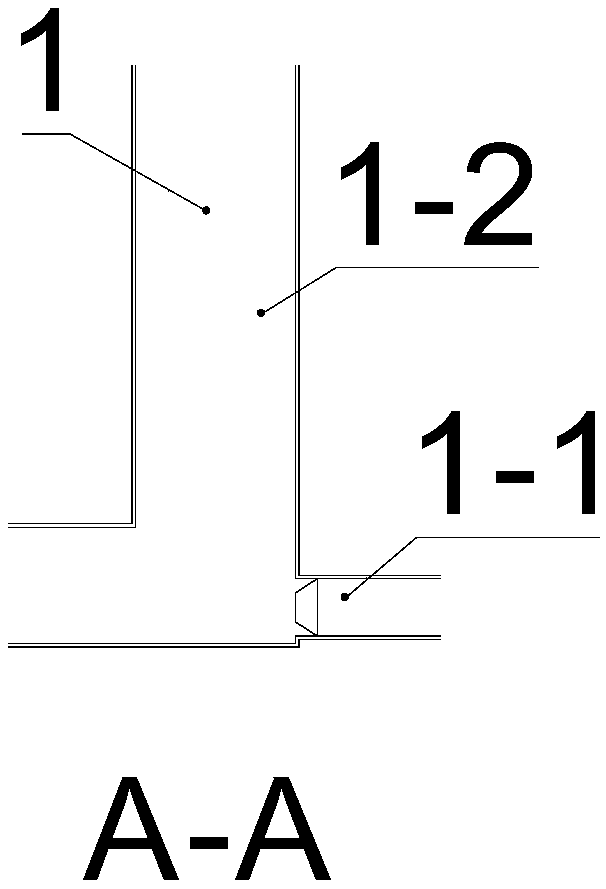

A circulating fluidized bed boiler bottom slag waste heat recovery device comprises an L-shaped ash control valve (1), a sorting section pipeline (2), a cross-flow moving bed heat exchanger (3) and aslag discharging device (4), wherein the sorting section pipeline (2) is a big-end-up opening contraction pipeline, the upper portion of the sorting section pipeline (2) is provided with a sorting section inlet (2-1), and the lower portion of the sorting section pipeline (2) is provided with a sorting section outlet (2-2); the cross-flow moving bed heat exchanger (3) is composed of a separation flow guide plate (3-1), a cooling flue (3-2) and a bottom slag channel (3-3), the upper portion of a cross-flow moving bed is connected with the sorting section pipeline outlet through a slag feeding pipe (5), and the width of the bottom slag channel (3-3) of the cross-flow moving bed is 200-2000 mm; the bottom slag flowing speed is controlled by the slag discharging device (4), meanwhile, after being pressurized by a recycling fan, flue gas transversely passes through the bottom slag channel in an S shape through the separation flow guide plate (3-1), and the included angle (alpha) between theinclined section of the separation flow guide plate (3-1) and the horizontal direction is 20-80 degrees. According to the circulating fluidized bed boiler bottom slag waste heat recovery device, the recirculating flue gas is adopted as a heat exchange medium, the vast majority of heat of the bottom slag is recovered back into a boiler, continuous stable operation of the waste heat recovery deviceis ensured, boiler ash slag physical heat losses are decreased, and the boiler efficiency is improved.

Owner:CHONGQING UNIV

Boiler ash and slag removing system

A boiler ash and slag removing system comprises a cooling mechanism, a conveying mechanism and a treatment mechanism. The cooling mechanism comprises a slag cooler set. The slag cooler set comprises a first slag cooler and a second slag cooler. The treatment mechanism comprises a dust collector and a slag bin. The cooling mechanism and the treatment mechanism are connected through the conveying mechanism. A chain conveyor is arranged at the bottom end of the slag cooler set. The slag outlet end of the first slag cooler and the slag outlet end of the second slag cooler are located at the upper end of the chain conveyor. Waste heat recycled by the slag coolers can be utilized, and waste is reduced. Through a sewage pump, fine dust in bottom slag conveyed on the chain conveyor can be removed, and the efficiency of the ash and slag removing system is improved. The slag bin can be connected with a wet ash and slag removing device or a dry coal ash removing device, the ash and slag removing efficiency is improved, the ash and slag removing manner is added, and the using efficiency of the system is improved.

Owner:JIASHAN YONGJIN METAL PROD

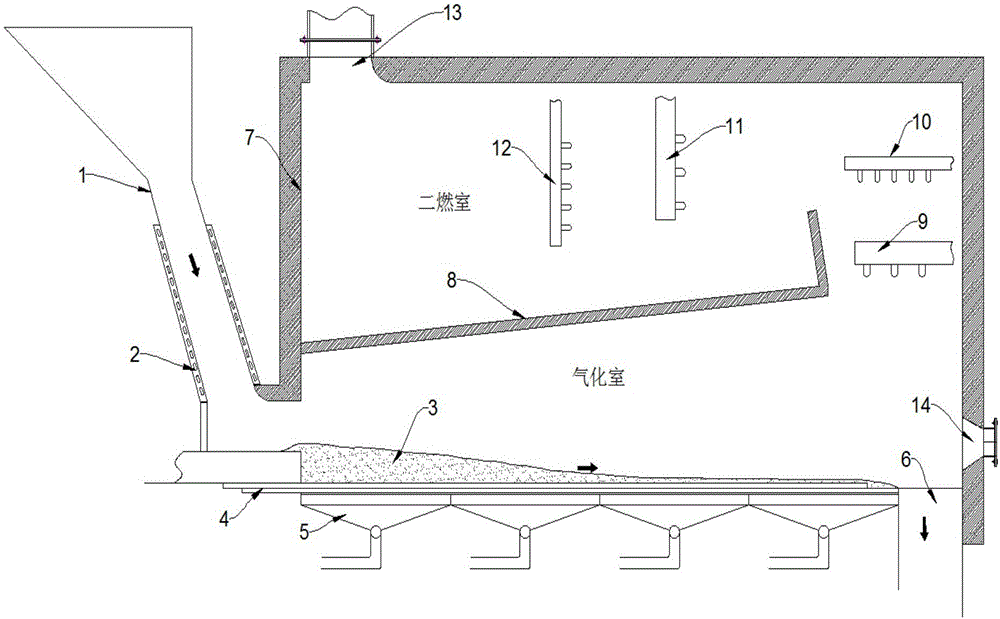

Gasifying incinerator applicable to household garbage with high heat value

ActiveCN106352343ASolve various disadvantages caused by incinerationEmission reductionDamper arrangementBlast-producing apparatusFlue gasCombustible gas

The invention provides a gasifying incinerator applicable to household garbage with high heat value. The gasifying incinerator is divided into a gasifying chamber and a secondary combusting chamber, wherein a horizontal grate is arranged at the bottom of the gasifying chamber, and a primary air bin is arranged at the bottom of the grate; the secondary combusting chamber is formed above the gasifying chamber, and secondary air and circulatory flue gas enter a hearth from the side surface of the secondary combusting chamber respectively to promote burn-out of combustible gas in the secondary combusting chamber and reduce the overall temperature of the secondary combusting chamber. The gasifying incinerator can effectively overcome various defects caused by a traditional household garbage incineration way and has the advantages that bottom ash has low carbon content, NOx emission is ultralow, concentration of fly ash is ultralow and the like, a flue gas treatment system is simplified, and investment cost and operation cost are reduced greatly.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD

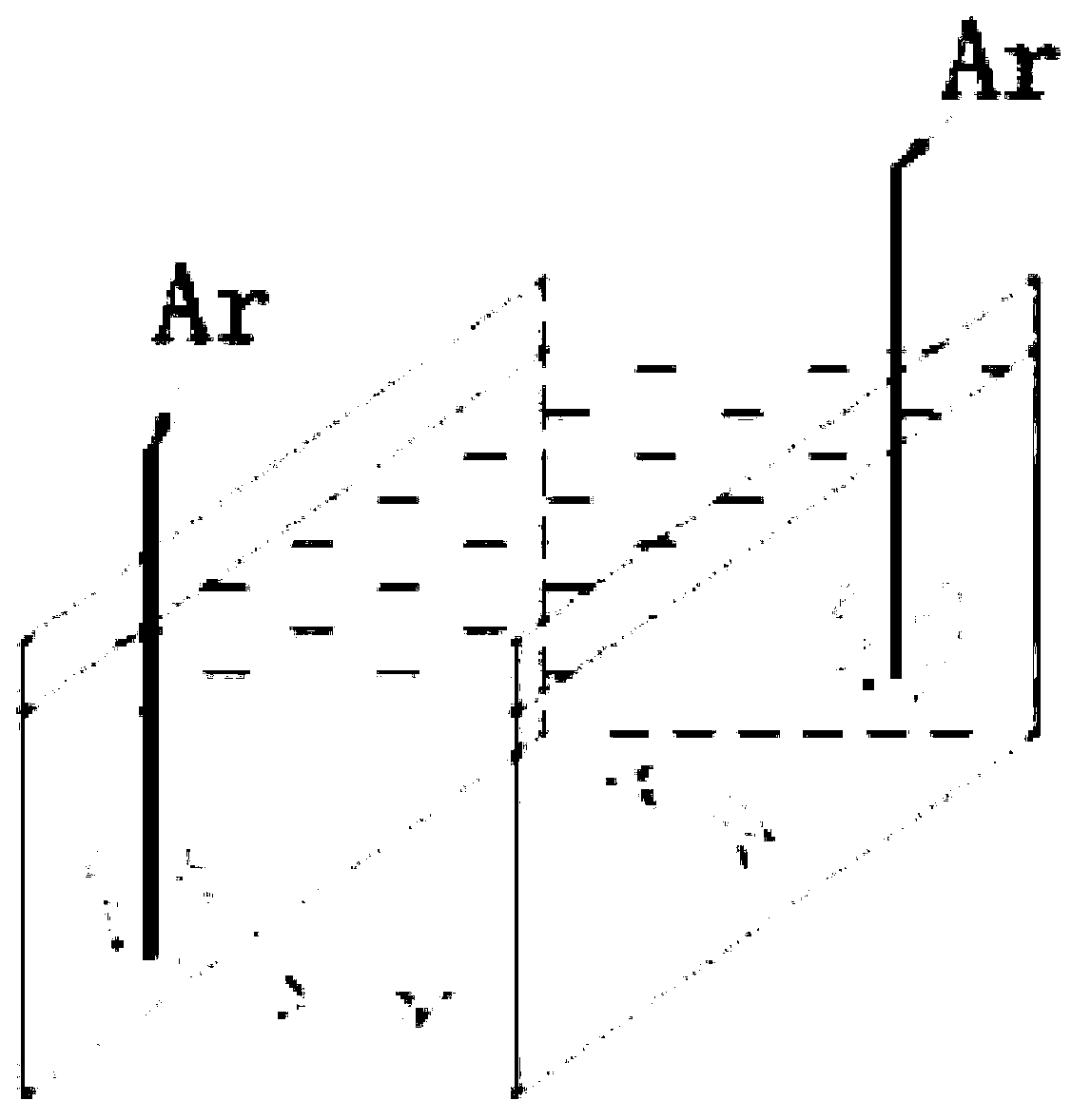

Method for removing bottom slag and dross in zinc pot

InactiveCN110592514AReduce aluminum contentPromote collision growthHot-dipping/immersion processesSolubilitySlag

The invention relates to a method for removing bottom slag and dross in a zinc pot. According to the method, strip steel soaked in zinc liquid is extracted, and the dissolution of Fe in the strip steel in the zinc liquid is reduced; and the aluminum content is increased to 0.32-0.40%, the temperature of the zinc liquid is decreased to 450+ / -2 DEG C, the solubility of iron in the zinc liquid is reduced, blowing is carried out on the bottom of the zinc pot by using argon, the zinc liquid is stirred and circulated, the bottom slag fully reacts with the dross to form surface slag, then the floating surface slag is timely removed by using a slag fishing ladle, at the moment, the Fe content in the zinc liquid can be practically controlled to be very low and is generally 0.004%-0.008%, the usageamount of transitional materials in the production process is decreased, the production period of a panel is prolonged, the bottom slag and the dross in the zinc pot can be removed, the iron content of the zinc liquid is decreased, and the requirements of high strength and high surface in industries such as automobiles are met.

Owner:SD STEEL RIZHAO CO LTD

Power plant desulfurization wastewater treatment system

InactiveCN108033516AAchieving zero emissionsImprove use valueWater/sewage treatment bu osmosis/dialysisWaste water treatment from gaseous effluentsVibrating membraneFiltration membrane

The invention discloses a power plant desulfurization wastewater treatment system, and belongs to the field of thermal power generation. The power plant desulfurization wastewater treatment system comprises a dry-type slag extractor and a spray pipe, a water inlet end of the spray pipe is connected with a concentration device and a water storage device, the concentration device comprises a tubularmicro-filtration membrane and a vibrating membrane, a plurality of nozzles are arranged on the spray pipe and positioned above the dry-type slag extractor, the water storage device is provided with aheating device, a temperature sensor and / or a humidity sensor is arranged on the head of the dry-type slag extractor, and the concentration degree of the concentration device for desulfurization waste water is adjusted according to the temperature and / or the humidity acquired by the temperature sensor and / or the humidity sensor. According to the system, the desulfurization waste water is concentrated and preheated, so that the desulfurization waste water can be completely consumed, zero emission of the desulfurization waste water is achieved, comprehensive utilization values of slag are improved, and the system overcomes the shortcomings that a secondary treatment device is introduced, cost is high, a power plant needs to be reconstructed, and pollution is generated.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com