Garbage incineration ash slag heavy metal solidifying method

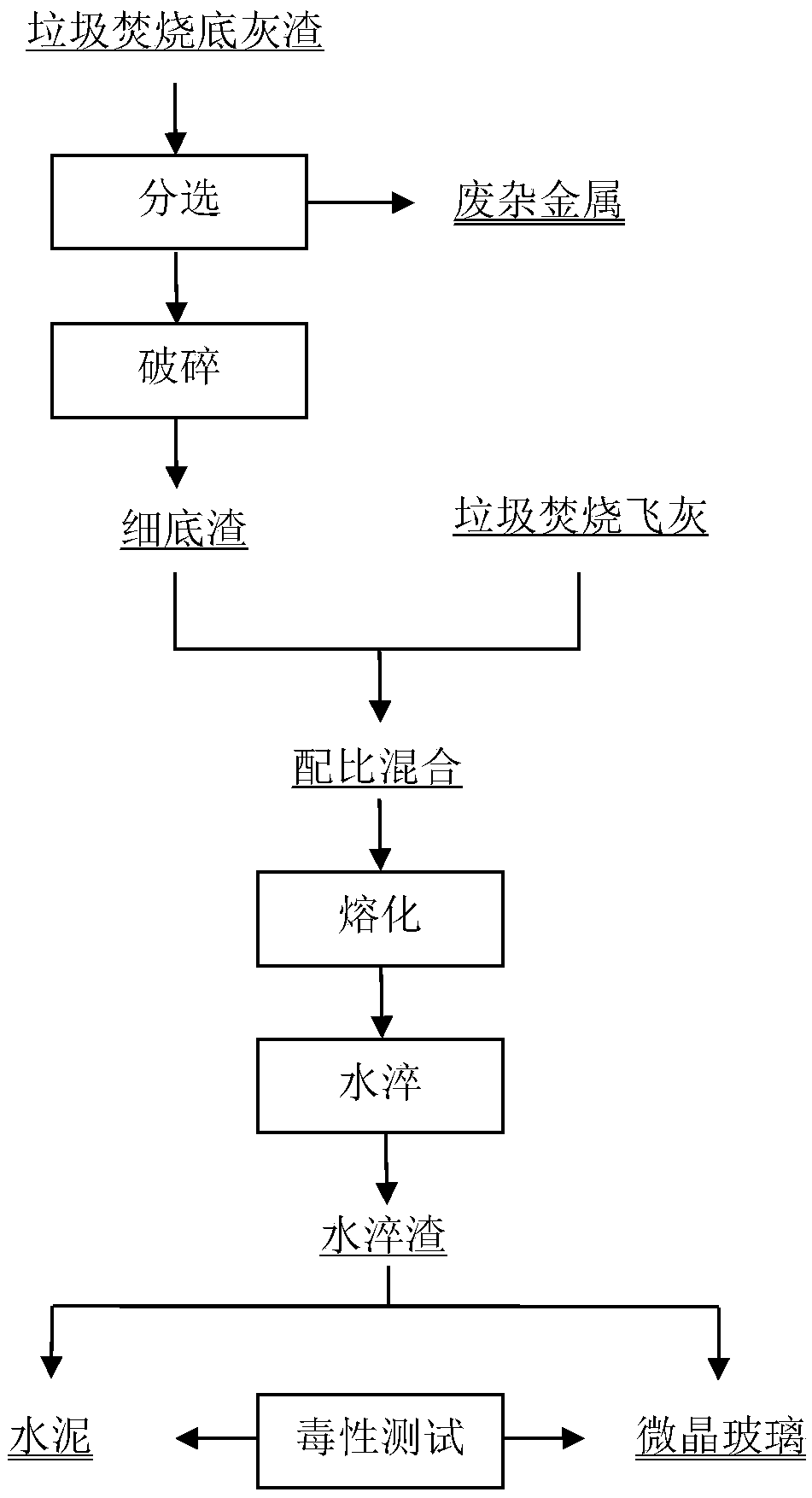

A technology of waste incineration ash and waste incineration fly ash, which is applied in the direction of cement production and process efficiency improvement, can solve the problems of excessive heavy metal content in permeable bricks, high risk of heavy metal secondary pollution, and high risk of heavy metal pollution, achieving significant economic and economic benefits. Double benefits of environmental protection, avoid heavy metal ion leaching, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The bottom ash of waste incineration is sorted by eddy current, and the waste metal with conductivity > 10 is sorted out, and the bottom ash of waste incineration without waste metal with conductivity ≤ 10 is crushed to ≤ 2.0mm, and fine Bottom slag. Mix 5 parts of fine bottom slag and 1 part of waste incineration fly ash evenly, heat to 1300°C and melt for 3.0 hours to obtain a melt, and water quenched to obtain water quenched slag. Water quenching slag is used to make cement, and the addition amount of water quenching slag is 10wt%; the leaching concentration of Cr in cement products is 2.79mg / L, the leaching concentration of Pb is 1.22mg / L, the leaching concentration of Cd is 0.47mg / L, and the leaching concentration of Ni is 0.47mg / L. The concentration is 4.27mg / L, the leaching concentration of Zn is 89.71mg / L, and the leaching concentration of Cu is 65.03mg / L.

Embodiment 2

[0039]The bottom ash of waste incineration is sorted by eddy current, and the waste metal with conductivity > 10 is sorted out, and the bottom ash of waste incineration without waste metal with conductivity ≤ 10 is crushed to ≤ 1.5mm, and fine Bottom slag. Mix 5 parts of fine bottom slag and 1 part of waste incineration fly ash evenly, heat to 1300°C and melt for 3.0 hours to obtain a melt, and water quenched to obtain water quenched slag. The water-quenched slag was remelted at 1300°C for 1.0h and nucleated and crystallized at 650°C for 3.0h to obtain glass-ceramic. The leaching concentration of Cr in glass-ceramic products is 0.23mg / L, the leaching concentration of Pb is 0.22mg / L, the leaching concentration of Cd is 0.11mg / L, the leaching concentration of Ni is 0.06mg / L, and the leaching concentration of Zn is 0.35mg / L. Cu leaching concentration is 0.41mg / L.

Embodiment 3

[0041] The bottom ash of waste incineration is sorted by eddy current, and the waste metal with conductivity > 10 is sorted out, and the bottom ash of waste incineration without waste metal with conductivity ≤ 10 is crushed to ≤ 2.0mm, and fine Bottom slag. Mix 4 parts of fine bottom slag and 1 part of waste incineration fly ash evenly, heat to 1350°C and melt for 2.5 hours to obtain a melt, and water quenched to obtain water quenched slag. Water quenching slag is used to make cement, and the addition amount of water quenching slag is 15wt%; the leaching concentration of Cr in cement products is 2.12mg / L, the leaching concentration of Pb is 2.35mg / L, the leaching concentration of Cd is 0.50mg / L, and the leaching concentration of Ni is 0.50mg / L. The concentration is 3.89mg / L, the leaching concentration of Zn is 75.22mg / L, and the leaching concentration of Cu is 51.78mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com