Device and process for preparing acid through desulfuration of sulfur-containing natural gas single well

A technology of natural gas and sulfuric acid, applied in the direction of steam engine equipment, gas fuel, sulfur compounds, etc., to achieve the effect of no chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

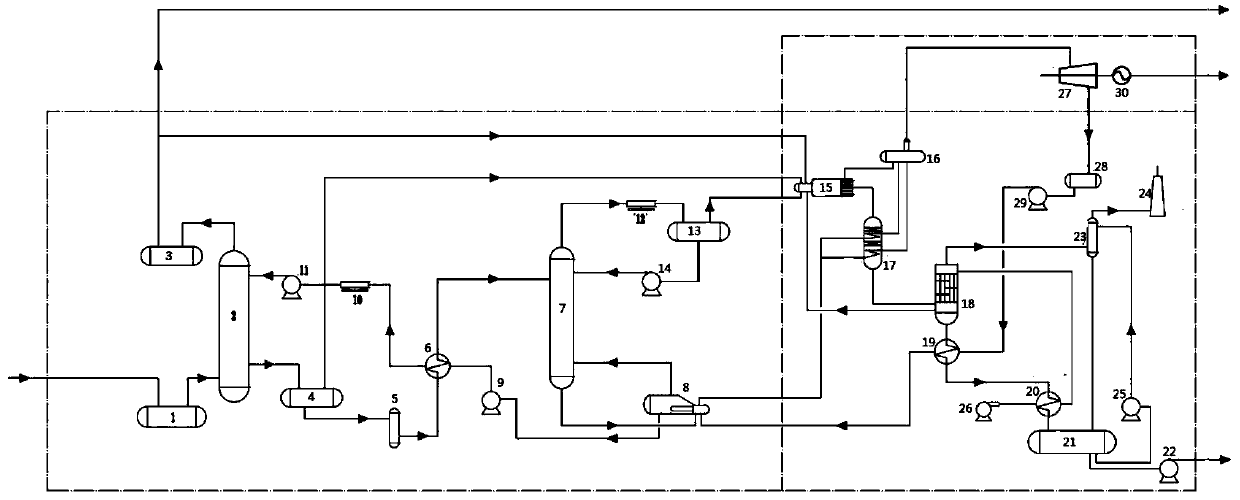

[0036] In this embodiment, the development and comprehensive utilization of a certain sour natural gas single well is taken as an example to further describe the invention and the device in detail.

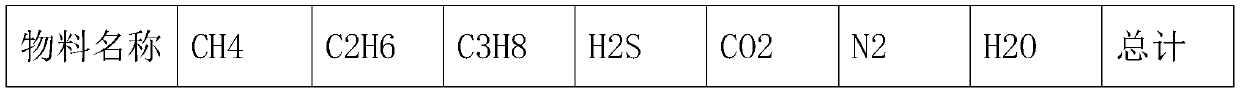

[0037] The natural gas production capacity of a single well of sour natural gas is 15×104Nm3 / d; the source pressure of sour natural gas is 5.0MPa, the gas source temperature is 20°C, and the gas composition is shown in the table below.

[0038] Table: Gas composition table of a certain sour natural gas well

[0039]

[0040]

[0041] The desulfurization process for a sour natural gas single well is as follows:

[0042] Sour natural gas (containing H2S 7.161%, CO 2 5.512%) first pass through the gravity sedimentation separator 1 to remove the entrained liquid droplets and solid impurities; then enter the absorption tower 2 and contact with the MDEA liquid at 40 ° C in countercurrent to remove H 2 S and CO 2 . The 43.3°C desulfurized purified natural gas from the top of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com