Environment-friendly wall-protecting slurry and preparation method thereof

A wall protection and mud technology, applied in the field of environmental protection wall mud and its preparation, can solve the problems of short wall stabilization time of deep pile foundations, low recycling rate, poor mud homogeneity, etc., and achieve enhanced physical anchoring effect and frictional resistance , Improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

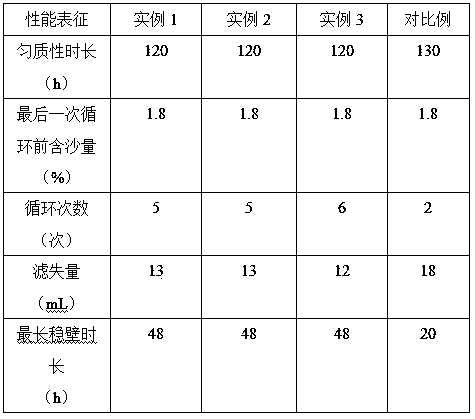

Examples

example 1

[0021] Take municipal solid waste incineration bottom ash and grind it in a grinder for 1 hour, pass through a 100-mesh sieve to obtain refined incineration bottom ash, take 0.2g p-toluenesulfonic acid, 15g ethyl orthosilicate, 5g methyltriethoxysilane , add 400g of absolute ethanol, stir and heat at 300r / min to 40°C, keep warm for 20min, then add 15g of silane coupling agent KH-550, 200g of finely incinerated bottom ash, continue to stir for 1h, stand and filter at 100 Dry at ℃ to constant weight to obtain pretreated incineration bottom ash. Take 400g of sodium bentonite, 100g of magnesium lithium silicate, 200g of pretreated incineration bottom ash, 16g of vegetable gum, 20g of sodium polyacrylate, and 10g of starch, and add them to 40L of deionized water. After mixing and stirring at 3000r / min for 20min, the material is discharged to obtain the mud for environmental protection wall.

example 2

[0023] Take municipal solid waste incineration bottom ash, grind it in a grinder for 1.5 hours, and pass through a 100-mesh sieve to obtain refined incineration bottom ash. Take 0.3g of p-toluenesulfonic acid, 22g of ethyl orthosilicate, 7g of methyl triethoxy Add silane into 600g of absolute ethanol, stir and heat at 350r / min to 45°C, keep it warm for 25min, then add 22g of silane coupling agent KH-550, 250g of finely incinerated bottom ash, continue to stir for 1.5h, let stand and filter Dry at 103°C to constant weight to obtain pretreated incineration bottom ash. Take 450g of sodium bentonite, 125g of magnesium lithium silicate, 250g of pretreated incineration bottom ash, 18g of vegetable gum, 25g of sodium polyacrylate, 13g of starch, and add 45L of deionized In water, mix and stir at 350r / min for 25min and then discharge to obtain the mud for environmental protection wall.

example 3

[0025] Take municipal solid waste incineration bottom ash, grind it in a grinder for 2 hours, and pass through a 100-mesh sieve to obtain refined incineration bottom ash. Take 0.4g of p-toluenesulfonic acid, 30g of ethyl orthosilicate, and 10g of methyltriethoxysilane , add 800g of absolute ethanol, stir and heat at 400r / min to 50°C, keep warm for 30min, then add 30g of silane coupling agent KH-550, 300g of refined incineration bottom ash, continue to stir for 2h, stand and filter at 105 Dry at ℃ to constant weight to obtain pretreated incineration bottom ash. Take 500g of sodium bentonite, 150g of magnesium lithium silicate, 300g of pretreated incineration bottom ash, 20g of vegetable gum, 30g of sodium polyacrylate, and 15g of starch, and add them to 50L of deionized water. After mixing and stirring at 400r / min for 30min, the material is discharged to obtain the mud for environmental protection wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com