Preparation method and device of methyl tertiary-butyl ether (MTBE)

A technology of methyl tert-butyl ether and tert-butanol, which is applied in the direction of ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, ether separation/purification, etc. It can solve the problem of affecting the reaction balance and not considering the azeotropic problem of tert-butanol, etc. problems, to achieve the effect of increasing conversion rate, reducing equipment investment, and reducing material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

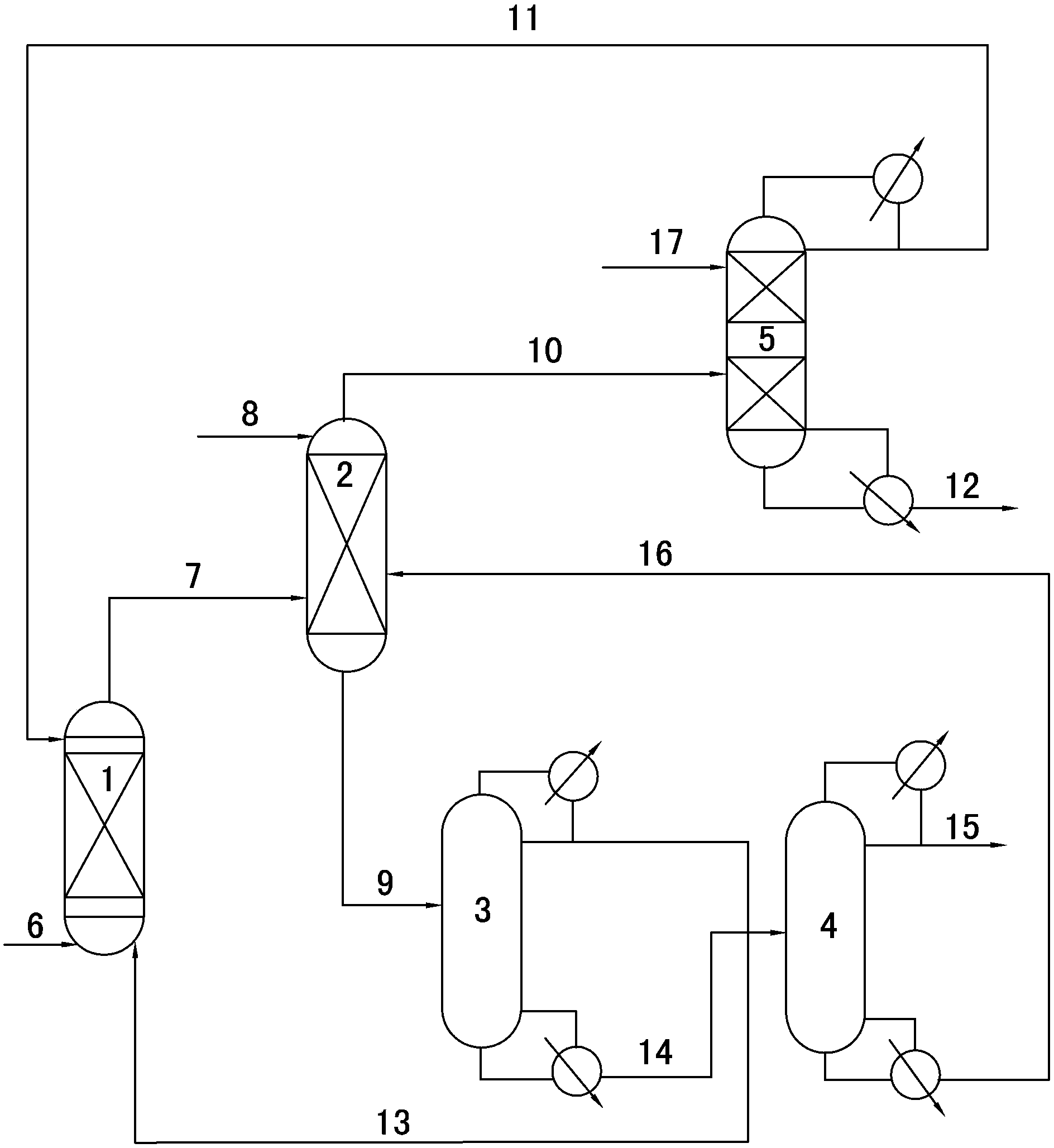

Image

Examples

Embodiment 1-3

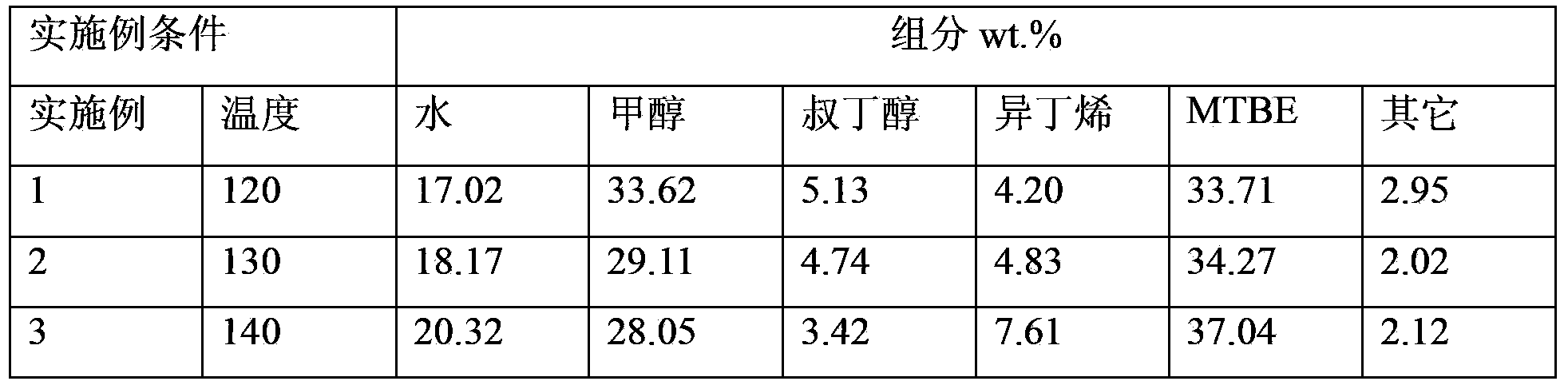

[0046] The components of the outlet product obtained under the different temperatures of the fixed-bed reactor are shown in Table 1, and the pressure is 1.5MPa:

[0047] Fixed-bed reactor reaction result table under different temperatures of table 1

[0048]

Embodiment 4-6

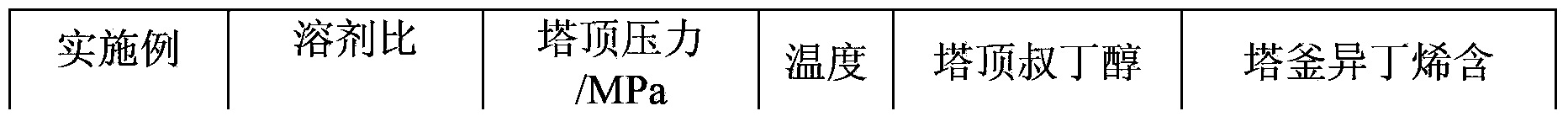

[0050] The gas phase form of the reaction product of the fixed reactor of Example 3 is fed from the middle of the extraction tower, and the extractant ethylene glycol is injected into the tower from the upper part of the extraction tower in liquid phase. The extraction results are shown in Table 2.

[0051] Table 2 Extraction Tower Data Sheet

[0052]

[0053]

Embodiment 5

[0055] The extraction tower bottom material of embodiment 5 enters the first extractant recovery tower, and the extraction tower bottom material is composed of methanol, tert-butanol, ethylene glycol, MTBE, and water.

[0056] The pressure at the top of the first extraction agent recovery tower is normal pressure, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 100°C. The rest of the operating conditions and analysis data Table 3 are as follows:

[0057] Table 3 The operating conditions and analysis results of the first extractant recovery tower

[0058] Example Reflux ratio Tank pressure / MPa Tower kettle tert-butanol content% Ethylene glycol content at the top of the tower, % 7 1 0.1 0.003 0.008 8 2 0.1 - - 9 3 0.1 - -

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com