Method for resource utilization of hazardous waste incineration bottom slag

A technology for incinerating bottom slag and hazardous waste, applied in combustion methods, incinerators, applications, etc., to achieve good economic benefits, relieve storage pressure, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

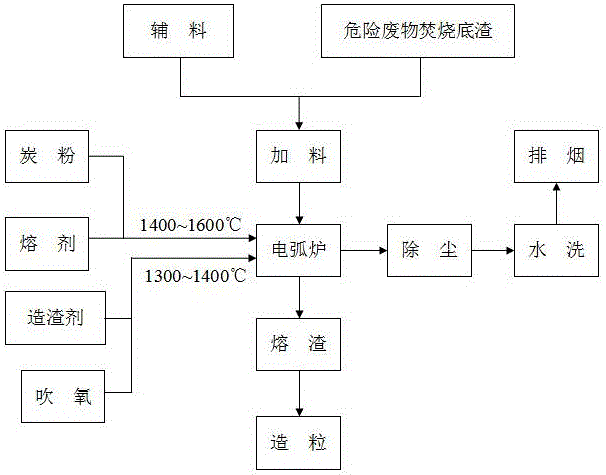

[0028] A method for resource utilization of hazardous waste incineration bottom slag provided in this embodiment, the treatment process is as follows figure 1 shown, including the following steps:

[0029](1) Mix the bottom slag of hazardous waste incineration with clay, fly ash and zeolite to make a mixture; the amount of clay, fly ash and zeolite added is to control the SiO 2 +Al 2 o 3 Quality score 70%;

[0030] (2) Put the above mixed material into the electric arc furnace, and the mixed material is granular or powdery before entering the furnace;

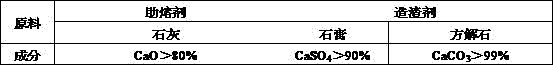

[0031] (3) The electric arc furnace is heated up to 1500°C. During the heating process, charcoal powder is blown into the furnace to maintain a weak reducing atmosphere in the furnace until the mixture in the electric arc furnace is in a state of molten glass; during the melting process, lime is added to help the melting, and the amount of lime added is controlled. The alkalinity of slag is 1.0;

[0032] (4) After all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com