Method for separating methyl acetate and methanol water solution through multistage cross flow liquid-liquid extraction

A methanol aqueous solution, methyl acetate technology, applied in chemical instruments and methods, carboxylate preparation, organic compound preparation and other directions, can solve the problems of complex process technology, high energy consumption, large waste water discharge, etc., achieve high purity, The effect of low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

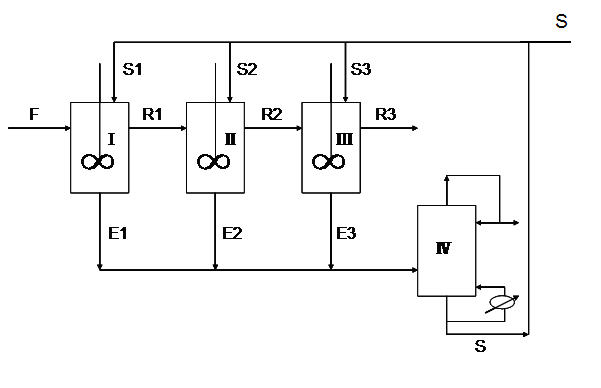

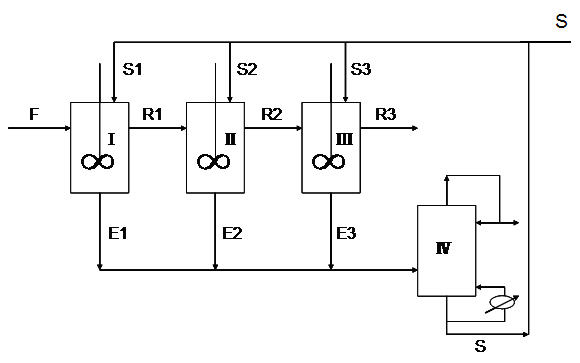

[0019] refer to figure 1 The process flow shown, using 3-stage cross-flow liquid-liquid extraction to separate methyl acetate and methanol aqueous solution, raw material is 20kg methyl acetate and methanol aqueous solution (containing 84% methyl acetate, 14% methanol and <1% water), extractant S is a mixed solvent of ethylene glycol and water, wherein the ratio of ethylene glycol: water is 1:0.25, and the dosage of each stage of extractant S1~S3 is 20kg respectively.

[0020] Under normal temperature conditions, press figure 1 As shown in the process flow, the raw material F or the raffinate phase R1, R2 enters the extractors I, II, and III in sequence, and is fully stirred with the extraction agent ethylene glycol and water mixed solvent, and the layers are left to separate, and the extraction phase (E1~E3) and The raffinate phase (R1~R3) reaches equilibrium in each stage of extractor. The process conditions that the extractor adopts in the separation process are shown in T...

Embodiment 2

[0028] It is basically the same as Example 1, except that the amount of extractants S1-S3 is 30, 20 and 10 kg respectively.

Embodiment 3

[0030] It is basically the same as in Example 1, except that the polyhydric alcohol in the extractant is changed to propylene glycol, and it is subjected to 4-stage cross-flow extraction. The amount of extractant for each stage is 20kg, in which propylene glycol: water is 1:0.25. After four-stage cross-flow liquid-liquid extraction of methyl acetate and methanol aqueous solution, propylene glycol is not included in the raffinate phase, the mass percentage of methyl acetate reaches 99.70%, and the yield reaches 97.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com