Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Claus process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Claus process is the most significant gas desulfurizing process, recovering elemental sulfur from gaseous hydrogen sulfide. First patented in 1883 by the chemist Carl Friedrich Claus, the Claus process has become the industry standard. C. F. Claus was born in Kassel in the German State of Hessen in 1827, and studied chemistry in Marburg before he emigrated to England in 1852. Claus died in London in the year 1900.

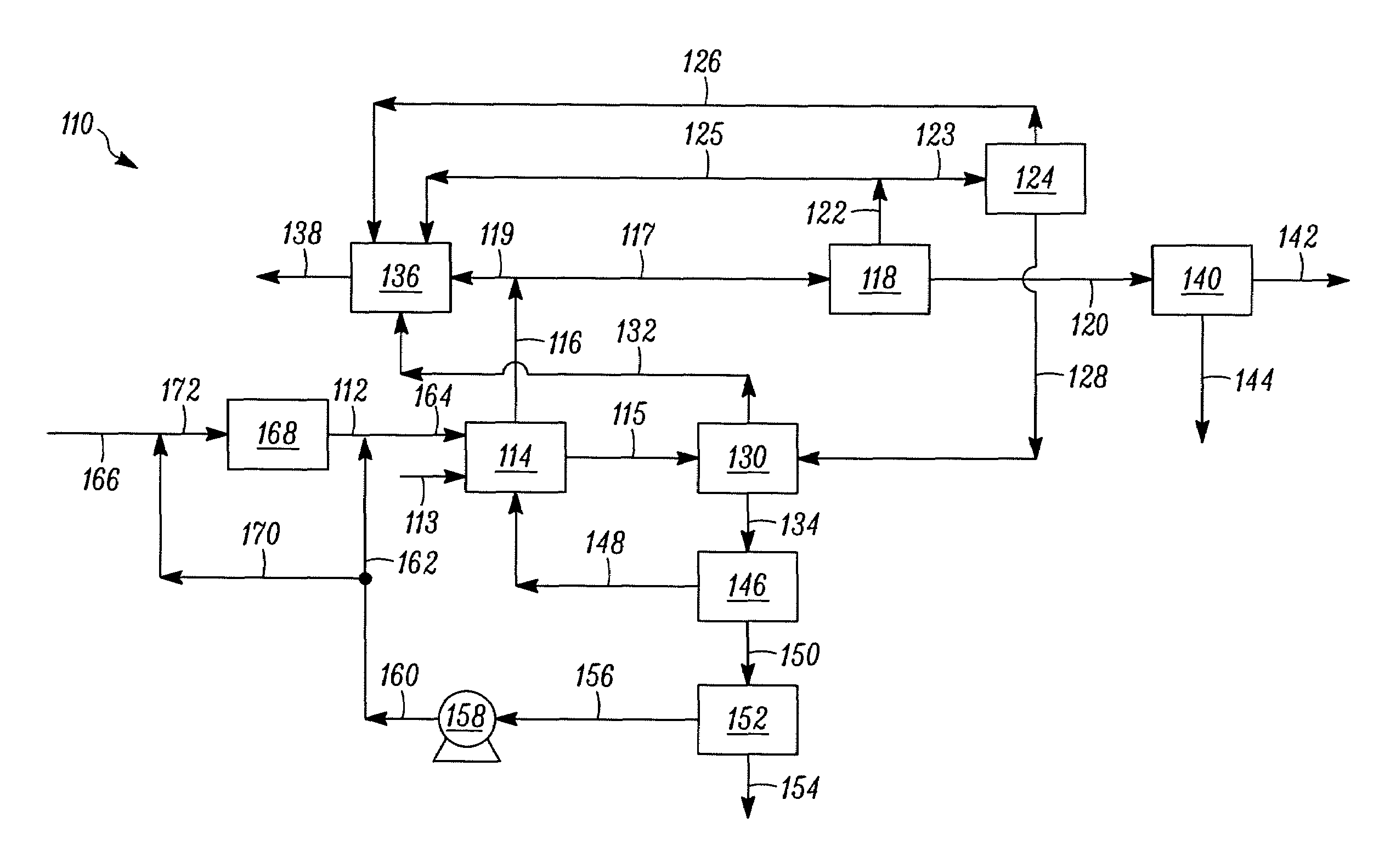

Integrated separation and purification process

InactiveUS7637984B2Improved arrangementSimple processGas treatmentCarbon compoundsMostly TrueSelexol

Increasing the economic and environmental compatibility in treatment processes in sour gas production. For 25 yr, Mobil Erdgas Erdoel GmbH (MEEG) has been treating considerable amounts of sour gas in N. Germany. In 9 fields with different gas qualities, there are ca 30 producing wells. The main processes of the sour gas production and treatment are described. The gas is dried at the well site and if the reservoir pressure is not sufficient, compressed for transportation to the central processing facility. In most cases the use of sulfur solvents is necessary at the wells. Natural gas scrubbers for the total removal of hydrogen sulfide and Claus units with downstream units to obtain sulfur are utilized. To increase the environmental compatibility and economics, a number of secondary processes have been introduced for emission control; glycol stripping; and the Purisol, Selexol, Sulfinol, and Claus processes.

Owner:UOP LLC

Method for treating claus technical tail gas

InactiveCN102847431ATake advantage ofReduce the burden onSulfur compoundsDispersed particle separationDesorptionCatalytic oxidation

The invention provides a method for treating claus technical tail gas. The method comprises the following steps of: continuously feeding the claus technical tail gas containing sulfur dioxide, oxygen and water into a reactor filled with a multihole carbon desulfurizing agent; generating catalytic oxidation reaction between the sulfur dioxide and the water in the tail gas on the surface of multihole carbon at the reaction temperature between 30 and 150 DEG C; and continuously introducing regenerative detergent into the reactor. By the method, adsorption, catalytic oxidation and desorption are synchronously carried out on low-concentration sulfur-containing waste gas in the claus technical tail gas which is difficult to treat; oxygen and water in the tail gas can be fully used; under the condition that oxygen is not required to be swelled and the water is not required to be compensated, standard discharging can be realized and sulfur resources can be recycled; an obtained by-product is dilute sulphuric acid which can be directly used in industrial production or used in the industrial production after being concentrated; the multihole carbon desulfurizing agent is low in cost and long in service life and can be recycled; the technical flow is simple, and the investment is low; and the running cost is competitive.

Owner:BEIJING FUNGHAN ENG CONSULTING

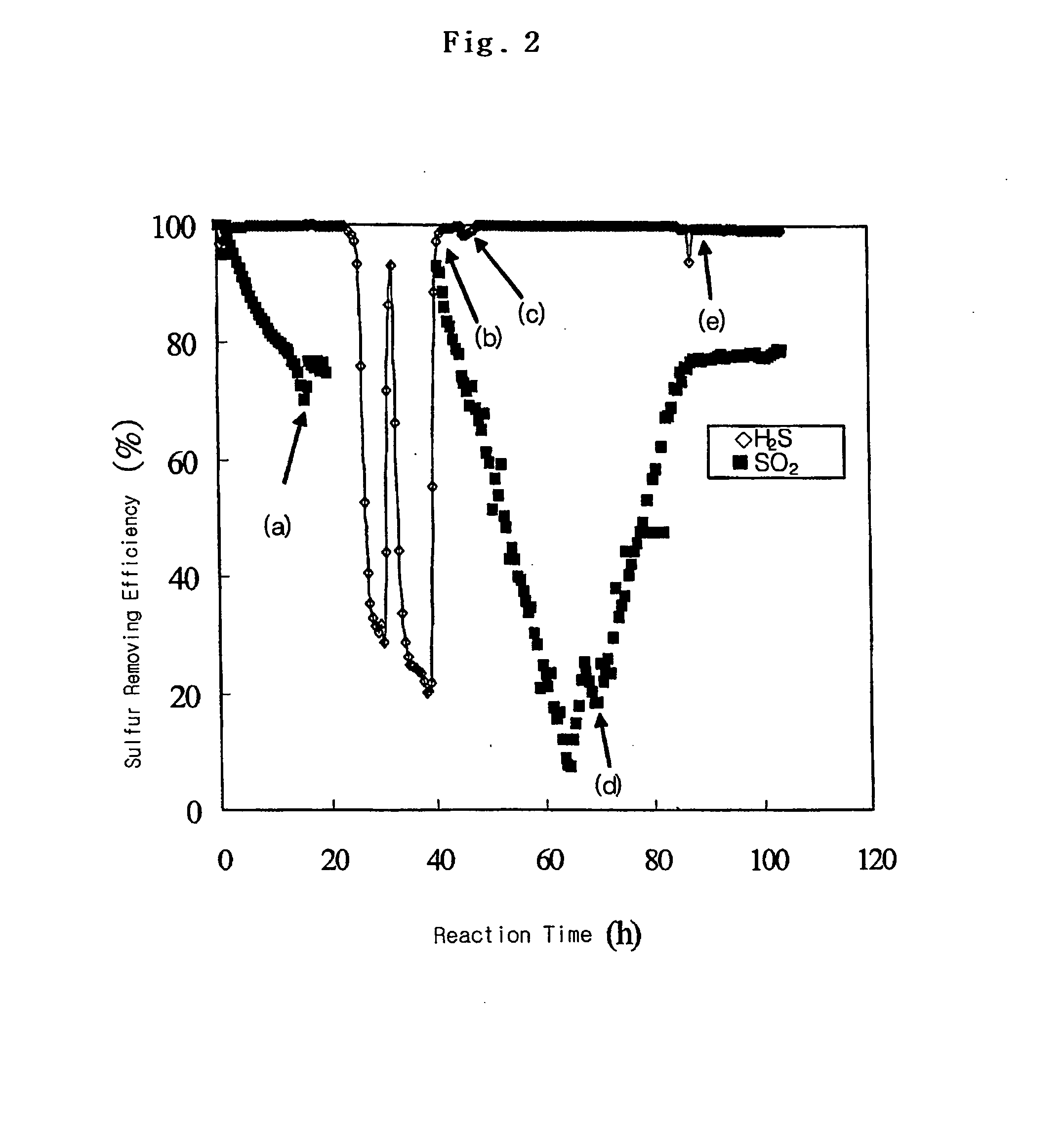

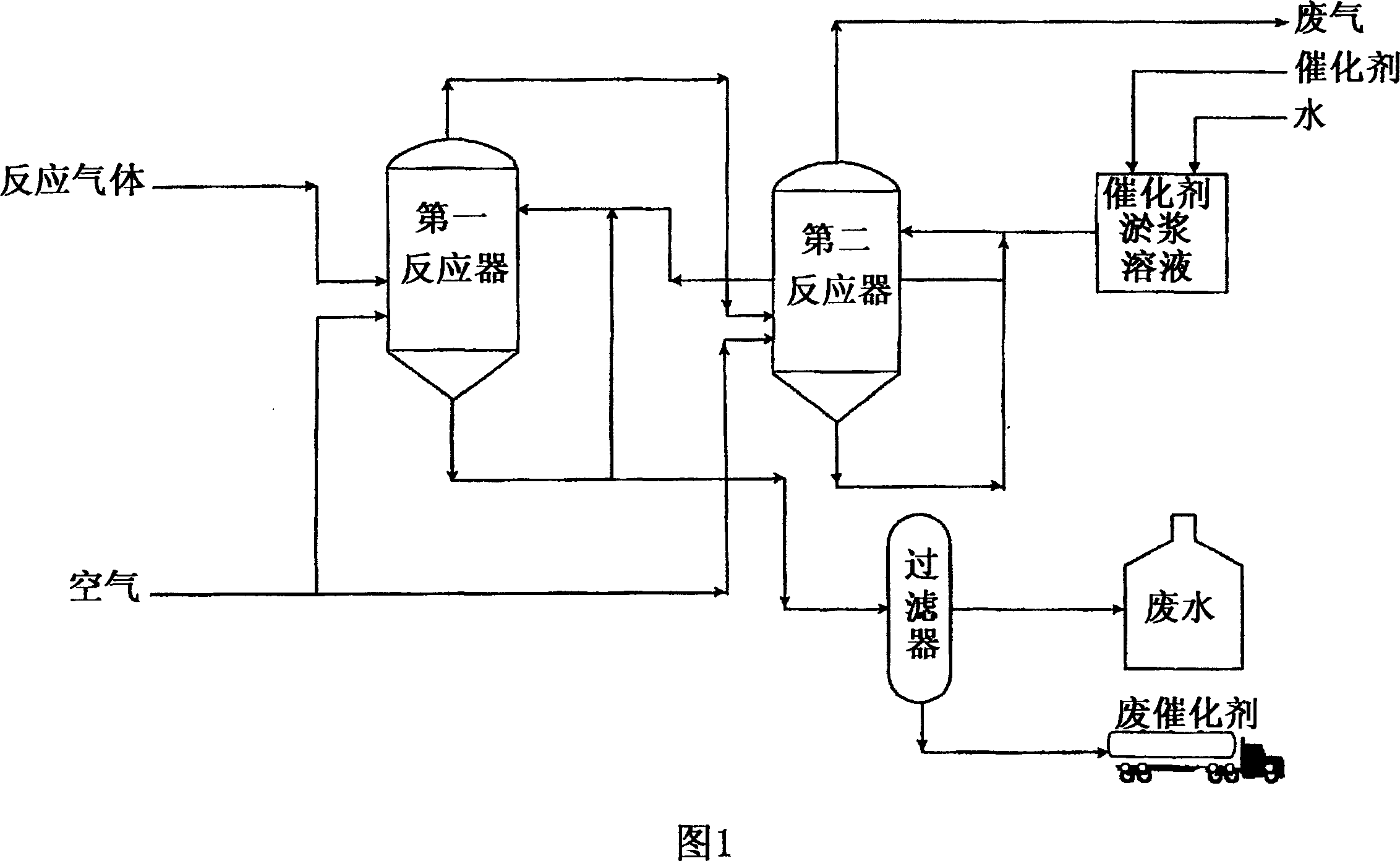

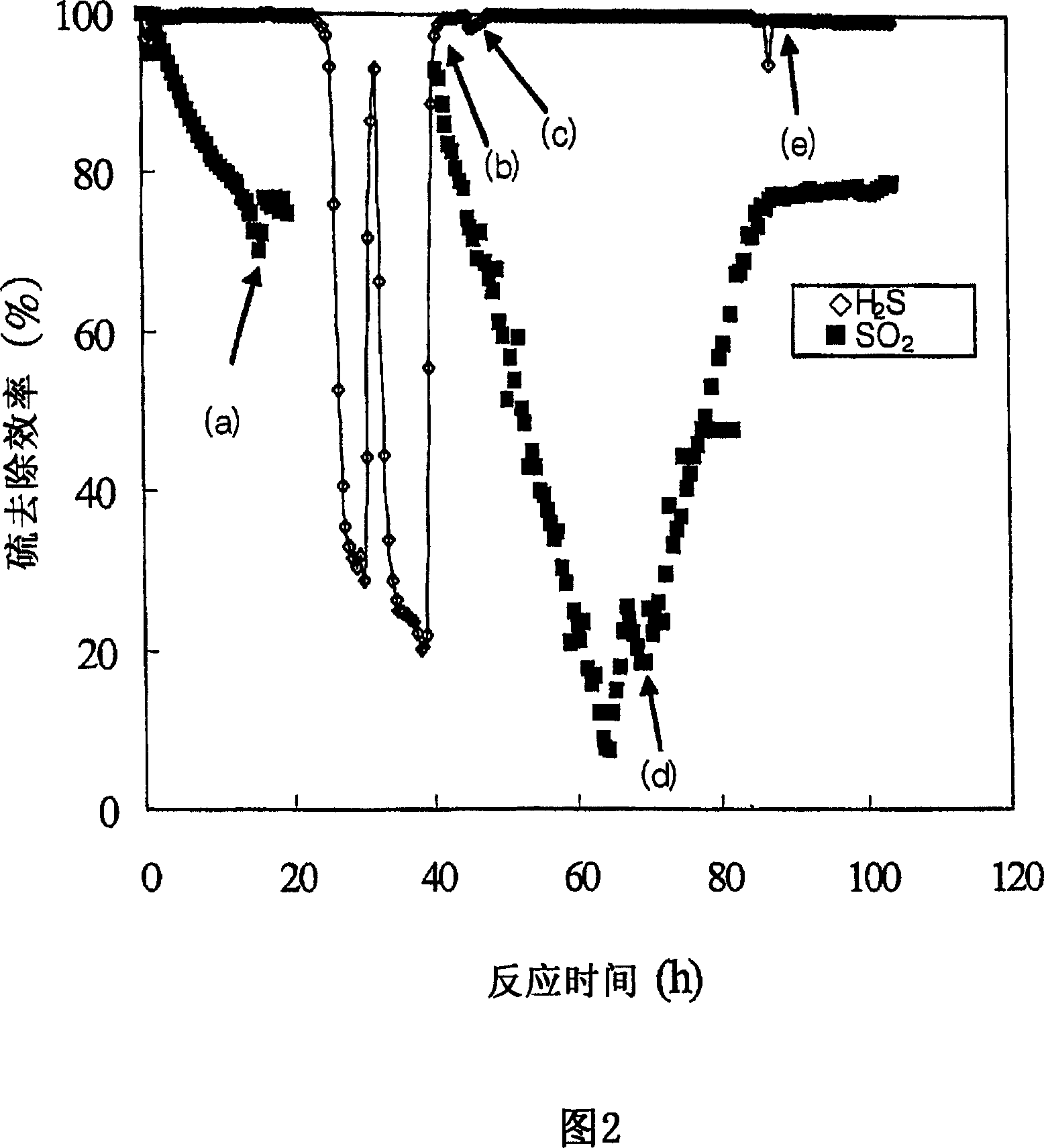

Desulfurizartion for Simultaneous Removal of Hydrogen Sulfide and Sulfur Dioxide

InactiveUS20070248518A1The method is simple and reliableLow costHydrogen sulfidesDispersed particle separationClaus processAqueous solution

A highly efficient desulfurization method for removing a hydrogen sulfide and a sulfur dioxide simultaneously comprises the step of contacting a gas containing the hydrogen sulfide and the sulfur dioxide with water, or an aqueous solution containing a first heterogeneous catalyst for desulfurization to oxidize the hydrogen sulfide with the sulfur dioxide. 3˜5% sulfur-containing tail gas exhausted from, especially, Claus Process can be treated at a high efficiency of over 99%.

Owner:KOREA INST OF SCI & TECH

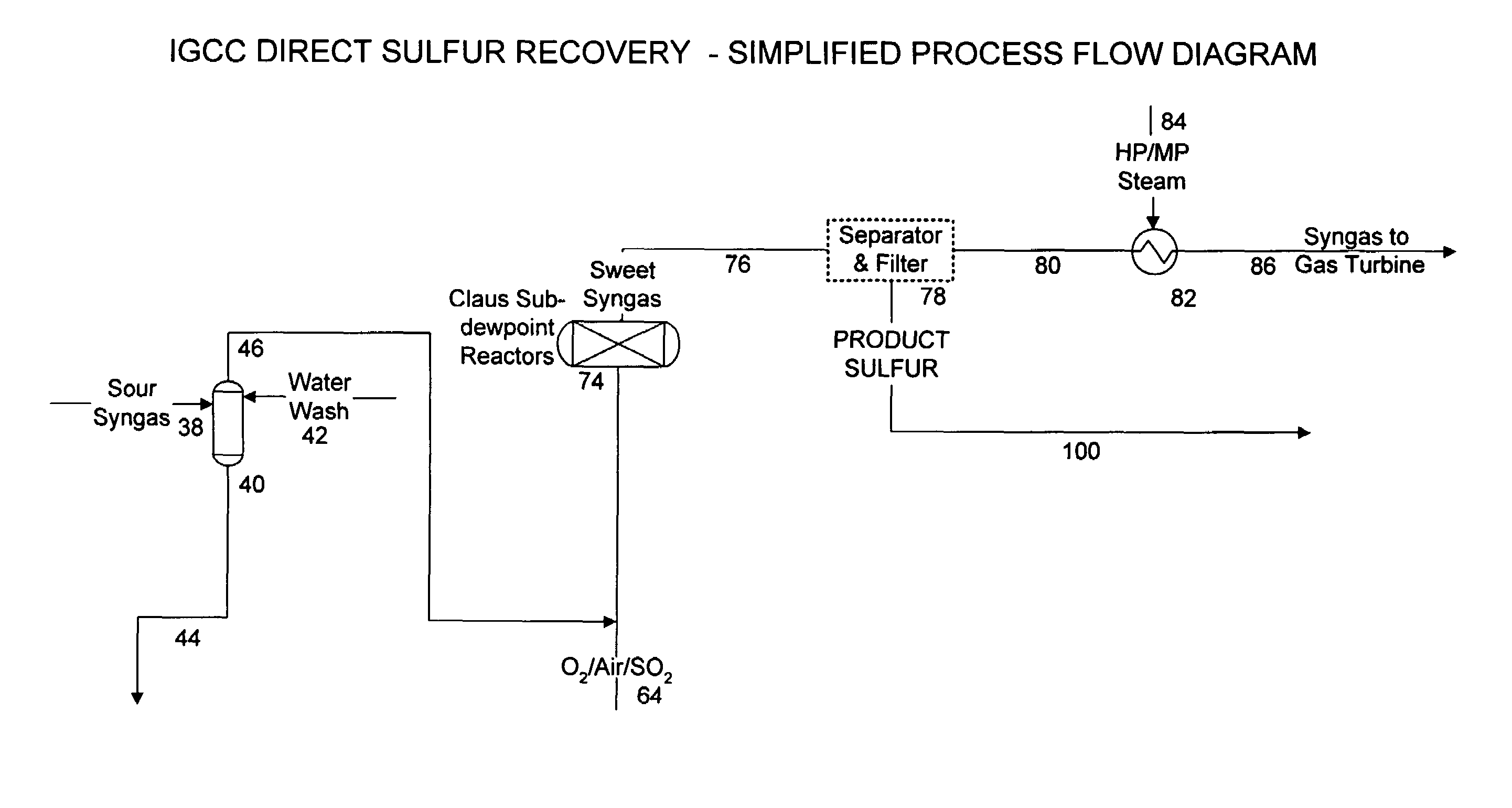

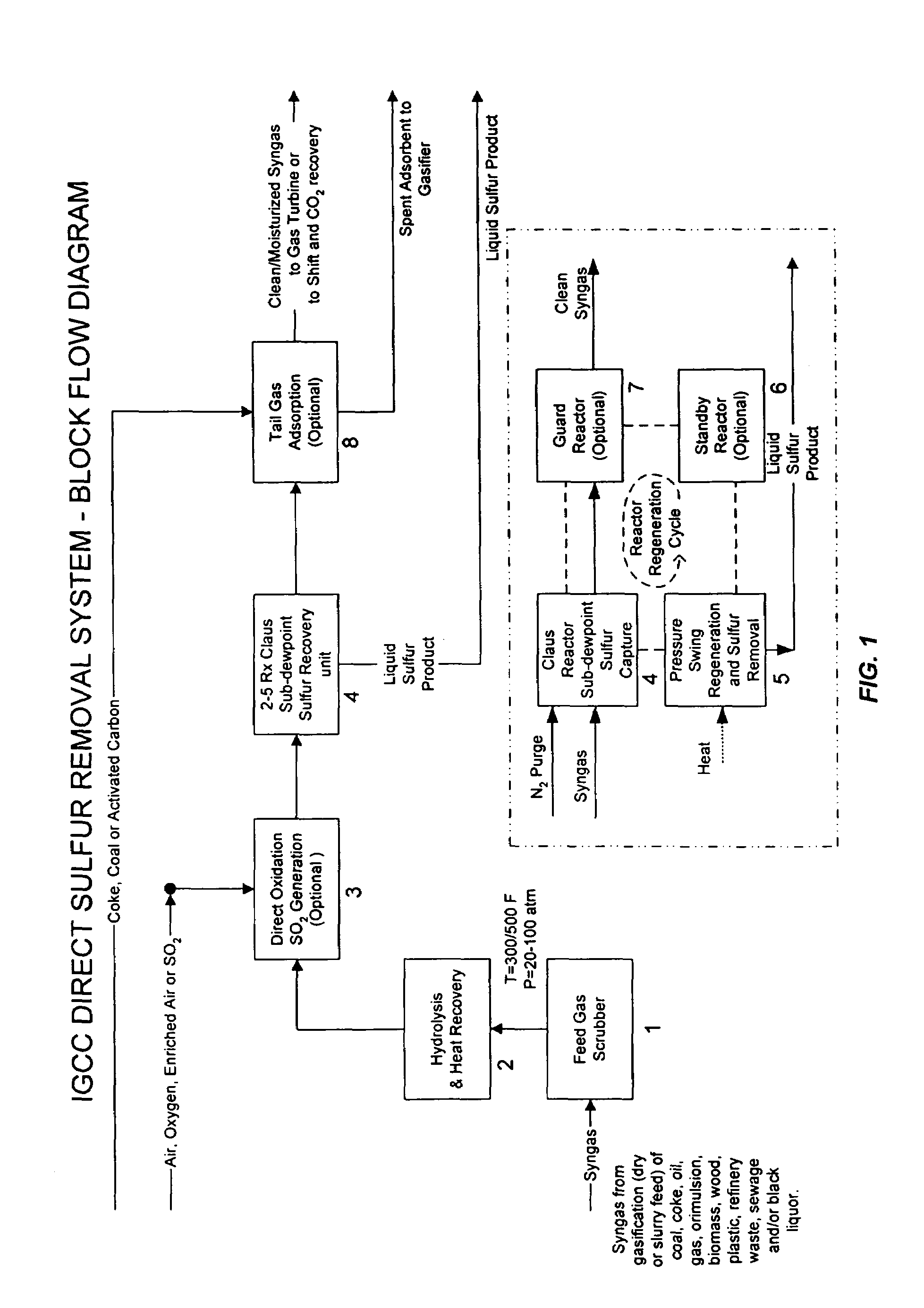

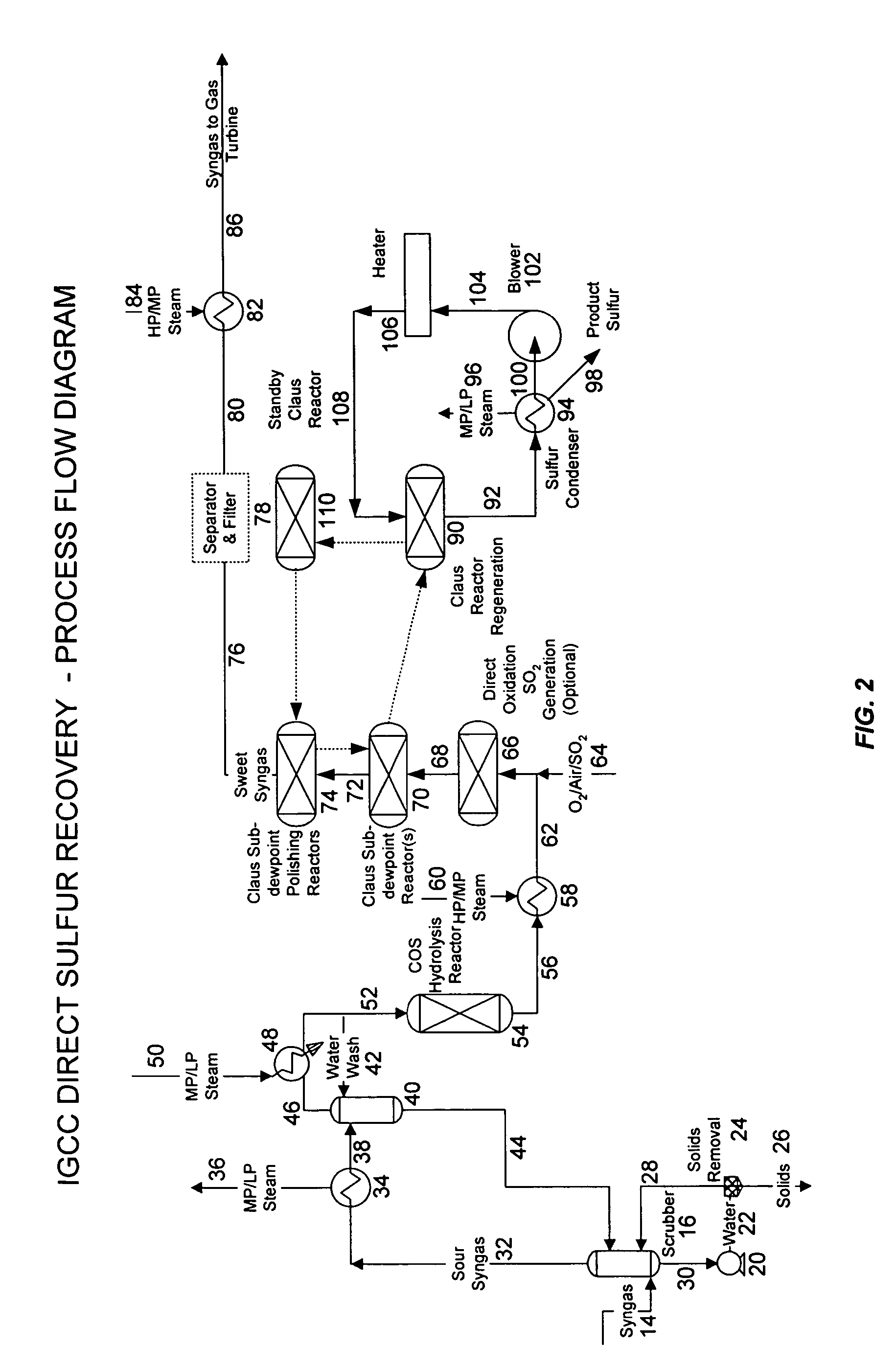

Direct sulfur recovery system

ActiveUS7374742B2Hydrogen separation using liquid contactDispersed particle separationActivated carbonSulfur

Owner:BECHTEL HYDROCARBON TECH SOLUTIONS INC

Desulfurization for simultaneous removal of hydrogen sulfide and sulfur dioxide

InactiveCN1964774AAvoiding Problems in Redox ProcessesDispersed particle separationProduct gasClaus process

Owner:KOREA INST OF SCI & TECH

A method for treating tail gas of Claus process

InactiveCN102847431BTake advantage ofReduce the burden onDispersed particle separationSulfur compoundsDesorptionReaction temperature

The invention provides a method for treating claus technical tail gas. The method comprises the following steps of: continuously feeding the claus technical tail gas containing sulfur dioxide, oxygen and water into a reactor filled with a multihole carbon desulfurizing agent; generating catalytic oxidation reaction between the sulfur dioxide and the water in the tail gas on the surface of multihole carbon at the reaction temperature between 30 and 150 DEG C; and continuously introducing regenerative detergent into the reactor. By the method, adsorption, catalytic oxidation and desorption are synchronously carried out on low-concentration sulfur-containing waste gas in the claus technical tail gas which is difficult to treat; oxygen and water in the tail gas can be fully used; under the condition that oxygen is not required to be swelled and the water is not required to be compensated, standard discharging can be realized and sulfur resources can be recycled; an obtained by-product is dilute sulphuric acid which can be directly used in industrial production or used in the industrial production after being concentrated; the multihole carbon desulfurizing agent is low in cost and long in service life and can be recycled; the technical flow is simple, and the investment is low; and the running cost is competitive.

Owner:BEIJING FUNGHAN ENG CONSULTING

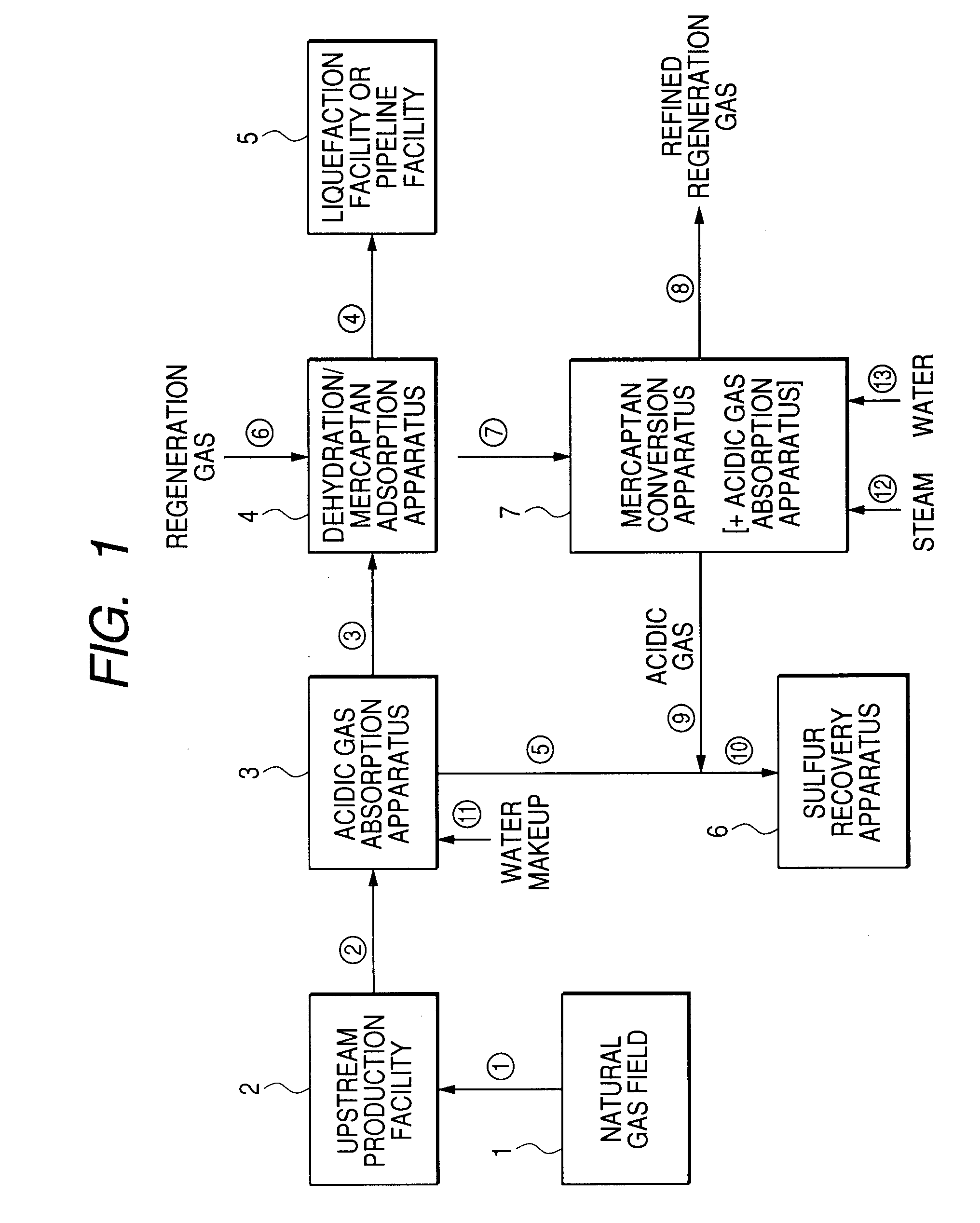

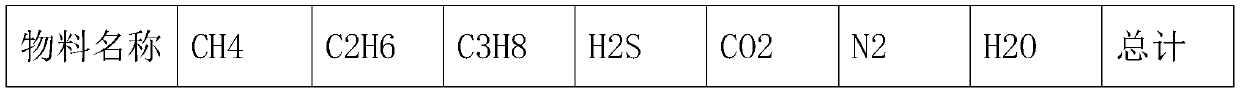

Method of removing sulfur compounds from natural gas

InactiveUS20090130009A1Improve conversion efficiencyImprove efficiencyProductsHydrogenMolecular sieveThiol

All sulfur compounds can be efficiently removed from natural gas that contains hydrogen sulfide and other sulfur compounds such as mercaptan without using physical absorption. The process comprises an absorption step of treating natural gas by means of a chemical absorption method using an amine-containing solution to mainly remove hydrogen sulfide and carbon dioxide, an adsorption step of flowing the natural gas from the absorption step through a packed bed of a molecular sieve to mainly remove mercaptan, a recovery step of recovering sulfur compounds by converting the hydrogen sulfide removed in the absorption step into sulfur by means of the Claus process, a regeneration step of desorbing the mercaptan adsorbed on the molecular sieve in the adsorption step using heated gas and a reaction step of converting the mercaptan in the regeneration exhaust gas exhausted from the regeneration step into hydrogen sulfide. The reaction step is conducted by injecting steam or water at a ratio of H2O / S=1 to 5 (molar ratio) relative to the sulfur in the regeneration exhaust gas in the presence of a catalyst under the conditions of a temperature level of 250 to 400° C. and a pressure level of 1 to 10 MPa.

Owner:CHIYODA CORP

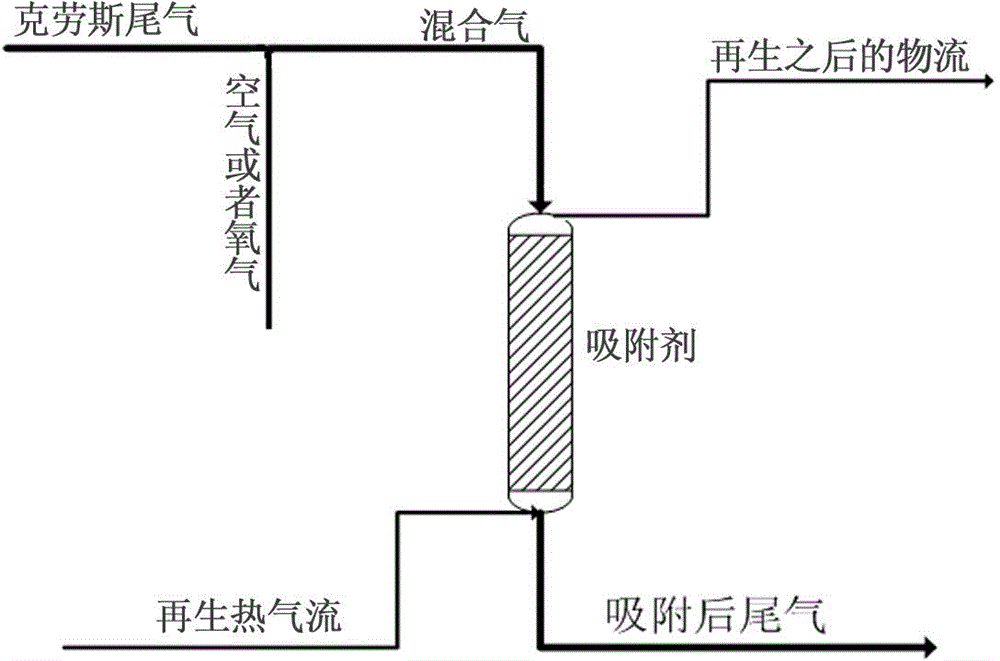

Method for treating Claus process tail gas by adopting modified adsorbing agent

ActiveCN104415657ANo change in adsorption activityReduce energy consumptionDispersed particle separationSorbentPhysical chemistry

The invention relates to a method for treating a Claus process tail gas by adopting a modified adsorbing agent. The method comprises the following steps: (1) immersing an adsorbing agent in a 1-10% metal ion solution, standing, drying after filtering to obtain a modified adsorbing agent; (2) placing the modified adsorbing agent in an adsorbing bed for removing sulfide in the Claus process tail gas; and (3) after the adsorbing agent in the adsorbing bed reaches adsorption saturation, performing regeneration by adopting hot airflow with a temperature of 150-500 DEG C, wherein the regenerated adsorbing agent can be recycled. According to the method, the sulfide in the tail gas of a Claus device is removed by adopting an adsorption-catalysis method, the modified adsorbing agent can be used for simultaneously treating H2S, SO2, COS and CS2 in the Claus process tail gas and recovering the H2S, the SO2, the COS and the CS2 in the Claus process tail gas in a sulphur or sulfuric acid form, and the adsorbing agent reaching the adsorption saturation can be regenerated and recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

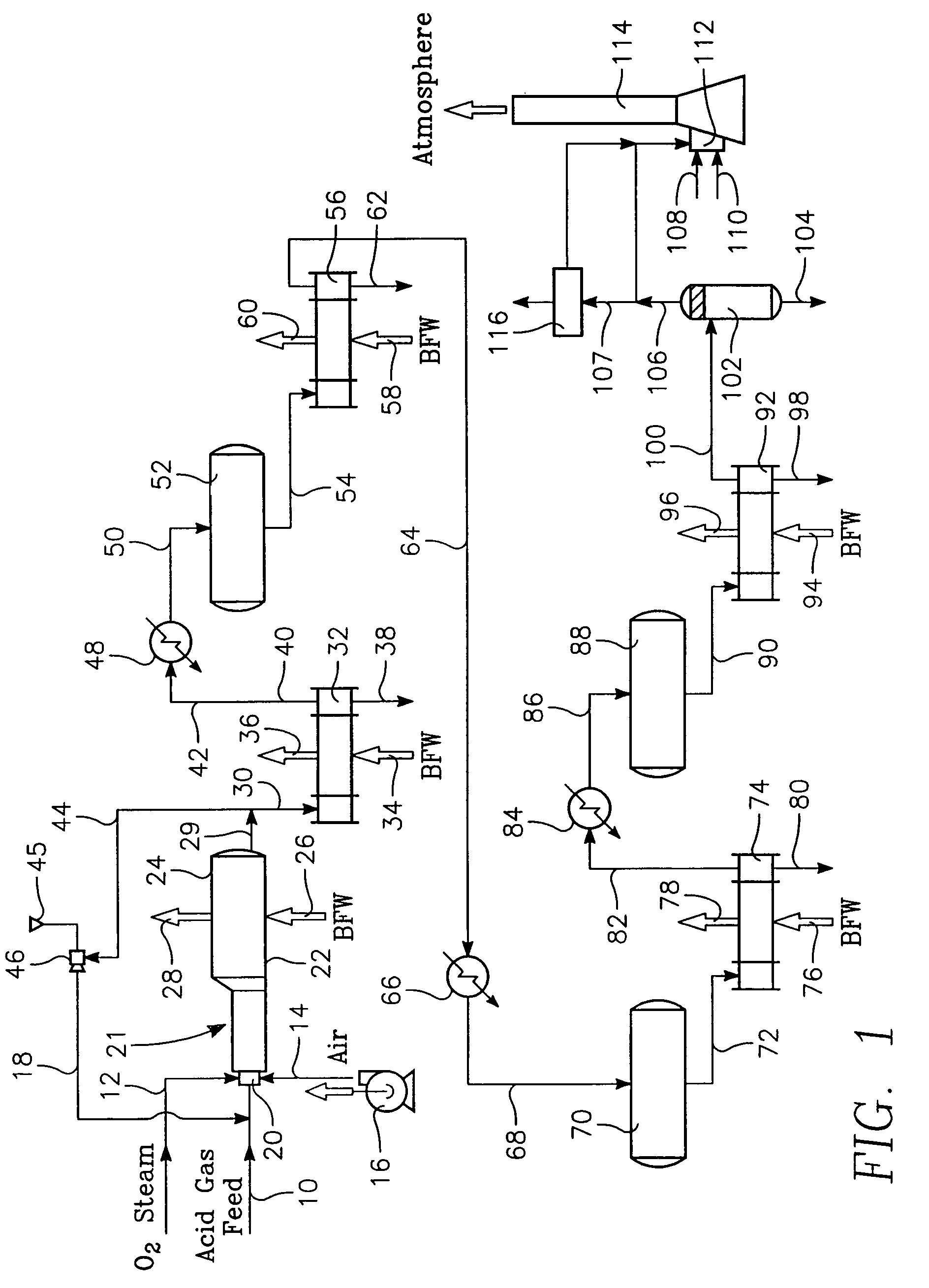

Steam modified Claus process

ActiveUS7597871B2Quantity minimizationMaximize feed rateSulfur preparation/purificationClaus processPhotochemistry

Disclosed is a method for treating a gas stream rich in hydrogen sulfide by providing one or more feed gas streams rich in hydrogen sulfide into a Claus reaction furnace, providing air into the Claus reaction furnace, providing supplemental oxygen into the Claus reaction furnace, and providing steam to the Claus reaction furnace, where the steam is in addition to any steam that may be present in gases that are recycled to the Claus reaction furnace. The components are then reacted at a temperature above about 2400° F. and at a pressure sufficient to cause hydrogen sulfide to be converted into sulfur.

Owner:AIR PROD & CHEM INC +1

Temperature moderated claus process

ActiveUS7172746B1Quantity minimizationMaximize feed rateSulfur preparation/purificationCombustionClaus process

Disclosed is a method for treating a feed gas stream rich in hydrogen sulfide by partially combusting the feed gas stream rich in hydrogen sulfide with an oxygen-enriched gas in a Claus reaction furnace to produce to a combustion reaction product stream containing sulfur. The combustion reaction product stream is split into a recycle stream and a treatment stream and the recycle stream directed back into the Claus reaction furnace, without first condensing sulfur out of the recycle stream, while the treatment stream is directed into a condenser to condense sulfur out of the treatment stream.

Owner:FLUOR TECH CORP

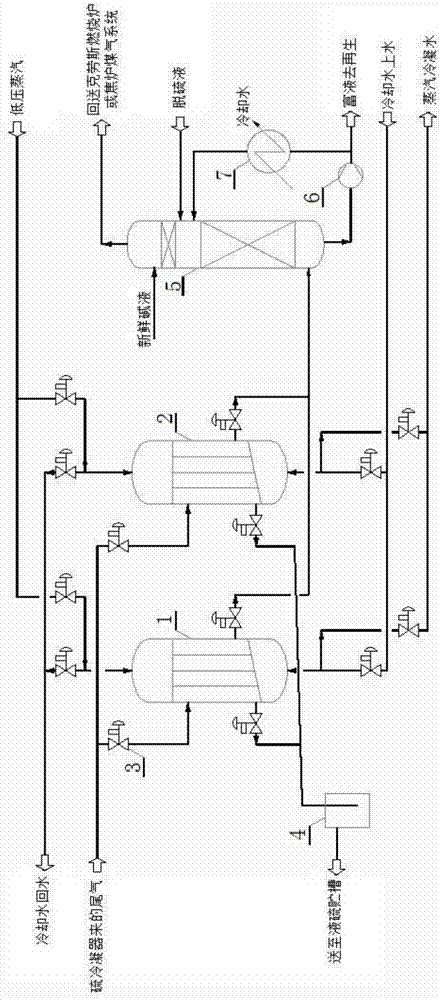

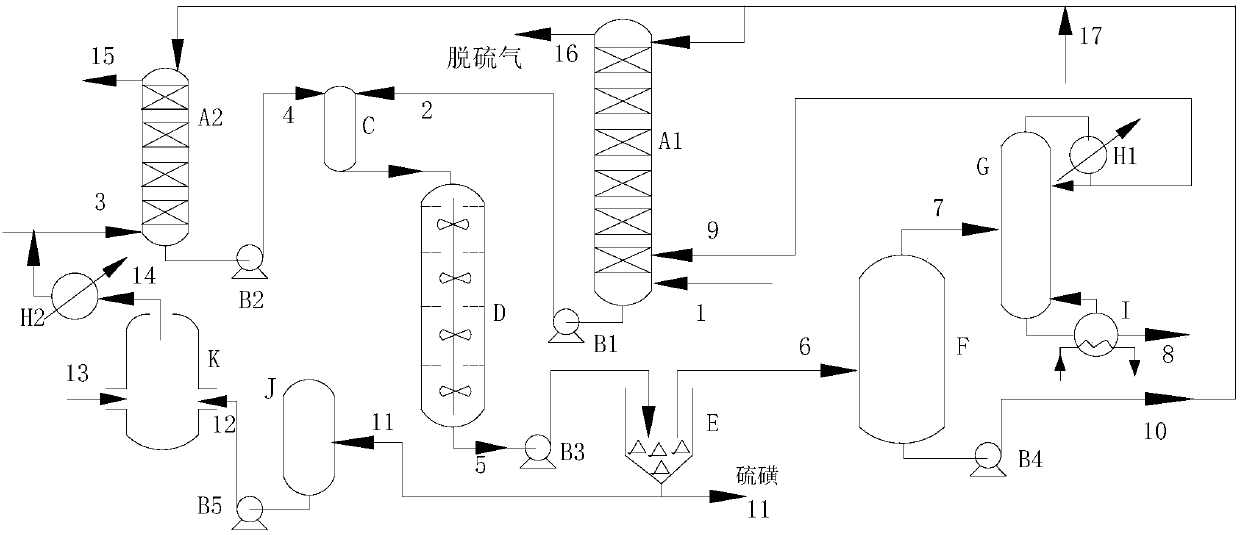

Claus tail gas condensing treatment process

The invention relates to a Claus tail gas condensing treatment process, which comprises the steps that Claus tail gas coming from a Claus process sulfur condenser enters a heat exchanger I, gaseous sulfur is condensed and removed; the gaseous sulfur-removed Claus tail gas is sent to a desulfurizing absorption tower and is sprayed by adopting a doctor solution coming from a gas purification device, rich liquor is returned to the gas purification device for regeneration, and regenerated acid gas is used as a raw material for a Claus process; the upper part of the desulfurizing absorption tower is provided with an alkali washing section, and alkali liquor is a replenishing solution coming from a desulfurizing unit of the gas purification device; after the removal of H2S, the Claus tail gas is sent to a coke oven gas system or is returned to a returned gas system; the heat exchanger I and a heat exchanger II work in a cyclic alternating pattern, and the continuous condensing of the gaseous sulfur in the Claus tail gas is realized. The Claus tail gas condensing treatment process has the remarkable advantages of small investment, low operating cost, energy conservation, greenness, environmental protection and the like.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

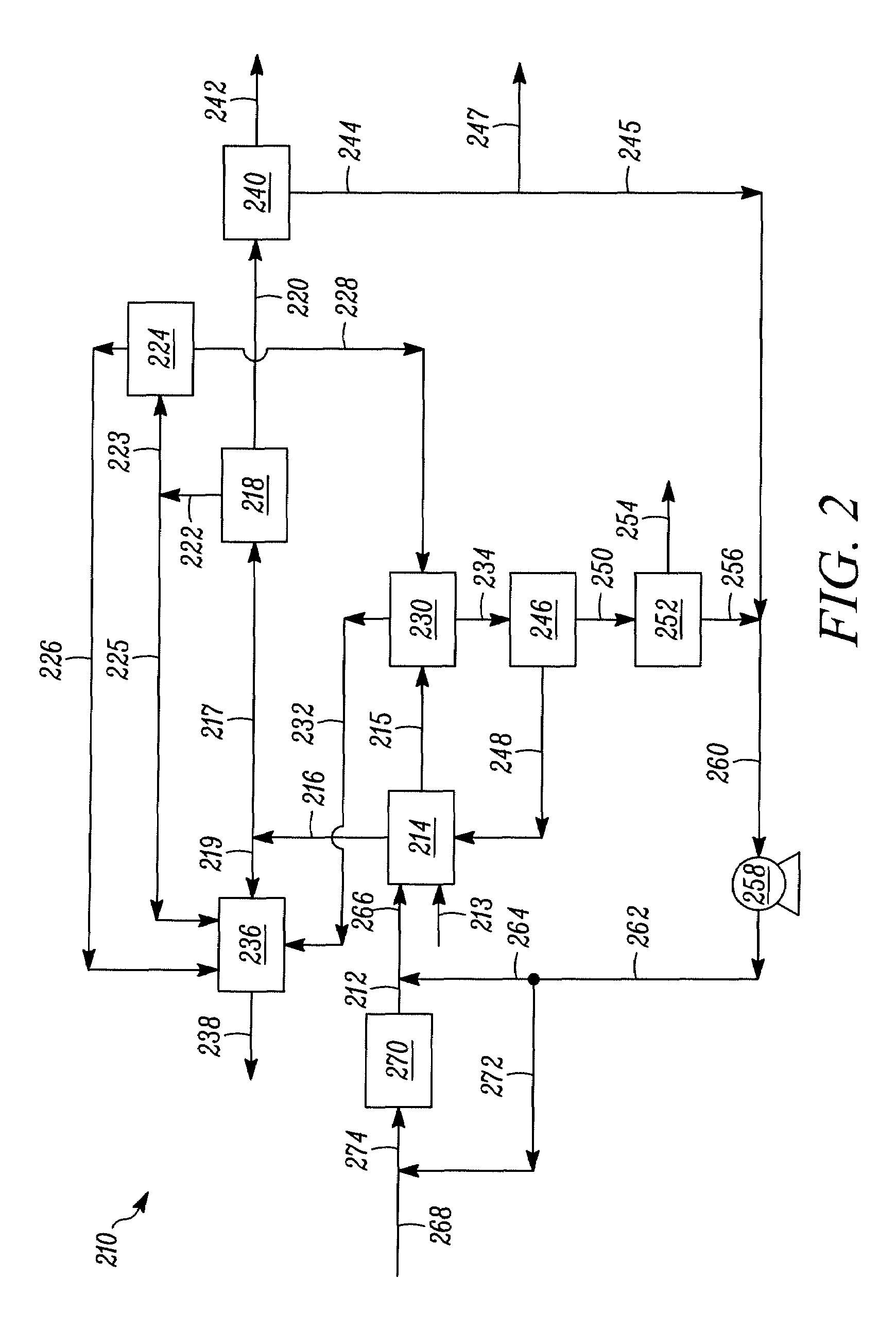

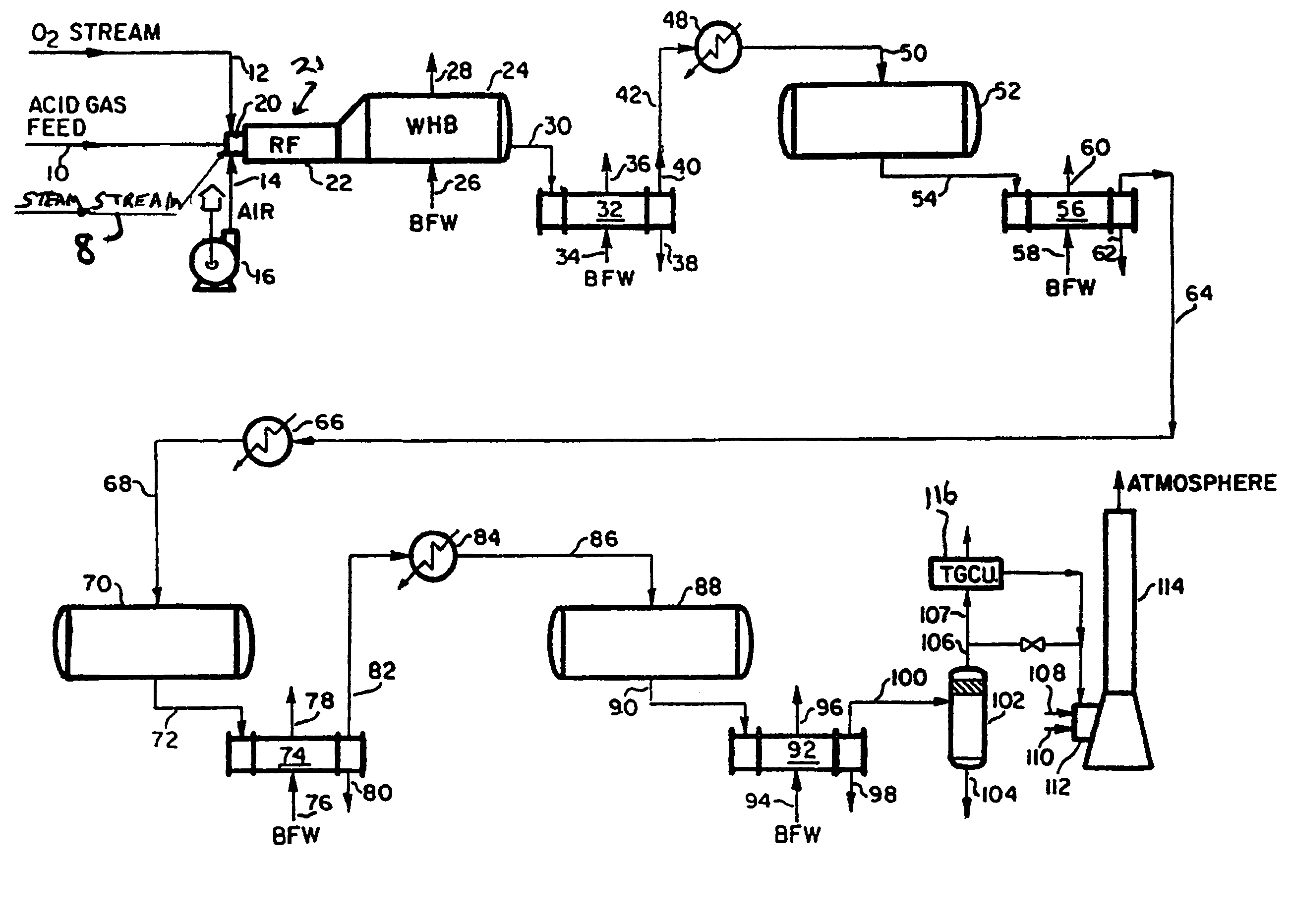

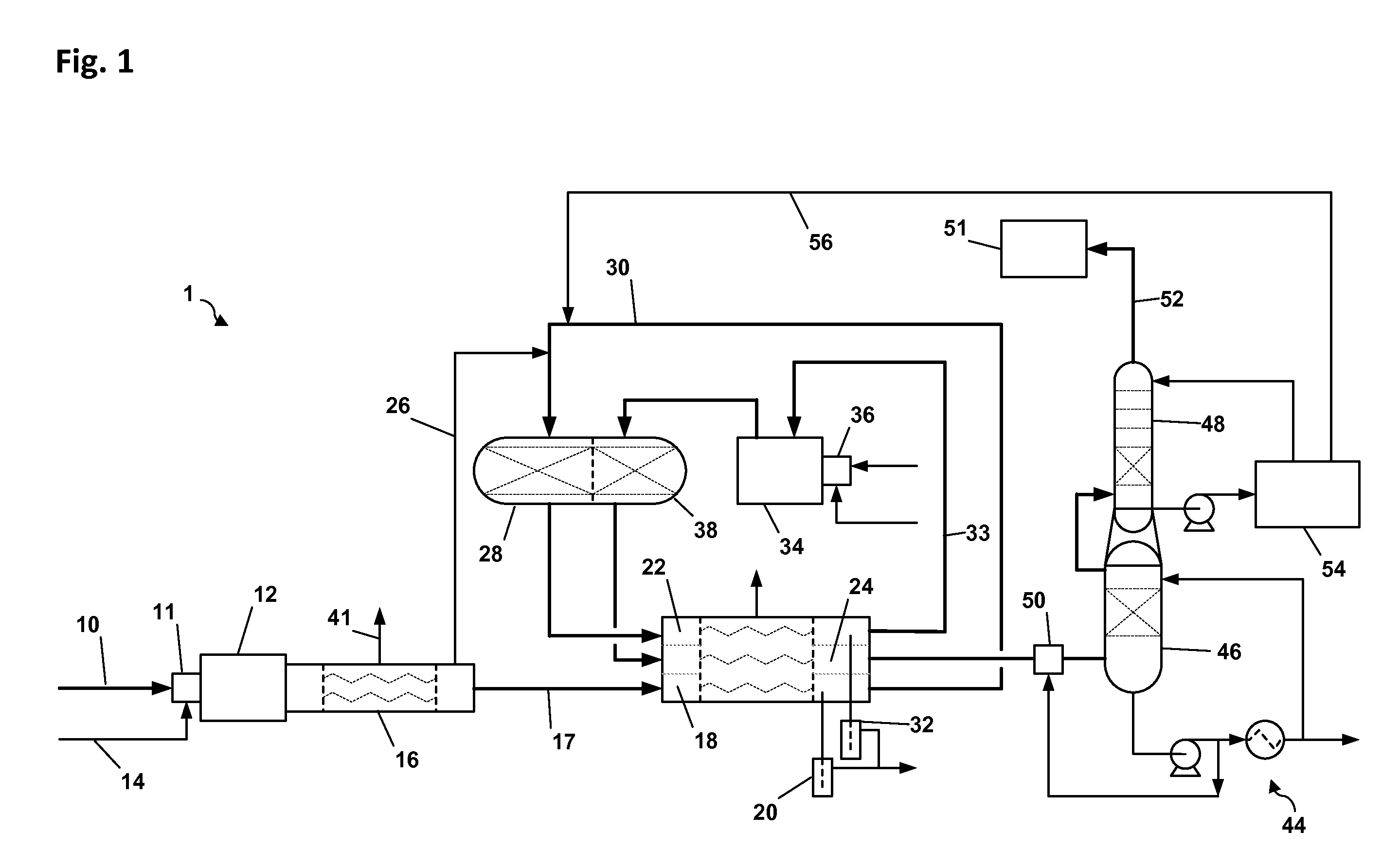

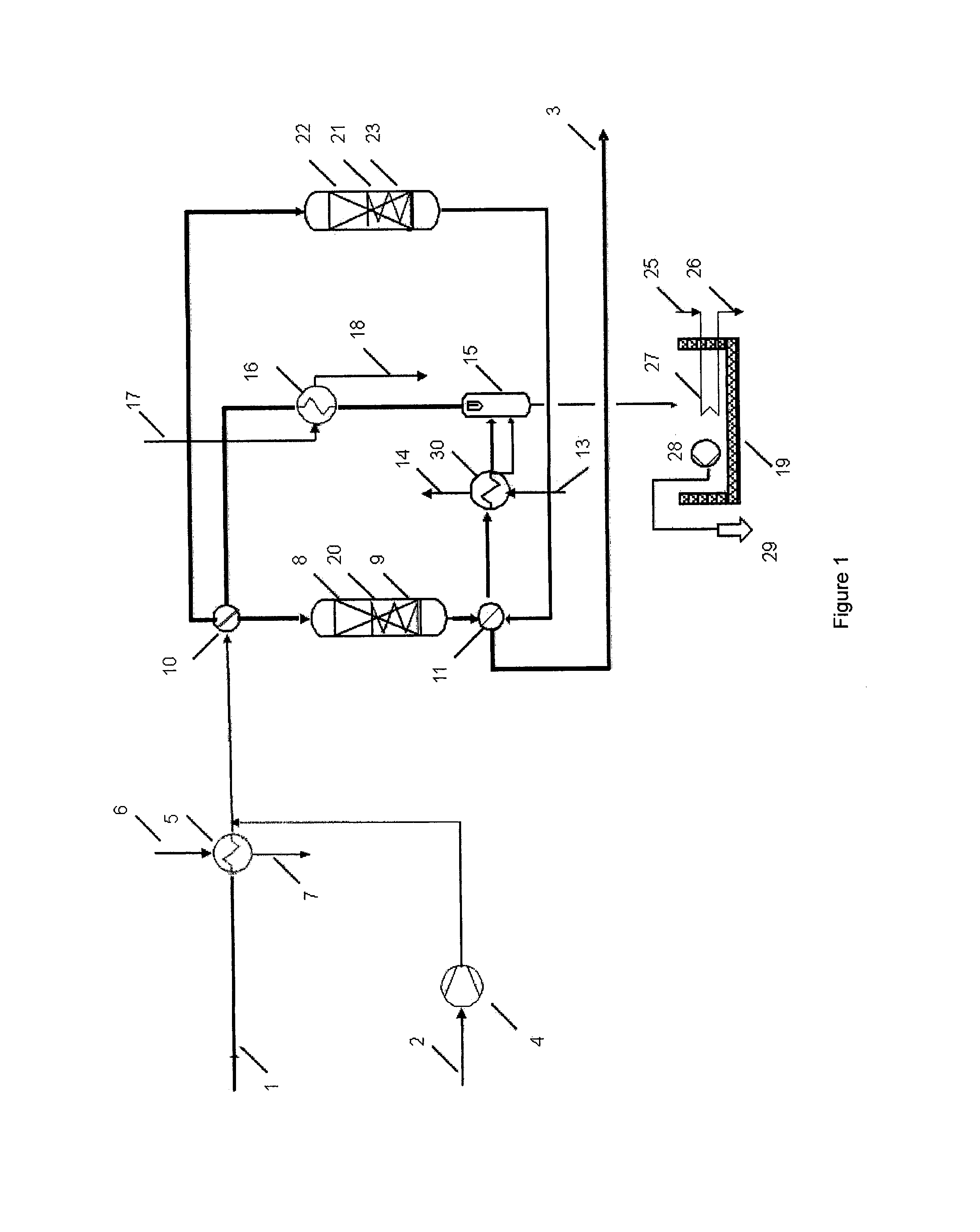

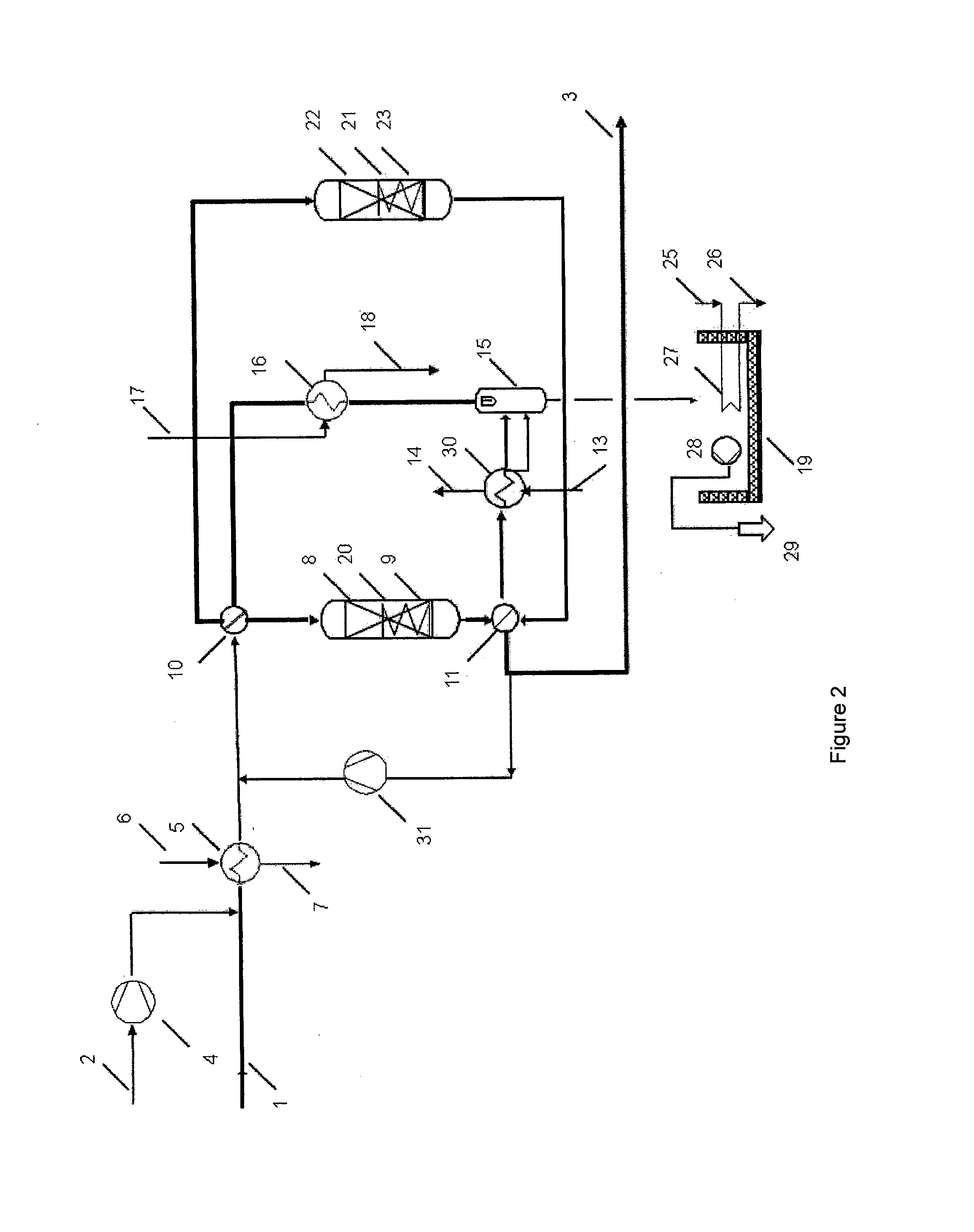

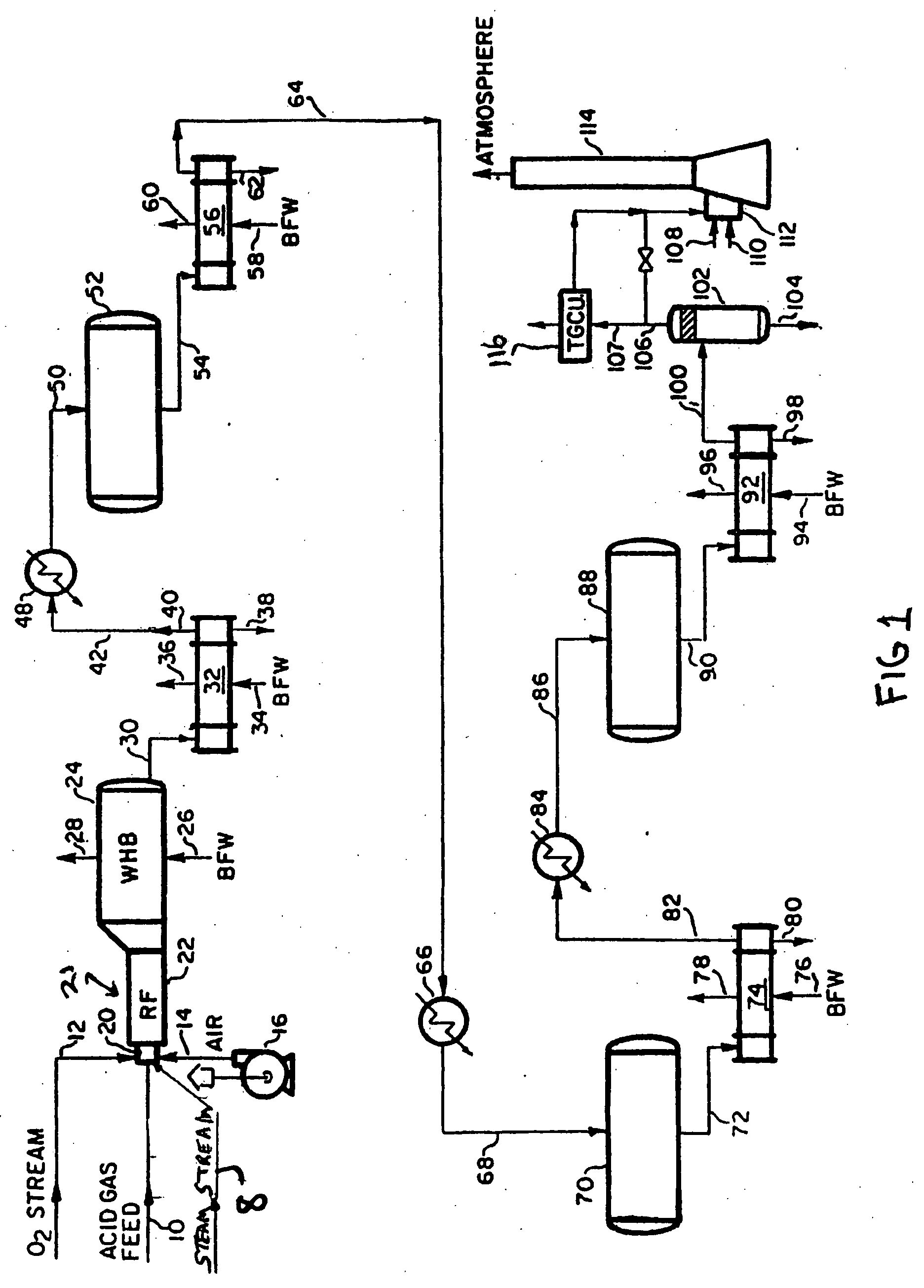

Method and Consolidated Apparatus for Recovery of Sulfur from Acid Gases

InactiveUS20110171115A1Minimizes amineExtra processingEnergy inputSulfur preparation/purificationSulfurProduct gas

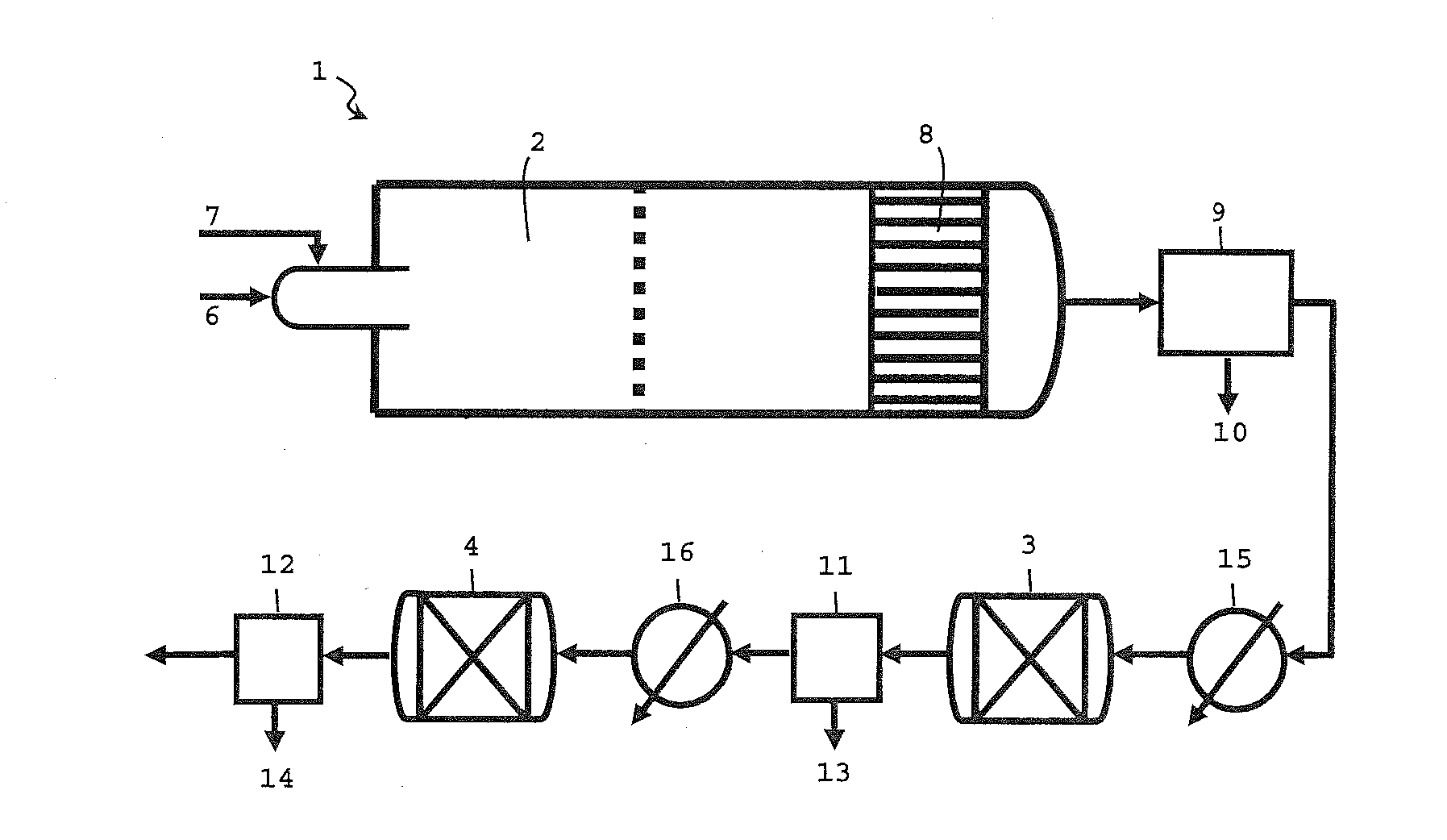

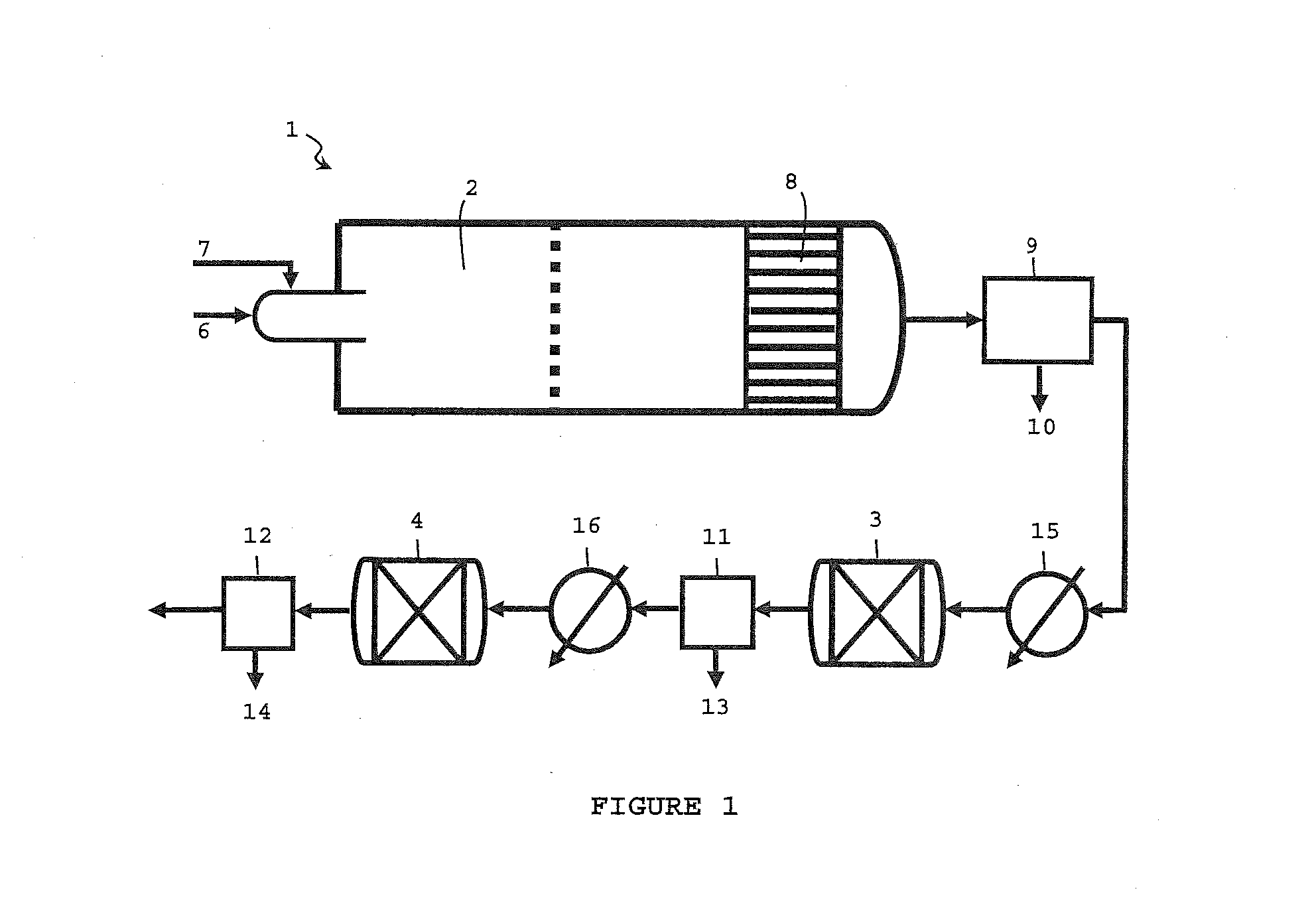

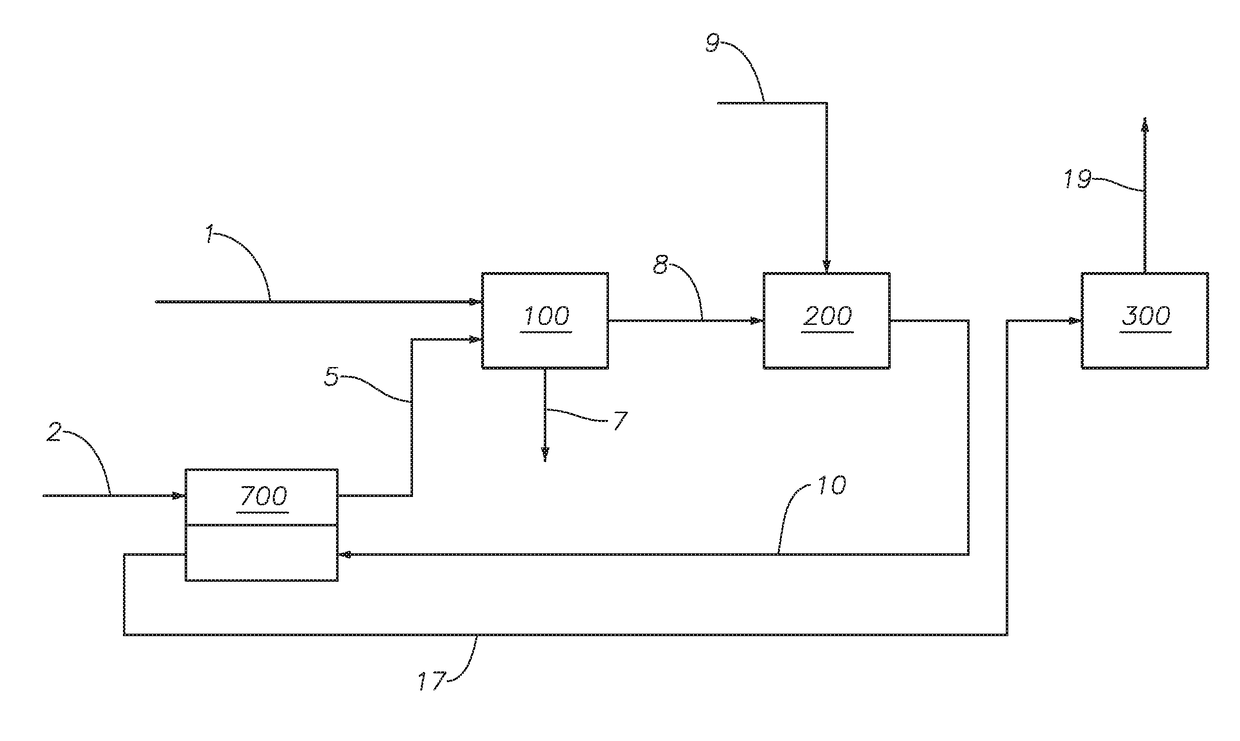

An improved method and consolidated apparatus for recovery of sulfur from acid gases using the modified-Claus process and Claus tail gas treating process of the hydrogenation / amine absorption type as classically practiced in the oil & gas industry. By implementing innovations to the acid gas processing strategy a wider range of feedstocks can be processed and improved performance is seen when processing conventional feedstocks; in addition, through consolidation and integration of the typical practice an improved apparatus is realized.

Owner:KPS TECH & ENG

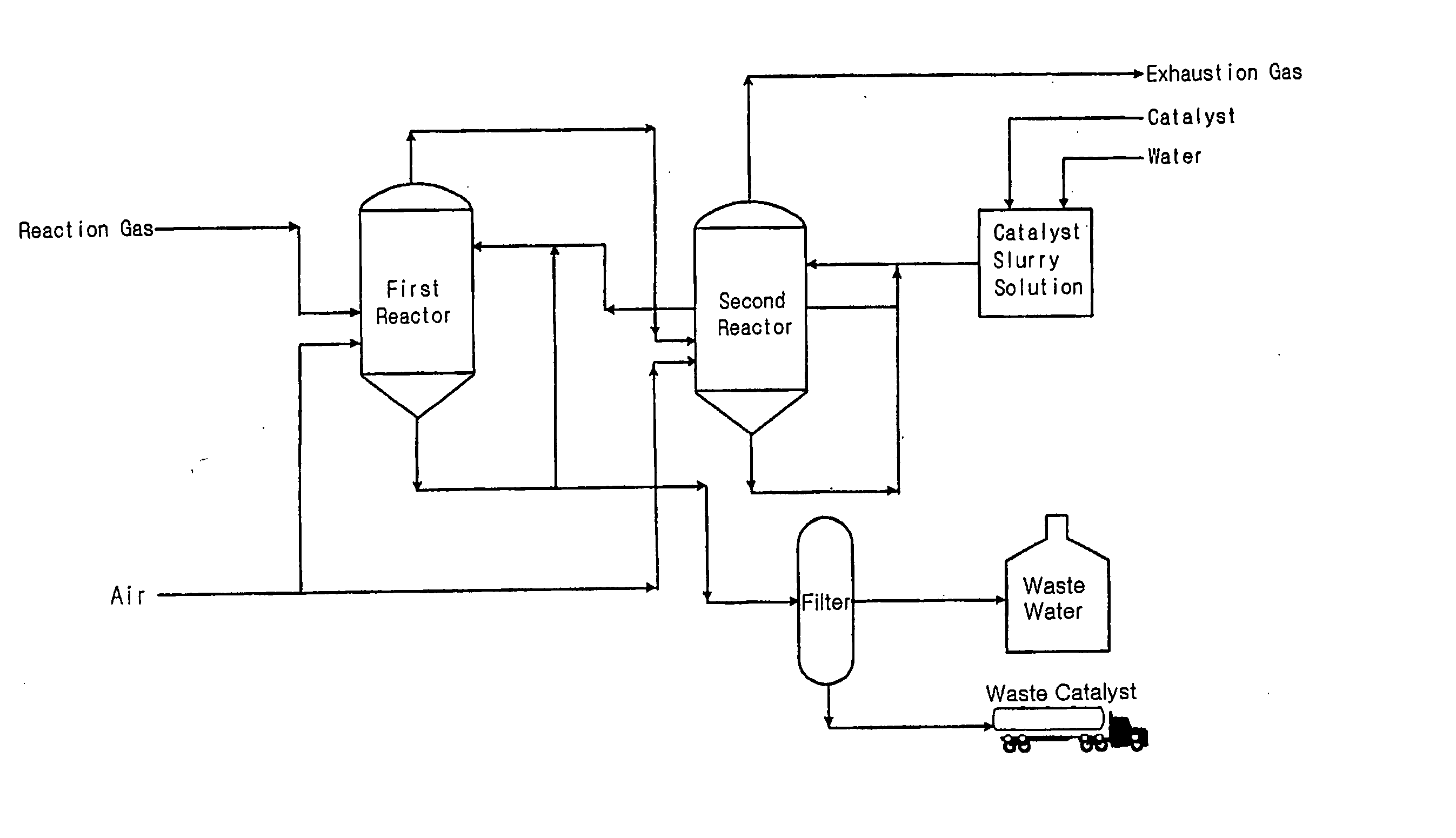

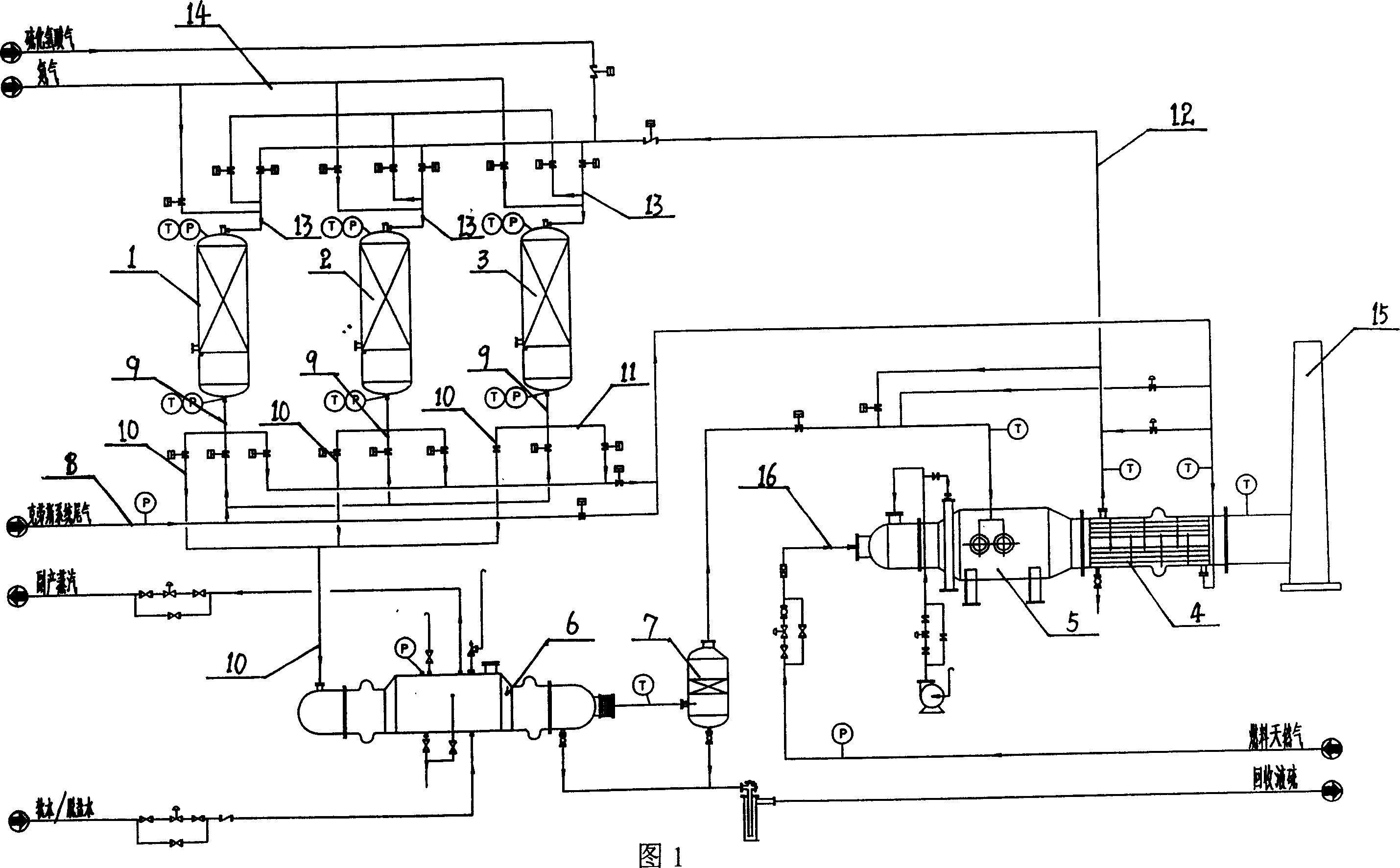

Equipment and method for treating exhaust gas for carbon bisulfide preparing process

ActiveCN1935646AReduce labor intensityReduce energy consumptionDispersed particle separationChemical recyclingCombustionProcess engineering

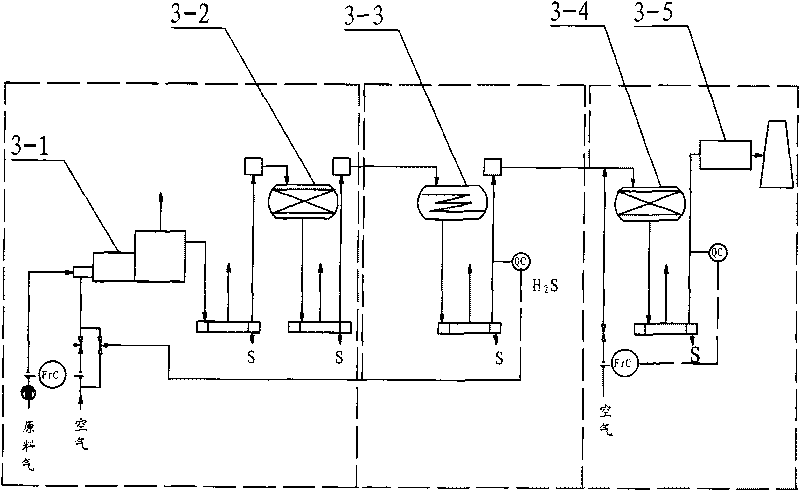

The invention relates to a tail gas processing device and method, concretely a tail gas processing device and method in the CS2 preparing course, adopting a mode of integrating multistage Claus combustion furnace with low-temperature Claus process to process the tail gas, and makes gross recovery of S up to 99.5% above; and in the whole operating course, the catalyst regeneration and cooling are both completed by the system itself, so that the energy comsuption is low, pollution is less, and the exhausted tail gas can completely meet the requirements of national related effluent stardards, and the whole operating course is controlled by PLC program controller, thus implementing continous operation and reducing workers'labor strength.

Owner:SHANDONG JINDIAN CHEM CO LTD

Enhancement of claus tail gas treatment by sulfur dioxide-selective membrane technology and sulfur dioxide-selective absorption technology

ActiveUS20180257936A1Improve sulfur recoveryMinimizing sulfur dioxide emissionProductsGas treatmentMembrane technologySulfur

A method for recovering sulfur from an acid gas feed is provided. The method comprising the steps of mixing the acid gas feed and an absorption process outlet stream to form a combined Claus feed, introducing the combined Claus feed and a sulfur dioxide enriched air feed to a Claus process to produce a Claus outlet gas stream, introducing the Claus outlet gas stream to a thermal oxidizer, treating the thermal oxidizer outlet stream in a gas treatment unit to produce a dehydrated stream, introducing the dehydrated stream to a membrane sweeping unit to produce a sweep membrane residue stream and a sulfur dioxide enriched air feed, introducing a sweep air stream to a permeate side of the membrane sweeping unit, and introducing the sweep membrane residue stream to a sulfur dioxide absorption process to produce the absorption process outlet stream and a stack feed.

Owner:SAUDI ARABIAN OIL CO

Double selectivity efficient sulfur recovery device

InactiveCN101717074ALower exhaust gas temperatureReduce CO

<sub>2</sub>

quantitySulfur preparation/purificationSulfurClaus process

The invention relates to a double selectivity efficient sulfur recovery device, belonging to the technical field of sulfur recovery. The device comprises a primary Claus reactor, a secondary Claus reactor and a third Claus reactor connected sequentially in series, and is characterized in that in the secondary Claus reactor, two different catalysts are filled in two sections, a Claus reaction catalyst is filled in the upper section, and a high selectivity direct reduction hydrogenation catalyst 1 is filled in the lower section; SO2 is hydrogenated and reduced into elemental sulfur by the reduction hydrogenation catalyst at 200-220 DEG C; a low-temperature selectivity direct oxidation catalyst is filled in the third Claus reactor; and H2S is selectively oxidized into elemental sulfur by the low-temperature selectivity direct oxidation catalyst. The device of the invention has high conversion rate of the H2S and less investment and does not need to strictly control the ratio of H2S / SO2 as 2:1 nor control H2S / SO2 to be larger than 2 / 1 as in the Super Claus process. Even the H2S is excess, the invention can adapt to larger changes of the acid gas flow rate and the H2S concentration caused by the fluctuation of an upstream device.

Owner:SHANDONG QILU PETROCHEM ENG

Sulfur recovery process and apparatus

InactiveCN104961103AGuaranteed concentrationImprove desulfurization efficiencySulfur preparation/purificationHydrogenSolvent

The invention belongs to the field of sulfur recovery, and particularly relates to a sulfur recovery process. Acidic gas containing hydrogen sulfide has Claus reaction to generate sulfur and sulfur production tail gas, the sulfur is recovered, the sulfur production tail gas is mixed with hydrogen and then is sent to a tail gas hydrogenation reduction system to have hydrogenation reduction reaction, then the mixture enters a H2S absorption and solvent oxidation system, H2S in the gas is oxidized to elemental sulfur, and the purified gas is emptied; finally the sulfur and solvent are separated. The process is a novel sulfur recovery and tail gas treatment process formed by combining the Claus process and a liquid-phase oxidation technology, so that the content of hydrogen sulfide in the discharged gas is minimized, the content of H2S in the treated exhausted gas is reduced to 5ppm or less, the equipment investment is less, the process flow is short, the energy consumption is low, the process flow is safe and reliable, and environmental friendliness can b e realized. The invention also provides an apparatus. The apparatus is simple in structure and easy to implement.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

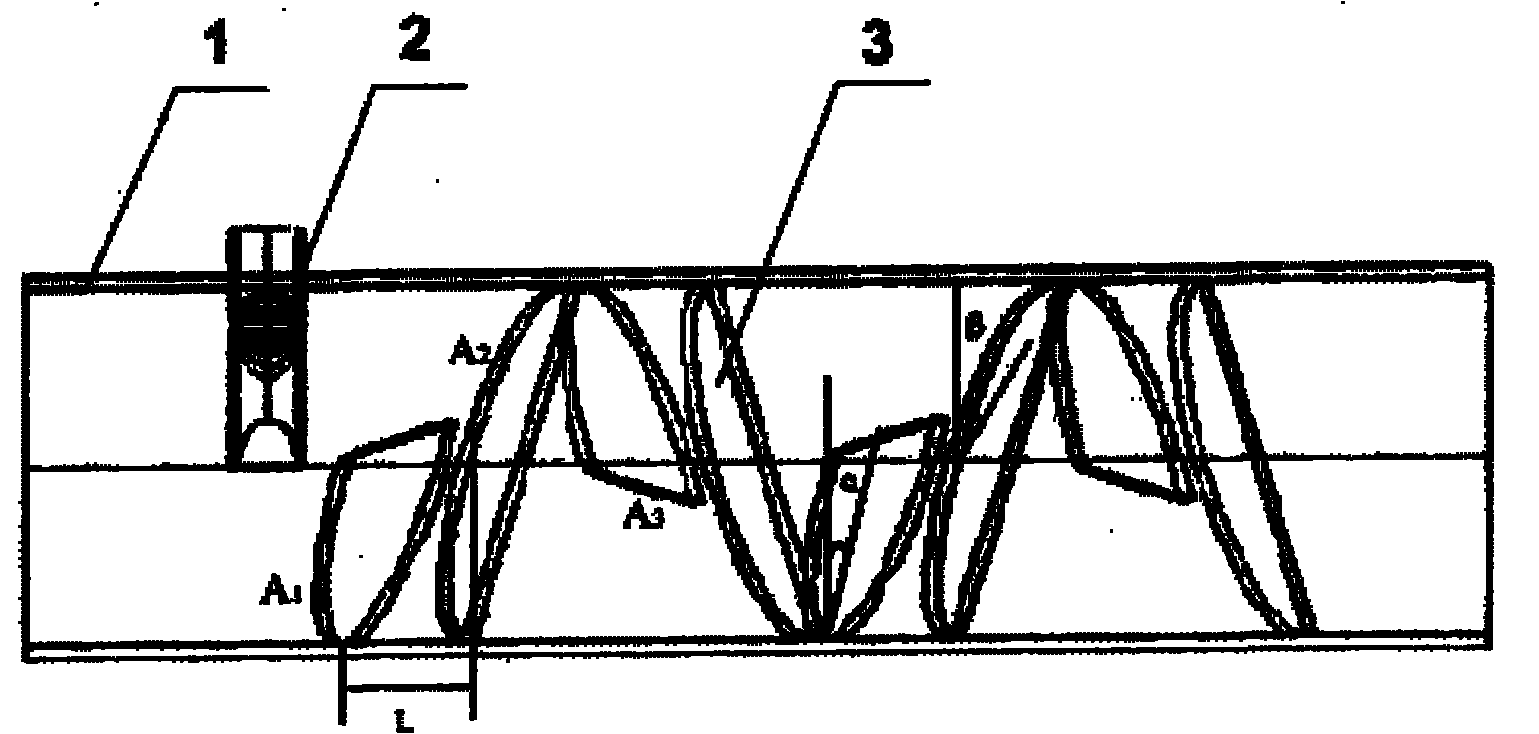

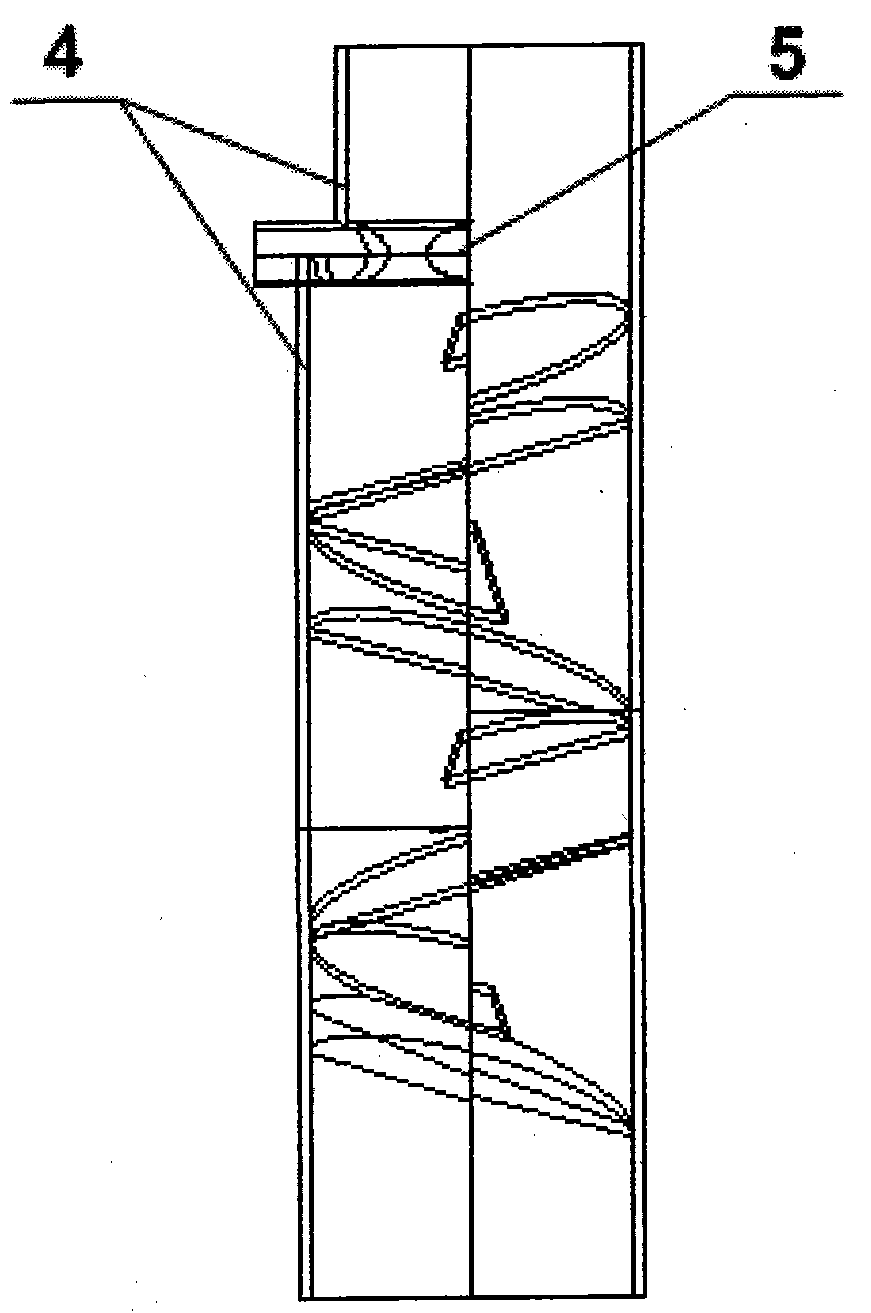

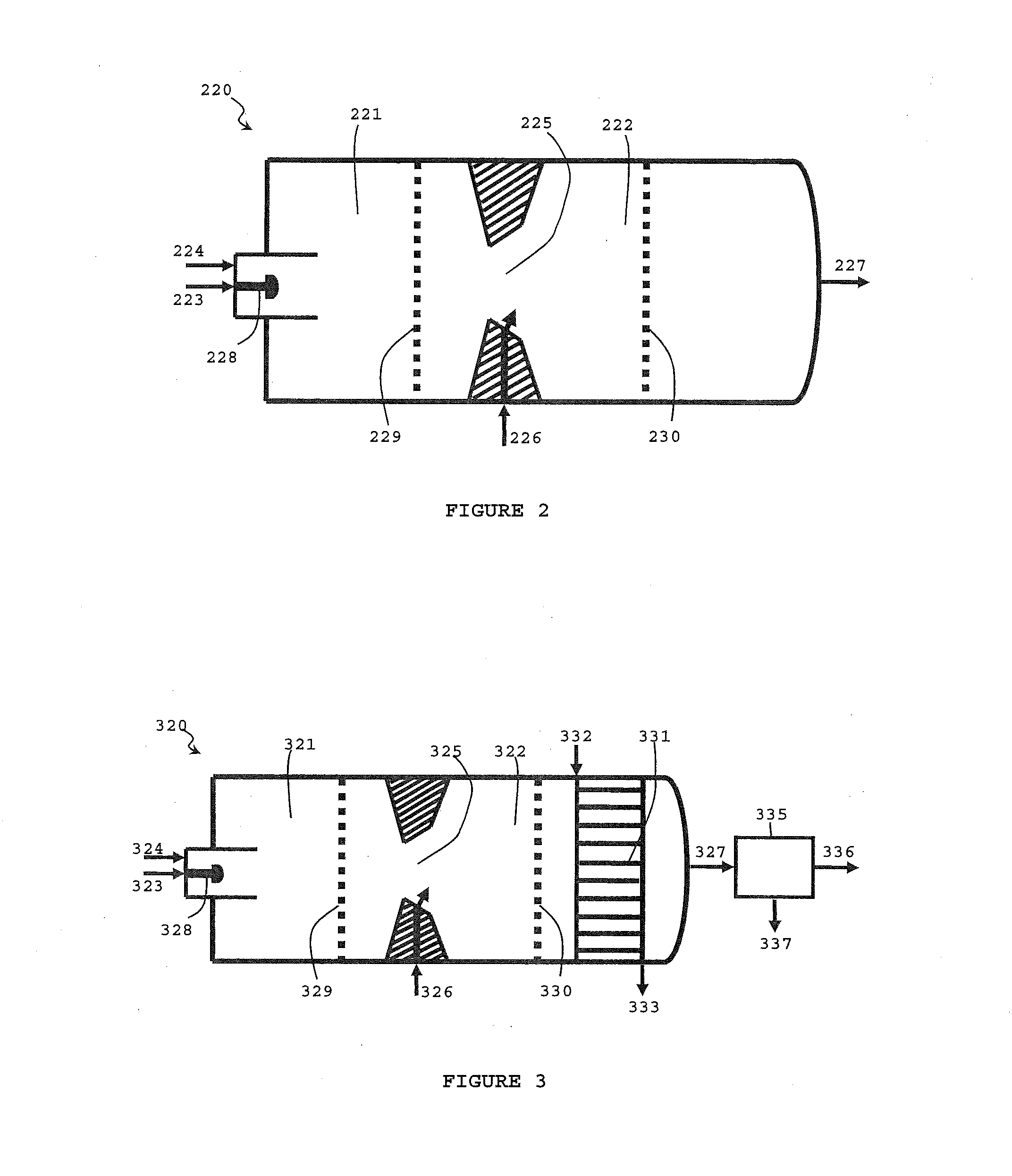

Novel static mixer for gas mixing

InactiveCN101940886AExtended stayIncreased turbulence intensityFlow mixersSulfur preparation/purificationSEMI-CIRCLESulfur

The invention relates to a novel static mixer for gas mixing in a natural gas sulfur recovery super Claus process, which can effectively solve the problem of full-mixing incapability in a turbulent mixing process and improve gas mixing effect. The technical scheme is that: a main pipe is a circular steel pipe, while an auxiliary pipe is vertically inserted into the main pipe from a central line of a right semi-circle of the section of the main pipe; an outlet of the auxiliary pipe has a wedged structure; eight blades are arranged in the main pipe; each blade has a circular arc shape, an inclined angle alpha, a rotating angle beta and a height H; an axial interval between every two blades is L; the pipe walls of the main pipe and the auxiliary pipe are 5 to 10mm thick; and the wedged outlet is 5 to 10mm wide. The static mixer can prolong the residence time of gases in the mixture, and improve the turbulence intensity of the gases to further improve the mixing rates of the mixed gases, and can be used for the natural gas purification sulfur recovery super Claus process.

Owner:SOUTHWEST PETROLEUM UNIV

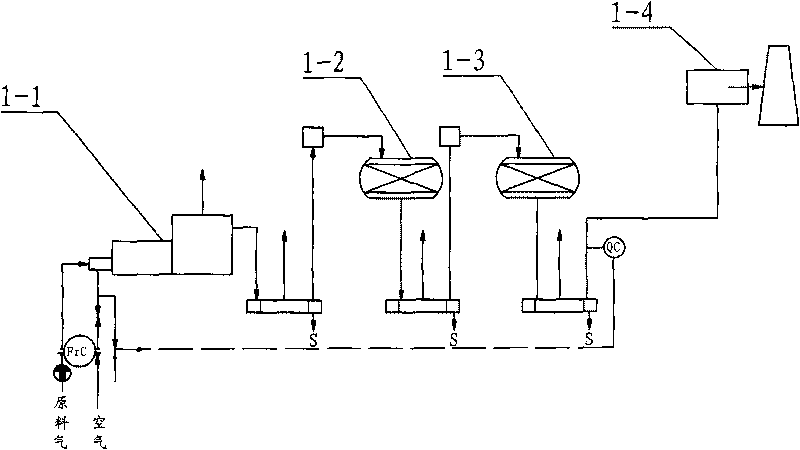

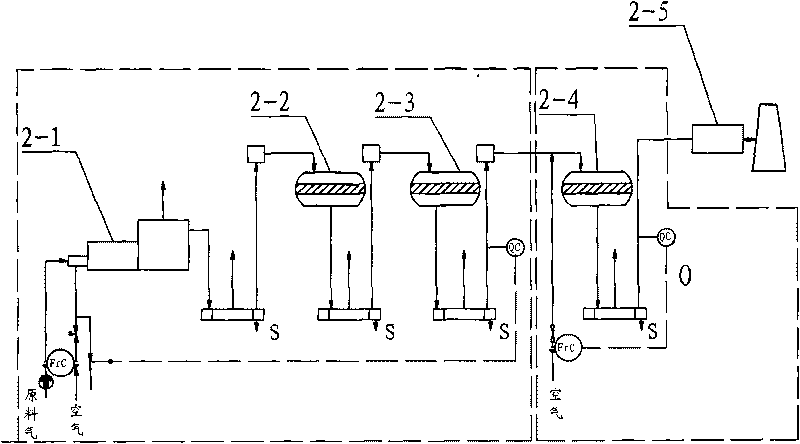

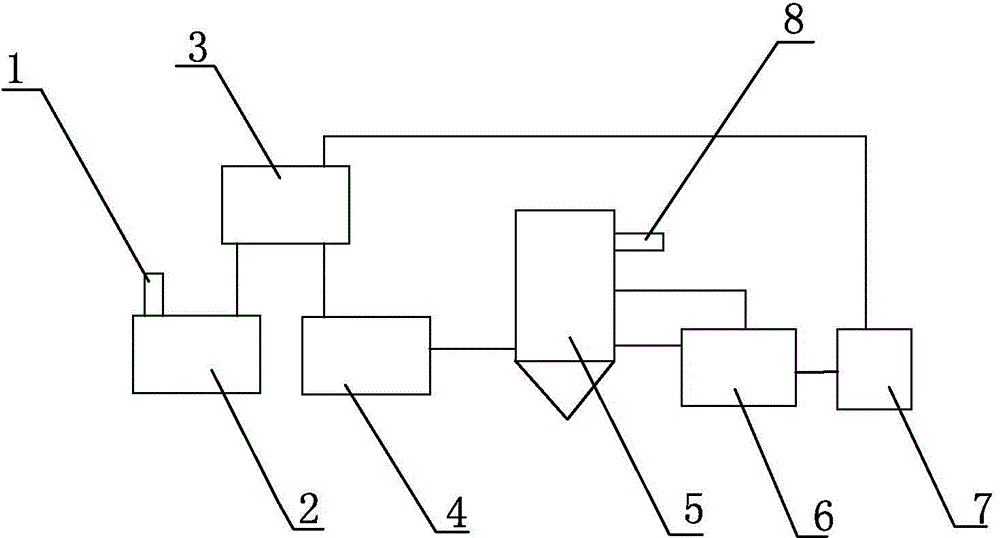

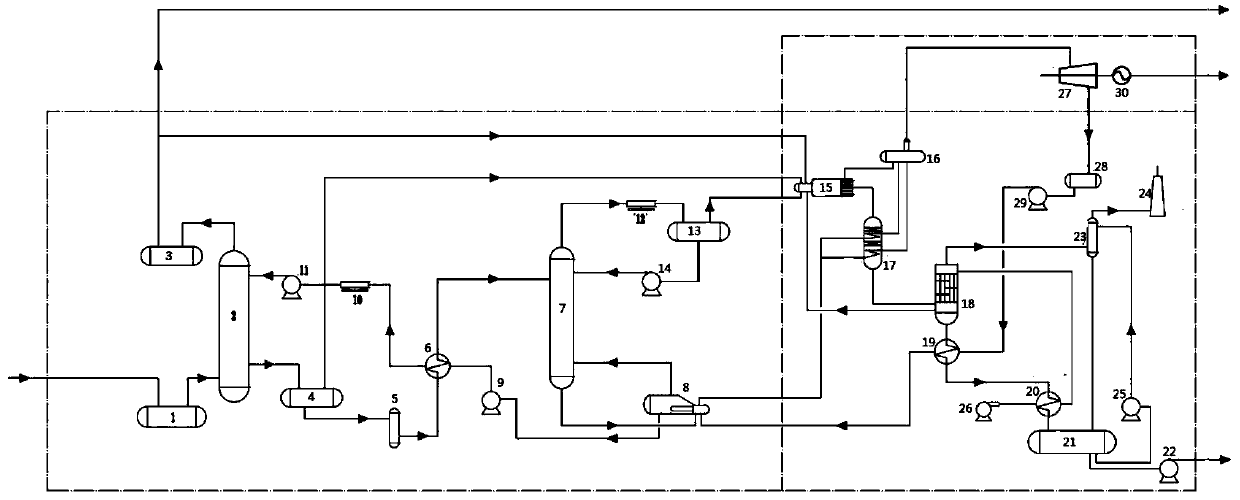

Device and process for preparing acid through desulfuration of sulfur-containing natural gas single well

InactiveCN109943375AHigh recovery rateNo pollution in the processProductsReagentsWastewaterClaus process

The invention belongs to the application field of the desulfuration technique of a sulfur-containing natural gas single well and particularly relates to a device and process for preparing acid throughthe desulfuration of the sulfur-containing natural gas single well. The device comprises an amine-method desulfuration and decarburization system, a wet-method acid preparation system and a waste heat power generation system. According to the process provided by the invention, the problems that the desulfuration construction period of a Claus process in the development process of the sulfur-containing natural gas single well, and the tail gas cannot easily reach the standard are solved, and the problems that a large number of wastewater, waste residue, waste gas and the like are produced in wet-method desulfuration (Lo-Cat process) are solved; and by generating power through the heat of a waste heat boiler, the operation cost of the system is greatly lowered, the security risk is reduced,and the problems of environmental pollution and the like are completely eradicated.

Owner:SICHUAN XUNSHENG OIL & GAS ENG TECH CO LTD +1

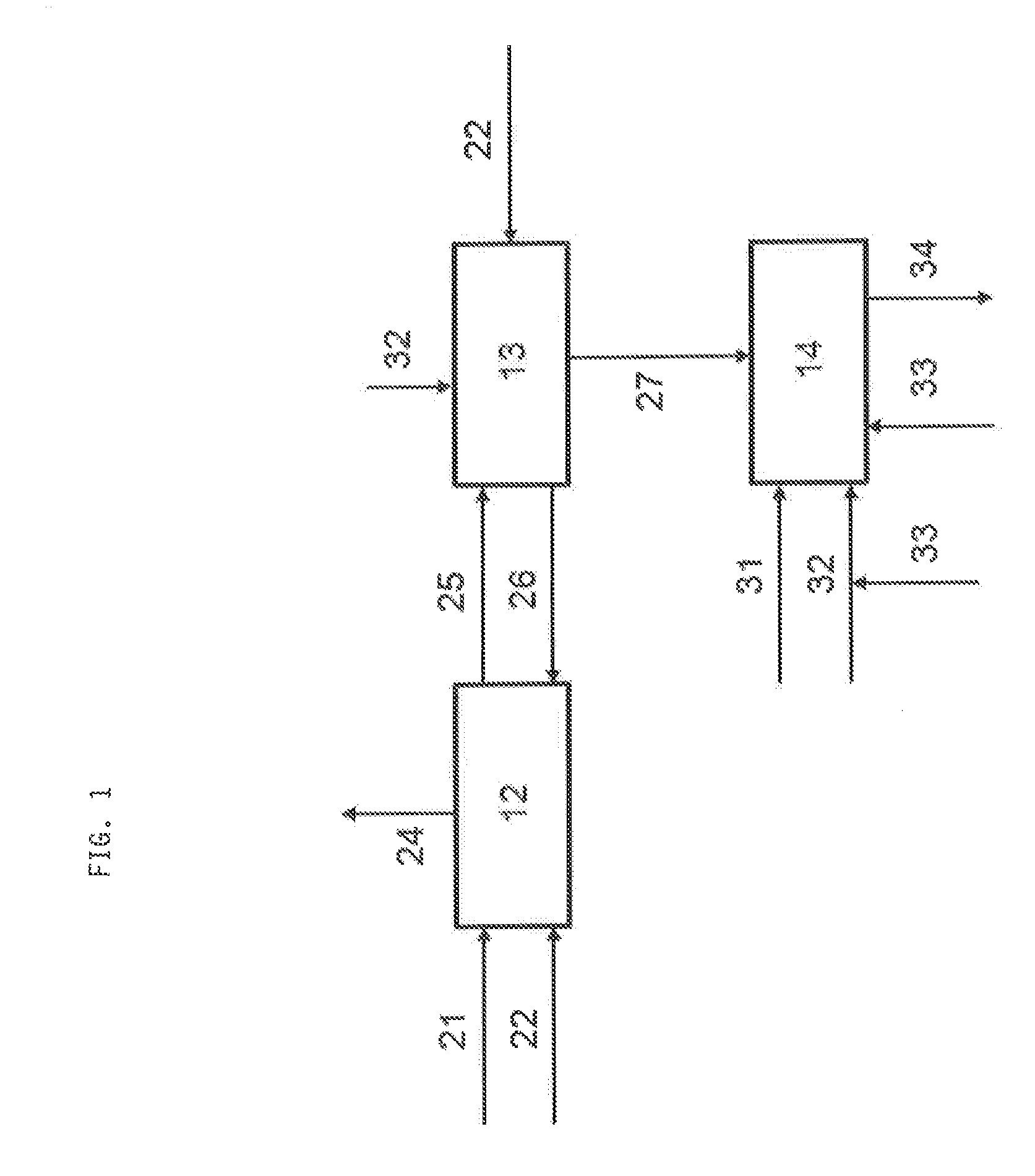

Method of removing sulfur compounds from natural gas

InactiveUS7780933B2Improve conversion efficiencyImprove efficiencyProductsHydrogenMolecular sieveThiol

All sulfur compounds can be efficiently removed from natural gas that contains hydrogen sulfide and other sulfur compounds such as mercaptan without using physical absorption. The process comprises an absorption step of treating natural gas by means of a chemical absorption method using an amine-containing solution to mainly remove hydrogen sulfide and carbon dioxide, an adsorption step of flowing the natural gas from the absorption step through a packed bed of a molecular sieve to mainly remove mercaptan, a recovery step of recovering sulfur compounds by converting the hydrogen sulfide removed in the absorption step into sulfur by means of the Claus process, a regeneration step of desorbing the mercaptan adsorbed on the molecular sieve in the adsorption step using heated gas and a reaction step of converting the mercaptan in the regeneration exhaust gas exhausted from the regeneration step into hydrogen sulfide. The reaction step is conducted by injecting steam or water at a ratio of H2O / S=1 to 5 (molar ratio) relative to the sulfur in the regeneration exhaust gas in the presence of a catalyst under the conditions of a temperature level of 250 to 400° C. and a pressure level of 1 to 10 MPa.

Owner:CHIYODA CORP

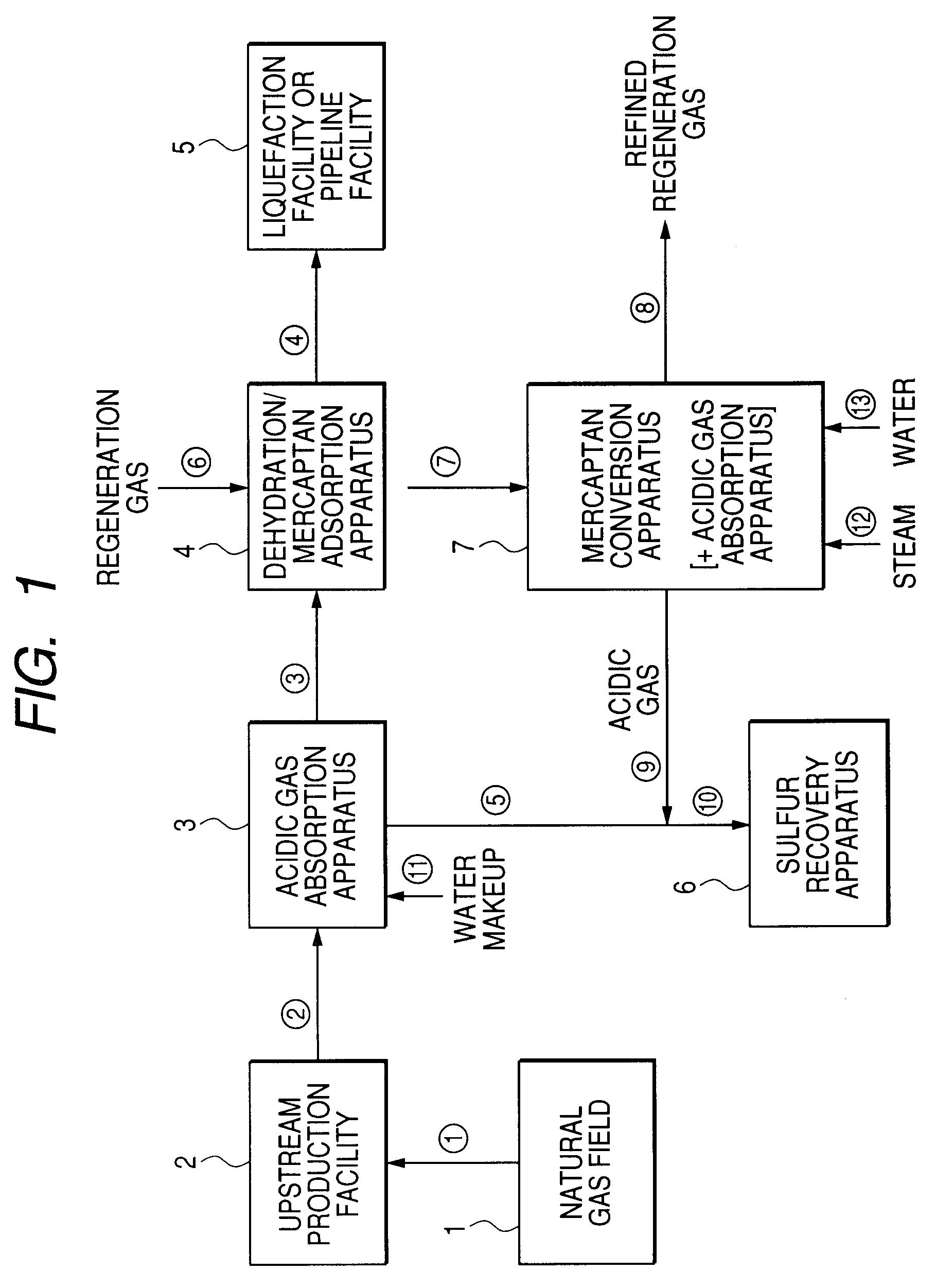

Water wall boiler for air and oxygen fired Claus sulfur recovery units

The thermal combustion step of the modified Claus process is carried out in a water-wall boiler instead of a refractory-lined reaction furnace. The water-wall boiler replaces the conventional refractory-lined furnace and waste heat boiler when air, oxygen, or oxygen-enriched air is used as the oxidant. The acid gas combustion may be hydrogen sulfide-rich or hydrogen sulfide-lean with or without contaminants such as hydrocarbons and ammonia. Thermal combustion is performed in a single stage, without a recycle, for all levels of oxygen enrichment.

Owner:WORLEYPARSONS GROUP

Staged combustion of sulfureous combustible effluents with recovery of the sulfur in the claus process

The invention relates to a process for advantageously efficiently treating a sulfureous combustible effluent stream by recovering the sulfur in elemental form. This process consists especially of the succession of two steps:a step of combustion of the sulfureous combustible effluent stream with an oxidant gas in excess,a step of post-combustion of the effluents from the combustion step with an acidic gas.The stream of the post-combustion effluents, free of chemical compounds that are harmful to the efficacy of the Claus catalysts, is treated in a Claus unit which performs the recovery of the sulfur in elemental form.

Owner:TOTAL PUTEAUX FR

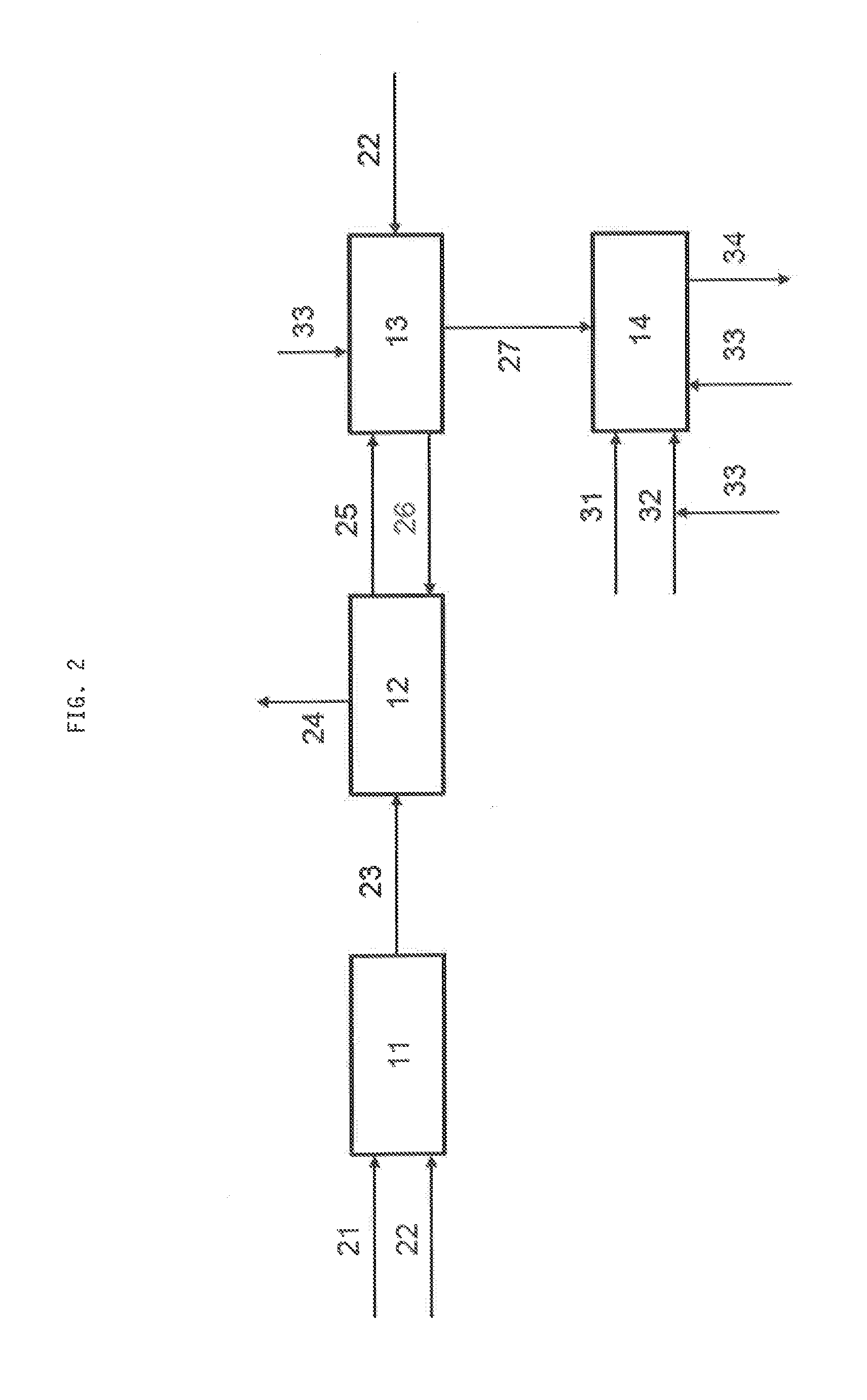

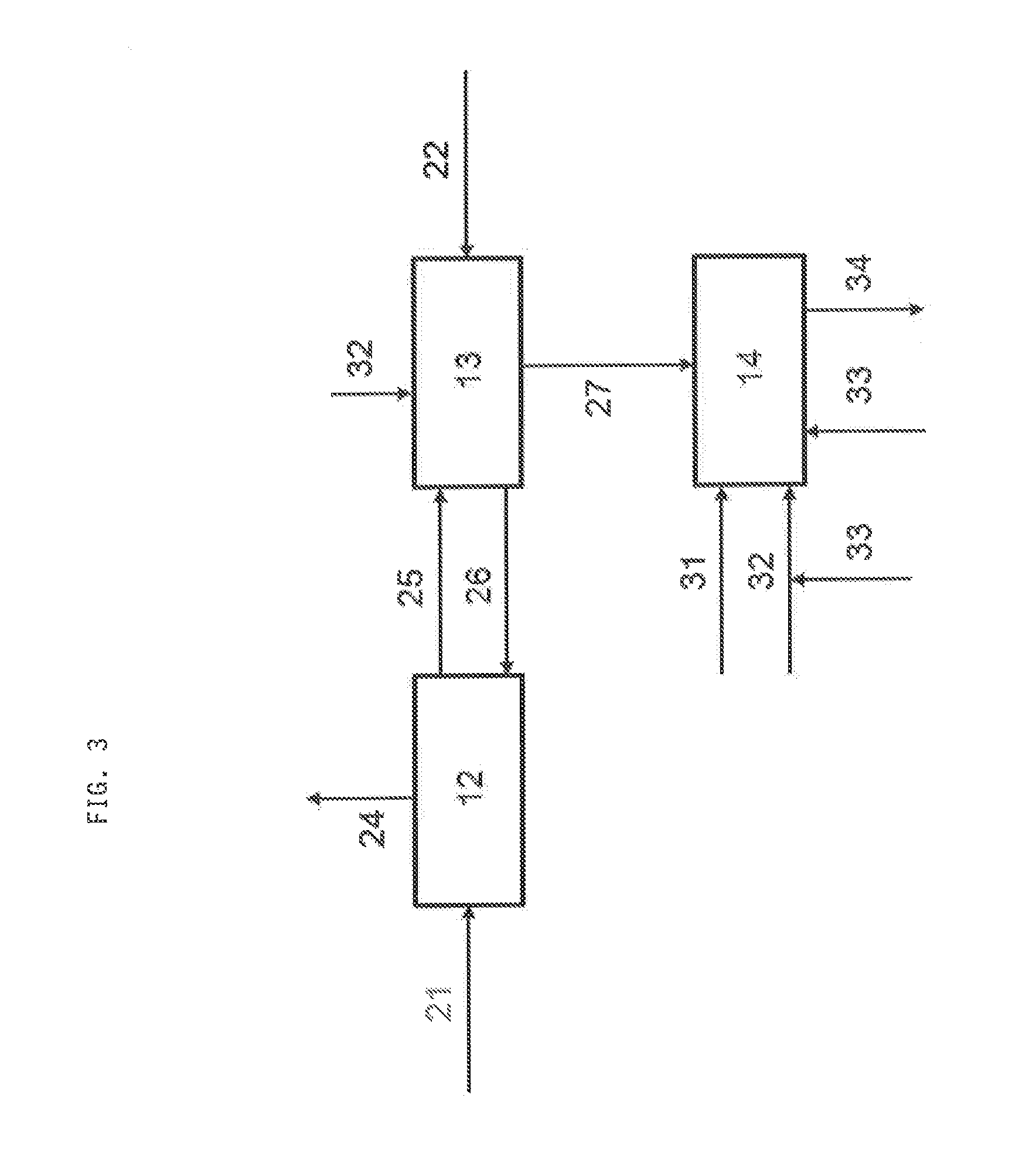

Sulfur removal methods

ActiveUS20140294719A1Inhibition formationAvoid foulingGas treatmentDispersed particle separationSorbentReaction temperature

A method for removing sulphur from a fluid by the steps of providing a first fluid comprising a sulphur-containing compound; adsorbing the sulphur of sulphur-containing compound onto an adsorbent; regenerating the adsorbent by oxidation of the adsorbed sulphur to sulphur dioxide thereby yielding an off-gas stream comprising sulphur dioxide; providing a second fluid comprising hydrogen sulphide, using the second fluid and the off-gas stream as reactants in a Claus process for producing elemental sulphur, wherein a part of hydrogen sulphide provided by the second fluid is oxidized to sulphur dioxide and water at reaction temperature, the residual hydrogen sulphide, the resulting sulphur oxide and the sulphur oxide provided by the off-gas stream are converted to elemental sulphur, the oxygen required for the oxidation of the hydrogen sulphide provided by the second fluid is provided by an air stream, and the off-gas stream dilutes the second fluid in the Claus process.

Owner:MESSER IND USA INC

Process for the Removal of Hydrogen Sulfide from a Gas Stream

The application relates to a process for the removal of hydrogen sulfide from a gas stream by catalytic direct oxidation without employing the combustion step of a Claus process. The process is particularly suitable for desulfurization of gas streams that contain hydrogen and allows sulfur recovery efficiency of better than 99%.

Owner:AXENS SA

Enhancement of claus tail gas treatment by sulfur dioxide-selective membrane technology and sulfur dioxide-selective absorption technology

ActiveUS10106411B2Improve sulfur recoveryEmission reductionProductsGas treatmentMembrane technologySulfur

A method for recovering sulfur from an acid gas feed is provided. The method comprising the steps of mixing the acid gas feed and an absorption process outlet stream to form a combined Claus feed, introducing the combined Claus feed and a sulfur dioxide enriched air feed to a Claus process to produce a Claus outlet gas stream, introducing the Claus outlet gas stream to a thermal oxidizer, treating the thermal oxidizer outlet stream in a gas treatment unit to produce a dehydrated stream, introducing the dehydrated stream to a membrane sweeping unit to produce a sweep membrane residue stream and a sulfur dioxide enriched air feed, introducing a sweep air stream to a permeate side of the membrane sweeping unit, and introducing the sweep membrane residue stream to a sulfur dioxide absorption process to produce the absorption process outlet stream and a stack feed.

Owner:SAUDI ARABIAN OIL CO

Apparatus for in-situ production of low dissolved hydrogen sulfide, degassed, sulfur from claus sulfur recovery

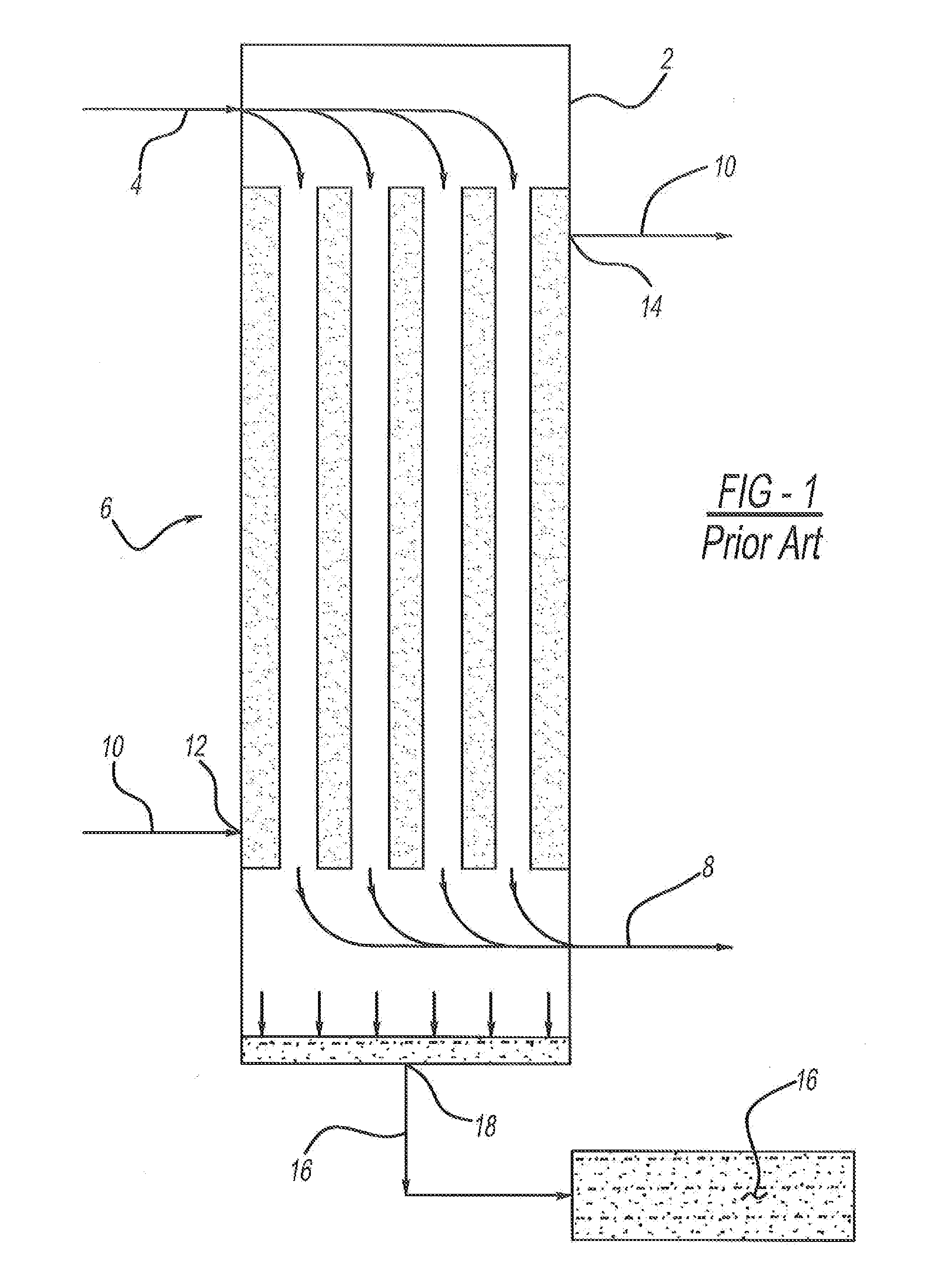

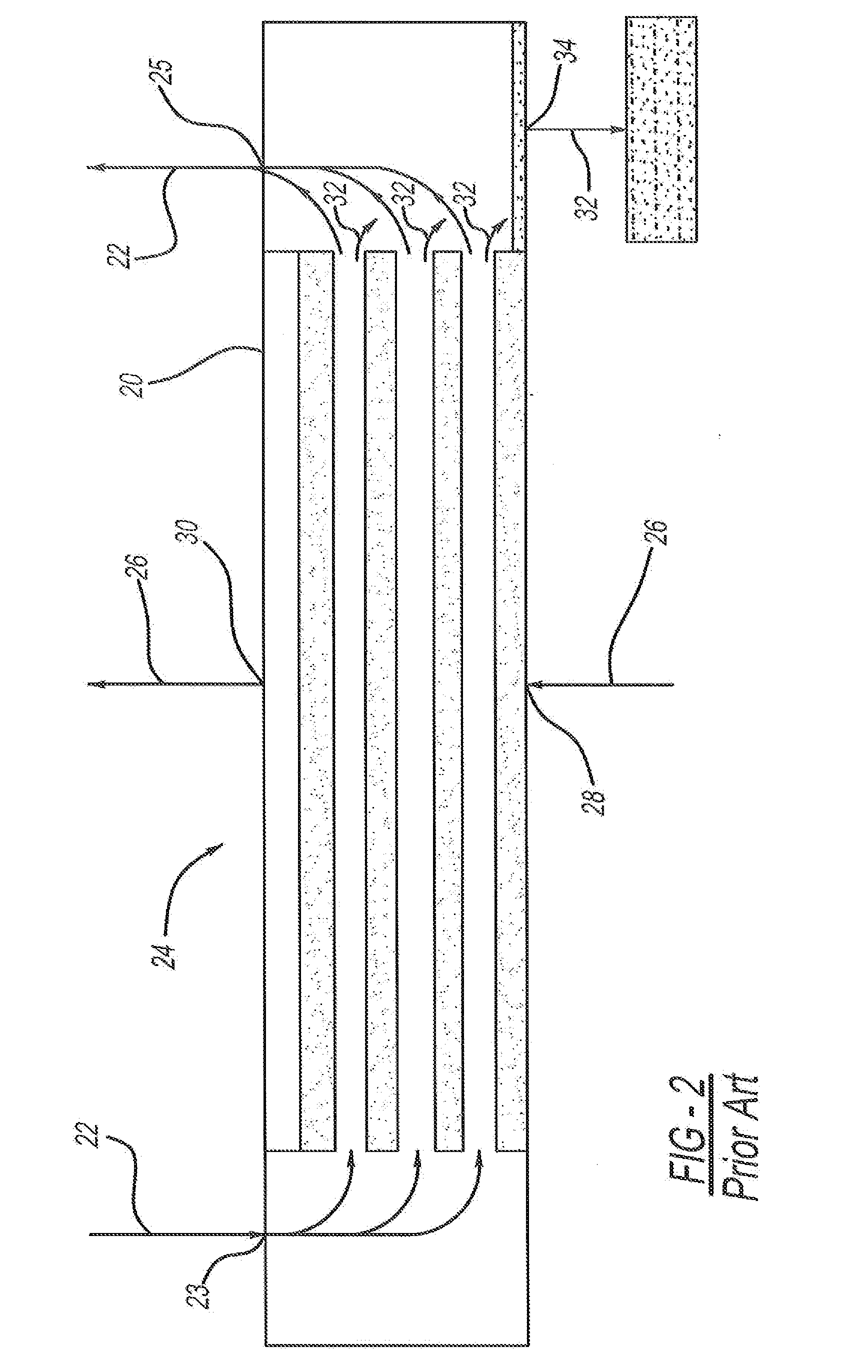

A horizontal sulfur condenser may include an exterior casing with a plurality of condenser tubes arranged longitudinally within the casing, a liquid sulfur reservoir at a longitudinal end within the exterior casing, and an internal baffle that protrudes into the liquid sulfur reservoir from the surface. The lowest of the plurality of condenser tubes is parallel to a wall of the exterior casing. A Claus process gas inlet is proximate a first end of the plurality of condenser tubes, which are arranged horizontally but are positioned vertically above the sulfur reservoir. A liquid sulfur outlet is located at the liquid sulfur surface. The baffle creates multiple chambers above the sulfur reservoir, such as a first chamber defined by the exterior casing and the baffle to receive condensed Claus sulfur in the liquid reservoir, and a second chamber defined by the exterior casing and the baffle to receive degassed liquid sulfur.

Owner:PHILLIPS 66 CO

Enhancement of Claus tail gas treatment by sulfur dioxide-selective membrane technology

ActiveUS10106410B2Improve sulfur recoveryEmission reductionGas treatmentDispersed particle separationMembrane technologySulfur

Owner:SAUDI ARABIAN OIL CO

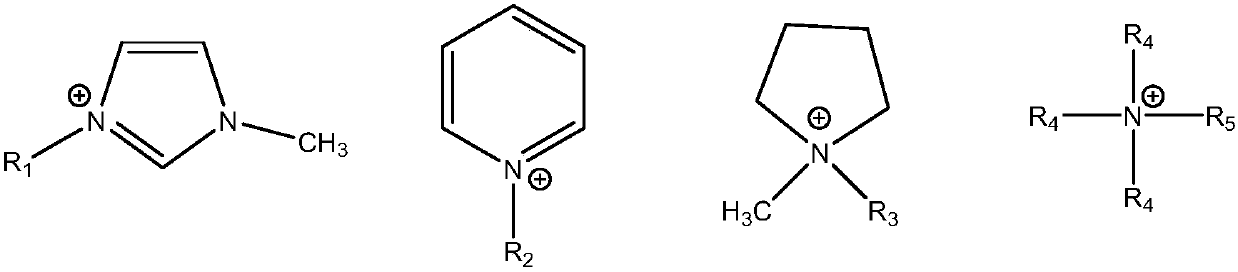

A normal temperature liquid phase claus process using ionic liquid as medium

ActiveCN105521696BHigh purityLower operating temperatureGas treatmentDispersed particle separationDissolutionClaus process

Owner:NANJING UNIV

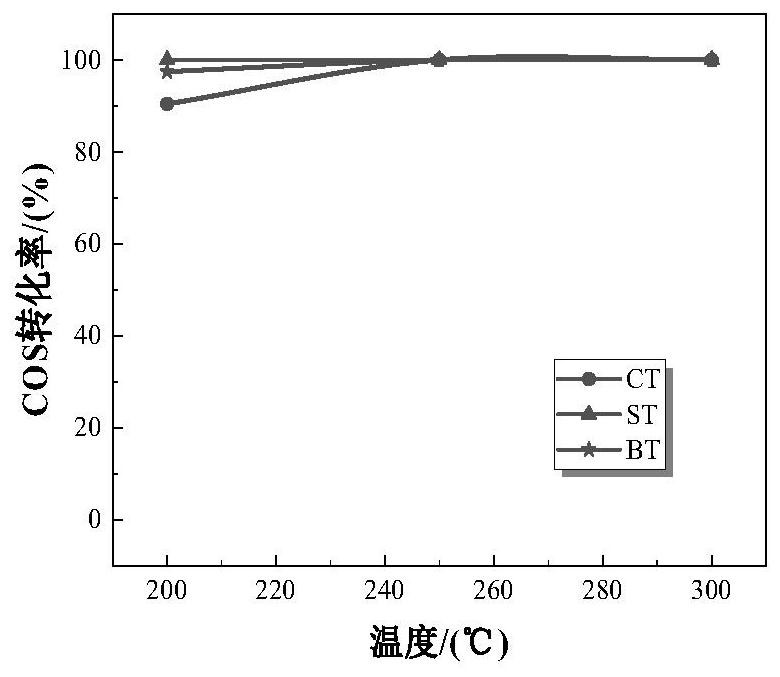

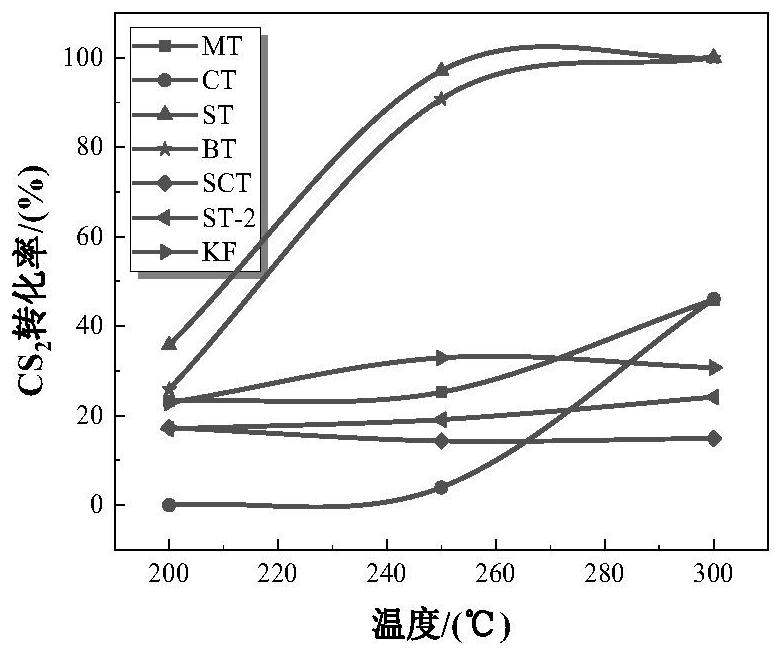

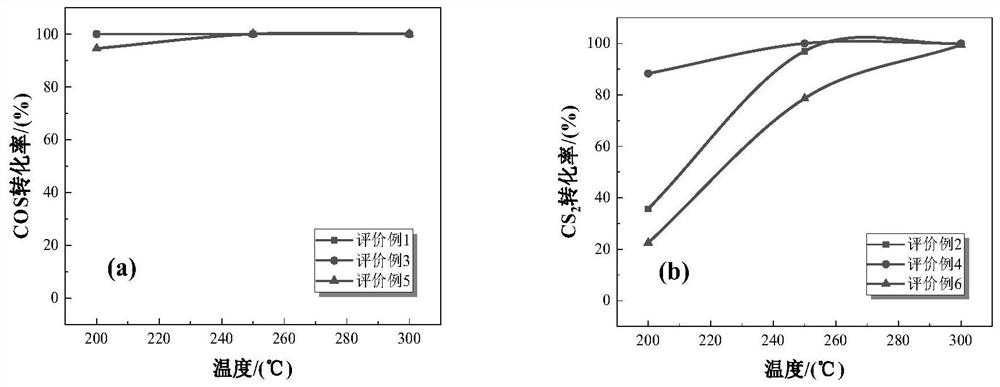

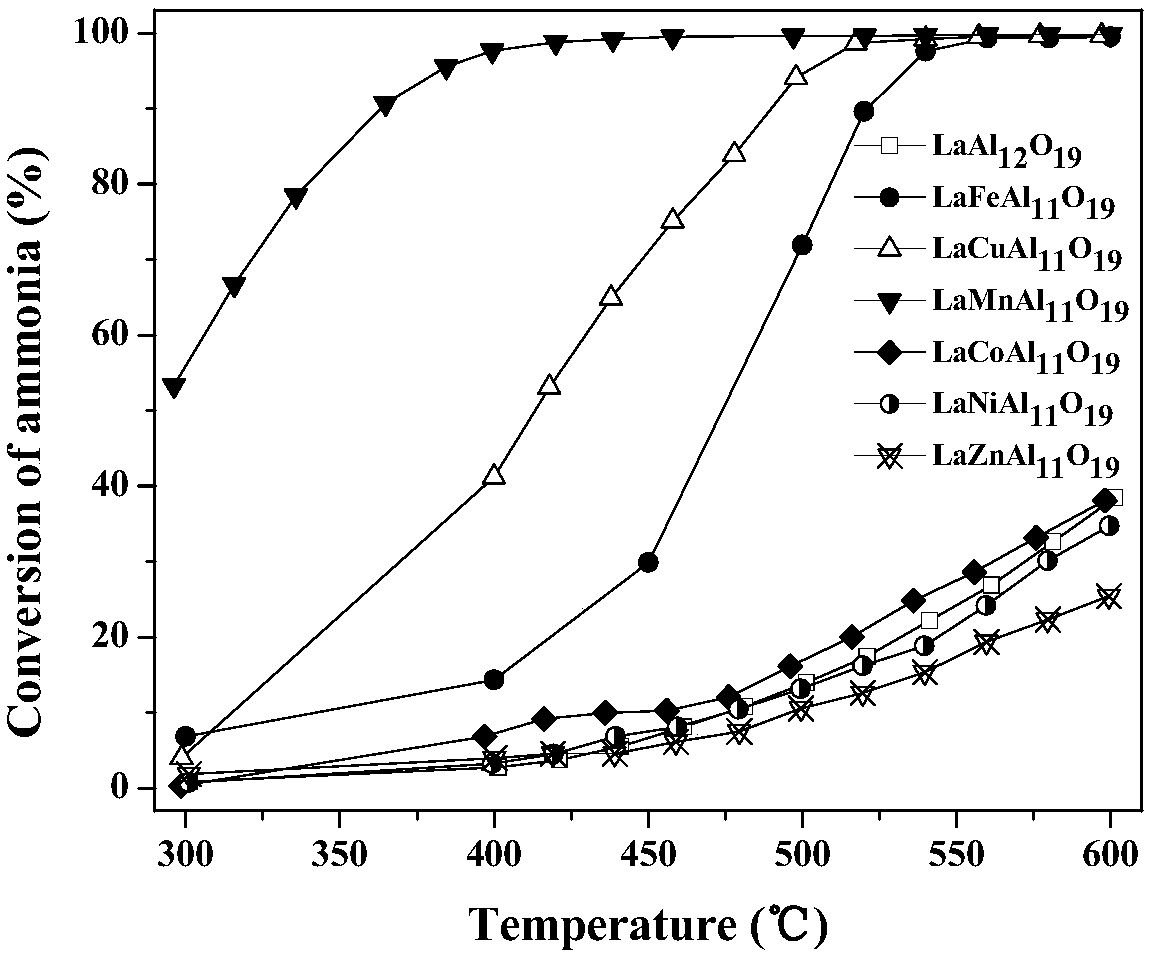

Organic sulfur hydrolysis catalyst applicable to Claus process as well as preparation method and application of organic sulfur hydrolysis catalyst

PendingCN113663665AStrong adjustableRich in acid and alkali sitesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

The invention belongs to the technical field of sulfur recovery processes, and particularly relates to an organic sulfur hydrolysis catalyst suitable for a Claus process and a preparation method of the organic sulfur hydrolysis catalyst. The general formula of the perovskite type composite oxide catalyst is ABOx, the perovskite type composite oxide catalyst is synthesized through a hydrothermal method, A is alkali or alkaline earth metal elements and comprises Na, K, Cs, Mg, Ca, Sr and Ba, B is transition metal elements and comprises Ti, Fe and Co, and x is equal to 1.5-3. The material has the characteristics of strong composition and structure adjustability, abundant surface acid-base sites and the like, and has excellent organic sulfur catalytic hydrolysis activity.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES +1

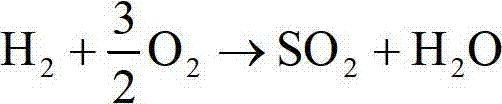

Claus process H2S acid gas catalytic combustion method

ActiveCN109114577AReduce material requirementsLow investment costIncinerator apparatusResource recoverySulfur

The invention relates to a Claus process H2S acid gas catalytic combustion method, and belongs to the technical field of sulfur resource recovery. The catalytic combustion method comprises the following steps that firstly, H2S raw material gas and air with a certain proportion through a premixing system to realize gas mixing; then the mixed gas passes through a hexaaluminate composite oxide catalytic bed layer maintained in a specific temperature range, under the action of the catalyst, H2S is oxidized into SO2 according to the designed amount, NH3 is efficiently catalytically decomposed intoN2, and the hydrocarbon is catalytically oxidized into CO2; and the purification gas of the catalytic bed layer enters a subsequent process to generate a Claus reaction. According to the Claus processH2S acid gas catalytic combustion method, a catalytic combustion method is adopted, ignition and flame burning are not needed, the combustion temperature, the equipment investment and the operation cost can be effectively reduced, and the operation is simple and safe.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Steam modified Claus process

ActiveUS20060153767A1Quantity minimizationMaximize feed rateSulfur preparation/purificationClaus processSulfur hydride

Disclosed is a method for treating a gas stream rich in hydrogen sulfide by providing one or more feed gas streams rich in hydrogen sulfide into a Claus reaction furnace, providing air into the Claus reaction furnace, providing supplemental oxygen into the Claus reaction furnace, and providing steam to the Claus reaction furnace, where the steam is in addition to any steam that may be present in gases that are recycled to the Claus reaction furnace. The components are then reacted at a temperature above about 2400° F. and at a pressure sufficient to cause hydrogen sulfide to be converted into sulfur.

Owner:AIR PROD & CHEM INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com