Circulating fluidized bed boiler bottom slag cooling system

A circulating fluidized bed and slag cooling technology, which is applied to fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. problems, to achieve the effect of low overall operating power consumption, low operating power consumption, and improved stability

Active Publication Date: 2011-01-19

TAIYUAN BOILER GROUP +1

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the shortcomings of the existing fluidized bed slag cooler, which has high operating power consumption and the drum slag cooler cannot perform selective slag discharge, the purpose of the present invention is to provide a CFB boiler bottom that can perform selective slag discharge and has low operating power consumption. Slag cooling method, thereby reducing the power consumption of the slag cooler and recovering fine particles in the bottom slag

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

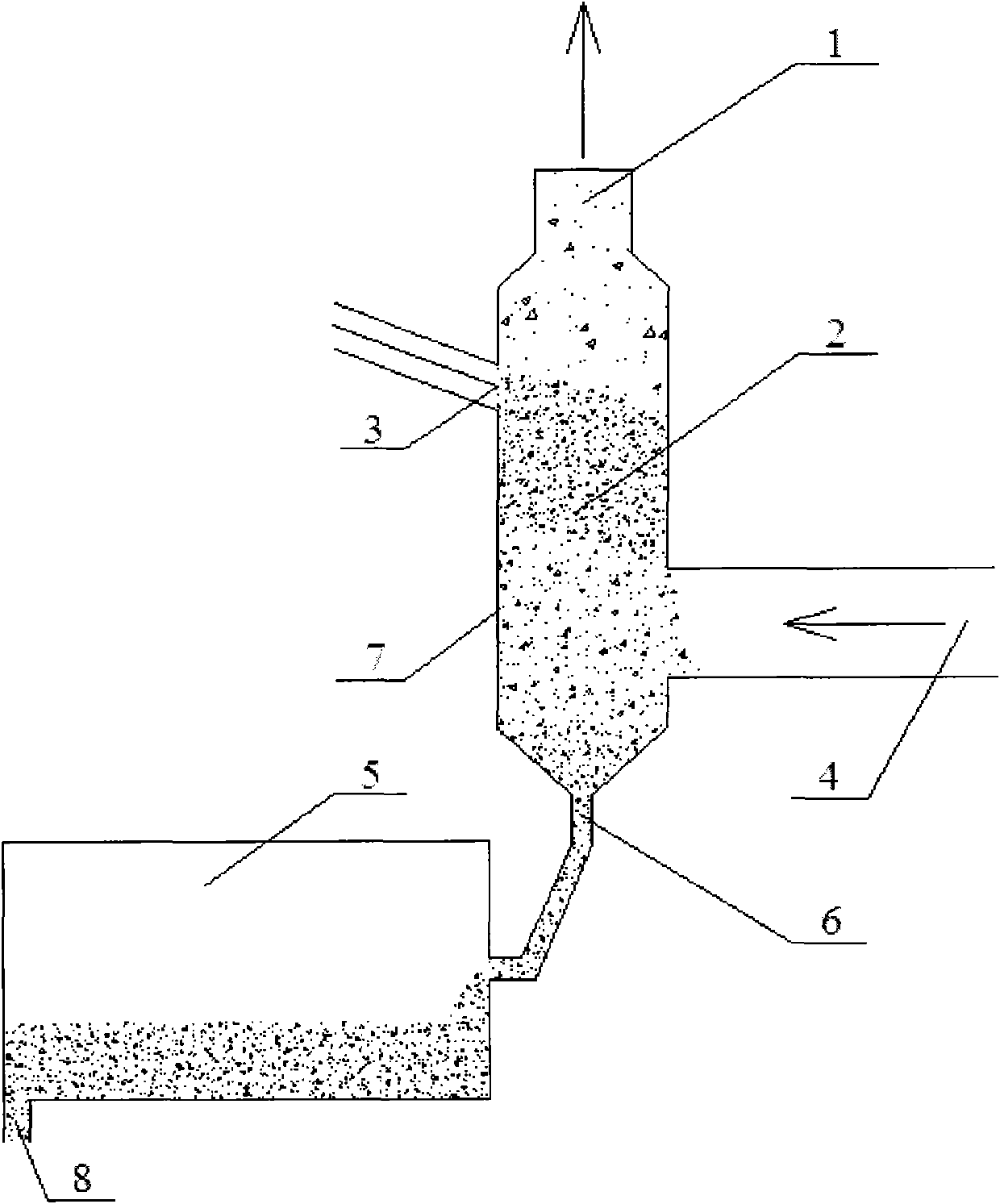

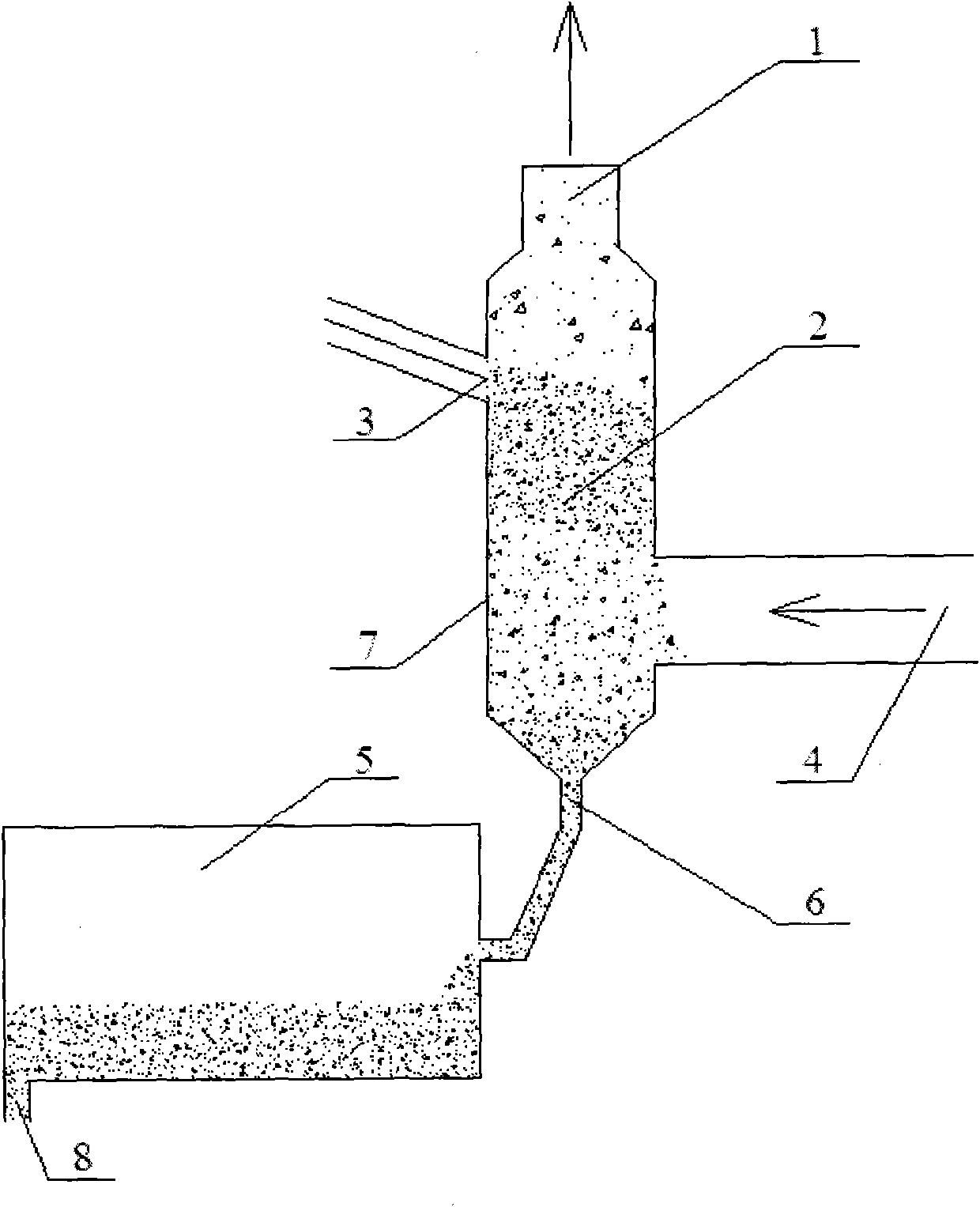

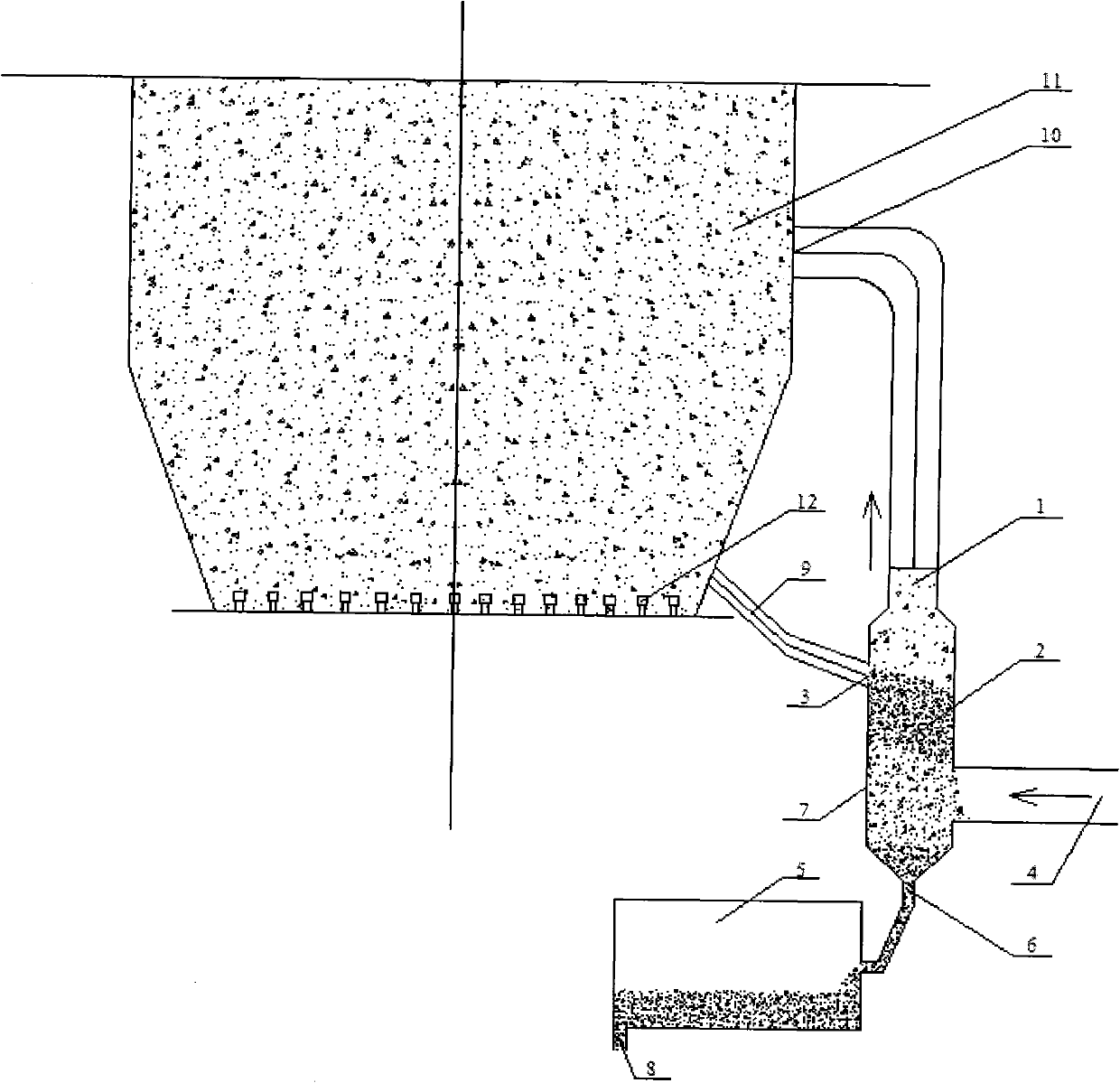

The invention discloses a circulating fluidized bed boiler bottom slag cooling system, and relates to combustion equipment bottom slag cooling technology. The system mainly comprises a slag cooler and a bottom slag thickness separator. The bottom slag thickness separator comprises a barrel, a bottom slag inlet, an air inlet, an air outlet and a bottom slag outlet. The bottom slag inlet is connected with a slag discharge port at the bottom of the circulating fluidized bed boiler through a boiler slag conveying pipe; the bottom slag outlet is connected with the inlet of the slag cooler; and the air inlet is connected with a secondary air pipe of the circulating fluidized bed boiler. Secondary air from an air pre-heater enters the bottom slag thickness separator through the air inlet to exchange heat with bottom slag before entering the hearth of the boiler and takes away fine granule materials in the bottom slag, finally the fine granule materials are returned to the hearth of the boiler through the air outlet to participate in material circulation, and the coarse granular slag falls to the slag cooler on the lower part for further cooling. The system can realize selective slag discharge, and solves the problems of local coking of the fluidized bed slag cooler and the like so as to further improve the running stability of the boiler.

Description

technical field The invention relates to a bottom slag cooling technology of combustion equipment, which belongs to the technical field of combustion equipment. Background technique In a circulating fluidized bed boiler (CFB), the raw coal comes out of the coal mill and enters the furnace with a certain wide sieving particle size distribution for combustion. The fine particles formed by combustion enter the tail flue with the flue gas in the form of fly ash and fly out. Boiler, large particles leave the bed from the bottom of the boiler at high temperature to form bottom slag. Due to the small capacity of the early circulating fluidized bed boilers and less slag discharge, the high-temperature bottom slag was generally discharged directly. However, with the continuous increase of boiler capacity, the discharge of boiler bottom slag is also increasing. Not only is it unfriendly to the environment, but also causes a lot of heat loss. Therefore, for clean production and heat ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23C10/26

Inventor 司小东吕俊复杨海瑞岳光溪

Owner TAIYUAN BOILER GROUP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com