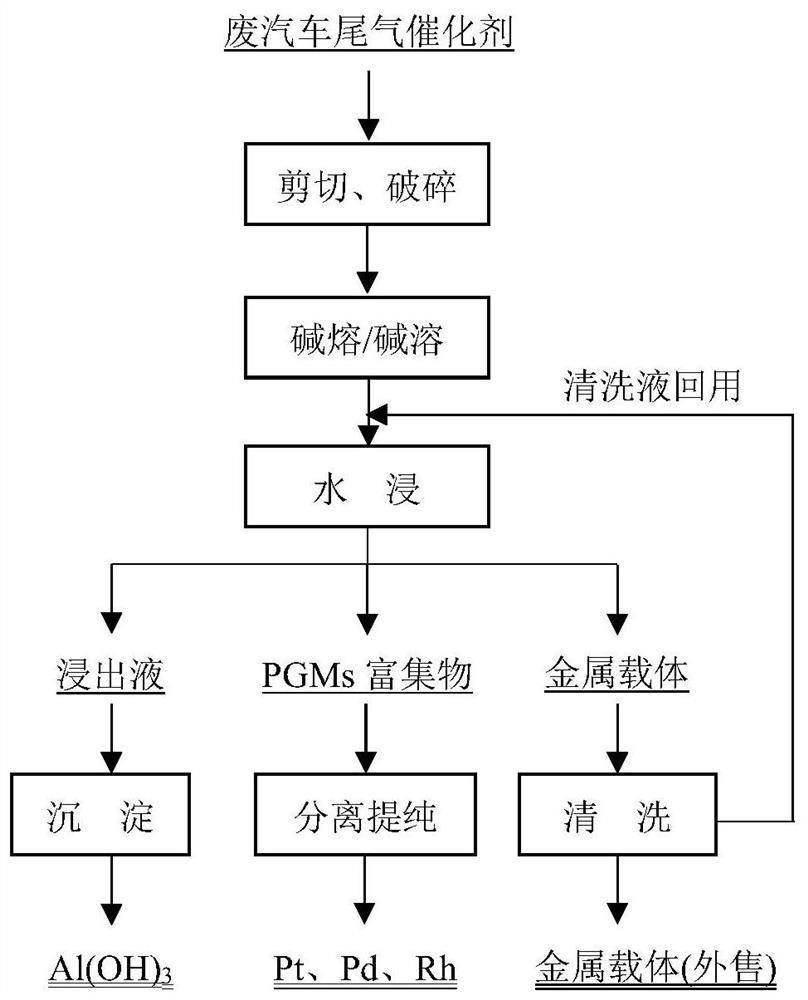

Method for recovering platinum group metals from metal carrier waste automobile exhaust catalyst

A technology of automobile exhaust gas and metal carrier, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption of total dissolved substances, low recovery rate of ultrasonic-acid leaching, etc., and achieves high direct yield, low cost, and enrichment multiple. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Cut metal carrier waste automobile exhaust catalyst into 1cm 2 The flakes were mixed with sodium hydroxide at a mass ratio of 0.5:1, and the mixture was roasted at 600°C for 240min. The calcined product was dissolved at 30°C with a solid-to-liquid ratio of 1:3 to obtain PGMs-enriched materials and metal supports, and the dissolution time was 180 min. Use aqua regia to dissolve PGMs at 80°C, and then use 732 cation exchange resin to remove Fe in PGMs solution 3+ 、Al 3+ 、Na + and other impurity ions.

[0038] The purified PGMs solution adjusted H + The concentration is 0.1mol / L, extract Pd with diisoamyl sulfide, the volume ratio of organic phase to solution is 0.5:1, and the extraction temperature is 20°C; then use 0.1mol / L ammonia water for back extraction, repeat extraction 4 times, and finally reduce with formaldehyde Get 99.99% Pd. Adjust the Pd raffinate H + The concentration is 2.0mol / L, Pt is extracted with tributyl phosphate, the volume ratio of organic ph...

Embodiment 2

[0040] Cut metal carrier waste automobile exhaust catalyst into 5cm 2 The flakes were mixed with potassium hydroxide at a mass ratio of 1:1, and the mixture was roasted at 700°C for 200min. The calcined product was dissolved at 50°C with a solid-to-liquid ratio of 1:4 to obtain PGMs-enriched materials and metal supports, and the dissolution time was 140 min. Use aqua regia to dissolve PGMs at 90°C, and use 732 cation exchange resin to remove Fe in PGMs solution 3+ 、Al 3+ 、Na + and other impurity ions.

[0041] The purified PGMs solution adjusted H + Concentration 0.5mol / L, extract Pd with diisoamyl sulfide, organic phase to solution volume ratio 1:1, extraction temperature 30°C; then back extraction with 0.5mol / L ammonia water, repeated extraction 4 times, and finally reduction with formaldehyde Get 99.99% Pd. Adjust the Pd raffinate H + Concentration of 3.0mol / L, Pt was extracted with tributyl phosphate, the volume ratio of organic phase to solution was 3:1, and the ex...

Embodiment 3

[0043] Cut metal carrier waste automobile exhaust catalyst into 10cm 2 The flakes were mixed with sodium carbonate at a mass ratio of 3:1, and the mixture was roasted at 800°C for 120min. The calcined product was dissolved at 30°C with a solid-to-liquid ratio of 1:5 to obtain PGMs-enriched materials and metal supports, and the dissolution time was 180 min. Use aqua regia to dissolve PGMs at 95 °C, and then use 732 cation exchange resin to remove Fe in PGMs solution 3+ 、Al 3+ 、Na + and other impurity ions.

[0044] The purified PGMs solution adjusted H + Concentration 2.0mol / L, extract Pd with diisoamyl sulfide, organic phase to solution volume ratio 2:1, extraction temperature 60°C; then back extraction with 2.0mol / L ammonia water, repeated extraction 4 times, and finally reduction with formaldehyde Get 99.99% Pd. Adjust the Pd raffinate H + Concentration of 5.0mol / L, Pt was extracted with tributyl phosphate, the volume ratio of organic phase to solution was 5:1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com