Method of Reducing Toxicity of Heavy Metals in Soil by Decorating Garbage-Soil Mixed Treatment

A mixed treatment and heavy metal technology, applied in the field of solid waste resource utilization and soil remediation, can solve the problems of long phytoremediation cycle, less engineering application, additional carbon emissions, etc., and achieve co-processing of waste and cheap and easy-to-obtain materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

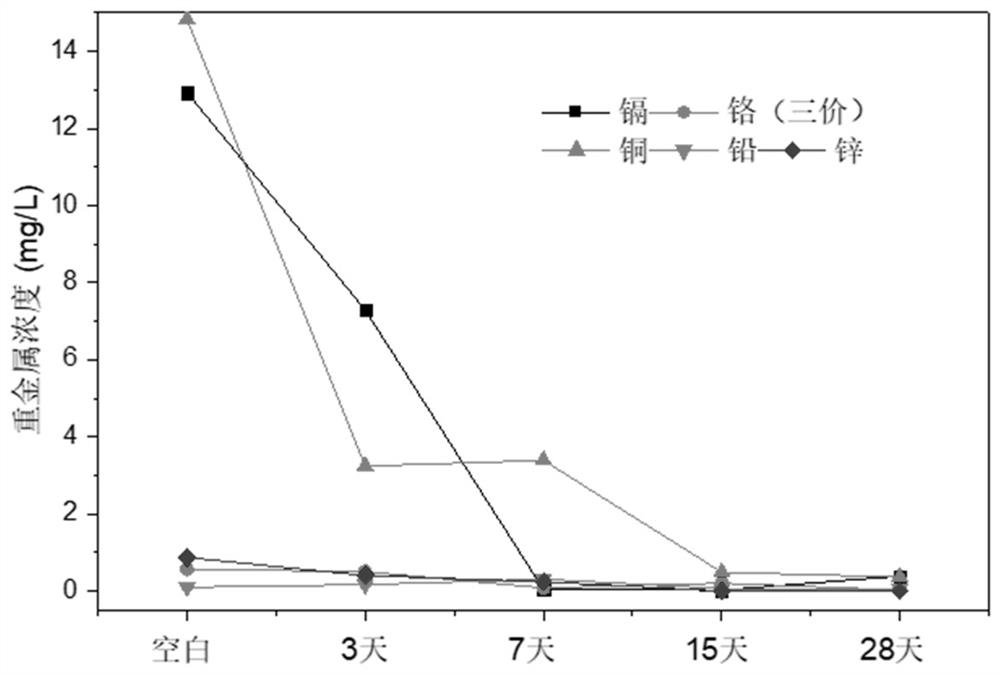

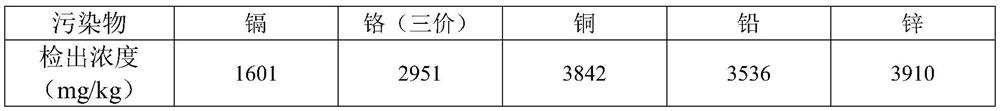

[0040] Take mixed decoration waste from a certain place in Shanghai, sieve out the large debris, and use a jaw crusher to crush it. According to construction aggregate: wood / chips: cardboard / chips: mortar: bentonite: quartz sand = 3:2:1: Prepare a mixed decoration waste system in a ratio of 3:1:1, and lead (Pb), trivalent chromium (Cr III), cadmium (Cd), copper (Cu), and zinc (Zn) to simulate heavy metal polluted soil according to the decoration waste: Mix the soil at a weight ratio of 1:2, fill the obtained mixed solid waste into a polytetrafluoroethylene column, add anaerobic water until it is about 5cm above the surface of the waste, cover it and let it stand. A total of 4 tanks were set up as a batch experiment for comparison. At the same time, a blank control was set up, and clean soil was added to the polluted soil to simulate the polluted soil-decoration garbage mixed system.

[0041] The measured concentrations of pollutants in the simulated polluted soil are listed i...

Embodiment 2

[0046] Using the mixed decoration waste system in Example 1, mixed with the contaminated soil obtained from a polluted site in Yangpu District according to the decoration waste: soil weight ratio of 1:2, wherein the contaminated soil was tested, and the heavy metals contained in it were mainly antimony, chromium, copper, Lead, Nickel and Zinc. The mixed solid waste obtained by mixing is filled into a polytetrafluoroethylene column, and anaerobic water is added to cover the surface of the waste by about 7-8cm, and it is airtight and left standing. A total of 4 tanks were set up as a batch experiment for comparison. At the same time, a blank control was set up, and clean soil was added to the polluted soil to simulate the polluted soil-decoration garbage mixed system.

[0047]On the 3rd day, the 7th day, the 15th day and the 28th day of the reaction, one tank was selected for sampling, and the total concentration of heavy metals in the solid-liquid system was determined. Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com