Equipment and method for treating exhaust gas for carbon bisulfide preparing process

A preparation process, carbon disulfide technology, applied in chemical instruments and methods, separation methods, chemical recovery, etc., to achieve stable operation, low energy consumption, and reduced work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

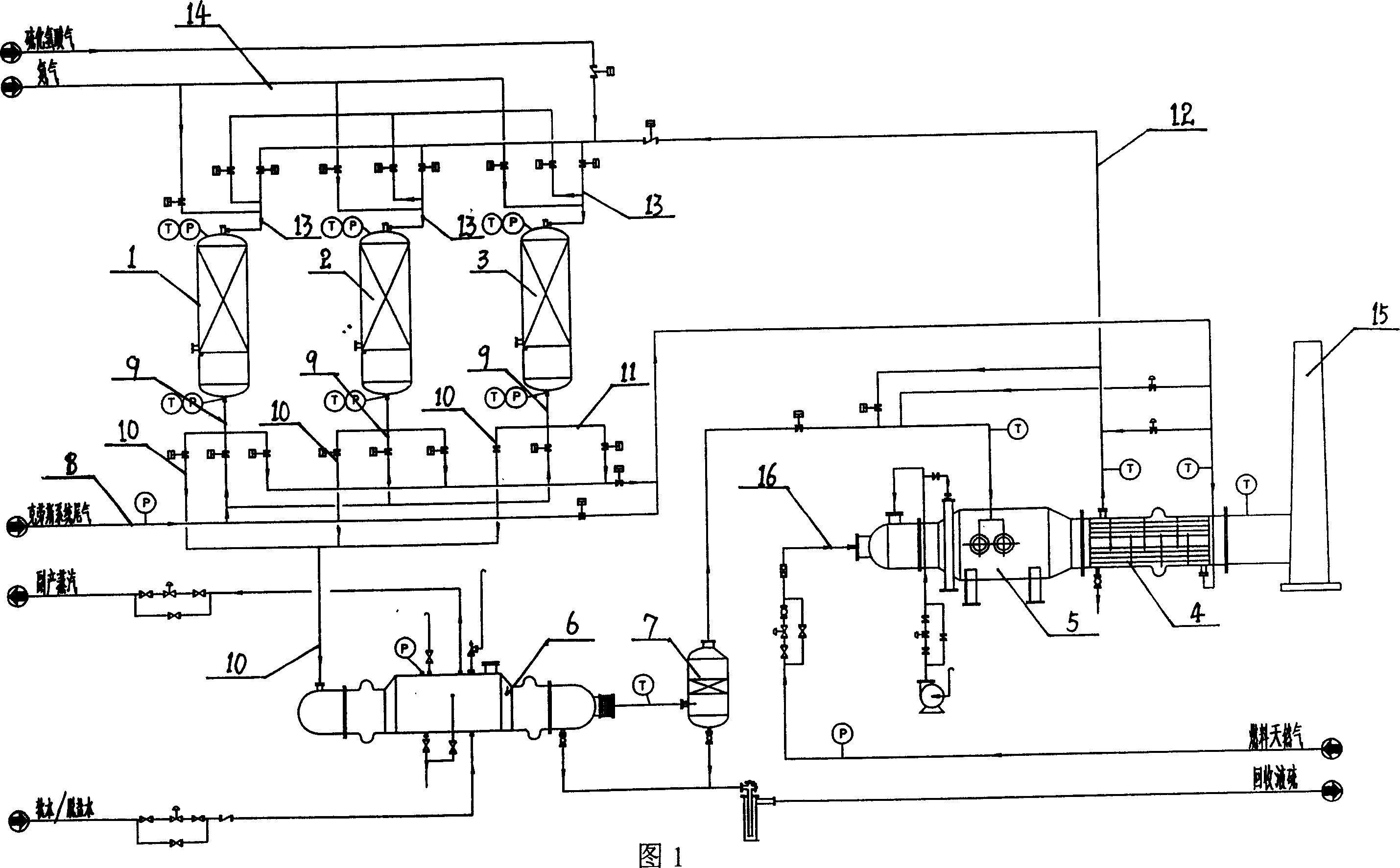

[0013] The tail gas treatment equipment in the carbon disulfide preparation process includes at least three Claus reactors 1, 2, and 3. The lower part of the reactor is respectively connected with the tail gas input branch pipe 9 communicated with the Claus tail gas main pipe 8, and the tail gas input branch pipe 9 is respectively The sulfur output pipe 10 and the cold gas output pipe 11 are connected, the other end of the sulfur output pipe 10 is connected to the front of the sulfur condenser 6, the tail of the sulfur condenser 6 is connected to the sulfur trap 7, and the top of the sulfur trap 7 is passed through a pipeline It is connected with the burning furnace 5, the tail of the burning furnace 5 communicates with the gas-gas heat exchanger 4, and the other end of the cold gas output pipe 11 communicates with the gas-gas heat exchanger 4, and the gas-gas heat exchanger 4 is also provided with a hot gas Input main pipe 12, the top of the reactor is provided with the hot ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com