Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Reduce material consumption and energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

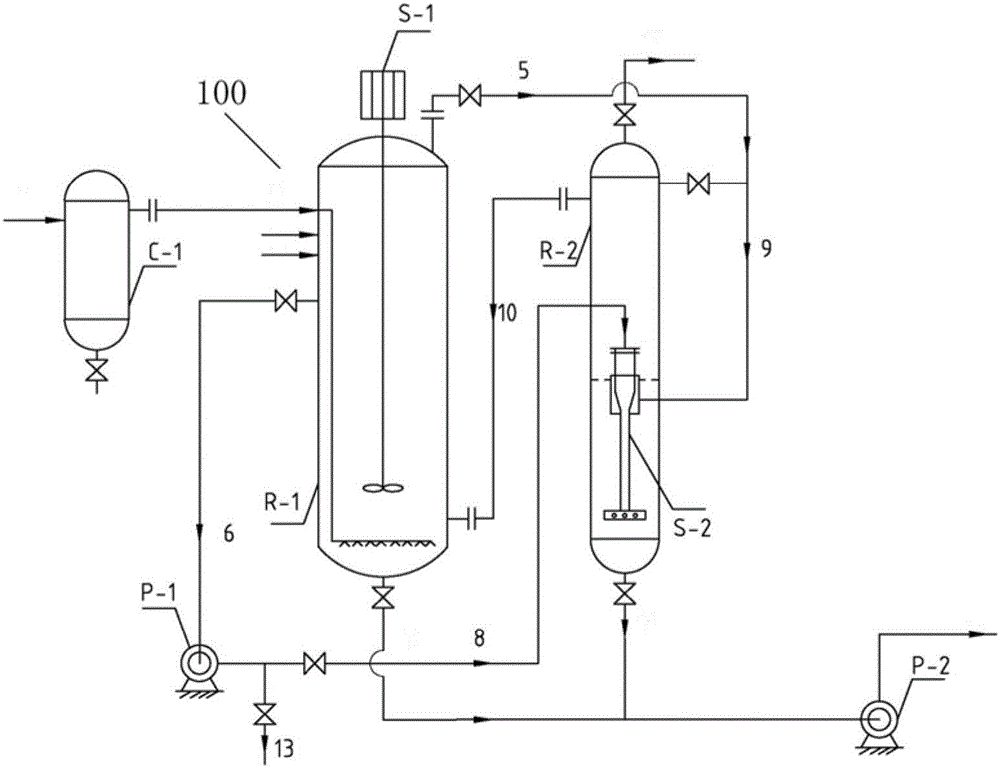

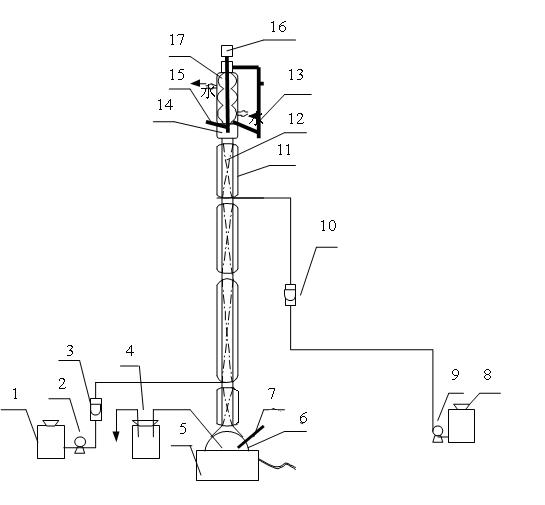

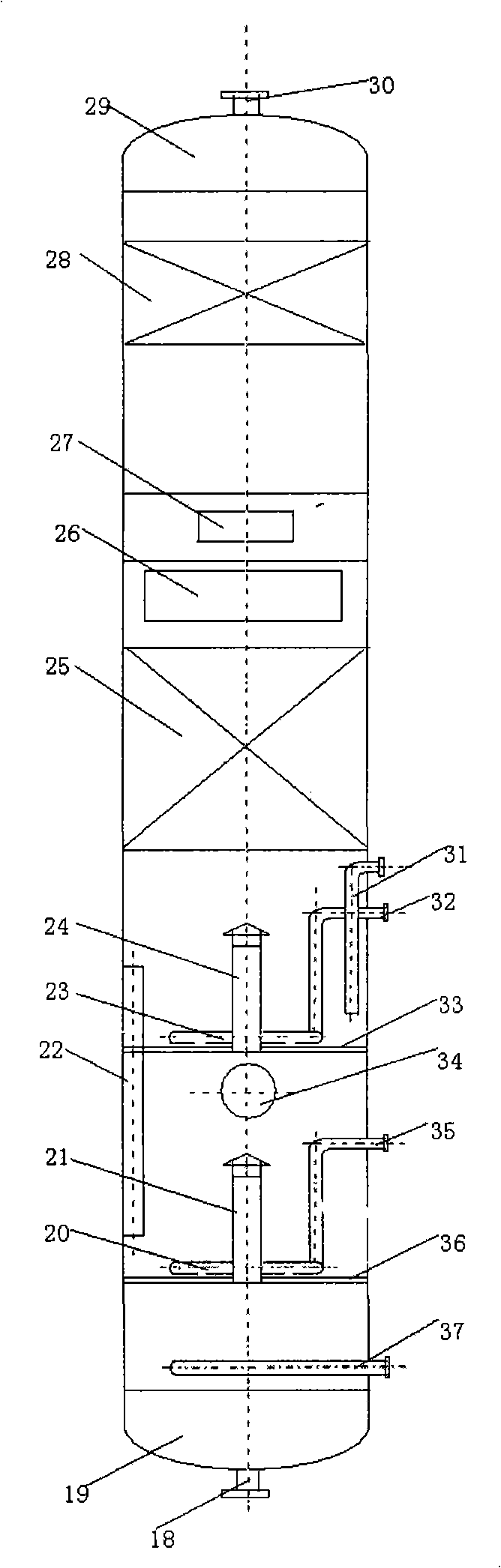

Device and technique for producing cyclohexane by benzene hydrogenation

ActiveCN106187660AImprove mass transfer efficiencyIncrease reaction rateHydrocarbon by hydrogenationBenzeneGas phase

The invention discloses a device and technique for producing cyclohexane by benzene hydrogenation. The device for producing cyclohexane by benzene hydrogenation comprises a reactor, a superfine bubble generator and a bubble breaker, wherein the reactor is provided with a first containing cavity; the wall of the first containing cavity is provided with a feed port, a circulation discharge port, a circulation return port and a gas phase outlet; the superfine bubble generator is provided with a second containing cavity; the wall of the second containing cavity is provided with a return port and a gas phase outlet; the return port of the superfine bubble generator communicates with the circulation return port of the reactor; the bubble breaker is arranged in the second containing cavity; the bubble breaker is provided with a gas phase inlet and a liquid phase inlet which communicates with the circulation discharge port of the reactor; and the gas phase inlet of the bubble breaker communicates with the gas phase outlet of the reactor. The device disclosed by the embodiment of the invention has the advantages of high mass transfer efficiency, high reaction rate, short reaction time, low material consumption and energy consumption, simple structure, low manufacturing cost and low maintenance cost.

Owner:NANJING UNIV

Ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and preparation method thereof

InactiveCN101570459AReduce material consumption and energy consumptionObvious superiorityInorganic oxygen-halogen salt explosive compositionsDiamineEthylenediamine

The invention discloses an ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and a preparation method thereof. The initiating explosive is a eutectic compound of ethylenediamine perchlorate and triethylene diamine perchlorate, can be initiated under the action of outside excitation energy and has better explosion output power. The preparation method is as follows: the eutectic compound of the ethylenediamine perchlorate and the triethylene diamine perchlorate is prepared by the neutralization reaction through using ethylene, triethylene diamine and perchloric acid as raw materials under the solution state, wherein the molecular ratio of the ethylenediamine perchlorate and the triethylene diamine perchlorate in the prepared eutectic compound is 1:1. The invention has the advantages of small moisture absorption, large explosion power, simple manufacture process, energy saving, consumption reduction, and no harm to environment.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of hydrogenated bisphenol A epoxy resin

The invention relates to a preparation method of hydrogenated bisphenol A epoxy resin. The preparation method comprises the steps of raw material pre-treatment, ring-opening addition and etherifying, ring-closing epoxidation, product post-treatment and the like. The specific steps are as follows: based on hydrogenated bisphenol A and epoxy chloropropane as raw materials, adding solvent; performing ring-opening etherifying by taking Lewis acid as a catalyst to produce chlorohydrin ether immediate; recovering part of the solvent, adding alkali solution and performing ring-closing dechlorinating reaction; carrying out post-treatment steps such as neutralizing, extracting, water washing, vacuum desolventizing to obtain hydrogenated bisphenol A epoxy resin, wherein the epoxide equivalent of the product is 210-240g / eq; the hydrolyzable chlorine content is not more than 1000ppm; the inorganic chloride content is not more than 10ppm; the viscosity is 2000-5000mPas at 25 DEG C; and the volatile component content is not more than 0.1%. The preparation method of hydrogenated bisphenol A epoxy resin has the advantages of stable process, low material and energy consumption, few by-products, simple water-washing and separating operation and high product yield, therefore, the preparation method can be applied in large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

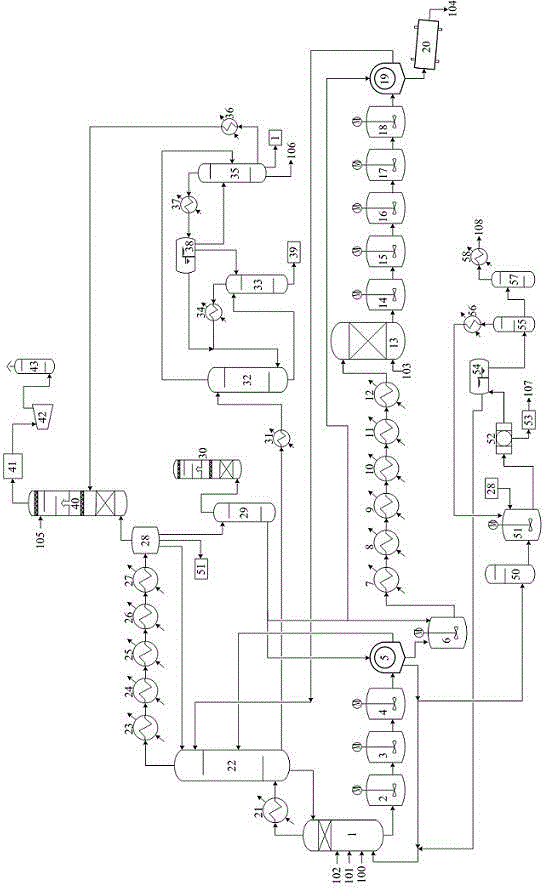

PTA production method with low energy consumption, low material consumption andlow refuse discharge

ActiveCN105001073AEfficient recyclingEmission reductionOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidSlurry

The invention relates to a Purified Terephthalic Acidproduction method with low energy consumption, low material consumption and low refuse discharge. The PTA production method comprises the following steps: tail gas of an oxidation reactor is outputted and passes through by-product steam of a first stage steam generator and is sent to an acetic acid regeneration tower for recycling acetic acid; a refined mother liquor is returned to the acetic acid regeneration tower, the original vacuum filtration filter is replaced by a pressure filter, and filter cakes are directly pulped and supplied to a refining section; through recovered acetic acid recovery extraction, an oxidized mother liquor is processed by extraction, and an acetic acid methyl ester removed tower top backflow liquid of the acetic acid regeneration tower is used for oxidizing, washing filter cakes of the refining section and blending slurries of the refining section. The method and system provided by the invention can effectively control acetic acid consumption in tail gas and waste water, recycle organic matters of the refined mother liquid, realize reuse of water, reduce consumption of steam and electric energy, reduce refuse discharge, and also can supply benzoic acid, mixed phthalic acids and other by-products. The invention has the advantages of short process flow, good operationality, low production cost and low apparatus investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

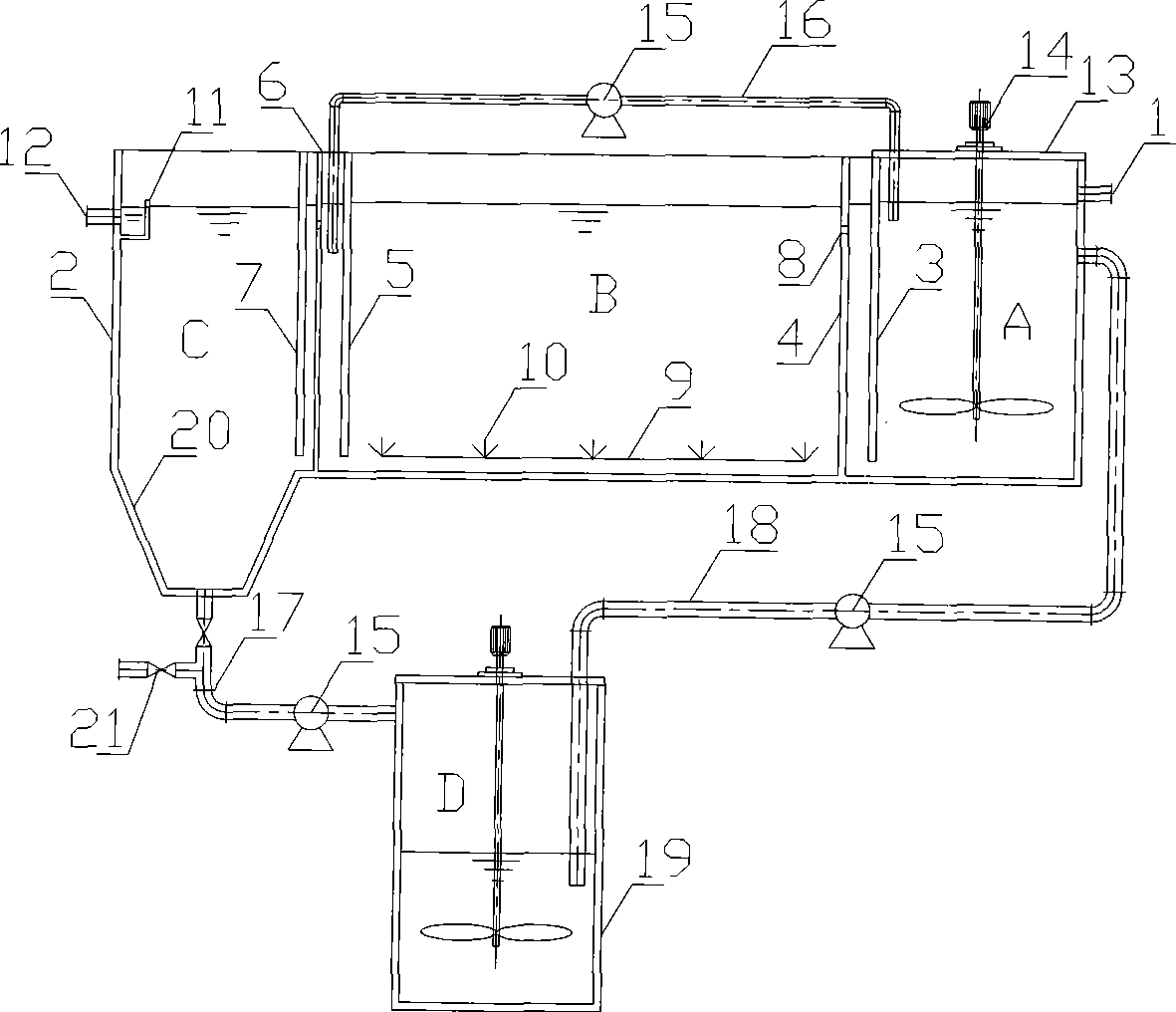

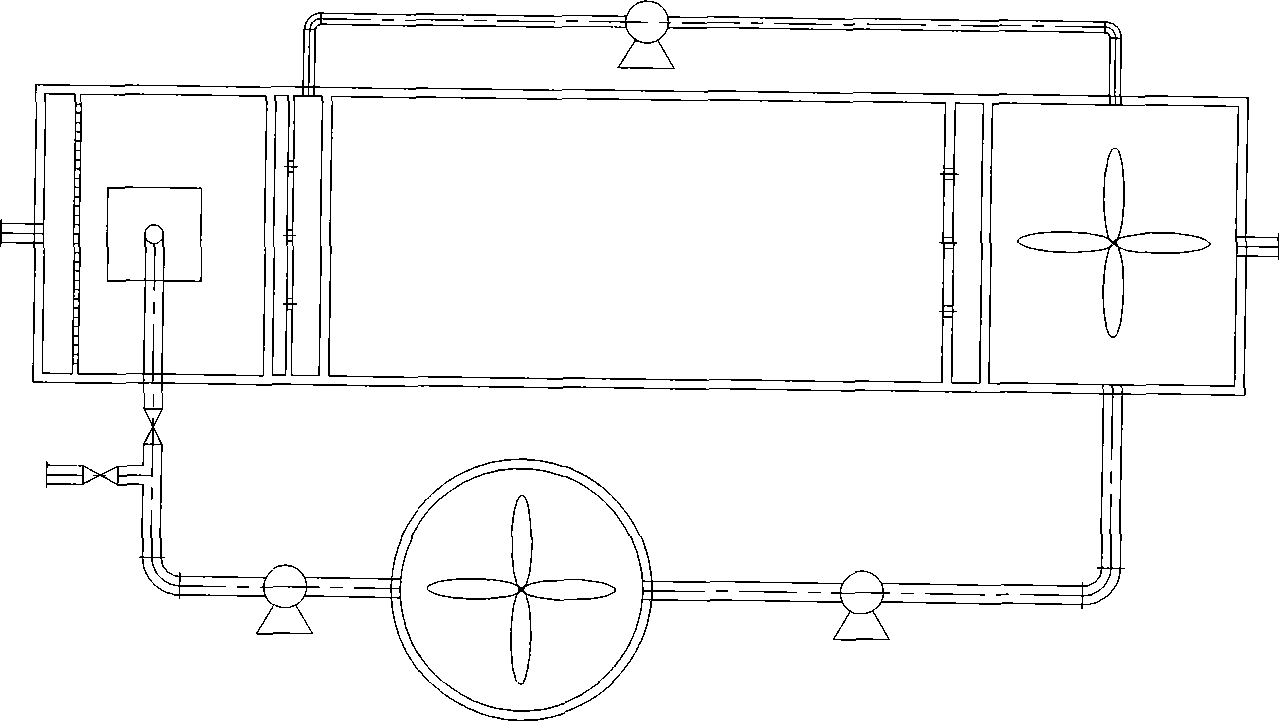

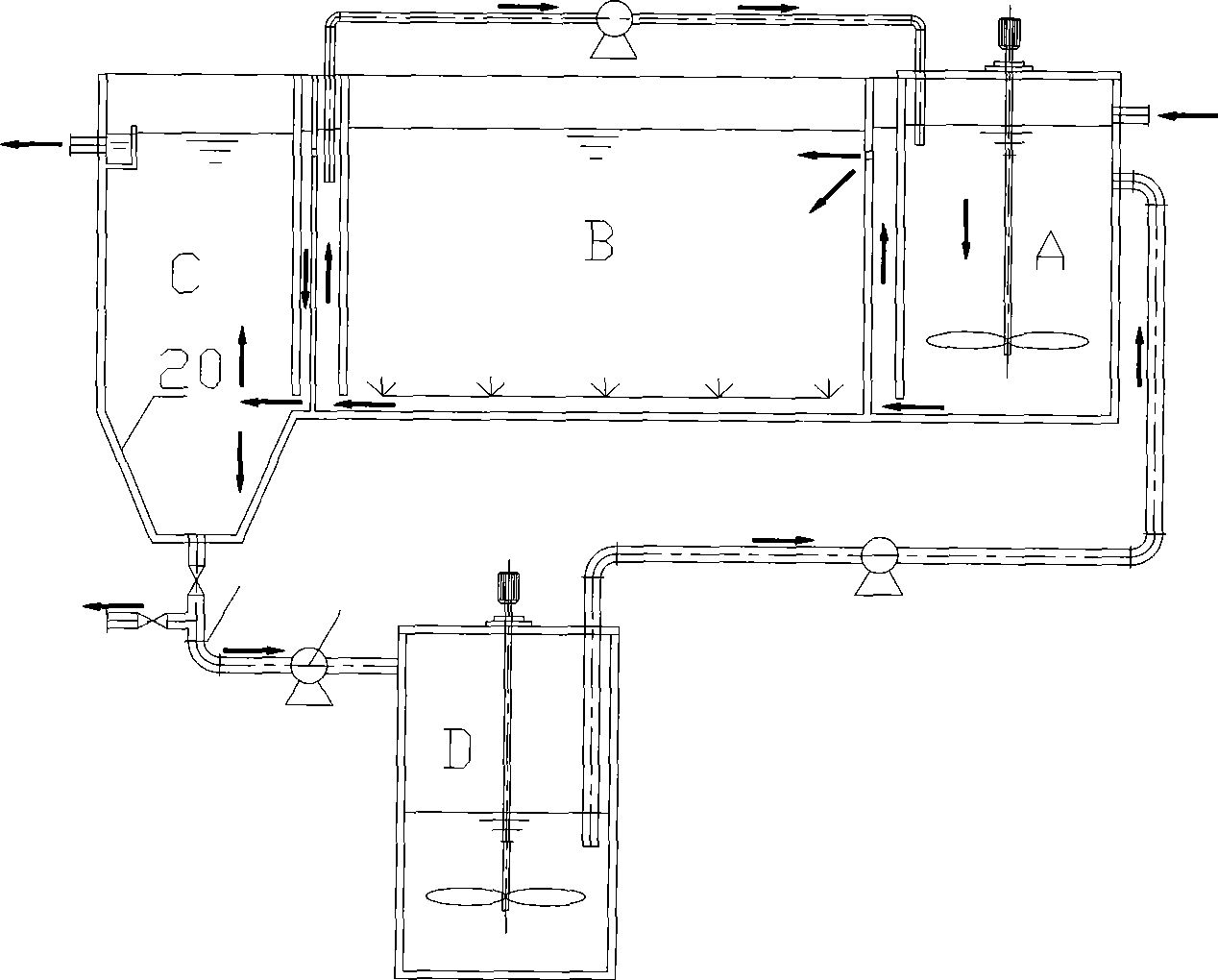

A/O denitrification sewage treatment process and device capable of realizing sludge reduction

InactiveCN101544423AAchieve reductionAchieve the effect of reducingTreatment with aerobic and anaerobic processesSludgeWater quality

The invention relates to an A / O denitrification sewage treatment process and a device capable of realizing sludge reduction. The process comprises the following steps: leading sewage in an anoxic zone to realize denitrification and then leading the treated sewage in an aeration zone to carry out aeration treatment; pumping part aerated sewage to the upper part of the anoxic zone to realize refluxing of mixed solution; leading residual sewage in a deposition zone to realize sludge-water separation through natural deposition; and pumping part deposited sludge to a sludge detention tank according to sludge refluxing ratio and then pumping the part deposited sludge to the upper part of the anoxic zone after 5.0 to 8.0 hours of detention to realize sludge refluxing. The A / O denitrification sewage treatment process and the device have the advantages that the process effectively combines sewage denitrification treatment and sludge reduction and has the advantages of both A / O denitrification process and OSA process, thereby realizing sludge reduction while ensuring effluent water quality; meanwhile, the process has simple flow and reduces material consumption and energy consumption; moreover, the process saves investment and does not cause potential problems in environmental safety; and the device has low investment and operation cost and convenient operation management.

Owner:CHONGQING UNIV

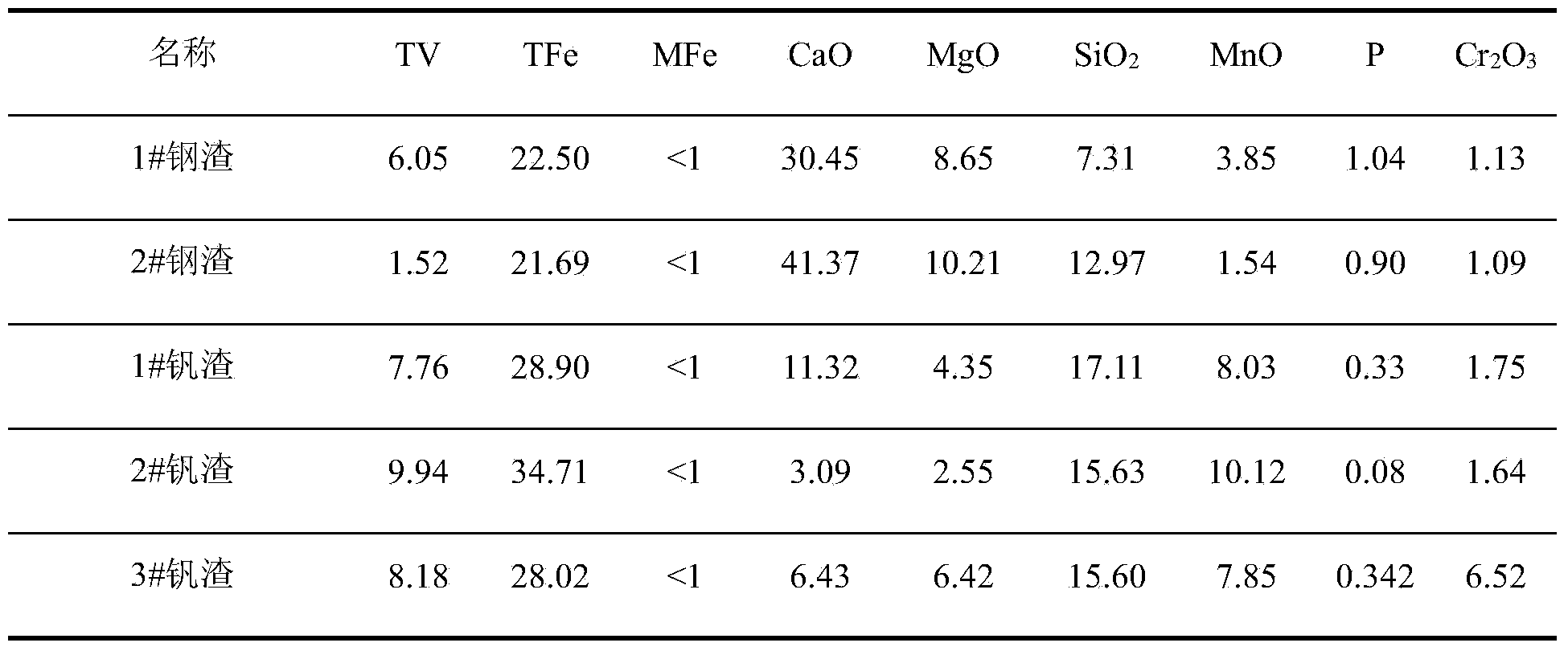

Method for extracting vanadium from vanadium-containing raw material

ActiveCN104388679AImprove roasting effectPromote leachingProcess efficiency improvementFiltrationSlag

The invention discloses a method for extracting vanadium from a vanadium-containing raw material. The method comprises the following steps: a, uniformly mixing the vanadium-containing raw material, sulfuric acid and / or a sulfate, and water, so as to obtain a mixed material; b, performing aerobic roasting on the mixed material, so as to obtain a roasted clinker; c, performing leaching on the roasted clinker by using a leaching agent, so as to obtain a leaching slurry; and d, performing filtration separation on the leaching slurry, so as to obtain tails and a vanadium-containing solution. The method has relatively strong adaptability on composition variation of the vanadium-containing raw material, and helps to realize economic feasible industrial production and extraction of vanadium by using steel slag, vanadium slag and other vanadium-containing raw materials with relatively high calcium and magnesium content. The method is simple, practicable, low in equipment requirement, convenient to operate, low in material consumption and energy consumption, and easy for industrialization, and has extremely good economic benefit and social benefit.

Owner:边悟

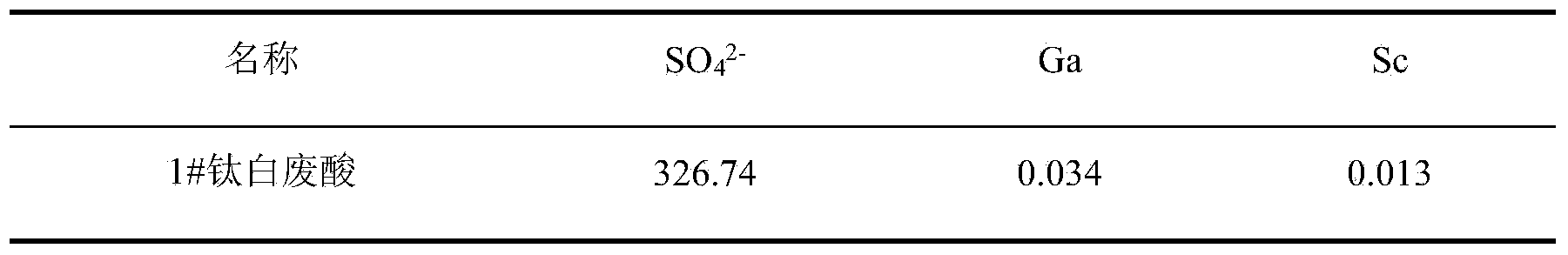

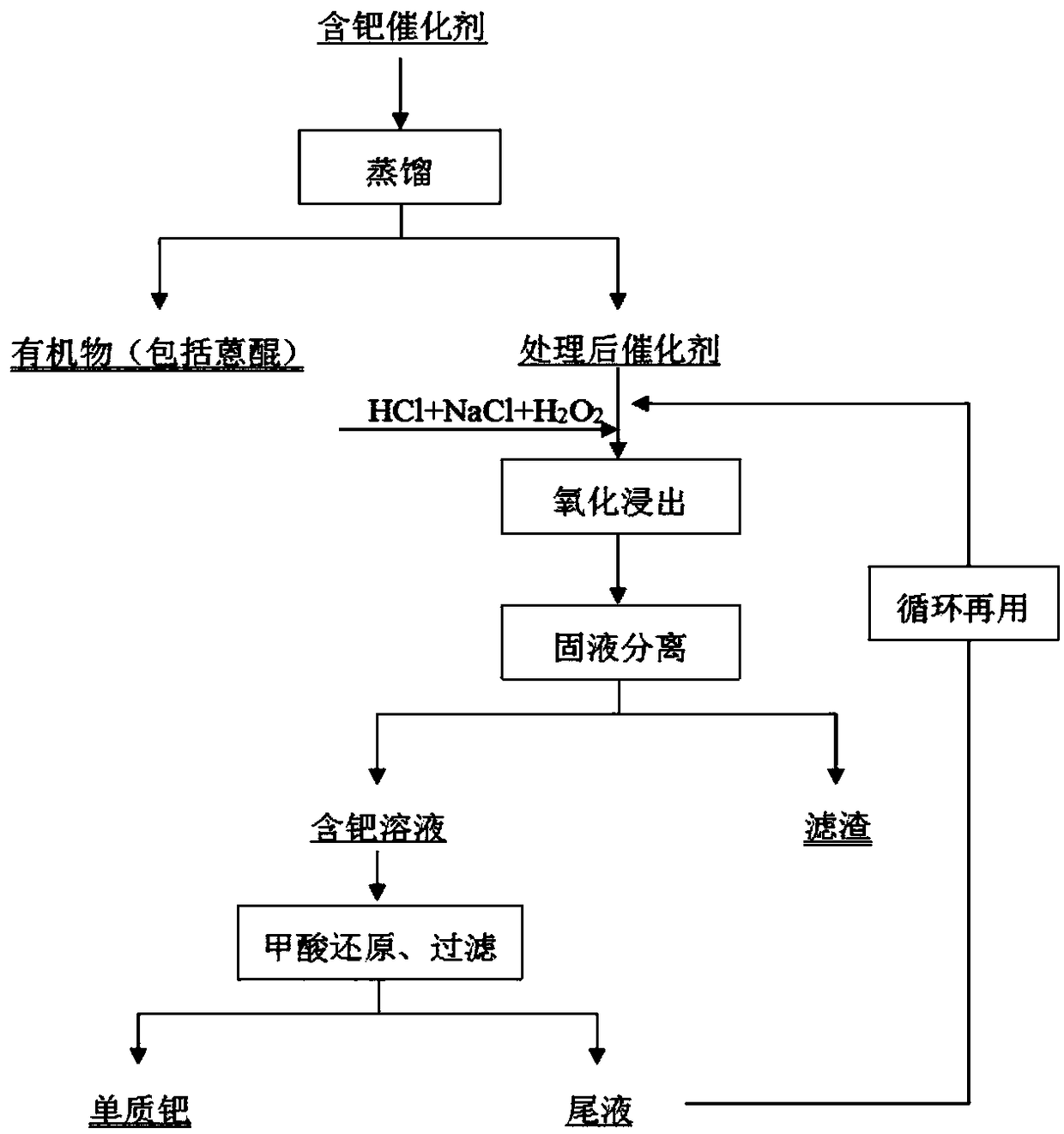

Method for recovering palladium from palladium-contained catalyst

InactiveCN108285978AImprove the ability to oxidize and complex palladium ionsImprove leaching rateProcess efficiency improvementRecovery methodDistillation

The invention mainly belongs to the technical field of waste recycling, and relates to a method for recovering palladium from palladium-contained catalyst. The method comprises the following steps: firstly, organic matters in the palladium-contained catalyst are separated and recovered through low-temperature distillation (150-350 DEG C); then, palladium is oxidized and leached by H2O2 in HCl+NaClsolution; and finally, simple substance palladium is obtained through reduction of formic acid. The method prevents environmental pollution caused by direct incineration, realizes recovery of anthraquinone organic matters, meanwhile, has the advantages of high palladium leaching rate, tail liquid recycling, greenness, environmental protection and the like, and is suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

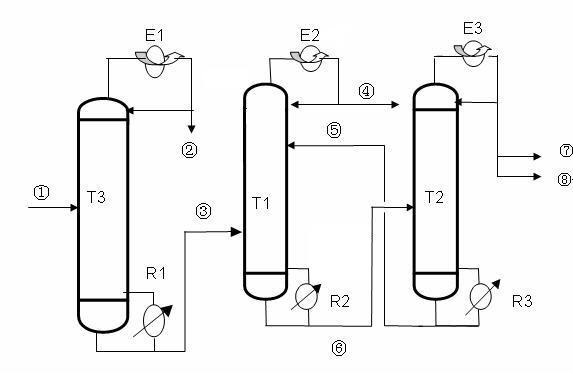

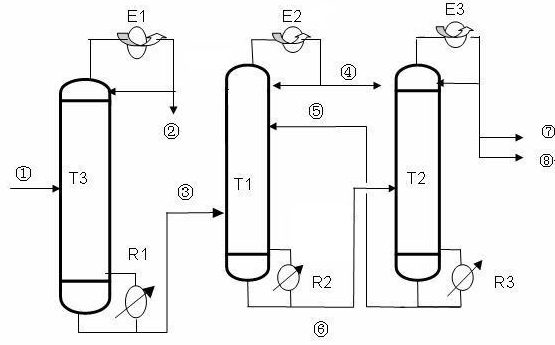

Method for extracting acetone from acetone-dichloromethane-methanol-water mixed liquor by azeotropy and composite extraction reditification integration and equipment thereof

InactiveCN101914001AThe process steps are simpleHigh purityDistillation separationCarbonyl compound separation/purificationSulfolaneExtractive distillation

The invention discloses a method for extracting acetone from acetone-dichloromethane-methanol-water mixed liquor by azeotropy and composite extractive distillation integration, comprising the following steps: (1) the mixed liquor of raw materials acetone, dichloromethane, methanol and water is performed with azeotropic distillation firstly, and 50-75% of acetone is obtained at the bottom of an azeotropy tower; (2) above 50-75% of acetone is extracted, rectified and separated by a mixed solvent of sulfolane and glycol, more than 98.5% of acetone is obtained on the top of a composite extractionrectifying column, and a mixed extractant containing methanol and water flows out of a tower bottom; (3) the mixed extractant is performed with rectification treatment by a regenerator, 98% of methanol and an aqueous solution are respectively obtained on the top of the regenerator, and the mixed extractant is obtained at the tower bottom; and the mixed extractant is recycled. The invention has simple processing step and high product purity; and because the mixed extractant can be recycled, energy consumption is low. The invention also discloses equipment for realizing the method.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation

InactiveCN104445067AHigh purityAchieving zero emissionsHydrogen separationAmmonia preparation/separationWater vaporGas phase

The invention relates to a tail gas refining method, and in particular relates to a method for preparing refined hydrogen through deamination in tail gas generated by preparation of cyclohexylamine and dicyclohexylamine through aniline hydrogenation, belonging to the technical field of chemical engineering. The method comprises the following steps: allowing tail gas discharged by a cyclohexylamine device and a dicyclohexylamine device to enter an ammonia absorption tower by virtue of a Roche hydrogen compressor and a degreaser, wherein most of ammonia is absorbed by water to be converted into ammonia water to be output from the tower bottom in the tower, and the gas output from the tower top is water-containing hydrogen; allowing the water-containing hydrogen to pass through a water segregator, a fiber filter and a water adsorption tower so as to further remove water vapor, thereby obtaining the refined hydrogen. The concentration of the refined hydrogen can be 98.0-99.8 percent, the material and energy consumption is reduced, and the aims of energy conservation and emission reduction are achieved. The refined hydrogen can serve as recycling gas to be used for an aniline hydrogenation reaction, and gas phase zero emission is realized.

Owner:NANJING UNIV OF TECH

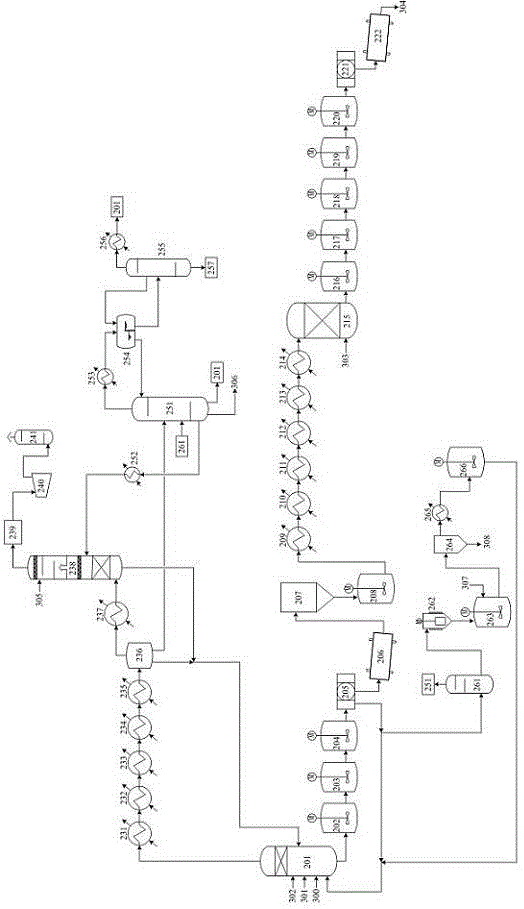

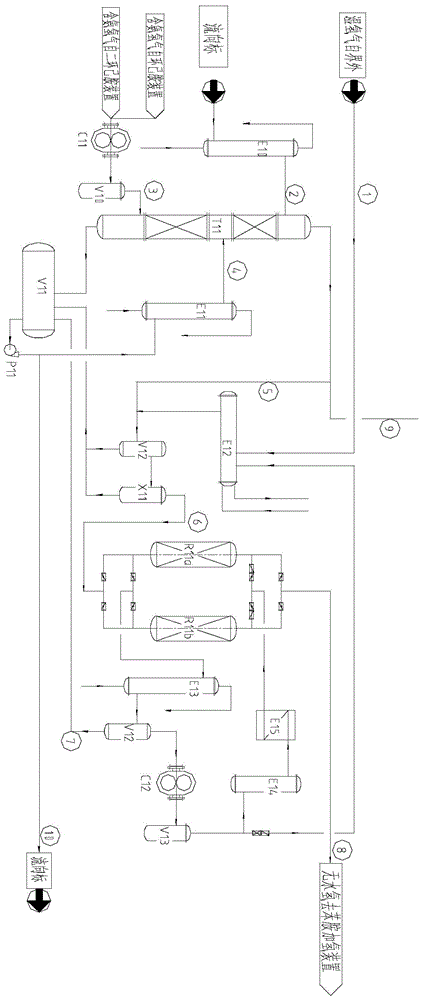

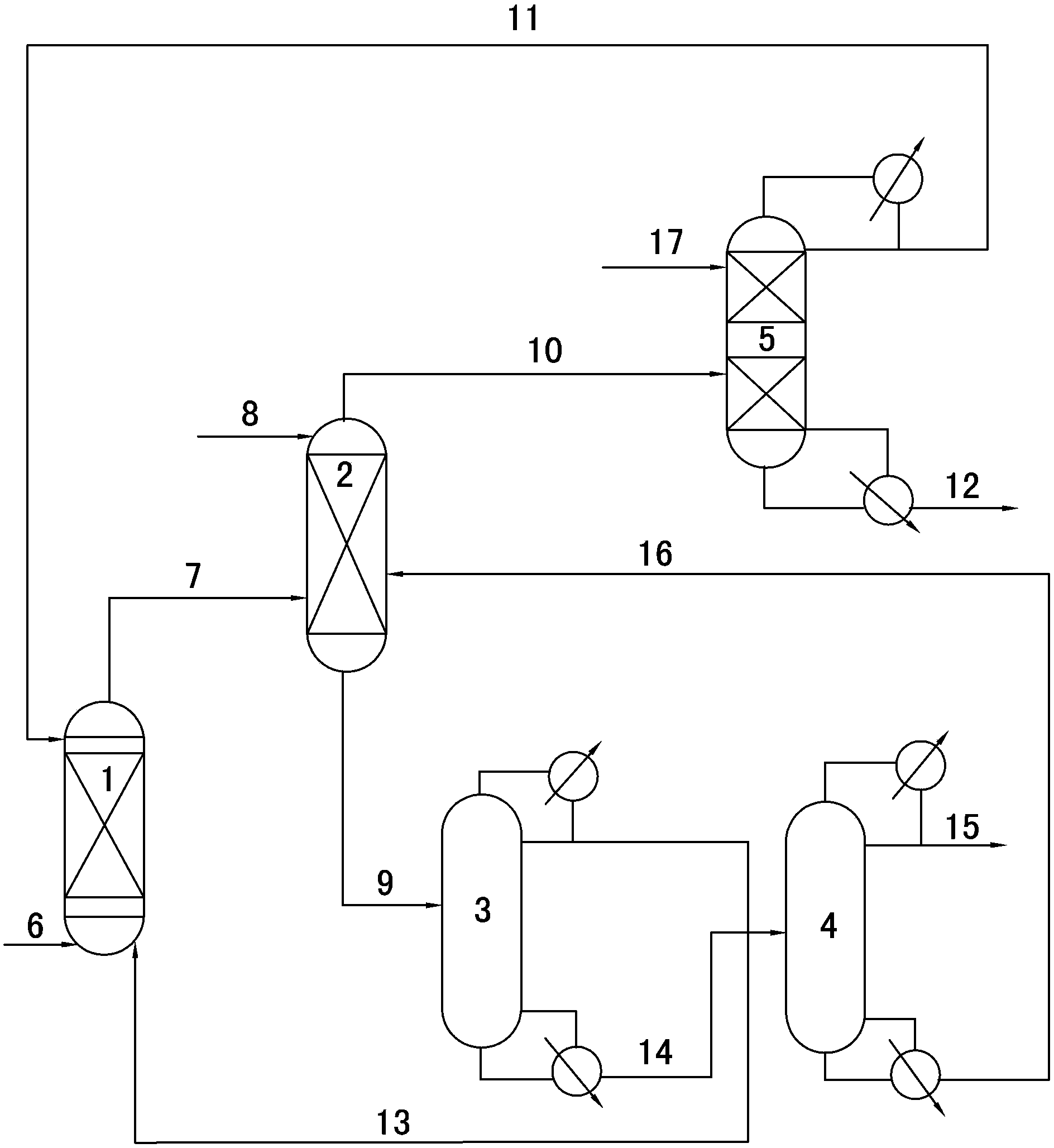

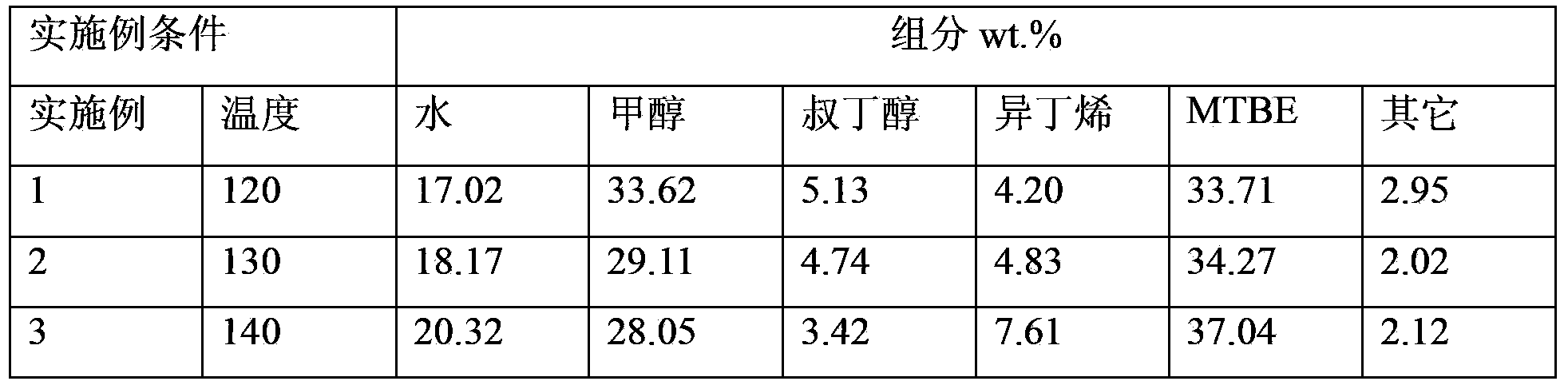

Preparation method and device of methyl tertiary-butyl ether (MTBE)

ActiveCN104250205AImprove conversion rateHigh yieldEther separation/purificationChemical industryWater flowCatalytic distillation

The invention relates to an ether production technology and especially relates to a method and production device for preparing methyl tertiary-butyl ether (MTBE) by a reaction of tertiary butanol and methanol. The method comprises that tertiary butanol and methanol are mixed and undergo a reaction to produce mixed gas, the mixed gas is fed into an extraction tower and is extracted, isobutene and MTBE are distilled off from the tower top, tertiary butanol, methanol, a trace amount of MTBE, water and an extractant flow out of the tower bottom, methanol is supplied for a tower top component of the extraction tower, the mixture is fed into a catalytic distillation tower, a methanol- and isobutene-containing tower top product of the catalytic distillation tower is fed back to a reactor and then undergoes a reaction, the MTBE is discharged from the bottom of the catalytic distillation tower, the materials discharged from the bottom of the catalytic distillation tower enters into a first extractant recovery tower, tertiary butanol, methanol and a trace amount of MTBE are distilled off from the top of the first extractant recovery tower, then are fed back to the reactor and then undergo a reaction, and the extractant and water flow out of the tower bottom, then enter into a second extractant recovery tower and then is recovered for recycle by reduced pressure distillation. The method and device solve the problem of azeotropy of tertiary butanol and water and improve a tertiary butanol one-step conversion rate to 87-94%.

Owner:CHINA PETROLEUM & CHEM CORP

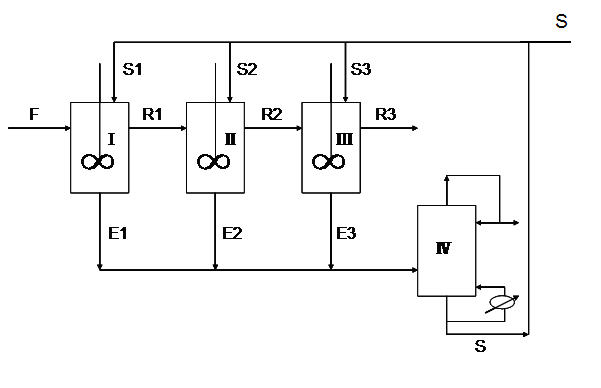

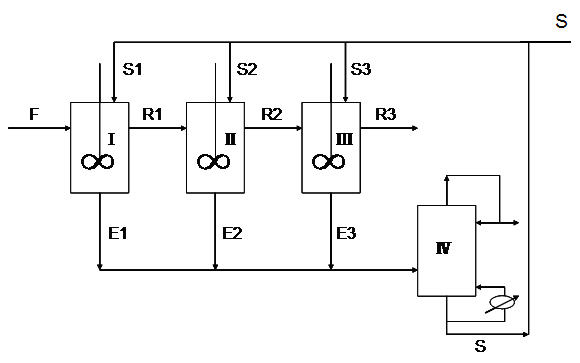

Method for separating methyl acetate and methanol water solution through multistage cross flow liquid-liquid extraction

InactiveCN101955427AHigh purityReduce material consumption and energy consumptionOrganic compound preparationCarboxylic acid esters preparationMethanol waterPolyol

The invention relates to a method for separating methyl acetate and a methanol water solution through multistage cross flow liquid-liquid extraction, which comprises the following steps of: carrying out multistage cross flow liquid-liquid extraction on methyl acetate and the methanol water solution as raw materials by using a mixed solvent of polyalcohol and water as an extracting agent; rectifying the extract residue phase to obtain the product of methyl acetate; and recycling the extract phase subjected to rectification. The separation method of multistage cross flow liquid-liquid extraction can be used for effectively separating the mixture of methyl acetate and the methanol water solution, the purity of methyl acetate reaches more than 99.7% for one-time extraction, and the yield reaches more than 97%. The product of methyl acetate has high purity and low material consumption and energy consumption, and the entire process has low cost and can not produce environmental pollution.

Owner:NANJING NORMAL UNIVERSITY

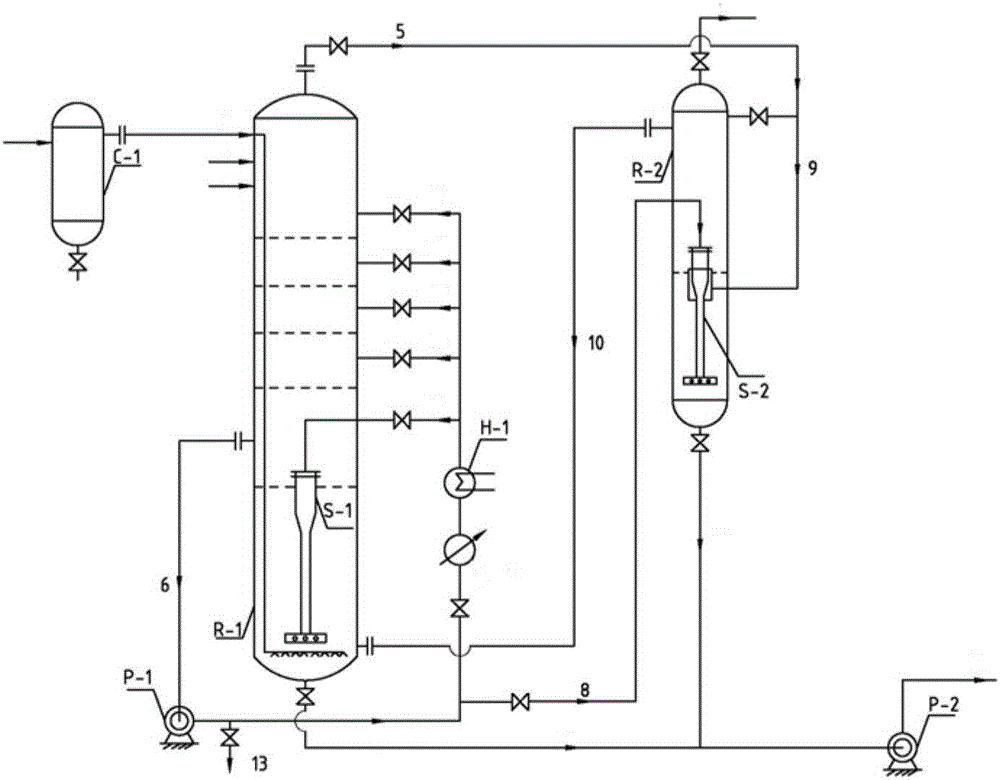

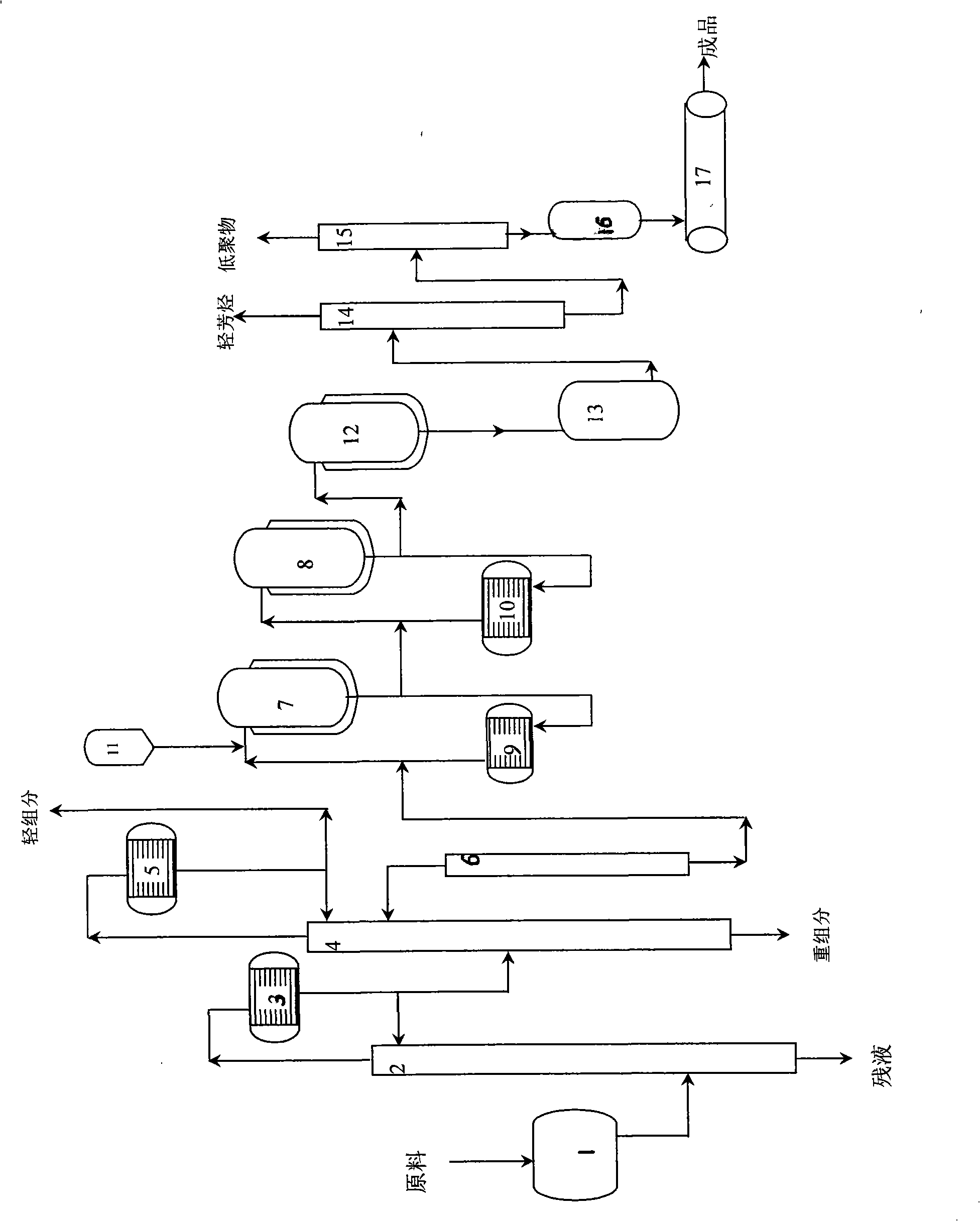

Process and equipment for continuous catalytic polymerization aggregation of C9 petroleum resin

The invention relates to a process and equipment for the continuous catalytic polymerization aggregation of C9 petroleum resin. The process adopts multi-tower refining for separating and refining C9 raw materials, and adopts a continuous catalytic polymerization technique and a solvent and low polymer stripping technique for realizing automatic continuous large-scale production, wherein a stripping tower used in the stripping technique comprises two major parts, namely a distilling section and a stripping section; the distilling section is provided with a plurality of layers of fillers for better separating gas and liquid components; and the stripping section adopts a multi-stage stripping device for stripping. The process and the equipment can overcome the drawbacks in the production process of the conventional process such as uneasy stable control, high energy consumption and unstable product quality. The C9 petroleum resin produced by the process and the equipment is improved in color phase and resin softening point.

Owner:DAQING HUAKE

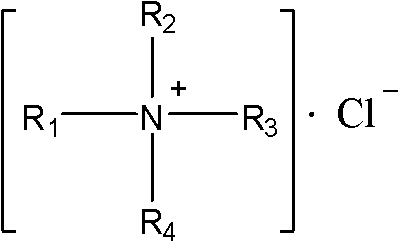

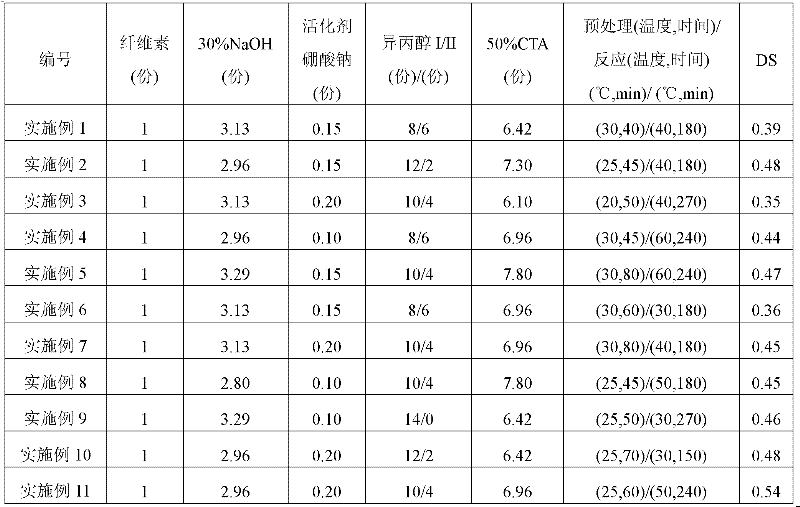

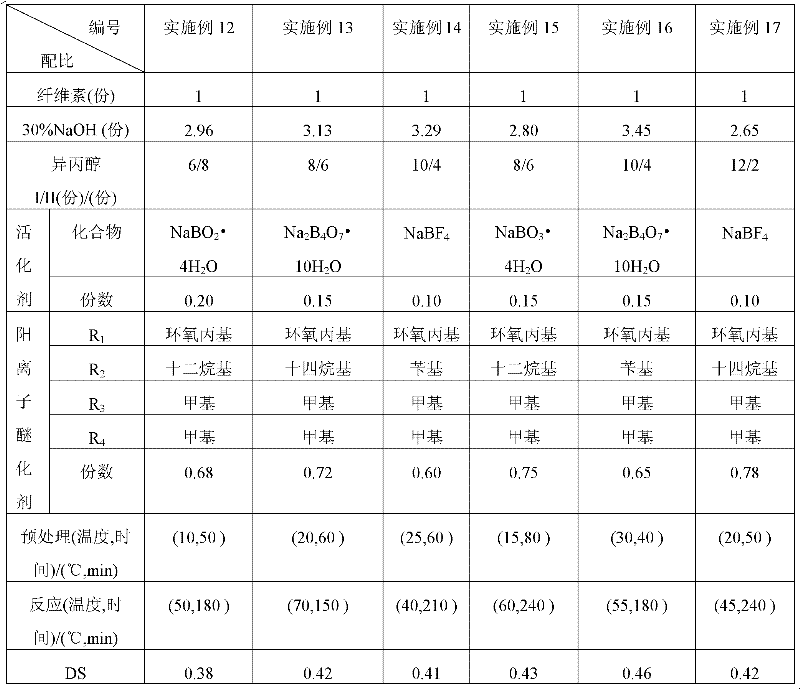

Cationic cellulose with high degree of substitution and its preparation method and application

InactiveCN102268096ARealize the cationization reactionEasy to industrializeDegree of substitutionSodium hydroxide

The invention discloses cationic cellulose with a high substitution degree and a preparation method and application thereof, and particularly discloses a reaction method for preparing cationic cellulose by adopting a technical process comprising cellulose activation, cationization reaction, purification (including filtration and elution) and drying for obtaining a product under the condition of normal temperature and normal pressure in a heterogeneous system. The method comprises the following steps of: firstly, uniformly mixing cellulose with isopropanol under the condition of stirring, adding a sodium hydroxide solution and an activating agent in sequence and activating at a temperature 10-30 DEG C for 40-80 minutes; secondly, adding isopropanol and a cationic etherifying agent once again and reacting at a temperature 20-80 DEG C for 2-4 hours; and lastly, cooling a reaction system, performing post-treatment processes such as filtering, washing and the like for impurity removal, anddrying to obtain a cationic cellulose product with high purity and a high substitution degree. According to the preparation method disclosed by the invention, the cationic cellulose of which the substitution degree is 0.35-0.54 is obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

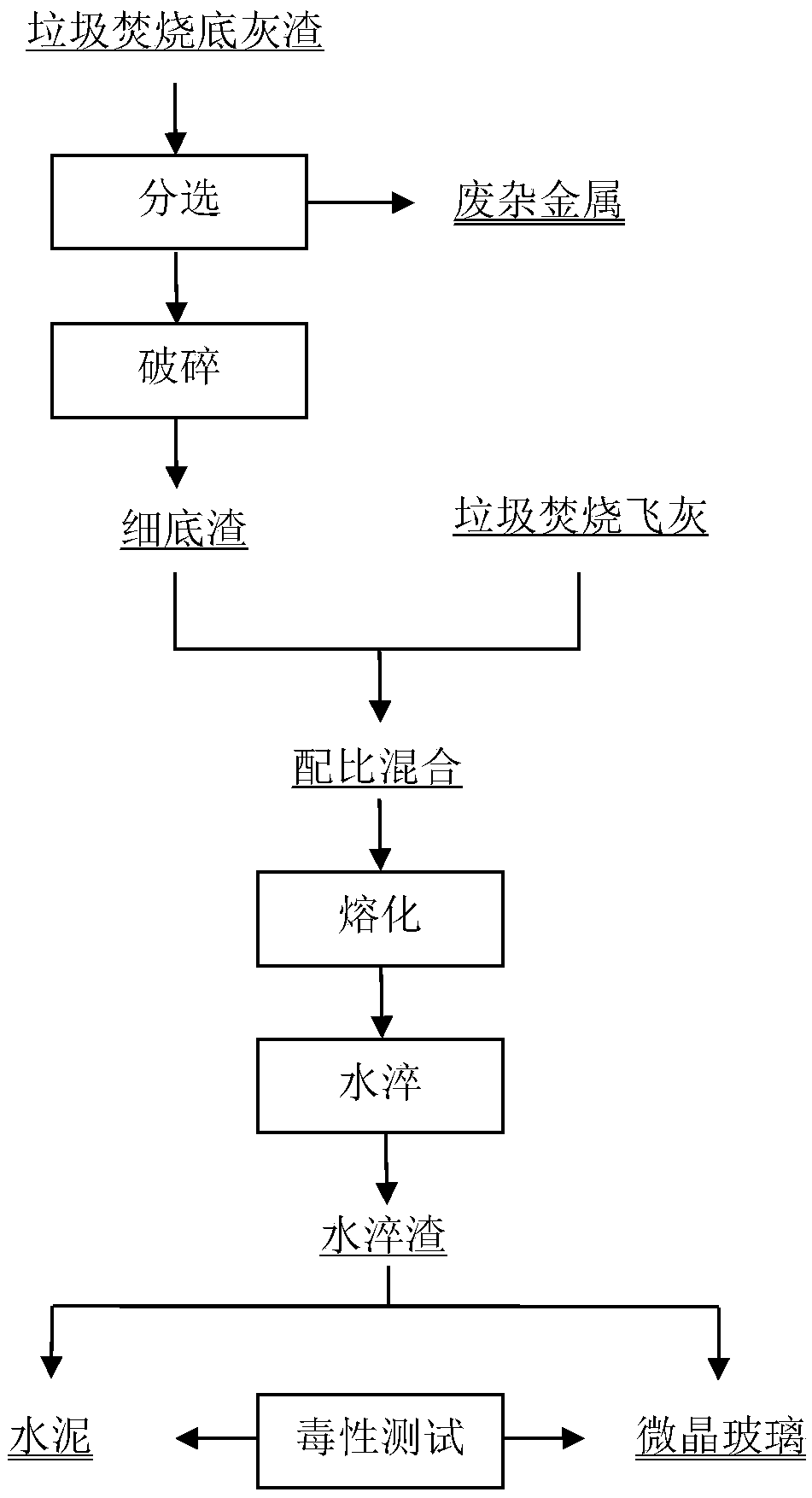

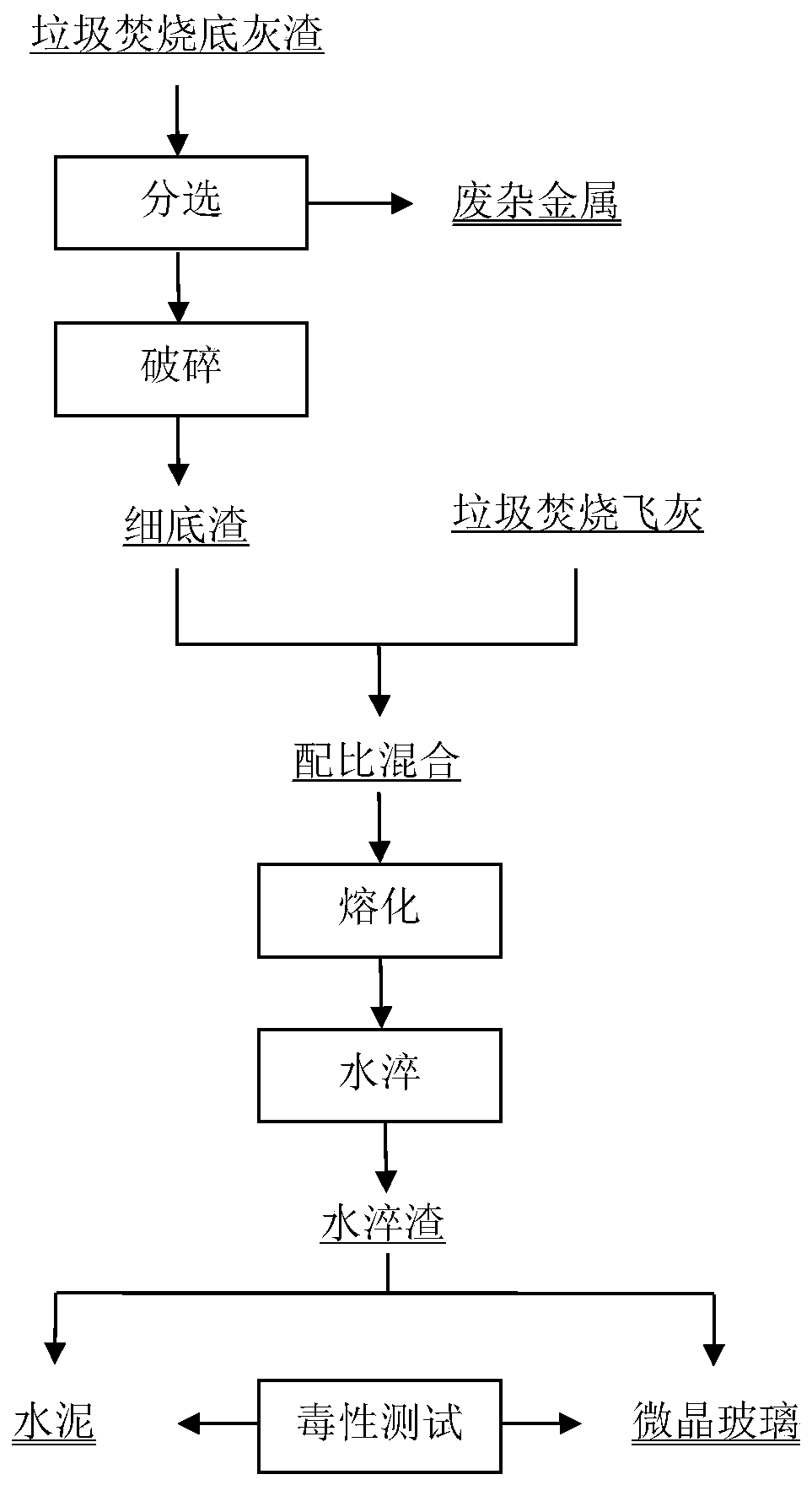

Garbage incineration ash slag heavy metal solidifying method

ActiveCN109516700AEnable co-processingReduce material consumptionCement productionProcess efficiency improvementResource utilizationSlag

The invention discloses a garbage incineration ash slag heavy metal solidifying method, and belongs to the field of solid waste disposal and resource utilization. The method comprises the following steps of obtaining waste sundry metal and fine bottom slag after sorting and crushing of the garbage incineration ash slag; using the waste sundry metal for metal regeneration; performing mixing, fusingand water quenching on the bottom fine slag with the garbage incineration ash slag; using the water quenching slag for cement and crystallized glass, wherein the heavy metal in the product is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The method provided by the invention has the advantages that the process is simple; the industrialization is easy; the goals of safely solidifying garbage incineration ash slag heavy metal and recycling the garbage incineration ash slag heavy metal for cement and crystallized glass can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

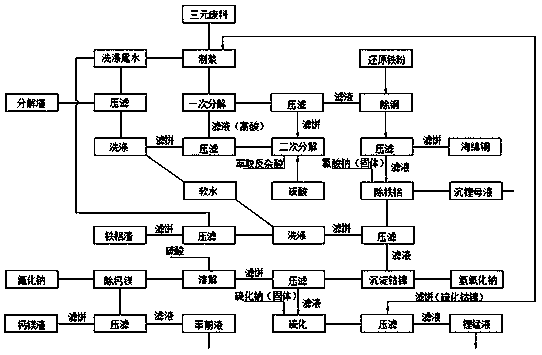

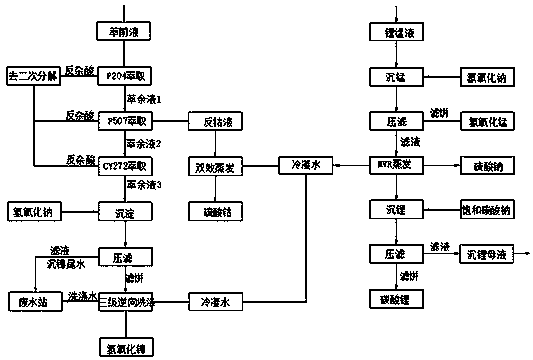

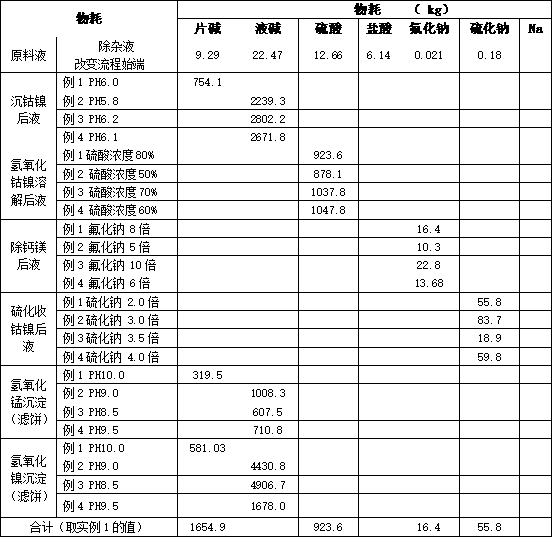

Novel method for comprehensively recovering cobalt, nickel, manganese and lithium elements from ternary battery waste

ActiveCN111092273AReduce recycling costsAvoid enteringWaste accumulators reclaimingProcess efficiency improvementManganeseNickel ions

The invention discloses a novel method for comprehensively recycling cobalt, nickel, manganese and lithium elements from ternary battery waste and relates to a recycling method of the battery waste. The method comprises steps of disassembling a waste ternary battery to obtain waste ternary battery powder, carrying out acid leaching, copper removal, iron and aluminum removal and the like to obtainimpurity removal solution, regulating a pH value of the impurity removal solution with sodium hydroxide, precipitating mixture of cobalt hydroxide and nickel hydroxide, vulcanizing and precipitating residual cobalt and nickel ions with sodium sulfide, separating manganese ions from cobalt and nickel ions, and directly precipitating manganese hydroxide to prevent manganese ions from entering the extraction process, dissolving the cobalt hydroxide and nickel hydroxide mixture with sulfuric acid, extracting to remove impurities, separating cobalt and nickel to obtain pure nickel sulfate solution,precipitating with sodium hydroxide, and reversely washing for three times to obtain a battery-grade nickel hydroxide product. The method is advantaged in that a problem of high recovery cost causedby the fact that the cobalt, nickel and manganese elements must be subjected to extraction and back extraction in the prior art is solved, by innovating a process route, most of manganese ions are separated and removed before extraction, nickel ions are not subjected to the full-extraction and full-reverse extraction process, and nickel hydroxide is directly precipitated only after the related impurities are removed by extraction. The method has advantages of simple process, reduction of material consumption and energy consumption and remarkable reduction of production cost.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

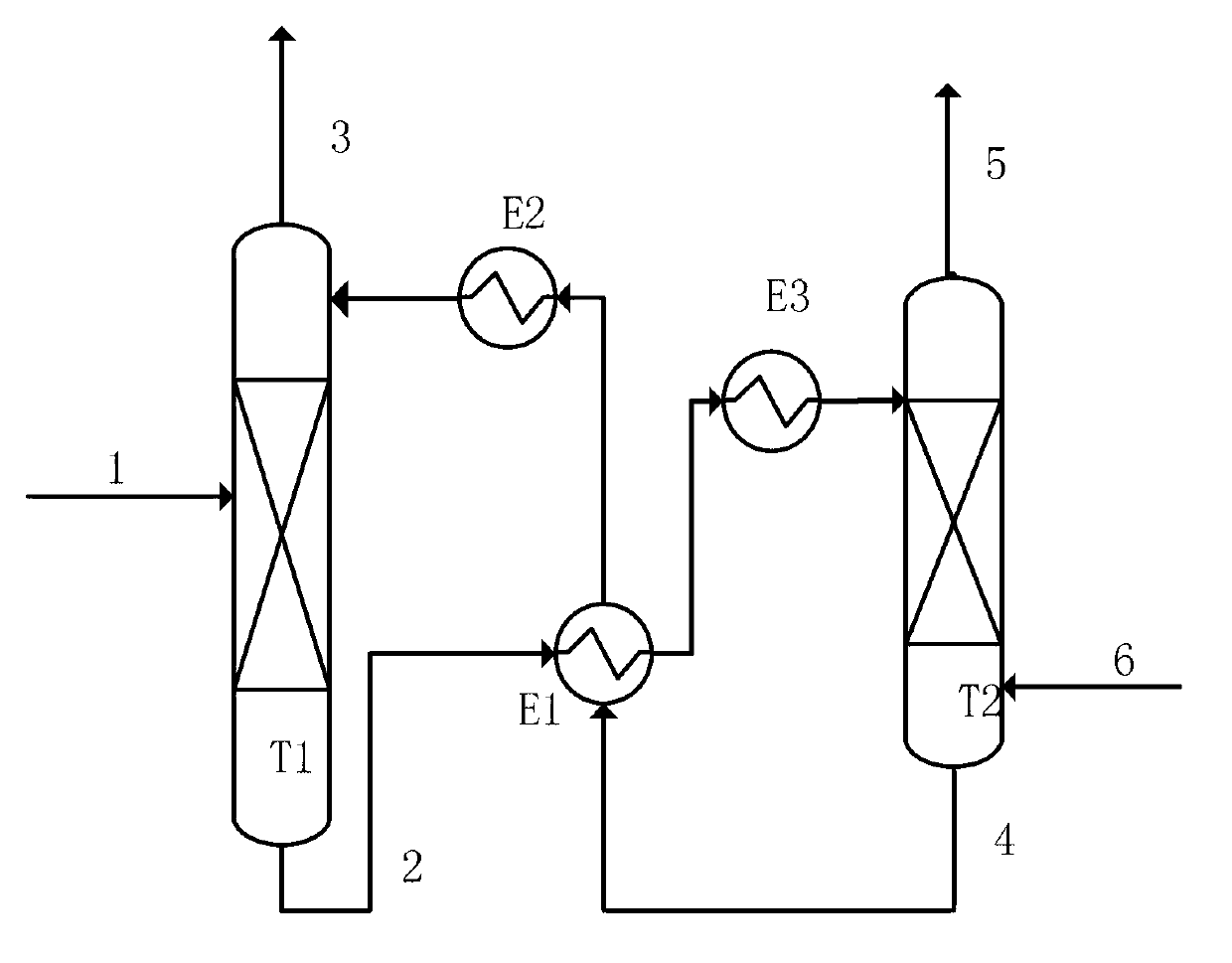

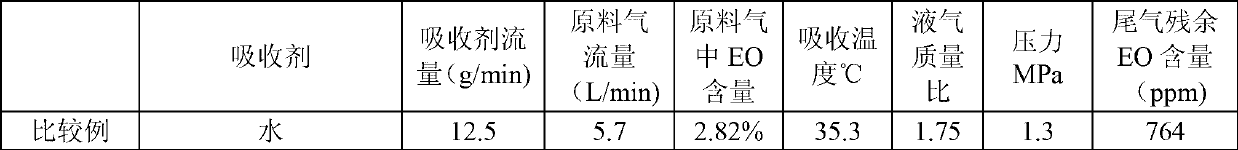

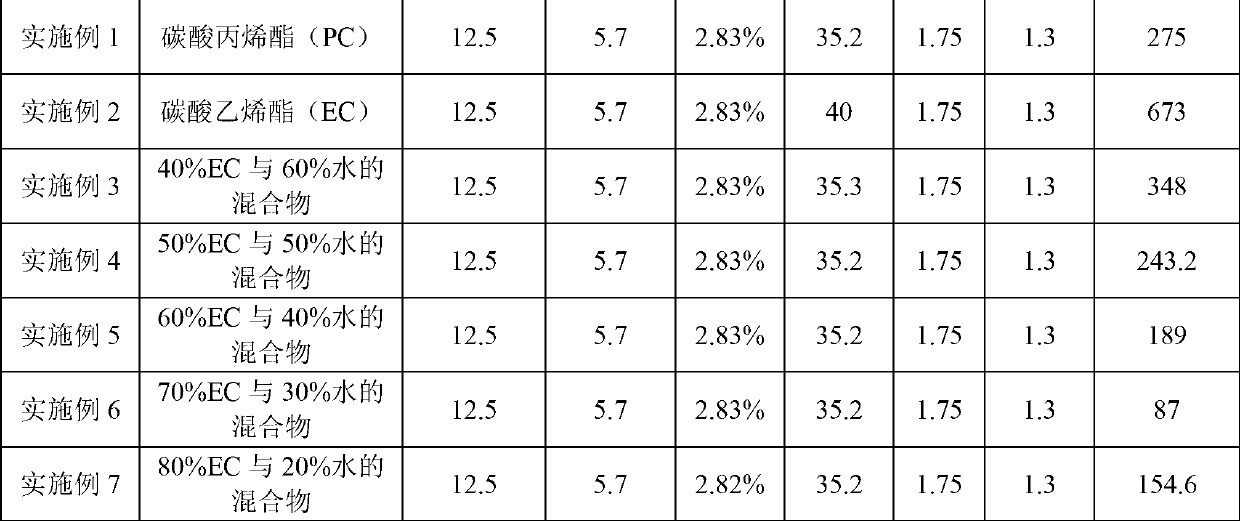

Method for separating and recovering EO (ethylene oxide) from direct oxidation products of ethylene

InactiveCN102911137APromote absorptionReduce residual EO contentOrganic chemistryWater vaporGas phase

The invention relates to a method for separating and recovering EO (ethylene oxide) from direct oxidation products of ethylene. The method comprises the following steps of: taking a mixed solvent of ethylene carbonate and water as an absorbing solvent, enabling the absorbing solvent to enter from a tower top of an absorption tower, introducing mixed raw material gas into the tower from a tower bottom of the absorption tower, enabling the mixed raw material gas to be in full contact with an EO-lean absorption solution in the absorption tower, enabling the EO in the mixed raw material gas to be absorbed by the EO-lean absorption solution and further enter a liquid phase, and exhausting absorption tail gas from the tower top; and enabling an EO-rich absorption solution at the tower bottom of the absorption tower to perform heat exchange and then enter the tower top of a stripping tower, stripping by taking steam or nitrogen as stripping gas, extracting a gas phase material flow from the tower top, cooling, then recovering, and enabling the EO-lean absorption solution to perform heat exchange with the EO-rich absorption solution after stripping at the tower bottom and then return to the tower top of the absorption tower so as to be recycled as an absorbent. According to the method disclosed by the invention, the absorbing ability of the absorbent against the EO can be greatly improved, the residual EO content in the absorption tail gas can be reduced, the elasticity and safety in the operation of devices can be increased, the material consumption and the energy consumption can be effectively reduced, and the benefits are significant.

Owner:CHINA PETROLEUM & CHEM CORP

Method for coproduction of dicumyl peroxide (DCP) and epoxybutane (CHPBO)

ActiveCN104774168AShort processReduce material consumption and energy consumptionOrganic compound preparationPeroxy compound preparationChemistryDicumyl peroxide

The invention relates to a method for coproduction of dicumyl peroxide (DCP) and epoxybutane (CHPBO) to mainly solve the problems that the method in the prior art is long in flow, low in CHP conversion rate and low in BO selectivity, consumes a reducing agent and hydrogen, and discharges sulfur-containing wastewater. The invention adopts the technical scheme that the method for coproduction of DCP and epoxybutane (CHPBO) adopts the technical means of oxidation reaction, epoxidation reaction, condensation reaction and the like to realize efficient coupling of industrialized DCP and BO processes, wherein the CHP conversion rate reaches 97.2-99.7%, the BO selectivity reaches 95.7-99.2%, and the consumption of sulfide and hydrogen and the discharge of the sulfur-containing wastewater are avoided, so that the problems are well solved. The method can be used for production of DCP and epoxybutane.

Owner:SINOPEC SHANGHAI ENG +1

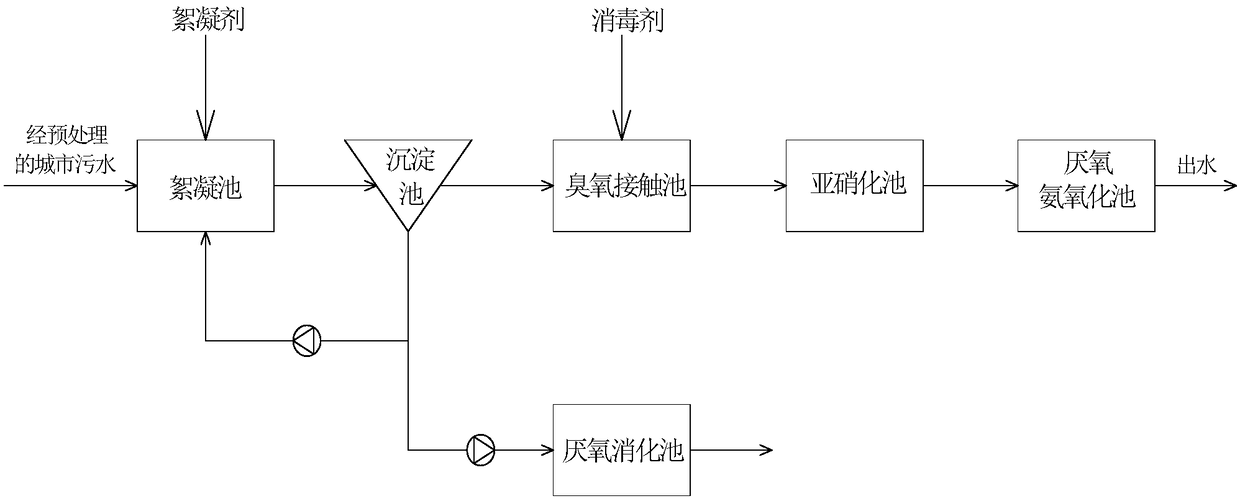

Efficient municipal sewage denitrification technology taking nitrosation-anaerobic ammonia oxidation as core

ActiveCN108483821AReduce adverse effectsNitrosation stableWater contaminantsTreatment with anaerobic digestion processesTotal nitrogenNitrosation

The invention relates to an efficient municipal sewage denitrification technology taking nitrosation-anaerobic ammonia oxidation as a core. The technology comprises the following steps: S1, carrying out pre-treatment on sewage by adopting a biochemical flocculation technology unit to remove almost organic matters, SS (Suspended Substance) and TP (Total Phosphorus) in the sewage, reducing a carbon-nitrogen ratio, controlling the OHO total amount in a system and realizing separation of the sewage and sludge; S2, carrying out sterilization treatment on the sewage which is discharged through the pre-treatment through an ozone disinfection technology unit; synchronously treating the sludge which is discharged through the pre-treatment through a sludge anaerobic digestion unit; S3, treating sewage subjected to the sterilization treatment through a nitrosation technology unit, and converting part of ammonia nitrogen in the sewage into nitrite nitrogen; S4, carrying out tail-end denitrification treatment on wastewater, which is treated through the nitrosation technology unit, through an anaerobic ammonia oxidation technology unit so as to enable TN (Total Nitrogen) of output water can stably reach first-grade A standards. The efficient municipal sewage denitrification technology provided by the invention has the advantages of good water quality of the output water, easiness for controlling operation, stability and high efficiency.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

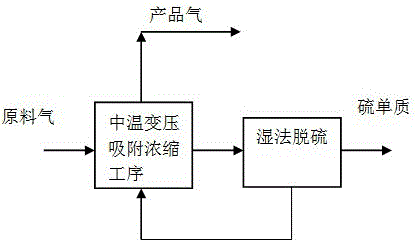

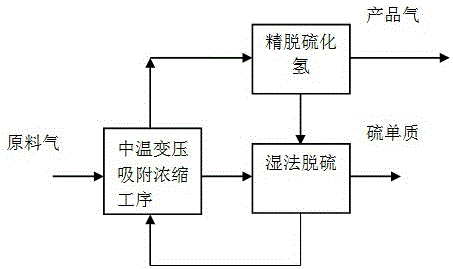

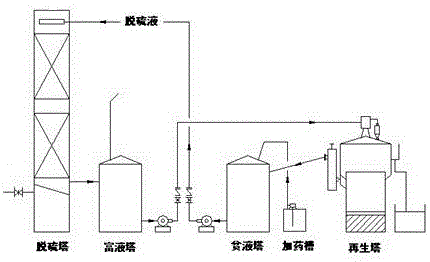

Full-temperature-range pressure-swing adsorption method for removing hydrogen sulfide from hydrogen rich gas source

ActiveCN105858604AReduce loadReduce material consumption and energy consumptionHydrogen separation by selective and reversible uptakeSulfur preparation/purificationSodium carbonateChemistry

The invention discloses a full-temperature-range pressure-swing adsorption method for removing hydrogen sulfide from a hydrogen rich gas source and relates to the technical field of gas desulfurization and purification. According to the technical scheme of the invention, after the full-temperature-range pressure-swing adsorption and concentration process, most of H2S in hydrogen rich gas are removed, and then remaining H2S in hydrogen rich gas can be continuously and deeply removed through selecting the pressure-swing adsorption method or the one-time adsorption method. After that, the H2S-enriched desorbed gas is directly fed into a desulfurization and sulfur-production device, and the gas amount of the above gas is reduced by 80% compared with the gas amount of raw materials. Meanwhile, the circulation volume of the desulfurizing liquid is reduced, and the energy consumption of a machine pump is reduced at the same time. The desulfurization and sulfur-production device can adopt the sodium carbonate desulfurizing and sulfur-producing process or the Claus process, and H2S in the H2S-enriched desorbed gas is removed to be about 100 ppm. Elemental sulfur foams produced during the desulfurizing process are made into sulphur by means of a sulfur retrieving device.

Owner:SICHUAN TECHAIRS

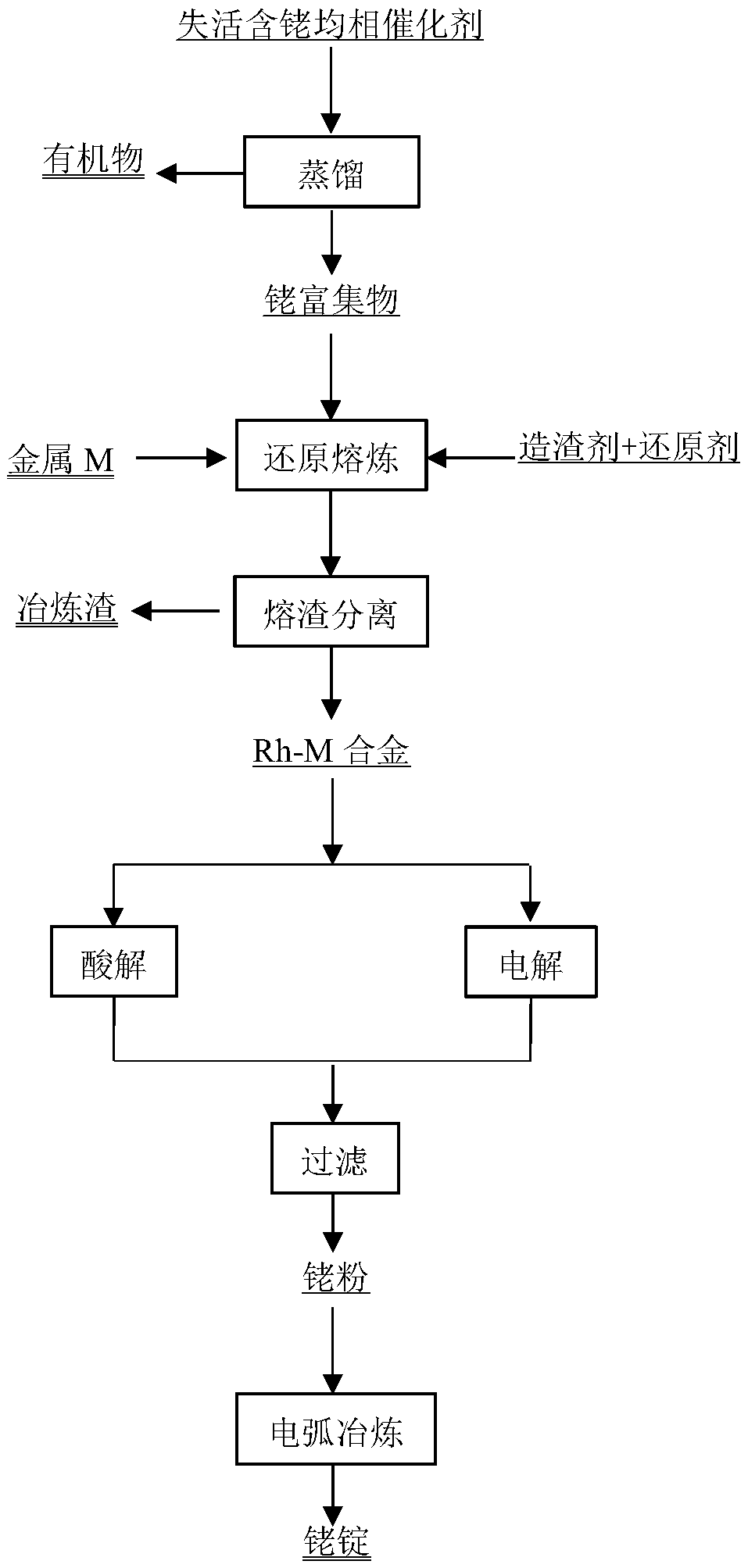

Method for recovering rhodium from inactive rhodium-containing homogeneous catalyst

ActiveCN108950233AAvoid pollutionHigh reactivityPhotography auxillary processesProcess efficiency improvementElectrolysisElectric arc furnace

The invention mainly belongs to the technical field of rhodium recovery and particularly relates to a method for recovering rhodium from an inactive rhodium-containing homogeneous catalyst. The methodcomprises the following steps that organic matter in the rhodium-containing homogeneous catalyst is recovered in a distillation mode at first, and rhodium concentrate is obtained; then the rhodium concentrate is mixed with transitional metal M, a reduction agent and a slag former, rhodium is recovered in a smelting manner and forms a low-melting-point Rh-M alloy together with the transitional metal M, then the Rh-M alloy is subjected to electrolysis or acidolysis to obtain rhodium powder, finally the rhodium powder is smelted through an electric-arc furnace, and accordingly a rhodium ingot isobtained. The method is suitable for various inactive rhodium-containing homogeneous catalysts, the situation that the organic matter is directly incinerated to cause air pollution is avoided, meanwhile, the high-melting-point rhodium can be converted into the low-melting-point high-reactivity Rh-M alloy, and subsequent rhodium smelting and purification are facilitated. The method has the advantages of being high in rhodium recovery rate and production efficiency, free of pollution and suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

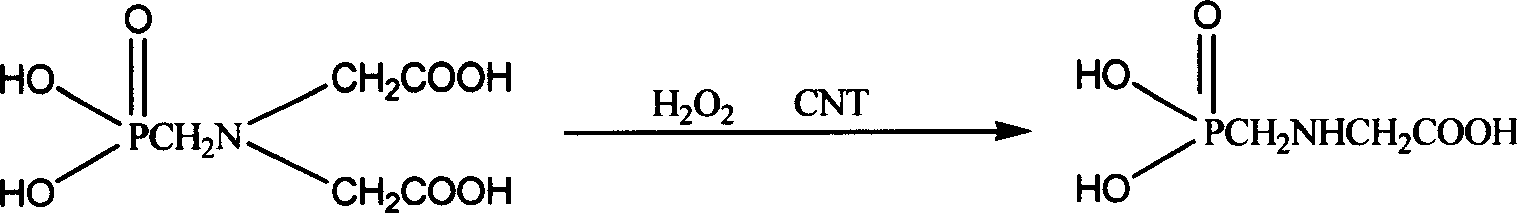

Method for preparing glyphosate by catalytic oxidation method

This invention discloses a method for oxidizing N-(carboxymethyl)-N-(phosphonomethyl)-glycine into glyphosate by using carbon nanotubes or modified nanotubes as a novel catalyst. The method has such advantages as high reaction selectivity, no need for reductant such as ferrous sulfate or sodium sulfite, repeated use of the catalyst, high product yield, high product quality, and little mother liquor. The method can avoid the problems of low solid glyphosate yield, low quality and large wastewater discharge faced by sodium tungstate-ferrous sulfate method.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

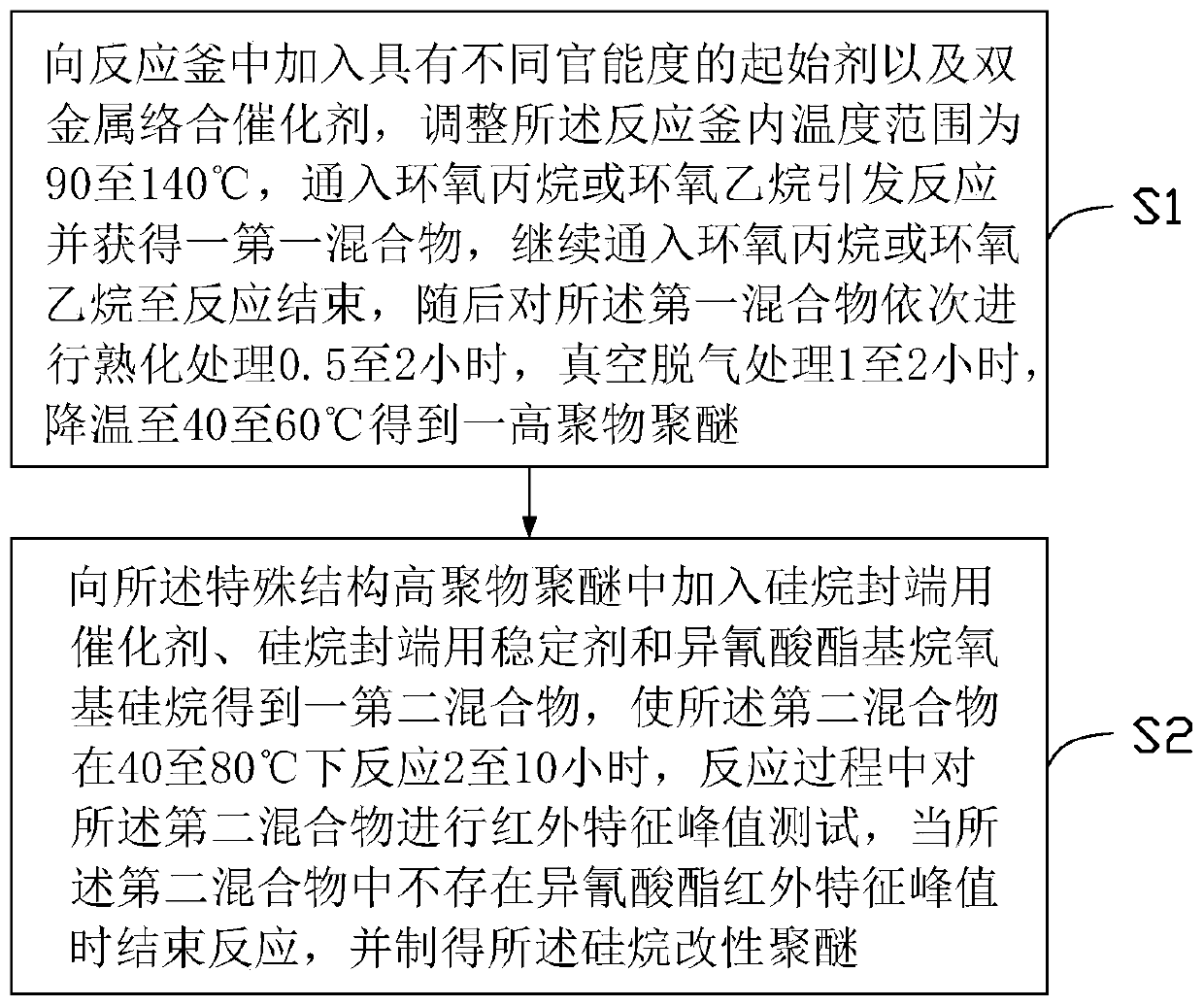

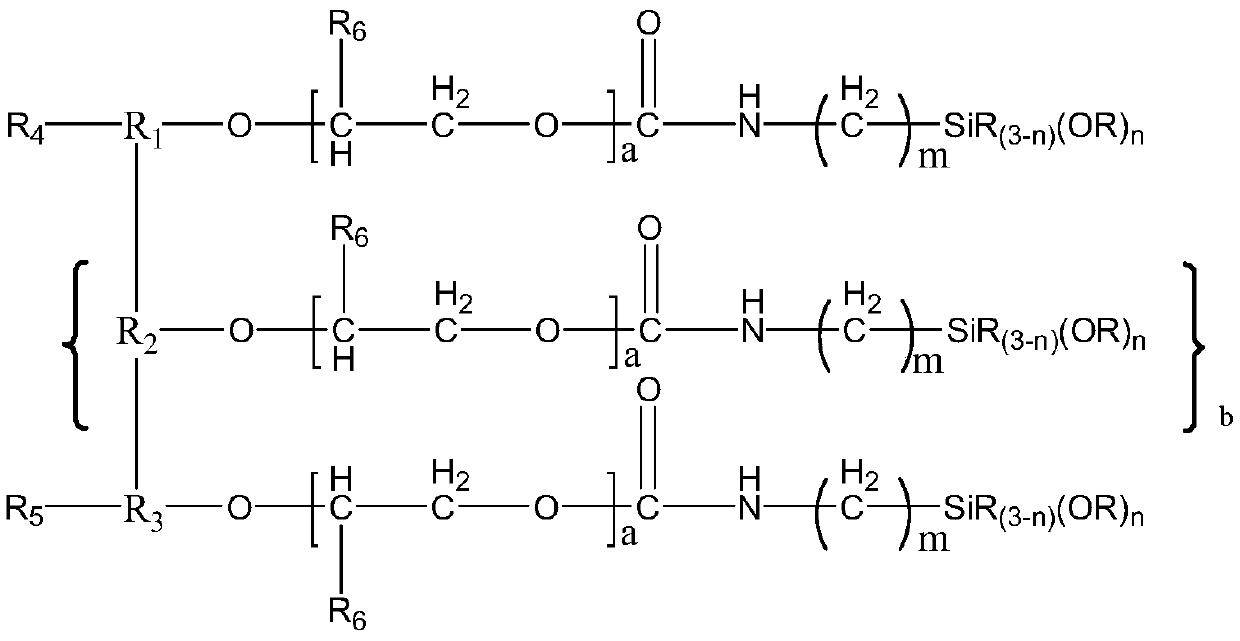

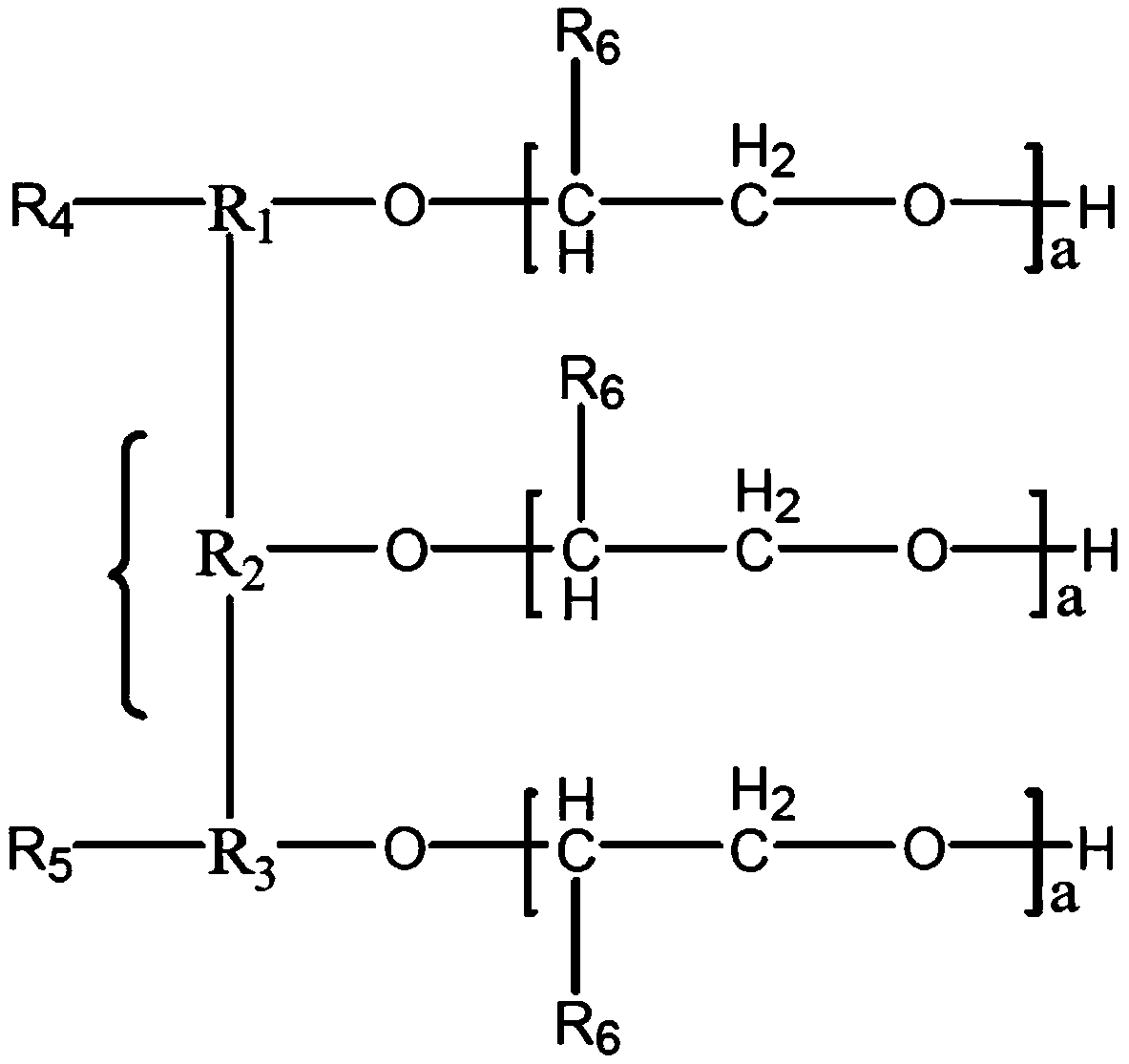

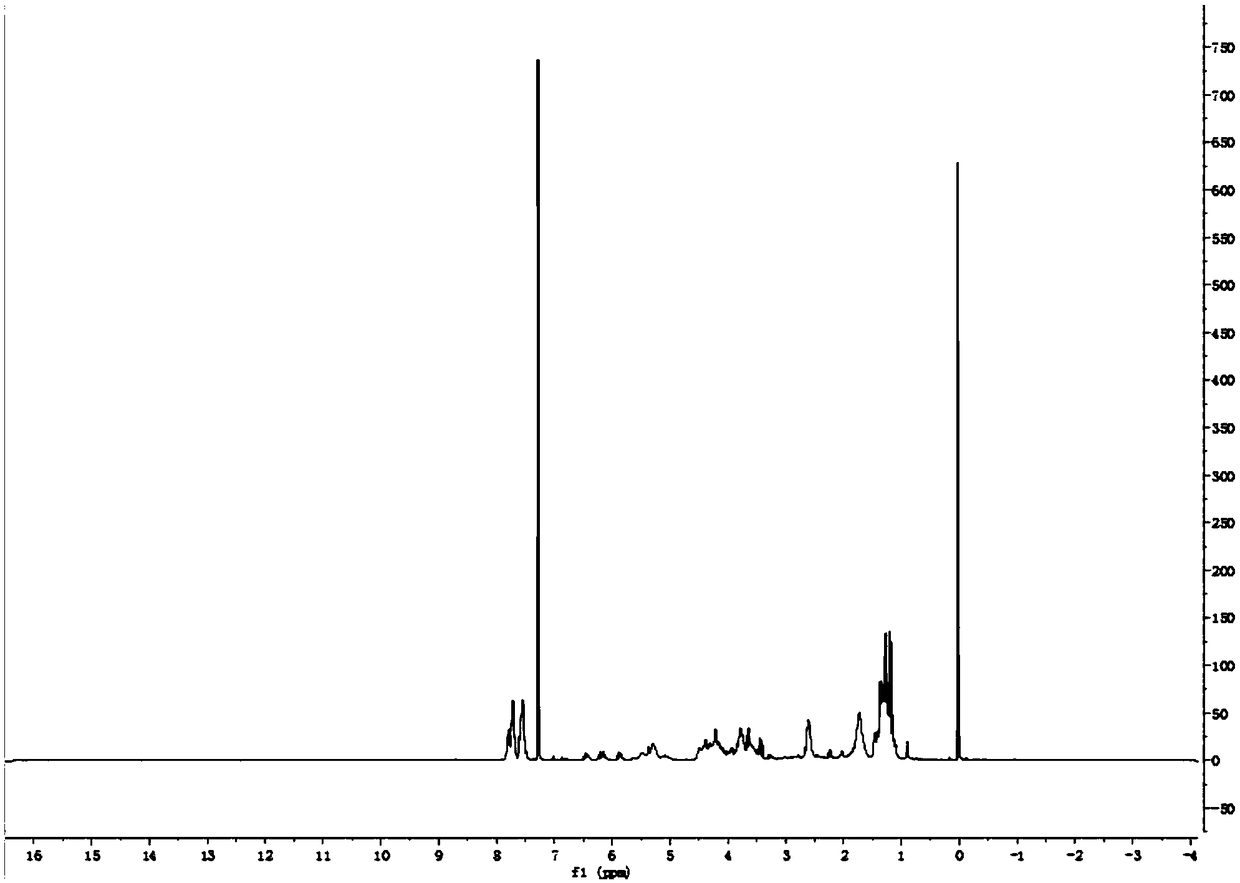

Silane modified polyether as well as preparation method and application thereof

The invention provides a preparation method of silane modified polyether. The preparation method comprises the following steps: adding a thermometal complexing catalyst and initiators with different functionality degrees into a reaction kettle, adjusting the temperature ranging from 90 DEG C to 140 DEG C in the reaction kettle, and introducing epoxypropane or ethylene oxide to initialize a reaction so as to obtain a first mixture; introducing epoxypropane or ethylene oxide till the reaction is completed, performing aging treatment on the first mixture for 0.5-2 hours, performing vacuum degassing for 1-2 hours, and performing cooling to 40-60 DEG C so as to obtain high polymer polyether of a special structure; adding a catalyst for silane termination, a stabilizer for silane termination andisocyanate group alkoxy silane into the polymer polyether of the special structure so as to obtain a second mixture, performing a reaction on the second mixture at 40-80 DEG C for 2-10 hours, collecting a sample of the second mixture in the reaction period, performing infrared characteristic peak testing on the sample, and terminating the reaction when detecting that there is no infrared characteristic peak, so as to obtain the silane modified polyether. The invention further provides the silane modified polyether and application thereof.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

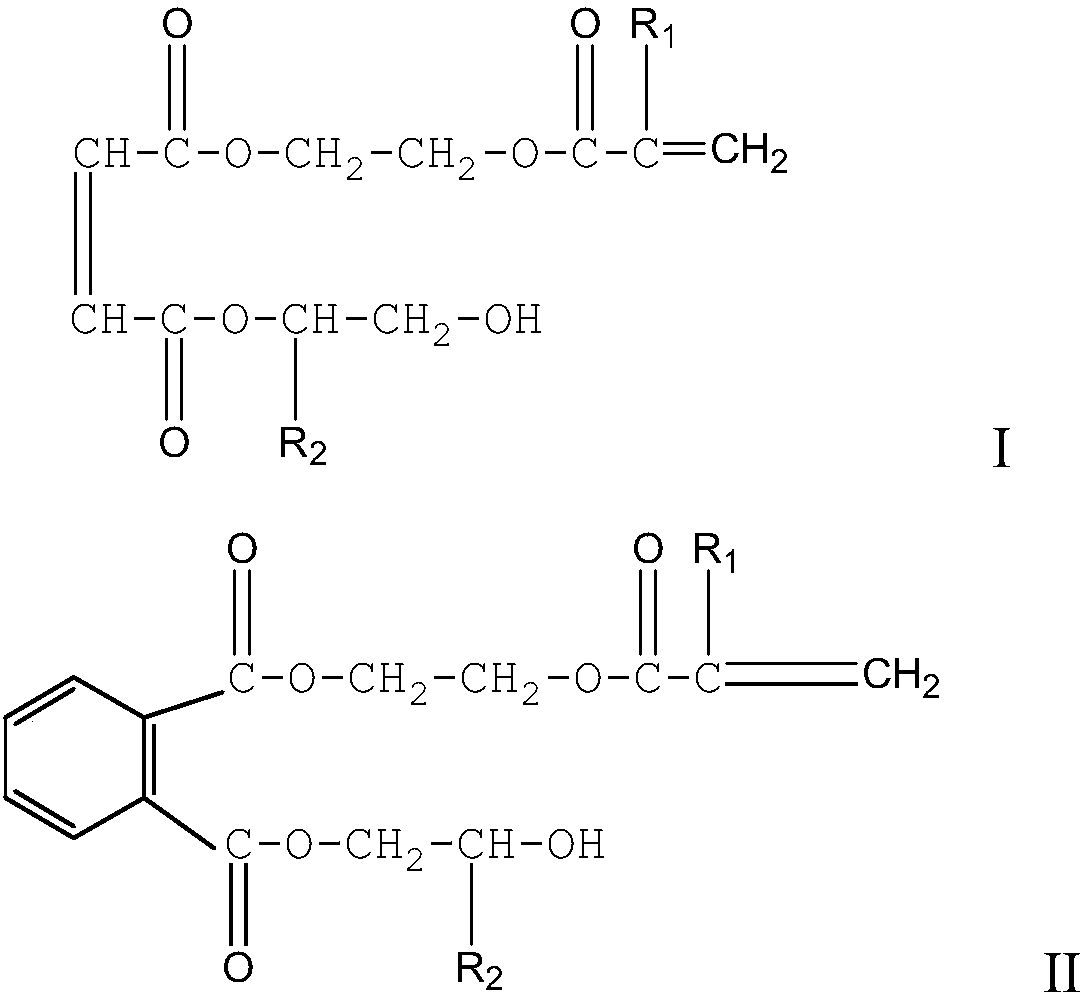

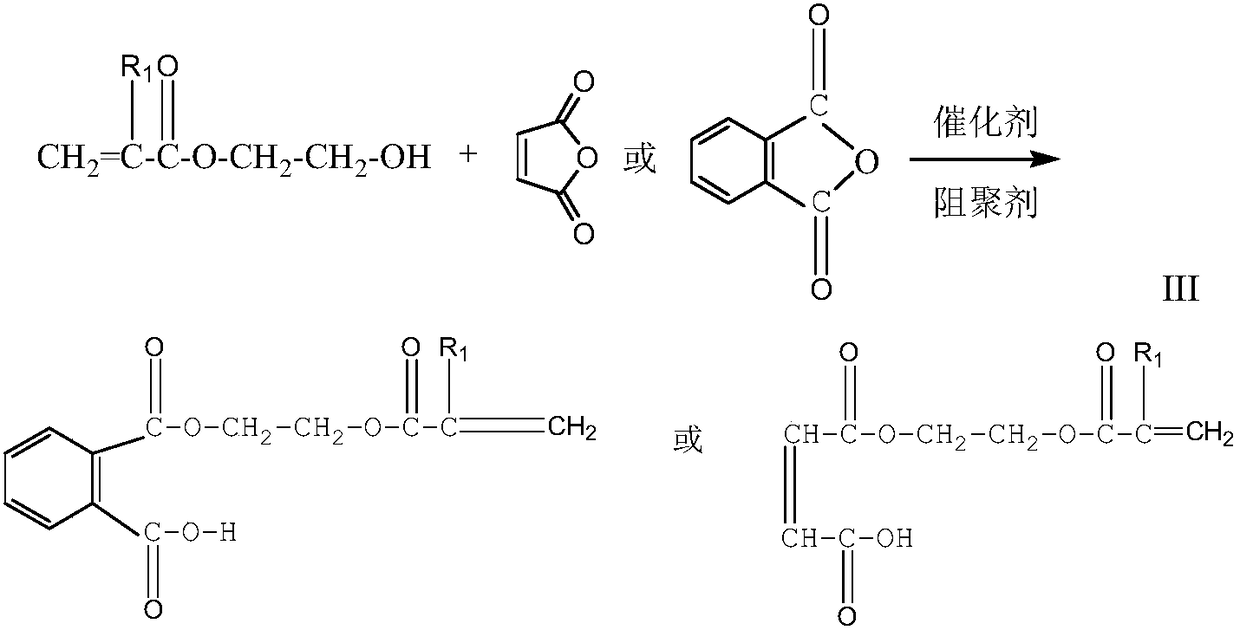

Acrylate based hydroxyalkyl acid ester reactive diluent and preparation method and application thereof

InactiveCN109180480AFast curingPracticalOrganic compound preparationCarboxylic acid esters preparationHalogenUV curing

The invention discloses an acrylate based hydroxyalkyl acid ester reactive diluent and a preparation method and an application thereof. The preparation method of the acrylate based hydroxyalkyl acid ester reactive diluent comprises an esterification reaction and an alkoxylation reaction. The preparation method specifically comprises the following steps: carrying out the esterification reaction onanhydride and a raw material containing hydroxyl acrylate; and then carrying out the alkoxylation reaction with ethylene oxide and propylene oxide to prepare a target product. The acrylate based hydroxyalkyl acid ester reactive diluent provided by the invention is a novel green compound, is used as a novel UV curing coating reactive diluent, is free of halogen, non-toxic and non-irritant, high incuring speed, high in practicality and superior to a common acrylate monomer in aspects, and is stable in preparation process, mild in reaction condition, simple to operate, free of post treatment steps, free of three waste discharge and green and environment-friendly.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

A method for solidifying heavy metals in waste incineration ash

ActiveCN109516700BEnable co-processingReduce material consumptionCement productionProcess efficiency improvementSlagProcess engineering

The invention discloses a garbage incineration ash slag heavy metal solidifying method, and belongs to the field of solid waste disposal and resource utilization. The method comprises the following steps of obtaining waste sundry metal and fine bottom slag after sorting and crushing of the garbage incineration ash slag; using the waste sundry metal for metal regeneration; performing mixing, fusingand water quenching on the bottom fine slag with the garbage incineration ash slag; using the water quenching slag for cement and crystallized glass, wherein the heavy metal in the product is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The method provided by the invention has the advantages that the process is simple; the industrialization is easy; the goals of safely solidifying garbage incineration ash slag heavy metal and recycling the garbage incineration ash slag heavy metal for cement and crystallized glass can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

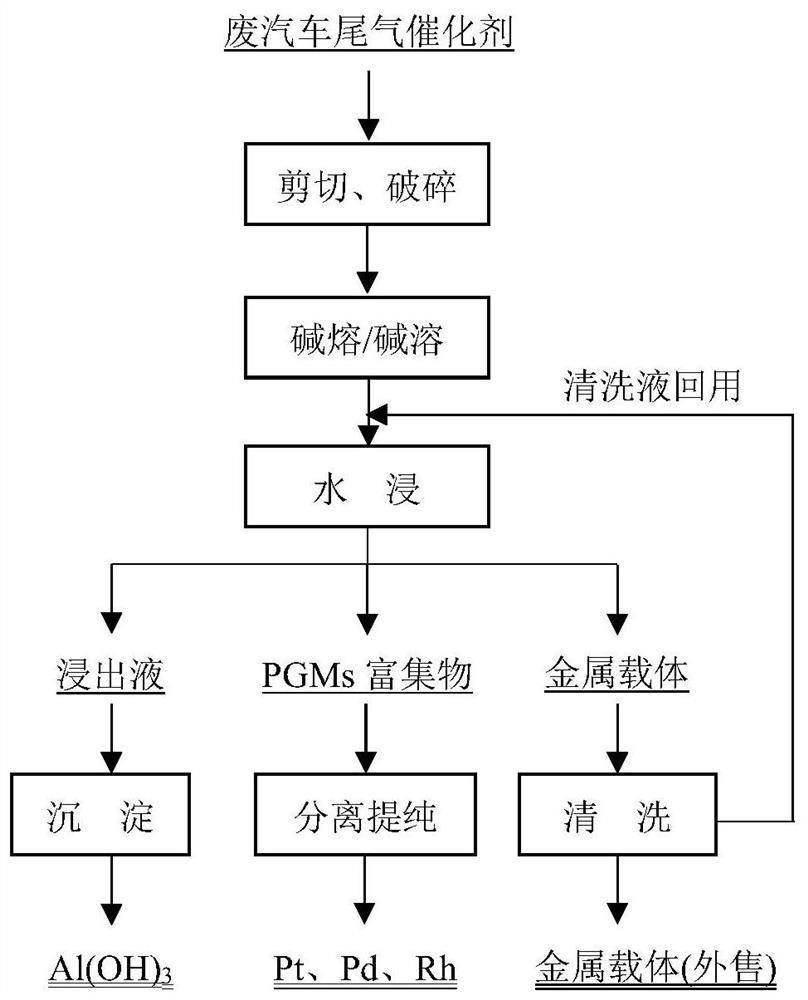

Method for recovering platinum group metals from metal carrier waste automobile exhaust catalyst

ActiveCN113293301ARealize resource utilizationEfficient separationProcess efficiency improvementPtru catalystPhysical chemistry

The invention relates to the technical field of recovery of platinum group metals (PGMs), and provides a method for recovering platinum group metals from a metal carrier waste automobile exhaust catalyst. The method comprises the following steps: crushing and shearing the metal carrier waste automobile exhaust catalyst into sheets; then carrying out alkali fusion or alkali dissolution on the sheet-shaped waste catalyst to selectively dissolve an Al2O3 coating; achieving efficient separation of a metal carrier, PGMs and the Al2O3 coating; washing the sheet-shaped metal carrier for sale; and separating and purifying PGMs enrichment to obtain Pt, Pd and Rh products with the purity being 99.99% or above. The method realizes efficient recovery of PGMs without dissolving a carrier, has the characteristics of low material and energy consumption, high recovery rate of PGMs, low cost and the like, and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation device and preparation method for super high-speed sealed spiral flow field graphene nanosheets

PendingCN109502576AReduce material consumption and energy consumptionHighlight technical advantages and vitalityGrapheneEngineeringGraphene nanoplatelet

The invention relates to a preparation device and a preparation method for super high-speed sealed spiral flow field graphene nanosheets. The dust-free pretreatment of raw materials is realized by a powder suction type premixing device; a stripping device adopting a sealed spiral flow field design acts materials moving in the stripping device according to the spiral flow field by using the hydraulic (laminar flow, turbulence and hole) effect produced by super high-speed rotation, thereby damaging Vanderwals force among graphene sheets and realizing stripping of the graphene nanosheets; the graphene nanosheets with different thicknesses and sizes are obtained by using a settling device and a centrifugal separation device. The related technologies and devices break through the technical bottleneck of the current high-quality and low-cost preparation field of graphene. The preparation device and the preparation method can realize the production with low pollution, high quality, multiple specifications and customization, and have outstanding technical advantages and vitality.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Preparation method of m-methanesulfonamide

ActiveCN109096152ARapid responseLess by-productsSulfonic acid amide preparationSurface-active agentsMagnesium

The invention discloses a preparation method of m-methanesulfonamide. The preparation method is characterized in that methylsufonyl chloride is dropwise added into a suspension of an optionally proportioned mixture acid-binding agent of m-phenylenediamine, a surface active agent, superfine calcium carbonate or magnesium carbonate or superfine calcium carbonate and magnesium carbonate with the meangrain size of 1 micron or below and water, low-temperature adding is performed, heat insulation is performed after adding, heating and heat insulation are performed, and cooling, filtration and the like are performed to obtain the m-methanesulfonamide. Calcium chloride wastewater or magnesium chloride wastewater or mixed wastewater of calcium chloride and magnesium chloride produced by the process reacts with sodium carbonate in the presence of polyethylene glycol to obtain a superfine acid-binding agent required by the process, and resources are fully utilized. By adding and jointly using the superfine acid-binding agent and the surface active agent, the product yield and quality are obviously improved. Compared with a traditional process, the method has the advantages of being quick, uniform and complete in reaction, producing by-products, simplifying operation, improving the yield and quality, decreasing the three wastes and the like and has good industrial prospect.

Owner:LEPING SAFELY PHARMA

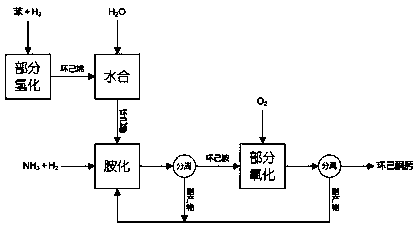

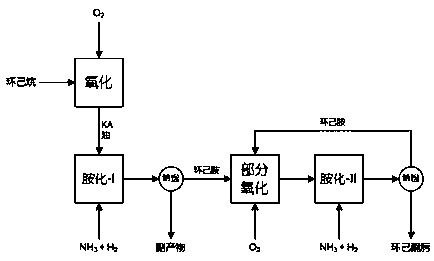

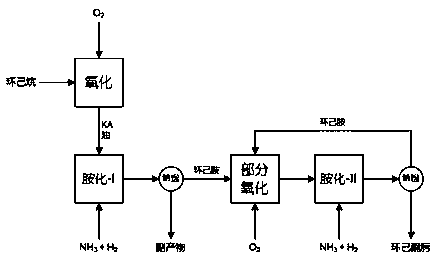

Preparation method of cyclohexanone-oxime

ActiveCN111153831AHigh yieldAvoid consumptionOrganic compound preparationPreparation by reductive alkylationPtru catalystPartial oxidation

The invention relates to a preparation method of cyclohexanone-oxime, which mainly comprises the following steps: (1) oxidizing cyclohexane and molecular oxygen under the action of a solid catalyst, carrying out one-step reaction to generate KA oil, and performing separation to obtain the KA oil; (2) directly aminating the KA oil with ammonia and hydrogen under the action of a solid catalyst to generate cyclohexylamine and a small amount of byproduct-A, and performing separation to obtain cyclohexylamine; (3) carrying out partial oxidation on cyclohexylamine and molecular oxygen under the action of a solid catalyst to obtain an oxidation product mainly composed of cyclohexanone-oxime, a small amount of byproduct-B and cyclohexylamine which may not be completely converted; and (4) aminatingthe oxidation product, namely, directly carrying out amination reaction on the oxidation product obtained in the step (3), ammonia and hydrogen under the action of a solid catalyst without separation, converting the byproduct-B into cyclohexylamine, and performing separation to obtain cyclohexanone-oxime. The method is short in technological process, small in occupied area and investment, low incost and environmentally friendly.

Owner:XIANGTAN UNIV

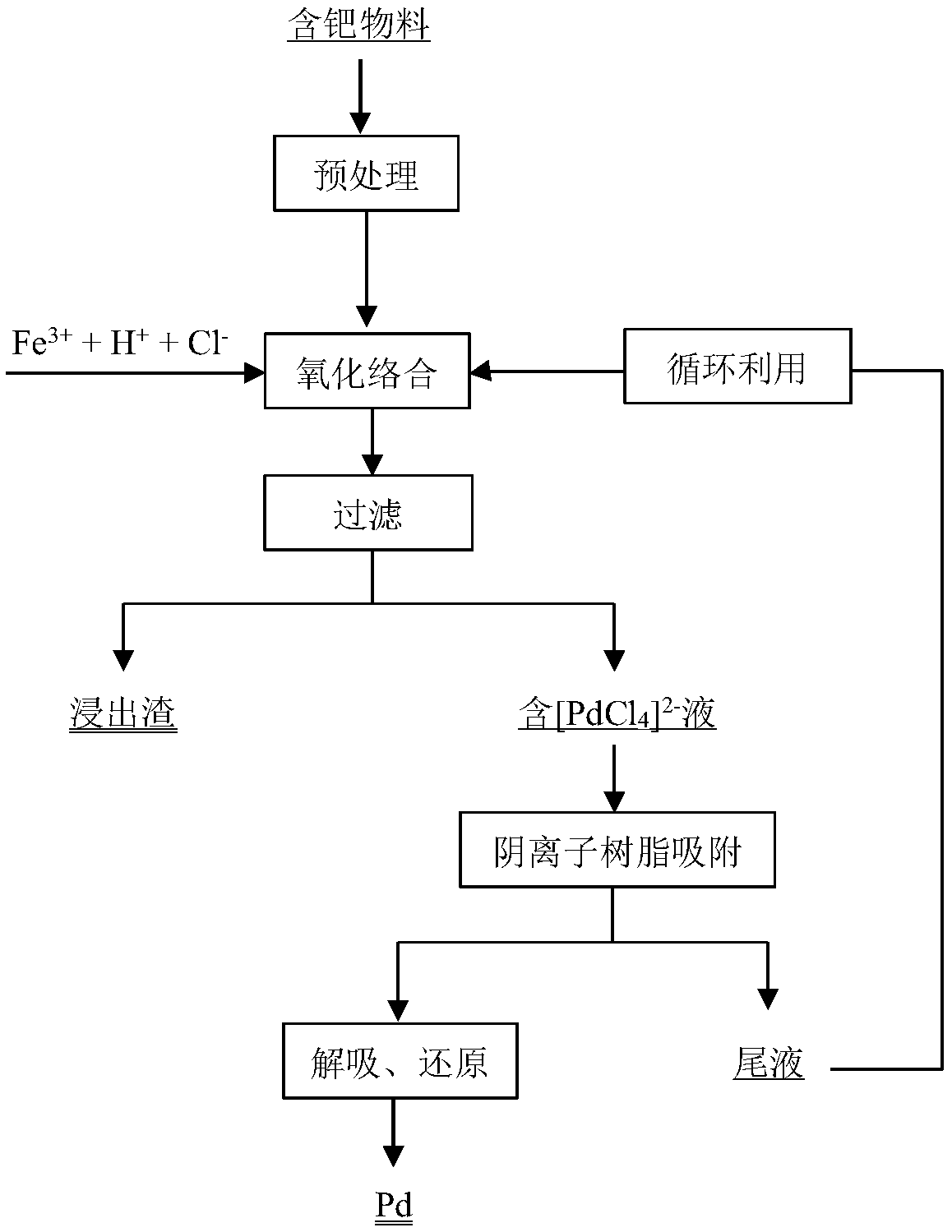

Method for environment-friendly recovery of palladium from palladium-containing waste

The invention mainly belongs to the field of secondary precious metal, and relates to a method for environment-friendly recovery of palladium from palladium-containing waste. The method comprises thesteps that the palladium-containing waste is subjected to pre-treatment such as ball grinding, calcination, reduction and distillation, palladium is oxidized in an acid system with Fe3+ as an oxidizing agent, and combined with chloride ions to enter a liquid phase, leachate selectively adsorbs [PdCl4]2 through anion exchange resin, elemental palladium is obtained in desorption and reduction modes,and Fe2+ is oxidized into Fe3+ for recycling. According to the method, the environment-friendly pollution-free Fe3+ oxidizing agent is adopted, palladium is adsorbed through the anion resin, tail liquid is recycled, and the method has the advantages of economical efficiency, environment friendliness, energy saving, emission reduction and the like and is suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

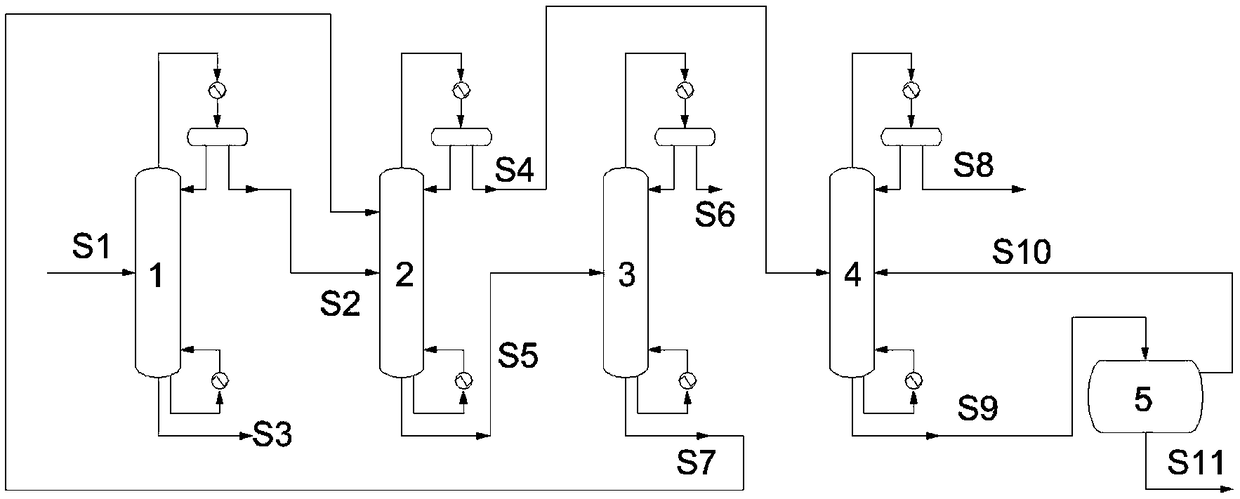

Rectification system capable of recovering epoxypropane raffinate and working process of rectification system

The invention discloses a rectification system capable of recovering epoxypropane raffinate and a working process of the rectification system. The rectification system comprises a heavy component removal tower, an extraction rectification tower, a solvent recovery tower, an azeotropic rectification tower and a phase splitting tank. By means of the operation manner of combining three operation manners including pretreatment, extraction rectification and azeotropic rectification, through reasonable selection of an extraction agent and an entrainer, a high-purity epoxypropane product is obtainedwith the rectification method, a process of impurity removal with a chemical method is omitted, equipment investment is reduced, operation difficulty is simplified, and meanwhile, material loss of epoxypropane in a reaction link is avoided, and the yield of epoxypropane is increased. In addition, the extraction agent and the entrainer can be recycled, and material consumption of the whole processis lower.

Owner:雅邦新材料研发南京有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com