Heat pipe type solar energy ORC (organic Rankine cycle) low-temperature thermal power generating system

A technology of Rankine cycle and power generation system, applied in the field of solar power generation, can solve the problems of poor pressure bearing capacity of solar low temperature thermal power generation system, and achieve the effects of strong pressure bearing capacity, high thermal efficiency and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

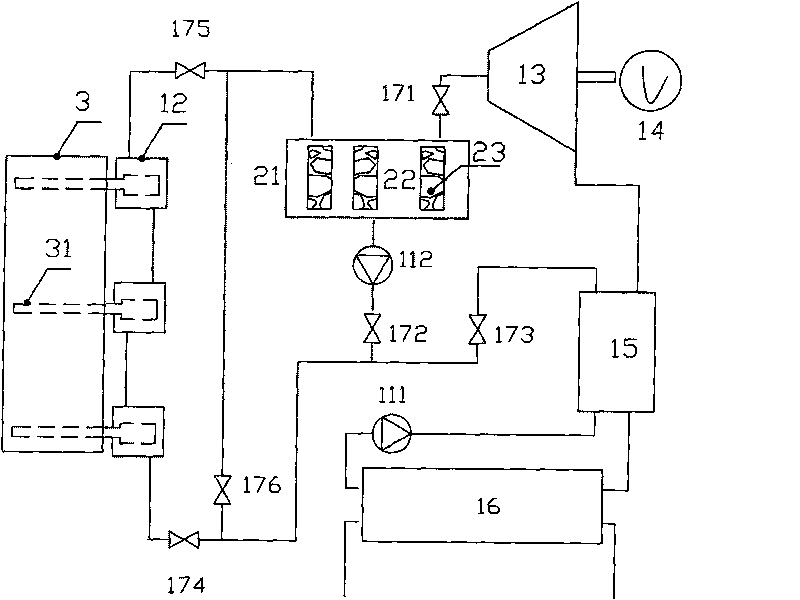

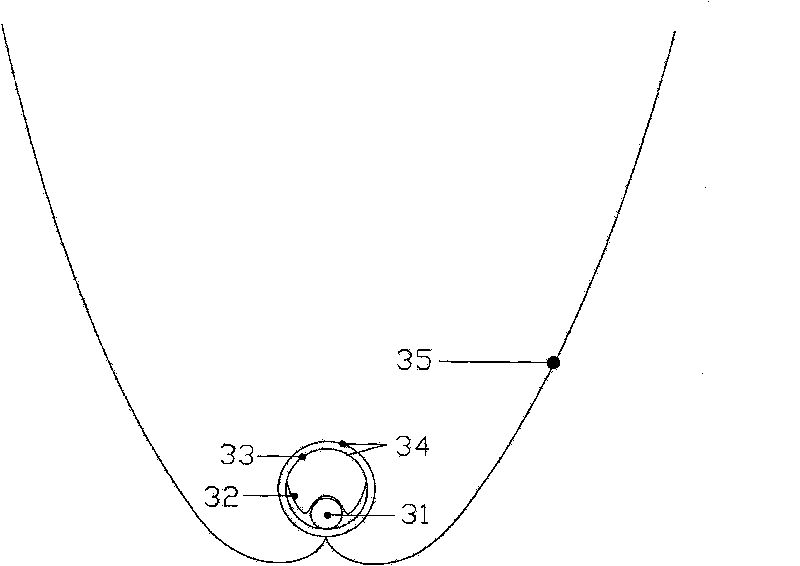

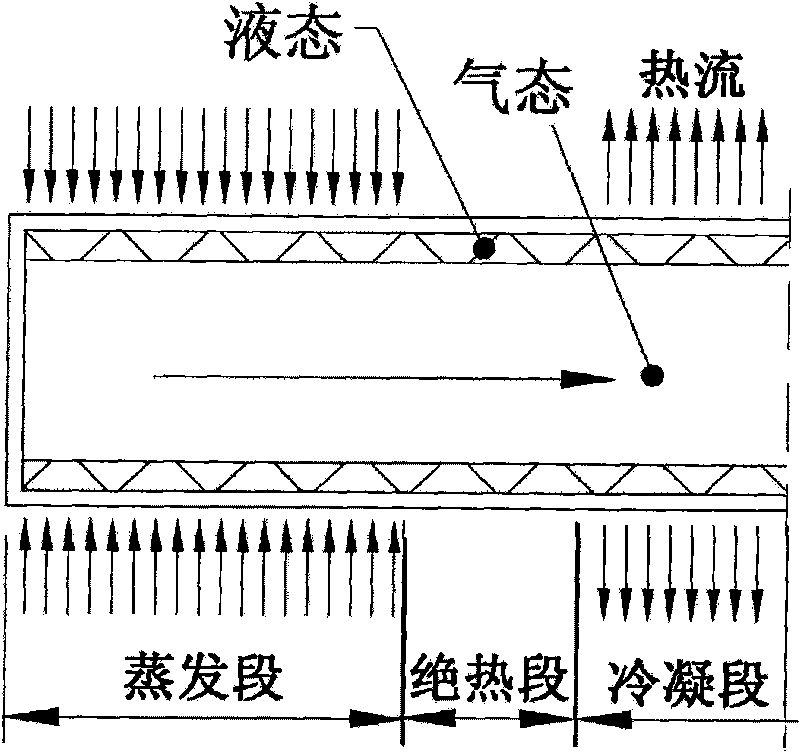

[0028] see figure 1 and figure 2 , heat pipe solar organic Rankine cycle low-temperature thermal power generation system, including organic Rankine cycle power generation system, heat storage system, heat pipe collector system3.

[0029] The organic Rankine cycle power generation system includes a working fluid evaporation casing 12, a steam turbine 13, a generator 14, a regenerator 15, a condenser 16, a regenerator pump 111, a liquid storage tank pump 112 and six valves. The output end of the steam turbine 13 is connected to the generator 14, the exhaust port of the steam turbine 13 is connected to the regenerator 15, the other port of the regenerator 15 is connected to the condenser 16, and the regenerator 15 is connected to the valve F176 through the valve C173 Liquid storage tank 21; the liquid storage tank 21 is connected to the air inlet of the steam turbine 13 through the valve A171, the other port of the liquid storage tank 21 is connected to the liquid storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com