Efficient municipal sewage denitrification technology taking nitrosation-anaerobic ammonia oxidation as core

A technology for anaerobic ammonium oxidation and urban sewage, which is applied in the high-efficiency denitrification process of urban sewage and in the field of urban sewage treatment. It can solve the problems of difficult implementation, low concentration, system collapse, etc., and achieve low control difficulty, high denitrification efficiency, The effect of low material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

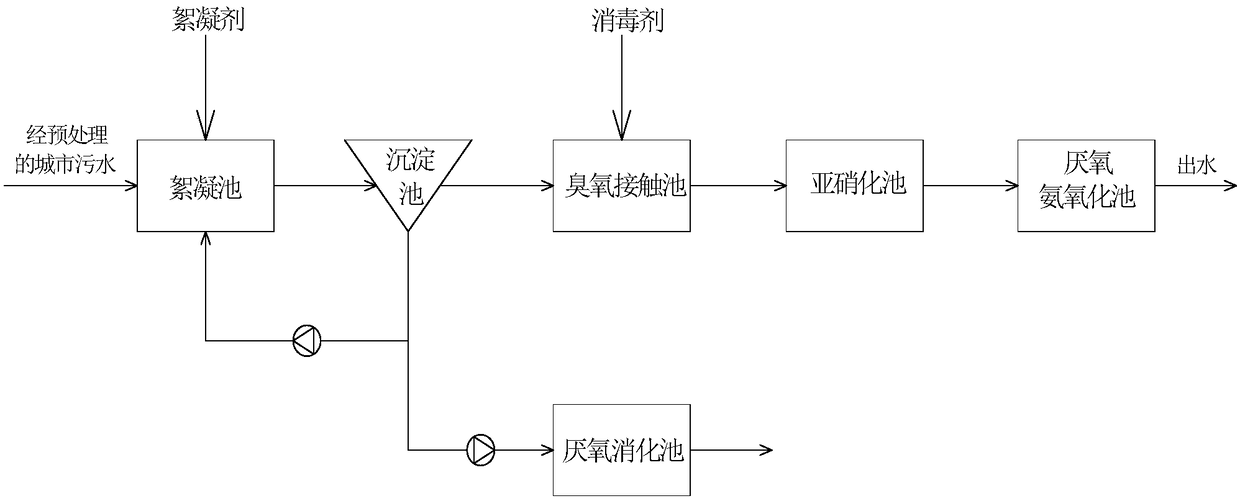

[0026] A high-efficiency denitrification process for urban sewage with nitrosation-ANAMMOX as the core, please refer to figure 1 The process features are as follows: firstly, the biochemical flocculation process unit is used to pre-treat the sewage, remove most of the organic matter, SS and TP in the sewage, reduce the carbon-nitrogen ratio, control the total amount of OHO in the system, and realize the separation of sewage and sludge ; Then the sewage discharged from the pretreatment is sterilized by the ozone disinfection process unit, and the sludge discharged from the pretreatment is treated by the sludge anaerobic digestion unit simultaneously; then the sewage after the sterilized treatment is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com