Method for manufacturing regenerated construction material by means of fine aggregate

A technology of fine aggregate and building materials, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

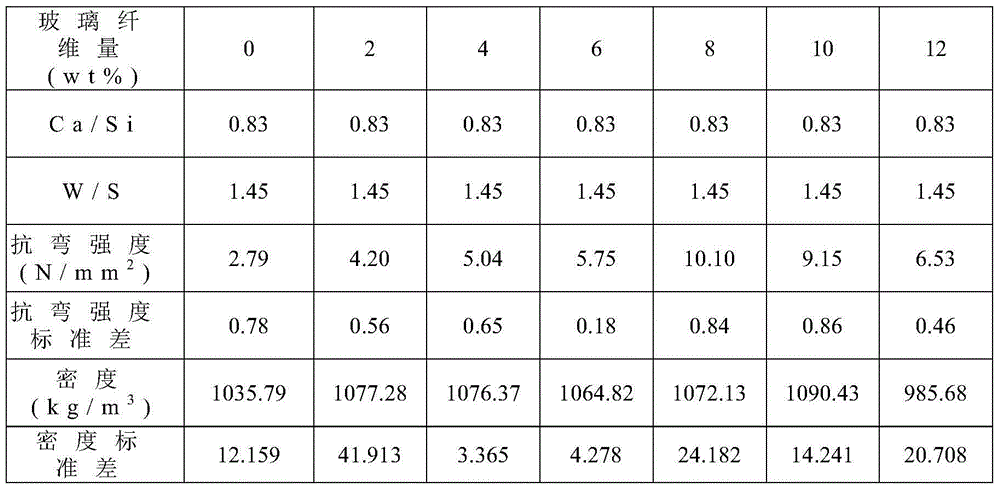

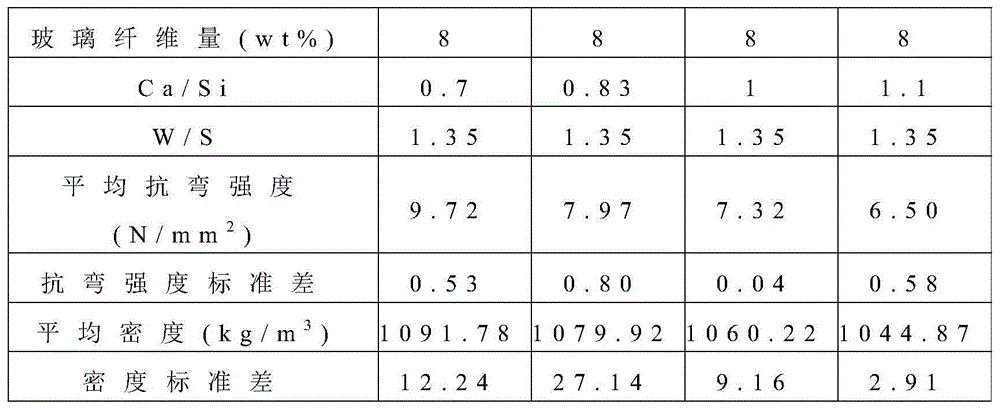

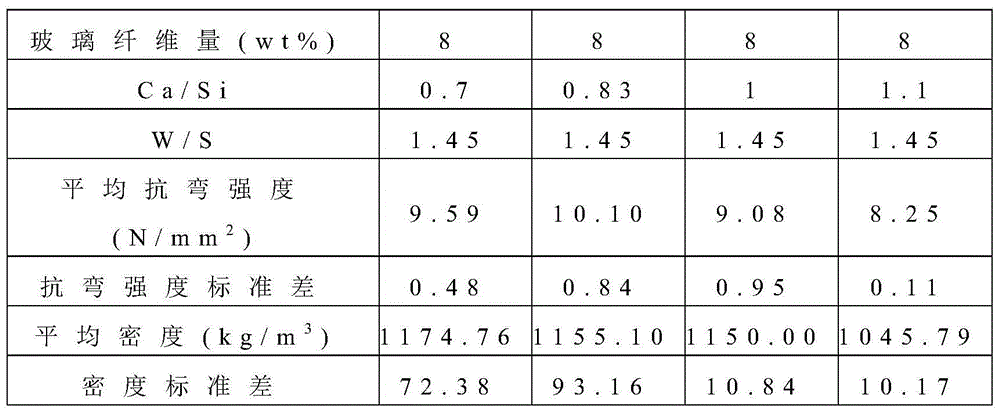

Examples

Embodiment Construction

[0008] The embodiment of the method for producing recycled building materials from bottom slag fine aggregates of the present invention includes the following steps: collecting the bottom slag of the incinerator and performing wet screening, magnetic separation, eddy current separation, stirring and washing, and separating the mud and sand, and collecting the bottom slag Fine aggregates with a particle size of less than 1mm.

[0009] Among them, the wet screening is carried out by installing a water supply unit in a trommel, and washing the bottom residue with a high-pressure water column while performing rolling screening in the trommel. The scouring method through the high-pressure water column can make the organic matter and chloride ions in the bottom slag dissolve in water and be taken away. At the same time, the high-pressure water injection can also flush the screen holes of the trommel screen to prevent the sieve holes from being blocked by the bottom slag and reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com