A two-stage air-water combined cooling scraper type cold slag conveyor

A combined cooling and slag conveying machine technology, applied in lighting and heating equipment, fluidized bed combustion equipment, combustion methods, etc., can solve problems such as difficult heat recovery, complex operation control, and many mechanical structure failures, so as to improve economic benefits , The system is simple and reliable, and the cooling effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

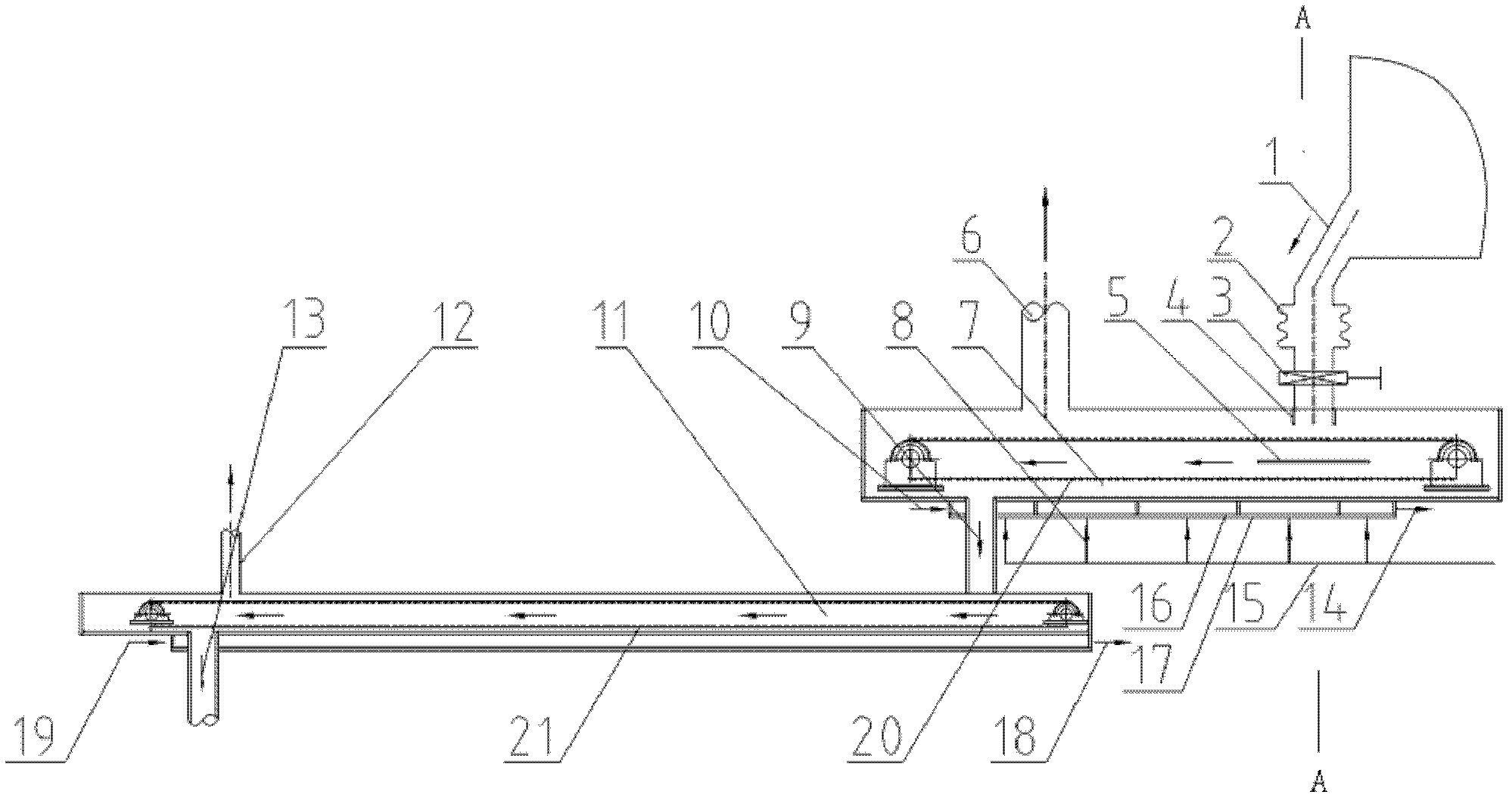

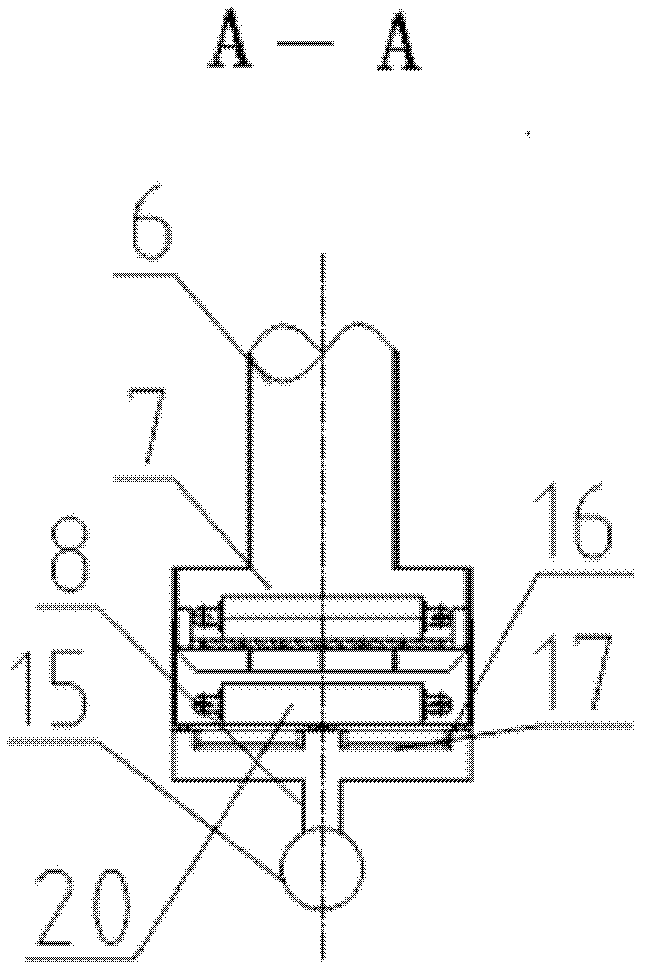

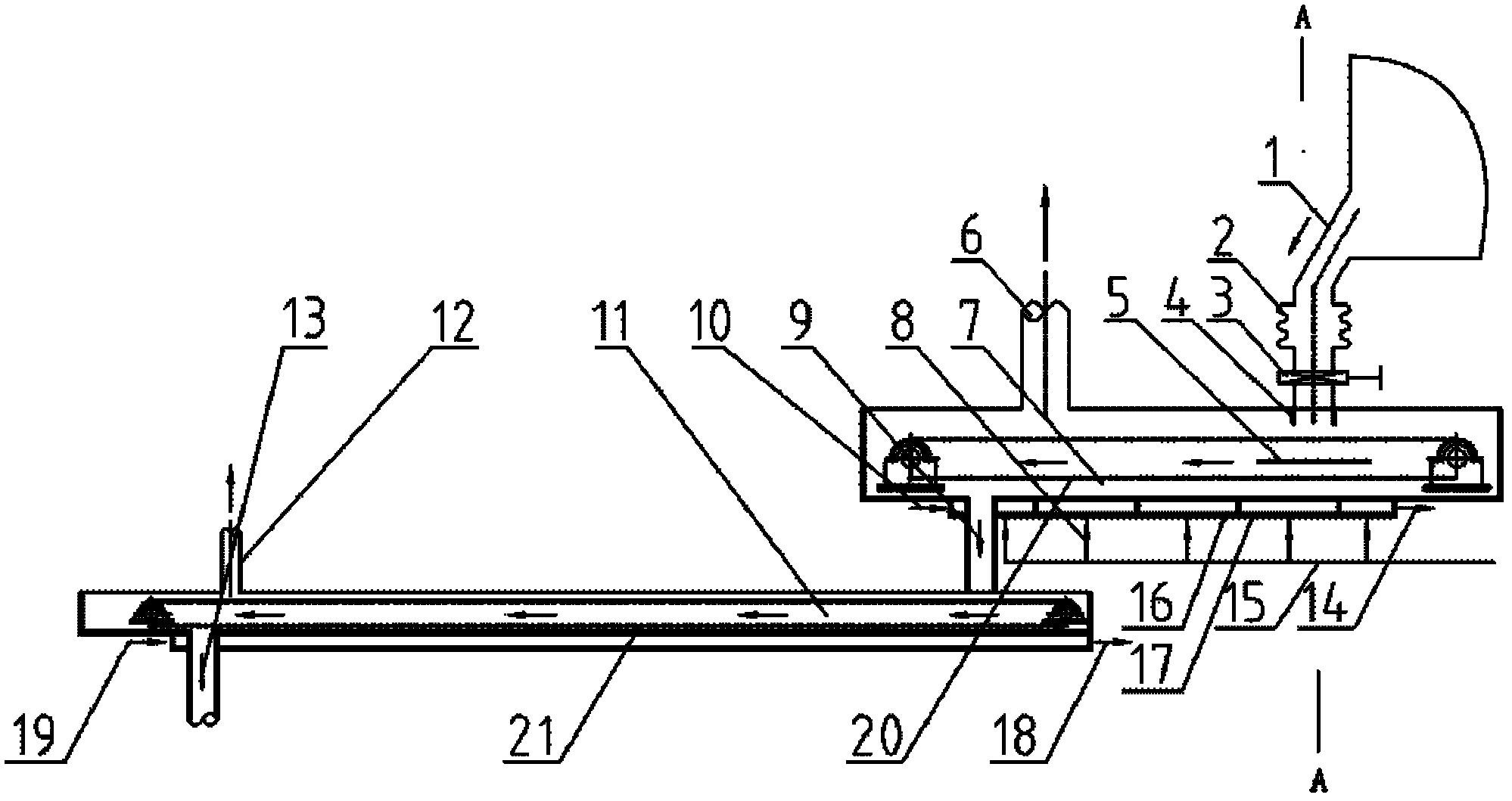

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , figure 2 As shown, a two-stage air-water combined cooling scraper type cold slag conveyor of the present invention includes a primary slag cooler 7 with an inlet at the upper front end and an outlet at the lower rear end, and the discharge temperature of the circulating fluidized bed boiler is about The bottom slag at 900°C enters the inlet of the primary slag cooler 7 through the slag discharge pipe 1 of the circulating fluidized bed boiler, the compensator 2 and the grate combination valve 3, and the material guide pipe 4 and sealing The plate 5 realizes the sealing of the high-temperature flue gas in the furnace, and prevents a large amount of hot flue gas from entering the primary slag cooler 7. The lower part of the primary slag cooler 7 is provided with an air distribution plate 16 and a cooling air cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com