Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253results about How to "High enrichment factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ionic liquid double-aqueous phase system for extracting residual antibiotic in foodstuffs and use thereof

InactiveCN101502722AEfficient extractionHigh sensitivitySolvent extractionPreparing sample for investigationInorganic saltsAntibiotic Y

An ionic liquid dual aqueous phase system for extracting residual antibiotics in food is disclosed. The dual aqueous phase system formed by ionic liquid and inorganic salt realizes efficient extraction of residual antibiotics in food. Specific pyridine ionic liquid and specific inorganic salt are mixed according to the proportion of 1-20% (w / v) ionic liquid and 40-56% (w / v) of inorganic salt to ensure the extraction rate of antibiotics in food by the ionic liquid dual aqueous phase system to be larger than or equal to 90%, thus remarkably improving the sensitivity and reliability of detection of antibiotics residual in food.

Owner:JIAXING UNIV

Ion mobility spectrometer with substance collector

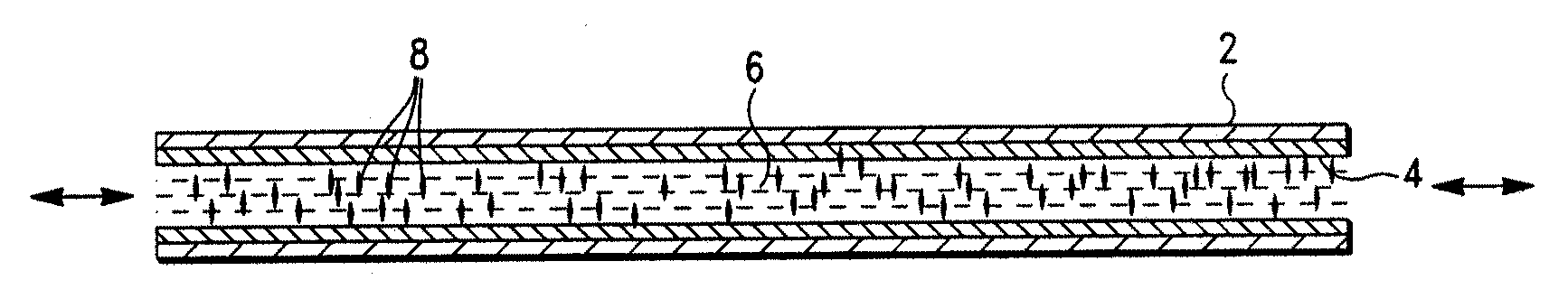

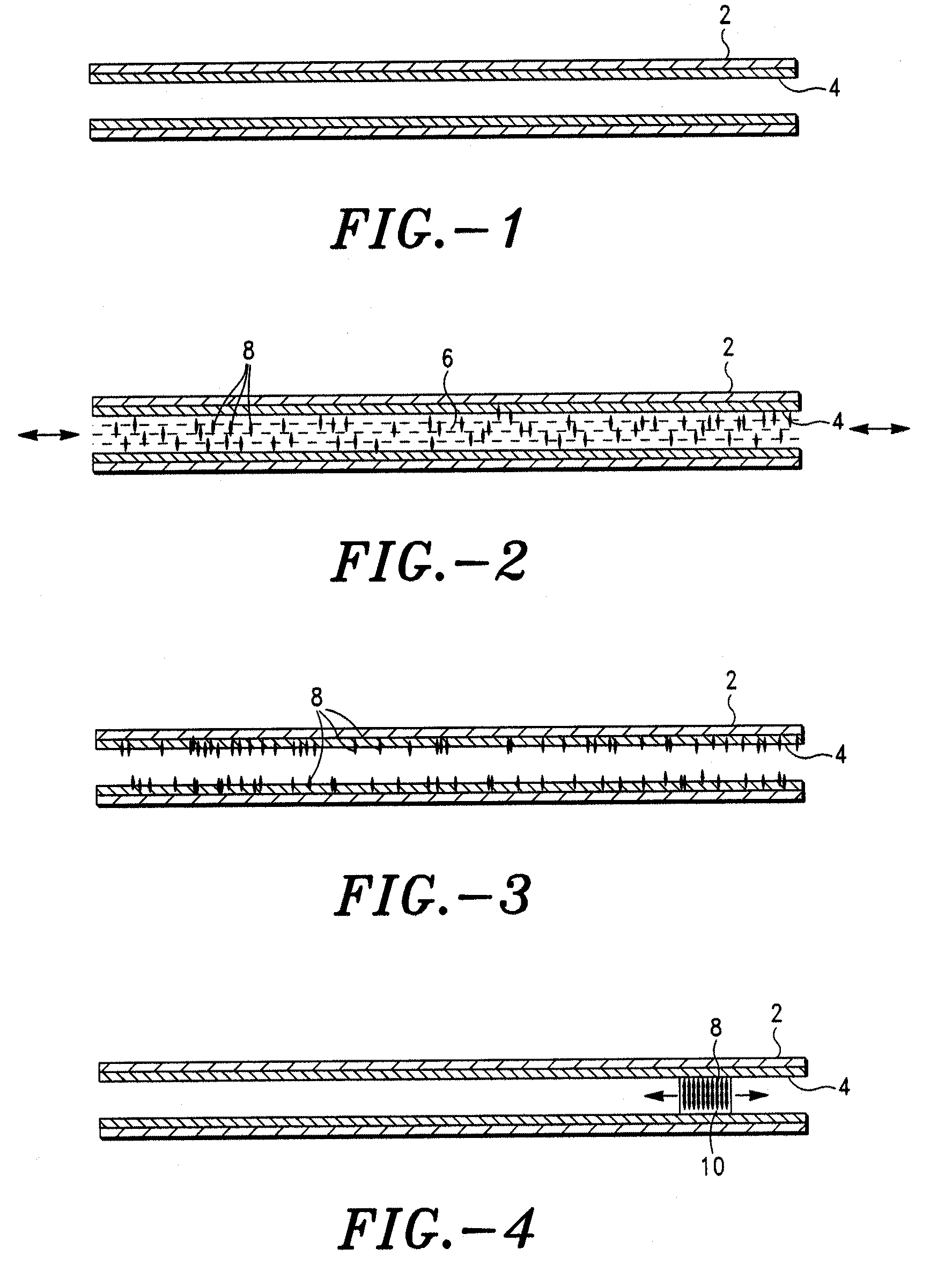

ActiveUS20090114812A1Increase storage spaceHigh enrichment factorTime-of-flight spectrometersMicrobiological testing/measurementAnalyteIon-mobility spectrometry

A method for operating an ion mobility spectrometer that comprises a measuring tube, a substance collector and a membrane inlet, the measuring tube, the substance collector and the membrane inlet defining a closed internal gas circuit, comprising separating the closed internal gas circuit from an external sample gas flow through the membrane inlet, transferring circulating gas containing an analyte substance from the membrane inlet to the substance collector, the analyte substance accumulated in the substance collector, releasing the accumulated analyte substances, and transferring the released analyte substances to the measuring tube.

Owner:BRUKER OPTICS GMBH & CO KG

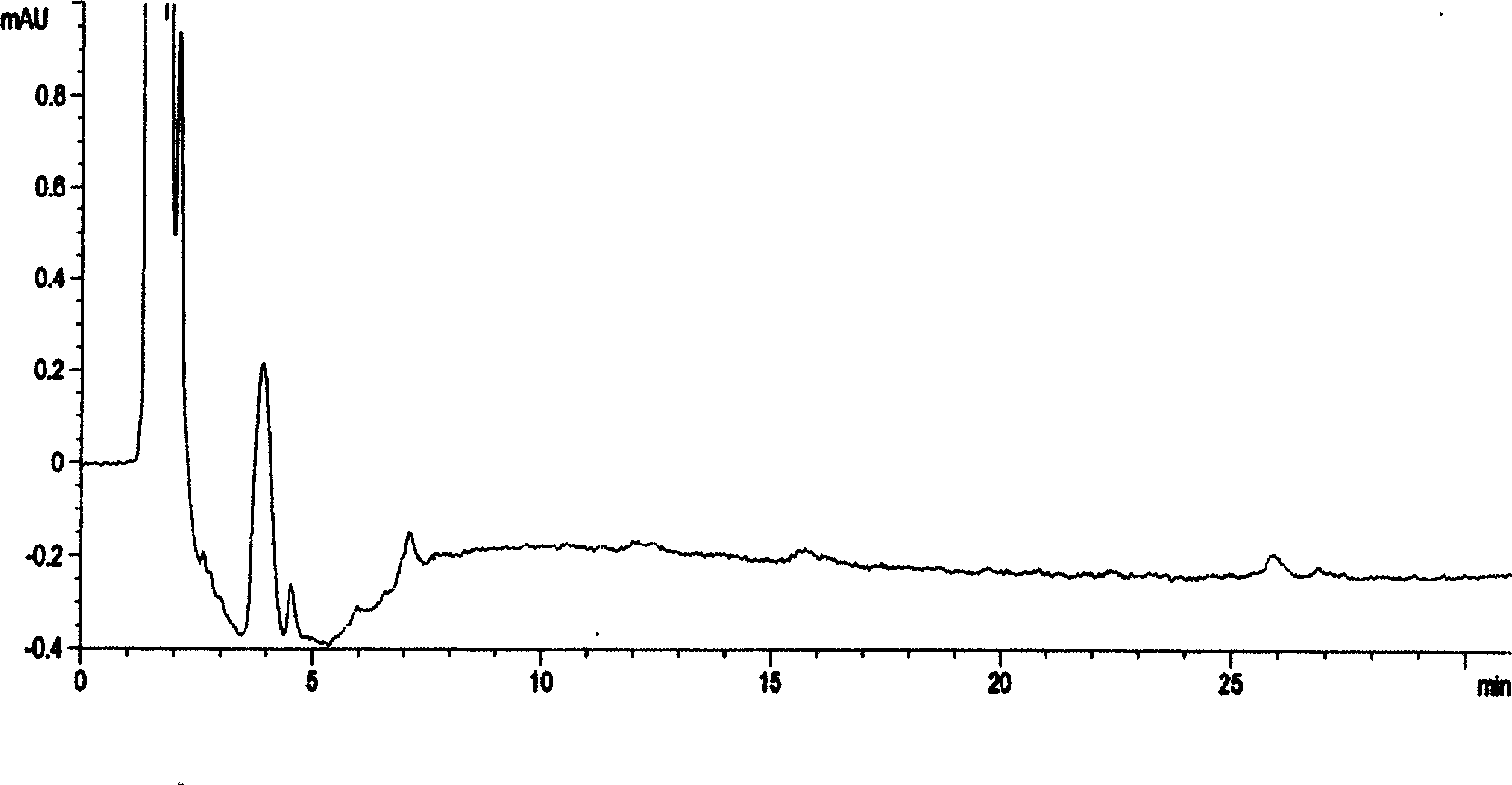

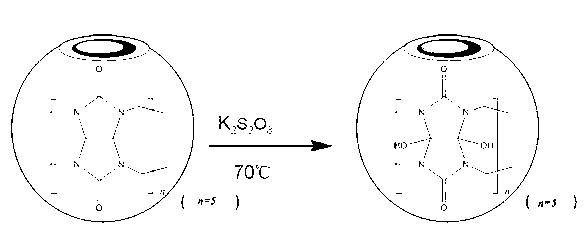

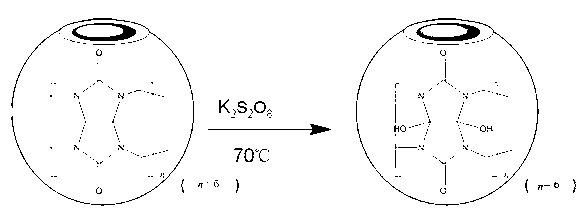

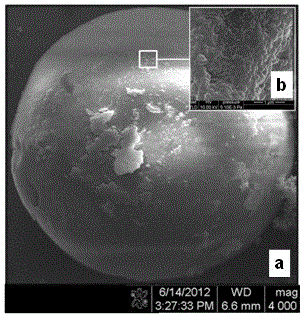

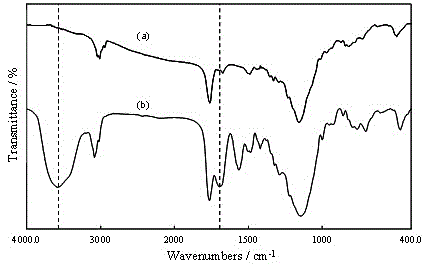

Solid phase microextraction coating of hydroxyl cucurbituril as well as preparation method and application thereof

InactiveCN103157453AIncrease surface areaHigh selectivityIon-exchange process apparatusComponent separationPotassium persulfateChemical reaction

The invention discloses a solid phase microextraction coating of a hydroxyl cucurbituril as well as a preparation method and an application thereof, relates to an analyzing sample pre-treatment technology, and belongs to the technical field of analytical chemistry. The solid phase microextraction coating is characterized in that a common pentabasic cucurbituril or six-membered cucurbituril is subjected to potassium peroxodisulfate oxidation and cation exchange resin separation and purification so as to obtain the hydroxyl cucurbituril through, the hydroxyl cucurbituril is bonded on a sol-gel mesh through a chemical reaction so as to obtain the solid phase microextraction coating, the coating is utilized to prepare a solid phase microextraction fibre which is combined with a gas chromatography, the environmental water sample containing polycyclic aromatic hydrocarbon is analysed, and the coating is utilized to prepare a solid phase microextraction stirring rod which is combined with a high performance liquid chromatography so as to analyze non-steroid antiinflammatory drugs. The solid phase microextraction coating provided by the invention has the advantages that the superficial area of the coating is large, and the extraction capacity is large; and the solid phase microextraction coating is a novel solid phase microextraction coating, is used for analyzing, high in selectivity, low in detection limitation, wide in linearity range, and good in selectivity.

Owner:GUIZHOU UNIV

Method for detecting potential inherent toxicity of organic pollutants in water body

InactiveCN101570785AHigh enrichment factorProtect healthMicrobiological testing/measurementMaterial analysis by electric/magnetic meansResearch ObjectGel electrophoresis

The invention discloses a method for detecting potential inherent toxicity of organic pollutants in a water body, which comprises the following steps: using resin to perform enrichment of water samples first; and applying a comet assay of Euglena gracilis to research the inherent toxicity of the organic pollutants in the water body. The key technique lies in the innovation of glue manufacturing process, namely adopting fractioning at a first layer, then adopting the conventional 'sandwich' glue manufacturing method, and manufacturing the glue by using a normal melting point glue with a higher melting point at a third layer, thus the defect that a rubber plate in the conventional method is easy to damage is overcome. By performing optimization research on cracking time and electrophoresis conditions of algae comets, a perfect image result is obtained. At present, the method for detecting the potential inherent toxicity of the organic pollutants in the water body through algae single cell gel electrophoresis (SCGE) is not reported, and algae are applied to the SCGE to widen the research objects of the SCGE.

Owner:NANJING UNIV

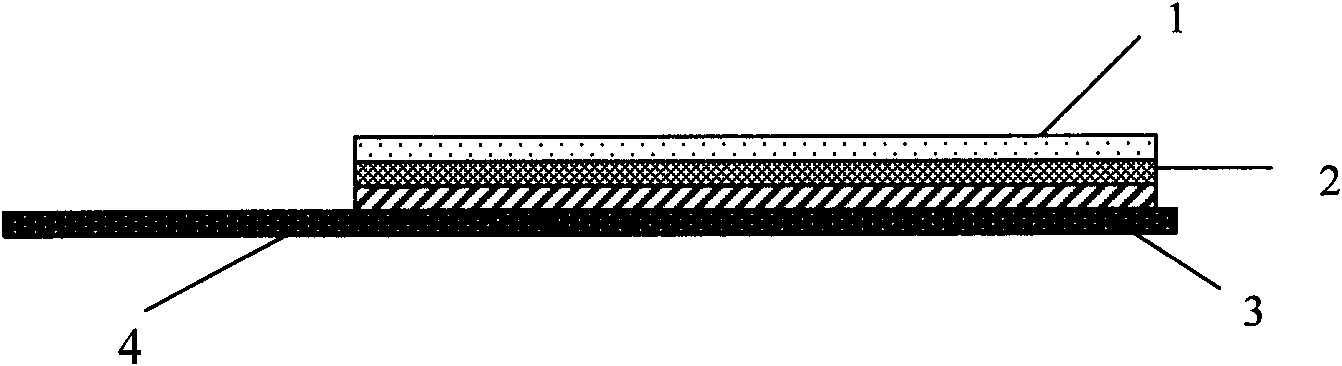

Solid phase micro-extraction device and method for preparing fibre extraction head thereof

InactiveCN101496958AIngenious ideaUnique designIon-exchange process apparatusIon-exchanger regenerationMetal fiberSolid-phase microextraction

The invention relates to a solid phase micro-extraction device and a method for preparing a fiber extraction head thereof. The solid phase micro-extraction device comprises a micro sample injector, the inside of a sample injector push rod is provided with a stainless steel capillary pipe, and the lower end of the sample injector push rod is inserted with the fiber extraction head. The preparation method for the fiber extraction head comprises: corroding one end of a metal fiber into aqua regia, while corroding the other end in HF; dissolving metal salt and organic ligand in a solvent in a hot water reaction kettle to obtain a reaction mixed liquor; and immerging the one end of the metal fiber corroded by the HF after pretreatment into the reaction mixed liquor, and controlling the temperature to between 50 and 220 DEG C and the time to between 6 and 90 hours to prepare the solid phase micro-extraction head of which the surface is grown with metal organic porous skeleton materials in situ. The solid phase micro-extraction device has the advantages of difficult damage of extracted fibers, high temperature resistance, low cost, good extraction performance, capability of replacing the extraction head, and large adsorption capacity. The method can grow porous skeleton materials with different structures on the extraction head aiming at different compounds so as to design high-selectivity enrichment to a target object, and has wide application prospect in the aspect of analytical chemistry.

Owner:NANKAI UNIV

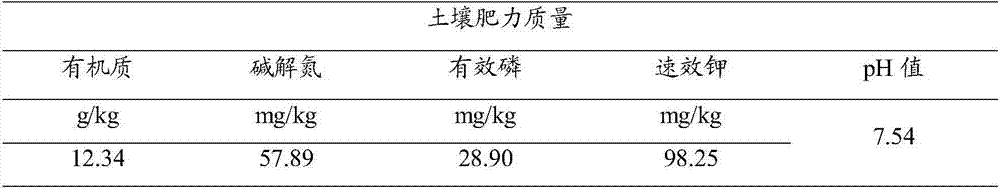

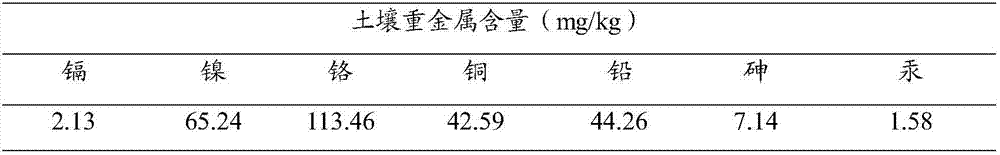

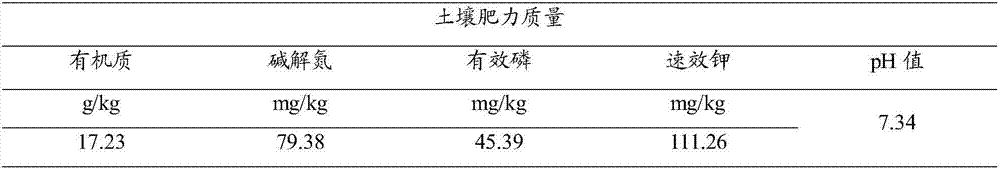

Phytoremediation method for cadmium polluted farmland

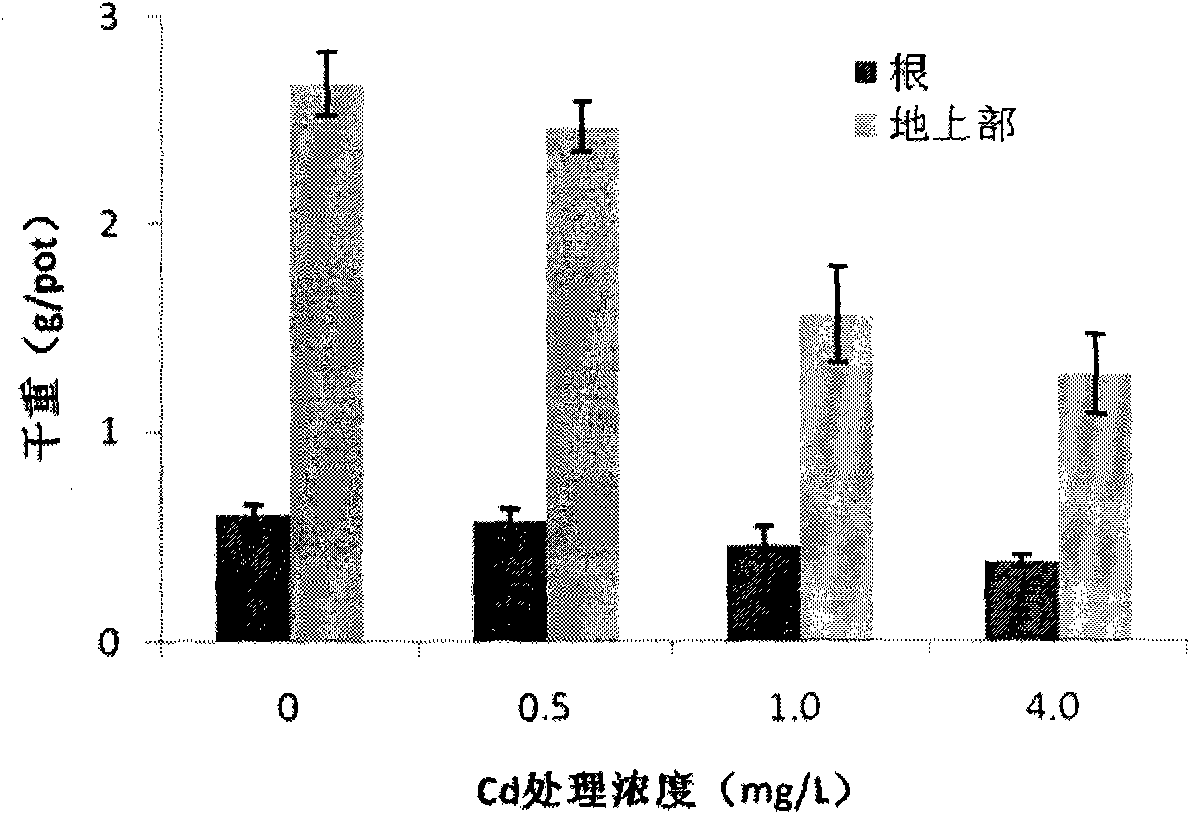

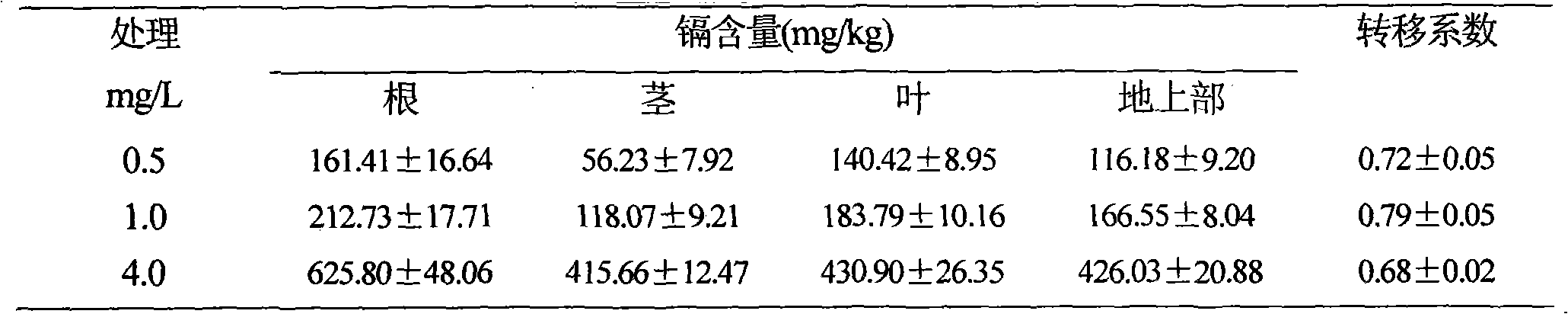

InactiveCN102114490ALarge biomassMake the most of planting timeContaminated soil reclamationPotassiumPhytoremediation

The invention relates to a phytoremediation method for a cadmium polluted farmland, comprising the following steps of: in a cadmium polluted farmland containing cadmium of below 8mg / kg, planting grain amaranth and red leaf amaranth in a crop rotation mode, applying potassium fertilizer, harvesting for many times, and concentrating all plant materials for landfill. According to the phytoremediation method for a cadmium polluted farmland, planting is performed thrice per year, wherein the grain amaranth is planted twice, and the red leaf amaranth with a short crop rotation period is planted between double planting of the grain amaranth, thus optimizing the arrangement of crop rotation; and on management, the grain amaranth planted for the first time is cut twice to fully utilize the favorable growing conditions in summer and accumulate more biomass, and the grain amaranth planted finally is not cut but grows to be ripe, thus optimizing the accumulation of biomass and the work efficiency. Such a crop rotation mode fully utilizes the planting time in a year, and is conductive to the growth of the grain amaranth planted thirdly. The invention has the advantages of high efficiency, easiness in operate, no secondary pollution and low cost.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

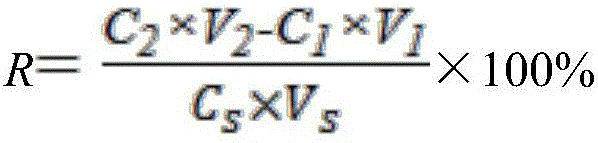

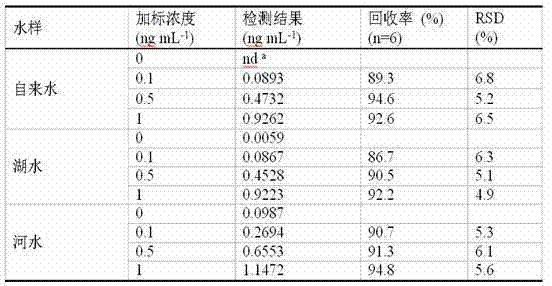

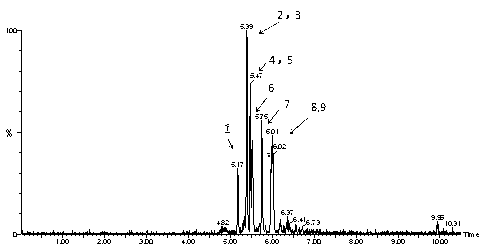

Method for simultaneously detecting six types of 24 antibiotics in livestock excrements by combination of ultrasonic extraction-solid phase extraction pretreatment and liquid chromatography-mass spectrometry technology

InactiveCN107907620AReduce chelationEfficient separationComponent separationInternal standardAntibiotic Y

The invention discloses a method for simultaneously detecting six types of 24 antibiotics in livestock excrements by combination of ultrasonic extraction-solid phase extraction pretreatment and a liquid chromatography-mass spectrometry technology. The method comprises the following steps: (1) adding an internal standard substance for indicating the recycling rate in advance, and performing ultrasonic extraction; (2) performing solid phase extraction to enrich and purify target antibiotics; (3) performing the liquid chromatography-mass spectrometry technology to detect the contents of the 24 antibiotics. According to the method, the residue conditions of the six types of 24 antibiotics in the livestock excrements can be simultaneously detected at one time; the time of the detection processis short, the detection precision is high, the sensitivity, the stability and the selectivity are high, and the detection limit is low; by optimization of an extraction solvent, chelation between theantibiotics and metal ions in the excrements can be effectively reduced, so that the target antibiotics are separated from a sample, and the recycling rate is increased; furthermore, the method is easy and convenient to operate, high in enrichment factor and high in repetitiveness. The internal standard substance for indicating the recycling rate is added before the whole pretreatment process, sothat the loss of target substances in the pretreatment process can be well expressed, and a final result is more real and reliable.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

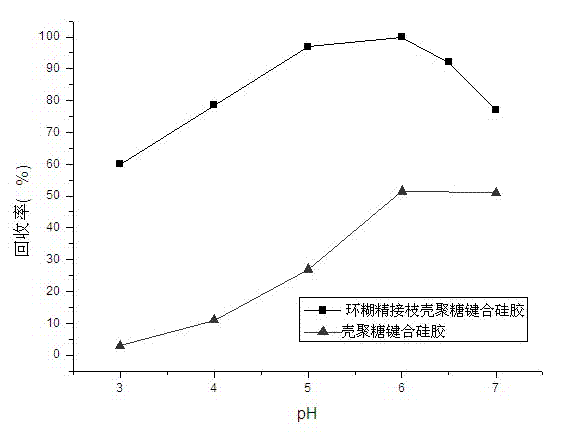

Preparation method of chitosan-grafted beta-cyclodextrin bonded silica gel absorbent

InactiveCN103111271AImprove stabilityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionCompound aFunctional monomer

The invention discloses a chitosan-grafted beta-cyclodextrin bonded silica gel absorbent as well as a preparation method and application of the chitosan-grafted beta-cyclodextrin bonded silica gel absorbent, and belongs to the technical field of the absorbent material preparation. The preparation method of the chitosan-grafted beta-cyclodextrin bonded silica gel absorbent comprises the steps of (1) activating silica gel, (2) bonding the silica gel with gamma-aminopropyl, (3) carrying out silica gel formyl group modification reaction, and (4) bonding chitosan with glutaraldehyde and grafting beta-cyclodextrin with the chitosan. According to the chitosan-grafted beta-cyclodextrin bonded silica gel absorbent provided by the invention, the activated silica gel surface is chemically modified by gamma aminopropyl triethoxy silane, and then, cyclodextrin-grafted chitosan is taken as a functional monomer to compound a solid-phase extraction material. By combining cyclodextrin recognition performance and a chitosan absorbing function, the chitosan-grafted beta-cyclodextrin bonded silica gel absorbent has the advantages of firmness in bonding, stable property, favorable reproducibility and selection, and large enrichment multiple, and the chitosan-grafted beta-cyclodextrin bonded silica gel absorbent can be used in a wide pH scope. The absorbent can be used in the enrichment pretreatment of trace Cu (I) and Cd (II) in an environmental water sample.

Owner:FUZHOU UNIV

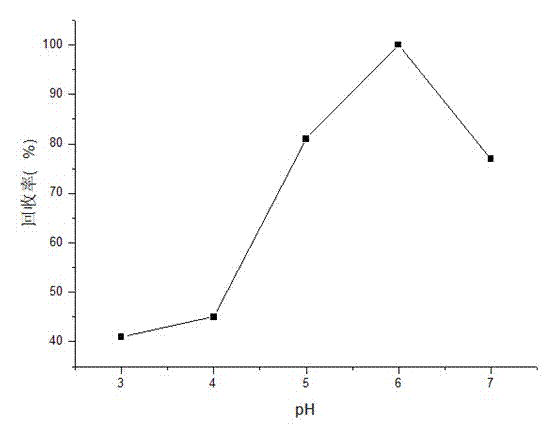

Hyperbranched polyamide-grafted chitosan adsorbent and its preparation method and use

InactiveCN105964227AImprove stabilityImprove adsorption capacityOther chemical processesWater contaminantsPolymer sciencePolyamide

The invention discloses a hyperbranched polyamide-grafted chitosan adsorbent and its preparation method and use and belongs to the field of adsorption material preparation. The preparation method comprises 1, amino-terminated hyperbranched polymer synthesis and 2, amino-terminated hyperbranched polyamide-modified chitosan synthesis. Under cross-linking action of glutaraldehyde as a cross-linking agent, amino-terminated hyperbranched polyamide is carried by chitosan as a carrier so that the solid phase extraction material is obtained. Through introduction of a lot of nitrogen-containing groups to chitosan, active group content is improved, adsorbent adsorption performances are improved, bonding strength is improved, properties are stable, reappearance is good and enrichment multiple is large. The hyperbranched polyamide-grafted chitosan adsorbent can be used for adsorption of heavy metal copper ions and dye in an environment sample.

Owner:FUZHOU UNIV

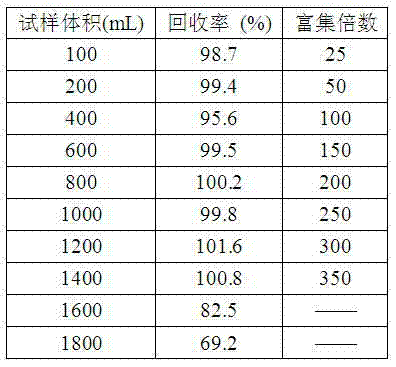

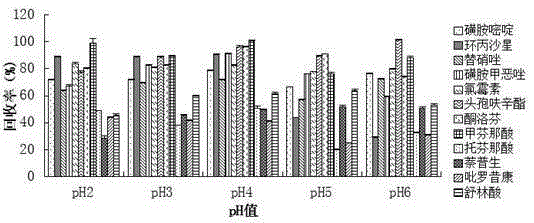

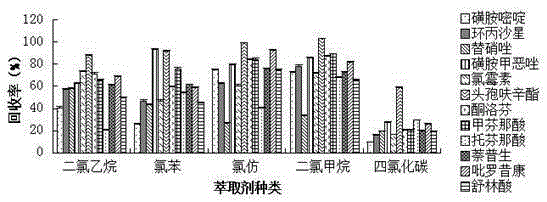

Method for measuring 12 types of remaining medicine in water environment through separation and enrichment

ActiveCN105424825ASimplified processing stepsImprove extraction efficiencyComponent separationWater dischargePretreatment method

The invention relates to a method for measuring 12 types of remaining medicine in a water environment through separation and enrichment at the same time, and belongs to the field of safety detection of a trace of organic pollutant residue in the water environment. The content of 12 types of frequently-used medicine in the water environment (drinking water, faucet water, river water and water discharged into and out of sewage treatment plants) is directly measured with an ultra performance liquid-chromatography-mass spectrometer (UPLC-MS / MS) as a detection tool after a water sample is subjected to solid phase extraction combined with ultrasonic-assisted dispersion liquid-liquid micro-extraction (UA-DLLME) separation and enrichment. The 12 types of antibiotic include ketoprofen, ciprofloxacin, tinidazole, tolfenamic acid, sulfadiazine, sulindac, naproxen, sulfamethoxazole, chloramphenicol, cefuroxime axetil, piroxicam and mefenamic acid. Inspection and optimization are conducted on a sample pretreatment method and instrument detection conditions of the water sample, and the optimal UA-DLLME method is established and is successfully applied to practical sample detection. Compared with a traditional method, the method has the advantages of being high in sensitivity, high in extraction and recycle rate, wide in suitable object, friendly to the environment, and the like.

Owner:SHENYANG PHARMA UNIVERSITY +1

Method for recovering noble metals from spent auto-catalyst

ActiveCN104073641AHigh enrichment factorReduce energy consumptionProcess efficiency improvementPlatinumPtru catalyst

The invention discloses a method for recovering noble metals from a spent auto-catalyst. The method comprises the following steps: (1) early treatment of materials; (2) burdening, and mixing, namely mixing the materials processed in the step (1) according to the ratio, wherein the materials comprise 75-85 parts of spent auto-catalyst taking cordierite as a carrier, 2-4 parts of magnetite, 1-3 parts of metallurgical coke, 10-13 parts of lime and 1-3 parts of fluorite mine; (3) processing the obtained materials by adopting a plasma furnace: a, introducing argon of which the purity is 99.99% into the plasma furnace, so as to keep micro negative pressure inside the furnace; b, beginning to feed the materials obtained in the step (2) to the plasma furnace when the temperature inside the plasma furnace is within the range of 1500-1600 DEG C; c, beginning to discharge slag from a slag phase discharge hole after smelting for 3-6 hours, d, carrying out heat preservation at 1600-1650 DEG C for 30 minutes after charging the materials obtained in the step (2), and then opening the metal phase discharge hole, so as to obtain alloy containing noble metals. By adopting the method, the total yield of platinum, palladium and rhodium is greater than 98%, the recovery rate of platinum is greater than 98%, the recovery rate of palladium is greater than 98%, and the recovery rate of rhodium is greater than 97%.

Owner:GUIYAN RESOURCE YIMEN

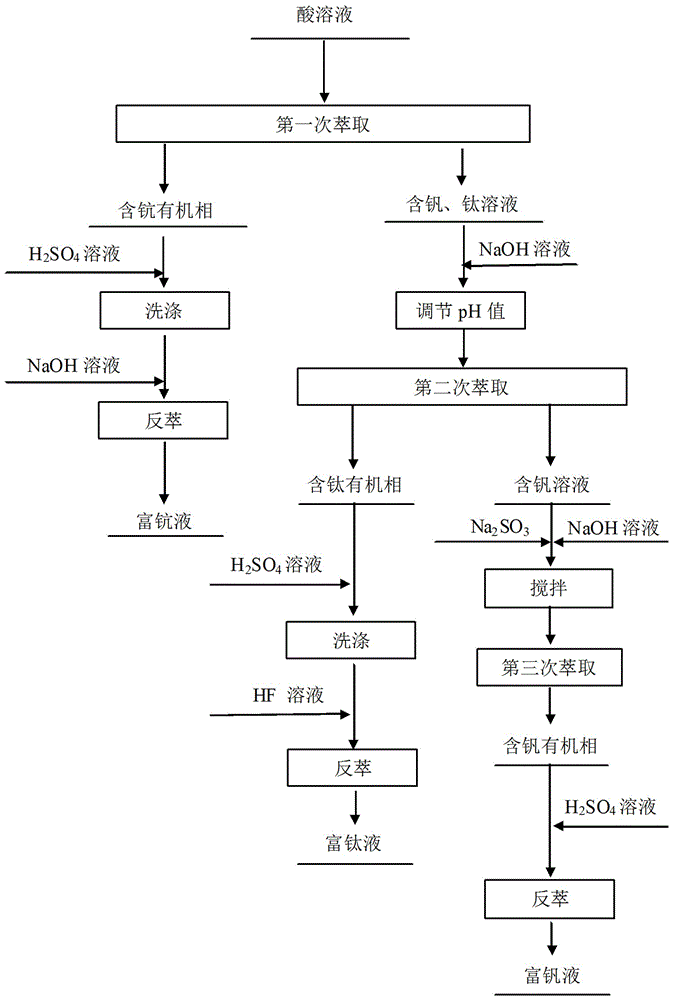

Technology for purifying scandium, titanium and vanadium from acid solution step by step

ActiveCN106191447AImprove leaching rateEfficient separation and extractionProcess efficiency improvementHydrofluoric acidKerosene

The invention relates to a technology for purifying scandium, titanium and vanadium from an acid solution step by step. According to the technology, the acid solution obtained by leaching red mud through sulfuric acid is subjected to three-time extraction work, and an extraction organic phase is composed of a P507 extraction agent, a TBP synergist and sulfonated kerosene; in the first-time extraction process, the acid solution is directly subjected to scandium extraction and enrichment without pH value adjustment, after two-phase separation, a scandium-enriched organic phase and a titanium and vanadium containing solution are obtained, the scandium-enriched organic phase is subjected to sulfuric acid scrubbing and reverse extraction of sodium hydroxide, and scandium-enriched liquid is obtained; after the titanium and vanadium containing solution is subjected to pH value adjustment, the second-time extraction work is conducted for enrichment and separation of titanium, after two-phase separation, a titanium-enriched organic phase and a vanadium-containing solution are obtained, and after the titanium-enriched organic phase is subjected to sulfuric acid scrubbing and reverse extraction of hydrofluoric acid, titanium-enriched liquid and the vanadium-containing solution are obtained; and after the vanadium-containing solution is subjected to pH value adjustment and reducing treatment, the third-time extraction is conducted, and after two-phase separation, a vanadium-enriched organic phase and raffinate are obtained. The technology has the beneficial effects that the separation efficiency is high, the enrichment multiple is large, the technology is simple, and the number of the kinds of extraction agents is small.

Owner:HENAN POLYTECHNIC UNIV

Open Channel Solid Phase Extraction Systems and Methods

InactiveUS20100111771A1High enrichment factorLarge sampling volumeComponent separationIon-exchanger regenerationAnalyteDesorption

The invention provides, inter alia, methods of extracting an analyte from a solution comprising the steps of: passing a solution containing an analyte through an extraction channel having a solid phase extraction surface, whereby analyte adsorbs to the extraction surface of said extraction channel; purging bulk liquid from said extraction channel; and eluting the analyte by passing a desorption solvent through the channel. In some embodiments, the analyte is a protein. The invention further provides reagents, channels, columns and instrumentation related to this and other methods.

Owner:PHYNEXUS

Technology for simultaneously detecting ten estrogens in water environment

ActiveCN103792314AReduce pollutionHigh sensitivityComponent separationFluid phaseMicrofiltration membrane

The invention relates to a technology for simultaneously detecting ten estrogens in water environment. The technology is characterized in that a water sample is pre-processed through a solid-phase extraction technology, and a liquid chromatogram tandem mass spectrometer is utilized to detect the content. The technology comprises the following steps: performing microfiltration membrane on a collected water sample to remove contamination particles suspending in water, concentrating for enriching estrogens in the water sample to a solid phase extraction column through a solid-phase extraction device, eluting the estrogens enriched on the solid phase extraction column by ethyl acetate, drying by using nitrogen, making constant volume, and detecting the content of the estrogens by adopting liquid chromatogram tandem mass spectrometer. The method provided by the invention has the advantages that the operation is simple, the recovery rate is high, the time consumption is low, and the multiple estrogens are simultaneously detected.

Owner:厦门中科育成中心管理有限公司

Aqueous two-phase extraction system of mixed surfactant

InactiveCN102430265AModerate conditions for phase formationPhase formation conditions are simpleLiquid solutions solvent extractionActive agentPhysical chemistry

The invention provides an aqueous two-phase extraction system formed by anion / cation mixed surfactant which is induced by fluoroalcohol, a preparation method and an application thereof. The aqueous two-phase extraction system comprises anion surfactant sodium dodecyl sulfate, cation surfactant hexadecyl trimethyl ammonium bromide, hexafluoroisopropanol and water. The extraction system has short phase forming time, wide phase forming range, gentle and simple phase forming condition, low consumption and high efficiency, so the extraction system is a novel extraction system. The invention can extract and separate different types of compounds through the phase forming conditions of the system, so the application prospect is good.

Owner:WUHAN UNIV

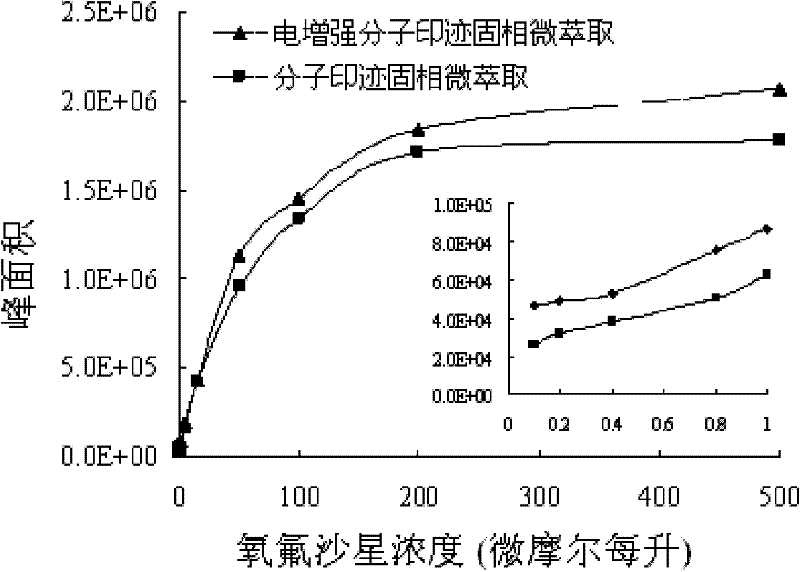

Electricity enhanced molecular imprinting solid phase micro-extraction method

InactiveCN102294131AFast extractionImprove extraction efficiencyComponent separationSolid sorbent liquid separationFiberCarbon nanotube

The invention relates to an electricity enhanced molecular imprinting solid phase micro-extraction method, characterized by: using a conductive molecular imprinting micro-extraction fiber as a working electrode, a platinum wire as an electrode and a saturated calomel electrode as a reference electrode, applying a bias voltage on the working electrode, letting a target compound be subject to electrophoresis and diffusion and migration to allow the target compound to reach the surface of the working electrode to complete the molecular imprinting identification extraction; and when extracting, providing a bias voltage to the working electrode through a electrochemical work station or potentiostat. The conductive molecular imprinting micro-extraction fiber is a metal wire with the diameter of0.5-1.0 mm, and one end of the fiber has a carbon nanotube-conductive molecular imprinting polymer composite coating with the thickness of 50-100 mu m and length of 1-2 cm. The extraction method is suitable for the extraction of ionic compounds and strong polar compounds. The conductive molecular imprinting micro-extraction fiber has simple preparation, large adsorption capacity to the target compound, high extraction efficiency, and good selectivity, can be reused more than 100 times, and has wide application prospects in the field of analytical chemistry and environmental analysis.

Owner:DALIAN UNIV OF TECH

Method for extracting metal ions from fatty acids

ActiveCN110408777ABalanced utilizationImprove leaching efficiencyProcess efficiency improvementRare earthFatty acid

The invention relates to the field of enrichment of metal ions, and discloses a method for extracting metal ions from fatty acids. The method comprises the following steps that (1) saponification is carried out on a fatty acid extraction agent through alkali; (2) the saponification-treated fatty acid extraction agent and an extraction mother solution are mixed, react with each other, are stirred uniformly and precipitated and are then subjected to solid-liquid separation to obtain a metal precipitate, and rare-earth metal ions or non-rare-earth metal ions in the mother solution are extracted;and (3) the metal precipitate is eluted through an acid liquid, and a metal-enriched solution and a regenerative fatty acid extraction agent are obtained after liquid separation. The fatty acid extraction agent used in the method can be directly extracted from animals and plants, can be acquired from numerous sources at low price, is convenient to convey and store, good in biological compatibilityand easy to degrade and causes less pollution to water bodies, the precipitates formed in the precipitation process are large in particle size, solid-liquid separation is easy, the recovery rate of metal ions is high, the enrichment factor is large, and the fatty acids can be recycled.

Owner:厦门熙途科技有限公司

Method for recycling sulphur from sulphur-containing residue

InactiveCN106315517AHigh enrichment factorLow sulfurSulfur compoundsOrganic solventEnrichment factor

The invention relates to a method for recycling sulphur from a sulphur-containing residue. The method comprises the following steps: mixing the sulphur-containing residue and an organic solvent in a proportion; heating, preserving heat, and stirring to melt the sulphur; keeping the temperature of a mixture and filtering; drying a filtered residue, and recycling the organic solvent; settling and layering a filtrate; returning the organic solvent on the upper layer into a system for reuse; cooling liquid sulphur on the lower layer to obtain finished sulphur. The method disclosed by the invention is simple in equipment, low in investment and energy consumption, high in sulphur recycling rate and low in residue amount; the sulphur content in the residue is low; the valuable metal enrichment factor is large; continuous production is convenient to realize.

Owner:ZHUZHOU SMELTER GRP

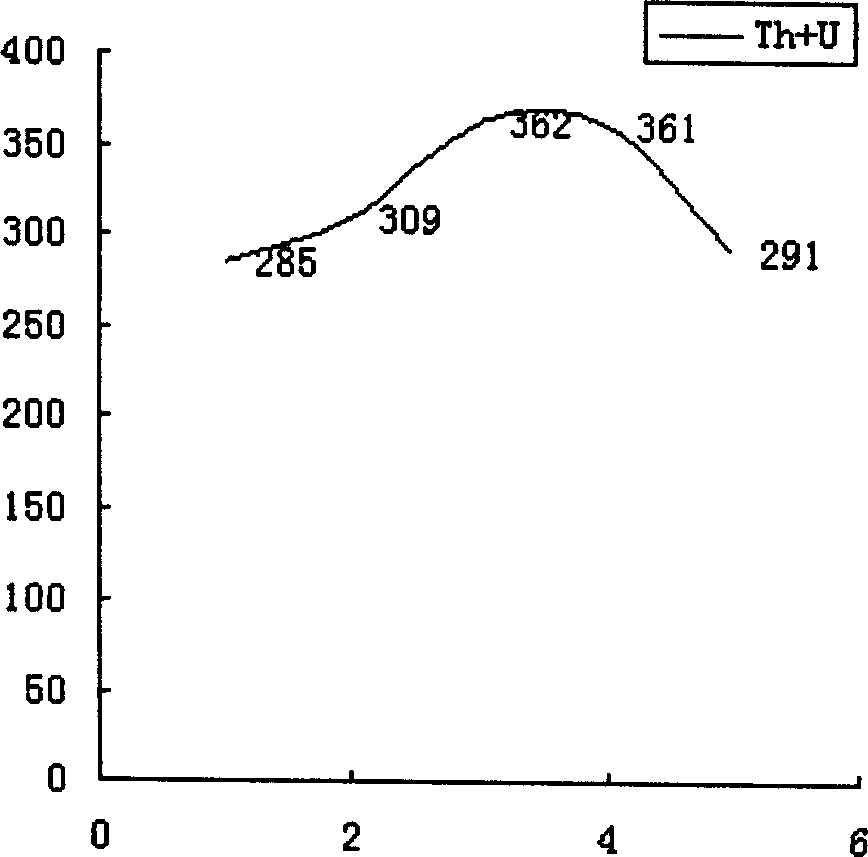

Foamed-plastic carried extraction and exploration method of blind uranium ore deposit

InactiveCN1421683AHas the nature of direct prospectingHigh enrichment factorMaterial analysis using wave/particle radiationPreparing sample for investigationHigh densityUranium ore

The present invention relates to the ore prospecting of blind uranium ore deposit and is one foamed plastic carried extraction and exploration method. Foamed high density polyurethane plastic carrying PMBP or N263 with very high adsorption to uranium (VI) is used as extracting material in adsorption extracting exploration or constant-voltage adsorption extracting exploration. The said method can find uranium ore deposit buried deep under to 400 m depth, and the present invention solves the difficult problem of finding blind uranium ore deposit. The present invnetion includes the preparation of foamed plastic carrying PMBP or N263 and field extraction job. The present invention has the features of great information amount, high abnormal peak, great enrichment coefficient and good ore finding effect.

Owner:中国科学院长沙大地构造研究所

Method for enriching nature tetracycline antibiotics in aquatic products

InactiveCN103076415AEfficient enrichmentHigh extraction recoveryComponent separationOther chemical processesBiotechnologyBenzoic acid

The present invention discloses a method for enriching nature tetracycline antibiotics in aquatic products, and relates to a sample pretreatment in the field of food safety analysis. The method comprises the following steps: a 0.1 mol / L disodium ethylenediaminetetraacetate / Mcllvaine extraction buffer solution pretreatment, phenol or benzoic acid-modified polystyrene superparamagnetic bead adsorption, elution collection and the like, wherein an eluent can be directly added to liquid chromatography or LC-MS to carry out analysis. Compared with the traditional sample pretreatment method for tetracycline antibiotics in aquatic products, the method of the present invention has the following characteristics that: a sample pretreatment operation process is substantially simplified, a sample pretreatment time is shortened, the adsorbent use amount is reduced, and an extraction yield of the tetracycline antibiotics in the sample is increased.

Owner:NANCHANG UNIV

Ecological risk evaluation method of PPCPs (pharmaceutical and personal care products) in water environment

InactiveCN106841431ALow costEasy to operateComponent separationPredicted no-effect concentrationTest organism

The invention discloses an ecological risk evaluation method of PPCPs (pharmaceutical and personal care products) in a water environment. The method comprises the following steps: (1) detection of PPCPs concentration in a water environment: water sample pretreatment, solid-phase extraction and quantitative detection by a high performance liquid chromatography-mass spectroscopy combined technique; (2) by using bacteria, algae, invertebrates, fish and other aquatic organisms as test organisms, determining the predicted no effect concentration (PNEC) by using toxicological data 50% effective concentration (EC50); (3) calculating the risk quotients (RQ) according to the formula RQ=MEC / PNEC, wherein MEC is the measured environmental concentration; and (4) evaluating the ecological risk degree of the target compounds PPCPs by an RQ process. The method is low in cost, friendly to the environment and convenient for operation. The detection method of PPCPs is simple to operate and easy to implement, has the advantages of high selectivity for target compounds, high sensitivity, high enrichment multiple and favorable reproducibility, and can simultaneously separate and determine multiple compounds.

Owner:TIANJIN UNIV

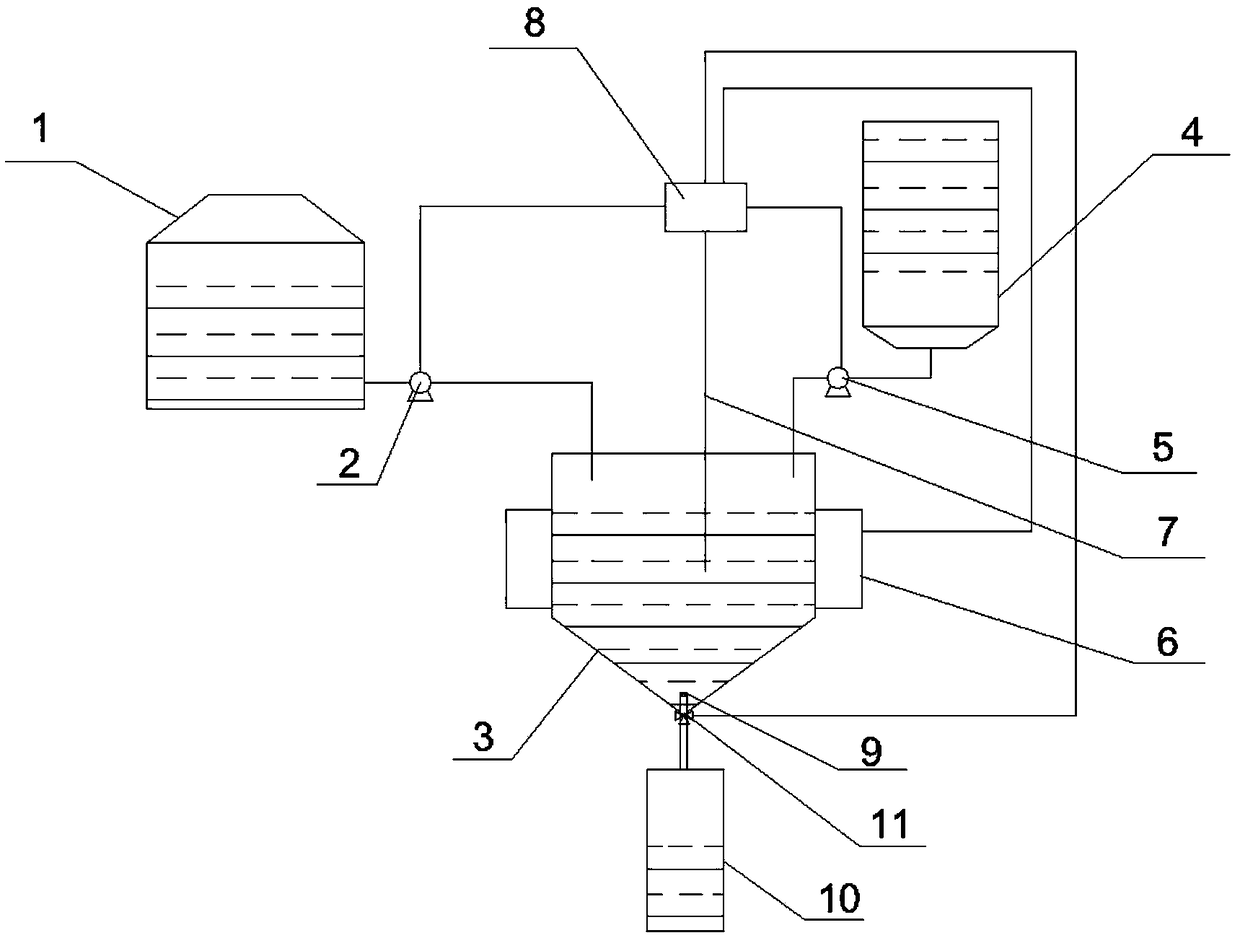

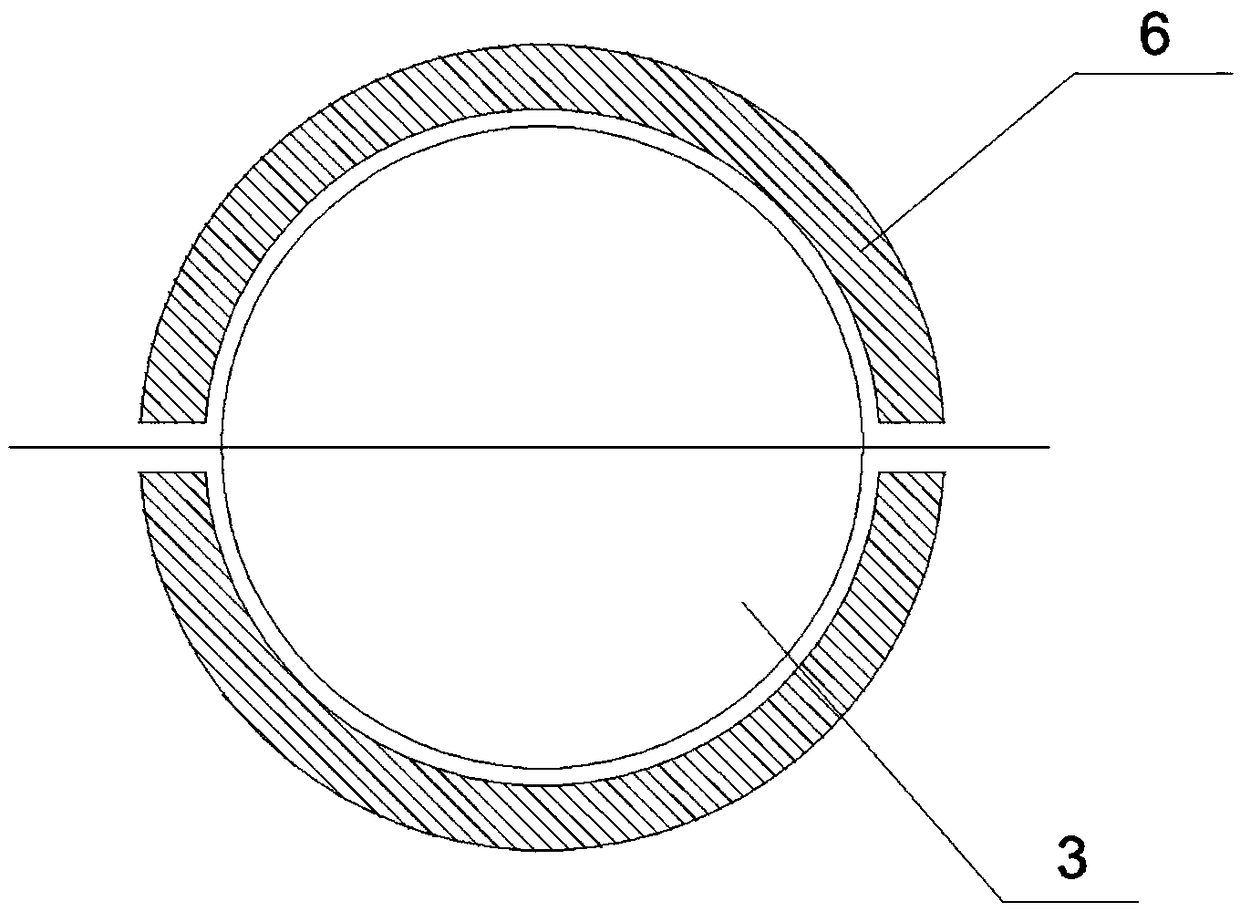

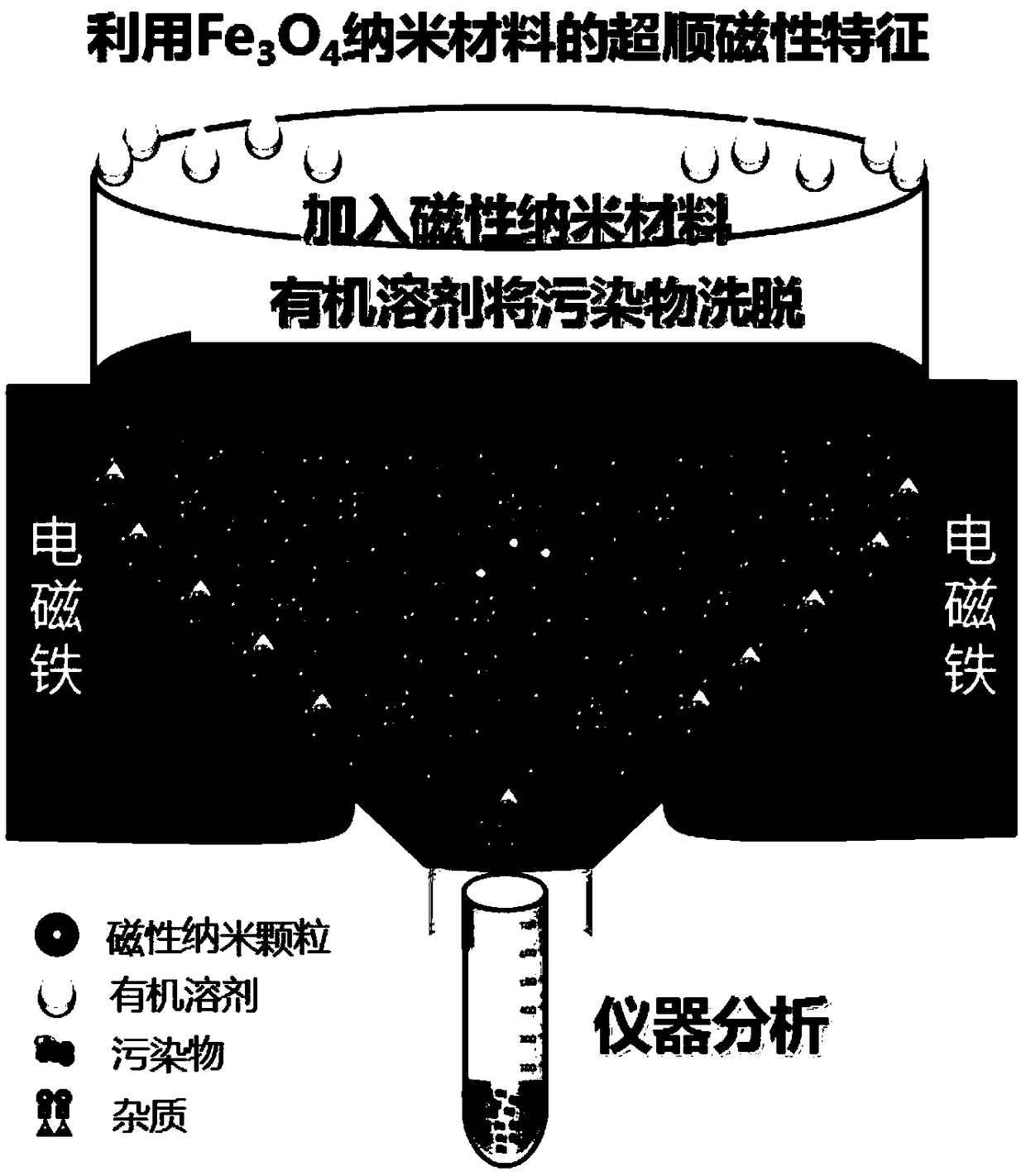

Magnetic nano solid phase extraction device based on electromagnetic separation, and extraction method of magnetic nano solid phase extraction device

ActiveCN108854157ASolve the difficulty of solid-liquid separationFast analysisSolid sorbent liquid separationPower flowEnvironment water

The invention provides a magnetic nano solid phase extraction device based on electromagnetic separation, and an extraction method of the magnetic nano solid phase extraction device, belonging to thetechnical field of solid phase extraction. The extraction device comprises an environment water supply unit, an elution unit, an extraction unit, a collecting device and a main control system, whereinthe extraction unit comprises an extracting device and an electromagnet. The invention firstly uses the electromagnet to replace a magnetic nano solid phase extraction technology of the conventionalpermanent magnet, whether the electromagnet has magnetism or not can be controlled by switching on or off current, and the magnetism can be adjusted by controlling the distance between the electromagnet and the extracting device or by controlling the current. Furthermore, due to the superparamagnetism of a magnetic nano-material, the magnetism of the material can also be controlled by switching onor off the current, and in-situ separation and an enrichment process can be realized by controlling the current; the magnetic nano solid phase extraction device and the extraction method have good application innovation, successfully solve the problem of difficult solid-liquid separation of the conventional solid phase extraction device, and greatly improve the analysis speed of a large-volume environmental water sample.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

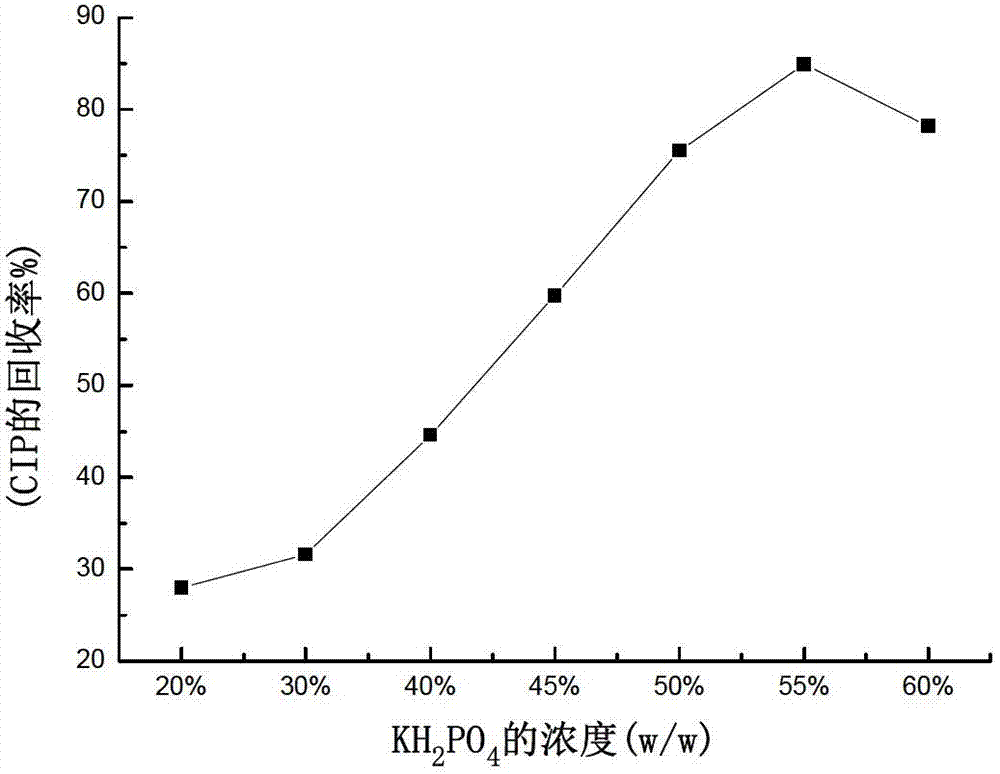

Method for separating/gathering trace ciprofloxacin in food

InactiveCN103191581AAchieve secondary extractionImprove extraction efficiencyComponent separationLiquid solutions solvent extractionInorganic saltsSeparation technology

The invention relates to a method for separating / gathering trace ciprofloxacin in food, belonging to the field of environment analysis technologies. The method is a novel separation technology in which thermo-sensitive polymer EOPO (ethylene oxide and propylene oxide copolymer) and salt are mixed, the property that the affinity of a surface active agent and water is changed under a temperature change condition is utilized, and an aqueous two-phase system is formed with the combination of inorganic salt to perform extraction separation. The novel separation system has the advantage of aqueous two-phase extraction, and can realize secondary extraction due to the temperature separation property of the thermo-sensitive polymer, so that the extraction efficiency is higher than that of one-time extraction, and besides, the recovery of phase components enables the experiment cost to be reduced.

Owner:JIANGSU UNIV

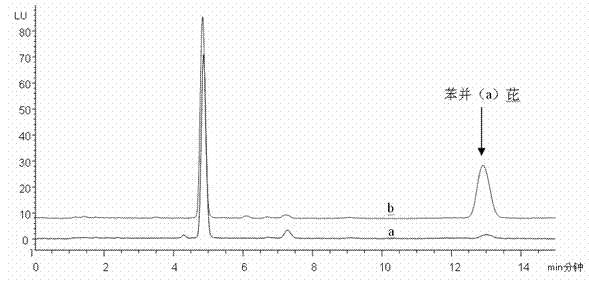

Method for detecting benzopyrene in environmental water sample

InactiveCN104749272AGood choiceGood water dispersibilityComponent separationLiquid Chromatography-FluorescencePretreatment method

The invention discloses a method for detecting benzopyrene in an environmental water sample. According to the method, alkyl carboxylic acid modified magnetic nano Fe3O4 is utilized to extract polycyclic aromatic hydrocarbon in the environmental water sample, and high performance liquid chromatography / a fluorescence detector is combined for content measurement; the modified magnetic nano Fe3O4 has large specific surface area, good dispersibility in aqueous solution, good selectivity for polycyclic aromatic hydrocarbon, and can reach high enrichment factor after elution of an eluent, and the detection sensitivity can be improved greatly; compared with the traditional sample pretreatment method, according to the pretreatment method, the cost is low and the operation is simple; and besides, the use of organic solvent is reduced greatly, the pretreatment time is shortened, and the magnetic nano Fe3O4 can be utilized repeatedly, is environmentally friendly, and has wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

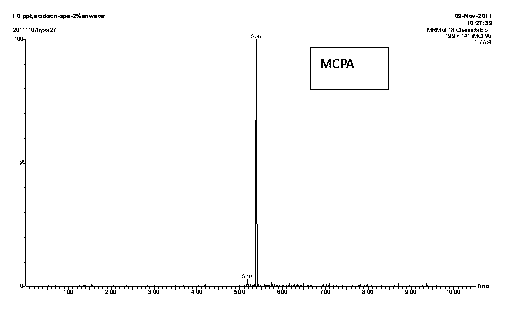

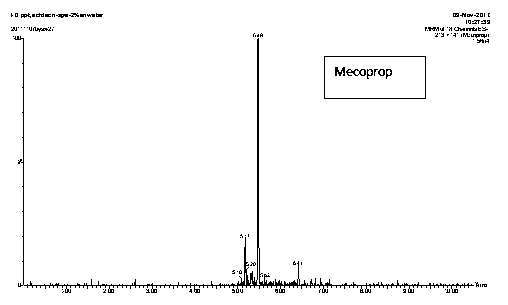

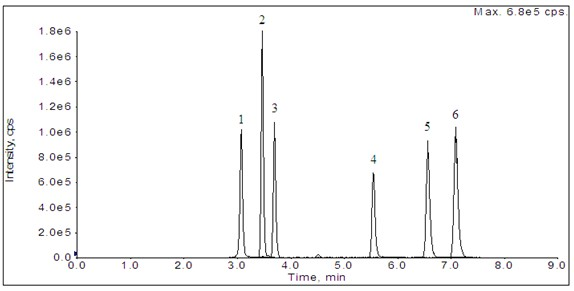

Method for fast detecting phenoxy carboxylic acid herbicide in water

The invention belongs to the field of analysis of organics in the environment and relates to a method for fast detecting a phenoxy carboxylic acid herbicide in water. The method is a full-automatic on-line solid phase extraction / ultra-high performance liquid chromatography-tandem mass spectrometry (Online-SPE / UPLC-MS / MS) method. The method comprises the following steps of 1, preparing a reagent, 2, determining on-line solid phase extraction conditions, 3, determining chromatography conditions, 4, determining mass spectrometry conditions and 5, carrying out qualitative and quantitative analysis. The method realizes full-automatic analysis of a water sample. A collected water sample is orderly subjected to filtration, loading analysis and data processing without manual operation. Compared with the manual operation method, the method has high data precision and stability, greatly eliminates personal errors, and realizes fast and green analysis.

Owner:江苏省苏力环境科技有限责任公司

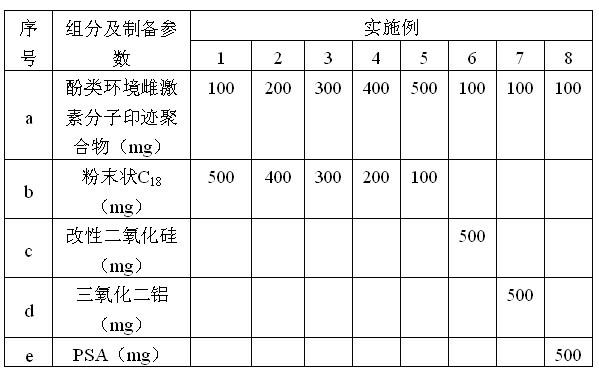

Preparation method of solid phase extraction column of molecular imprinted of phenolic environmental estrogens

InactiveCN102580353ASimple preparation processSpecific and selectiveSolid sorbent liquid separationOrganic solventEstrogen

The invention discloses a preparation method of a solid phase extraction column of molecular imprinted of phenolic environmental estrogens. The method comprises steps of: uniformly mixing 100-500mg of molecular imprinted polymer of phenolic environmental estrogens with 5-20mL of pure organic solvent, and uniformly mixing 100-500mg of traditional solid phase extraction packing with 5-20mL of pure organic solvent; orderly moving the mixtures into a hollow solid phase extraction column; plugging two ends of the solid phase extraction column with sieve plates; adding an acid organic solvent into the solid phase extraction column to wash after the solid phase extraction column being uniformly filled; flushing the filled solid phase extraction column with the pure organic solvent; purging the filled solid phase extraction column with inert gases to remove residual organic solvent; and drying to obtain the product. The preparation method disclosed by the invention is simple, and has particularity matching with the molecular imprinted polymer of phenolic environmental estrogens; and the prepared solid phase extraction column performs high selectivity and high recovery rate to the phenolic environmental estrogens, and is capable of obviously reducing the matrix effects.

Owner:NINGBO MUNICIPAL CENT FOR DISEASE CONTROL & PREVENTION

Method for remediating cadmium contaminated soil by using ornamental plant smooth joyweed

InactiveCN101941018AHigh enrichment factorLarge biomassContaminated soil reclamationProper treatmentGermplasm

The invention relates to phytoremediation technology in a heavy metal contamination environment, in particular to a method for remediating cadmium contaminated soil by using an ornamental plant smooth joyweed. In the method, the smooth joyweed (preserved in National Crop Germplasm Conservation Center, and the variety name is J589193) is planted on cadmium contaminated soil (including wet land), and a great amount of cadmium in the contaminated soil is absorbed through the root system of the smooth joyweed and is transferred to an overground part of the plant. When the plant grows to the end of the growing period or the biomass of the overground part is maximum, the overground part of the plant is moved away from the contaminated soil and is subjected to proper treatment, and the aim of continuously extracting and removing cadmium from the soil is fulfilled by repeatedly planting the plant and repeating the process. By remediating and treating the cadmium contaminated soil by using the enriched plant smooth joyweed, the method has the advantages of high efficiency, low cost, high operability, easy popularization and application, no damage to soil structure, no secondary contamination and the like, and also has good effect on soil erosion prevention and landscaping in contaminated fields.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI +1

Aminoglycosides molecular molecularly imprinted solid-phase extraction column

InactiveCN102974327AImprove adsorption capacityReduce pollutionComponent separationOther chemical processesCross-linkFunctional monomer

The invention discloses an aminoglycosides molecular molecularly imprinted solid-phase extraction column. Molecularly imprinted polymeric microspheres are filled in a columnar shell, and a preparation method for the molecularly imprinted polymeric microspheres comprises the steps of: taking 3-aminopropyltriethoxysilane or phenyltriethoxysilane as functional monomers, taking tetraethyl orthosilicate as a cross-linking agent and taking aminoglycoside antibiotics as template molecules, performing hydrolytic condensation by adopting a sol-gel method, forming a rigid network structure of an Si-O-Si bond on the surface of activated silica gel to form the polymeric microspheres; and eluting.by using template molecules, so as to obtain the molecularly imprinted polymeric microspheres. The extraction column is used for separating and concentrating target objects before sample pretreatment is performed on residue of veterinary drugs of the aminoglycoside antibiotics, and selectively adsorbing the target objects, and has the advantages of being simple and fast in separation, purification and concentration, little in organic solvent consumption and high in repeatedly used times, and the like.

Owner:CHONGQING UNIV +1

Energy plant remediation method for heavy metal contaminated soil and modifying agent for energy plant remediation method

InactiveCN106914478AAchieve absorptionPromote absorptionAgriculture tools and machinesOther chemical processesDigestionBiology

The invention provides an energy plant remediation method for heavy metal contaminated soil and a modifying agent for the energy plant remediation method. Improved soil is planted with energy plants, and thus, heavy metal in the soil can be absorbed; the modifying agent which comprises, by mass, 80-95% of a bio-organic fertilizer, 3-15% of peat soil and 2-5% of a pH regulator is adopted to control and adjust the soil fertility and the pH value, so that a more favorable growing environment is provided for the plants, the biomass and the enrichment effect of the plants for absorbing the heavy metal are remarkably improved, and accordingly, the plants are promoted to absorb the heavy metal; and in addition, large-scale digestion and save of crop straw and livestock excrement can be achieved, and the method and the modifying agent have prominent economic benefits and environmental benefits.

Owner:中华全国供销合作总社天津再生资源研究所

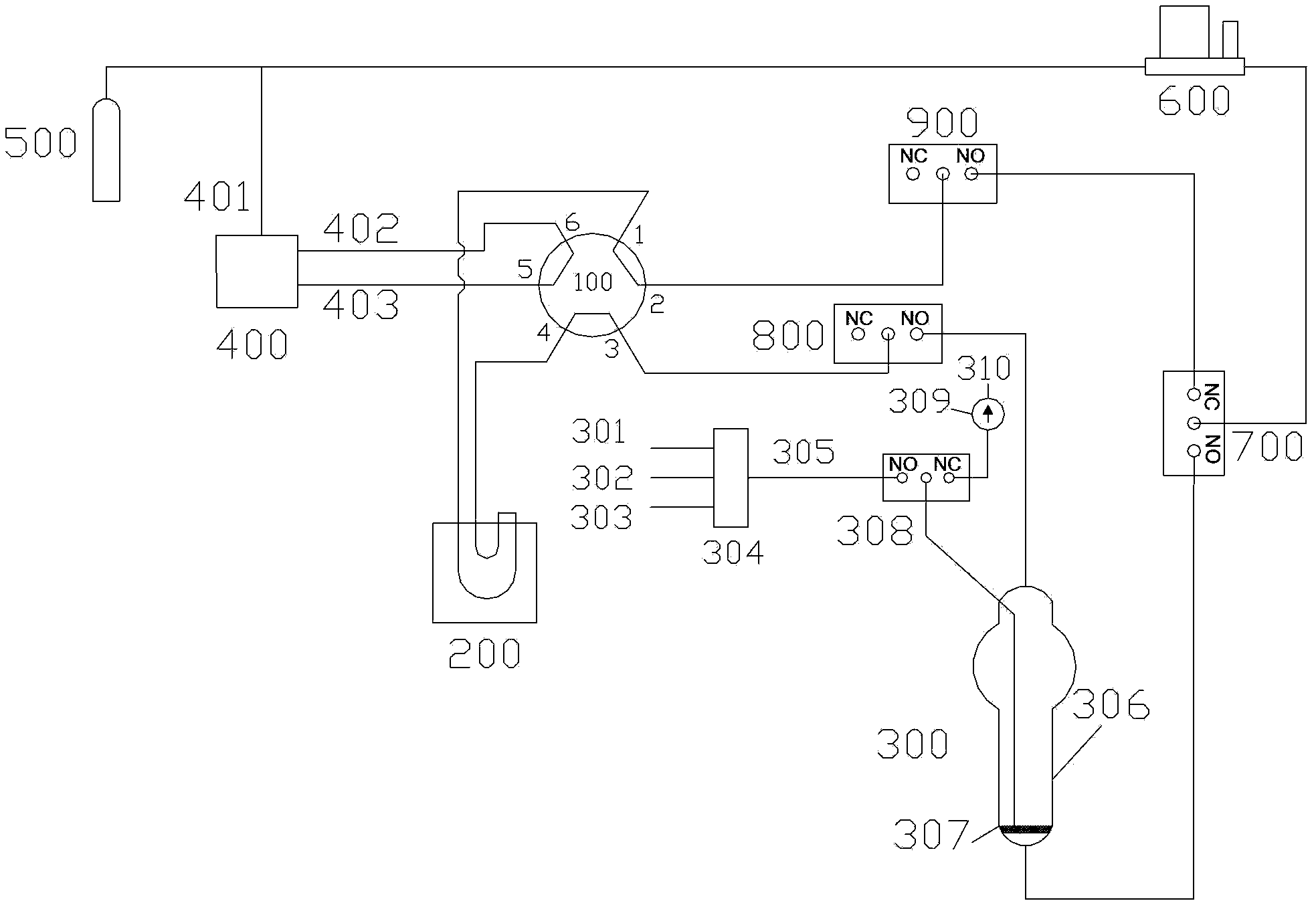

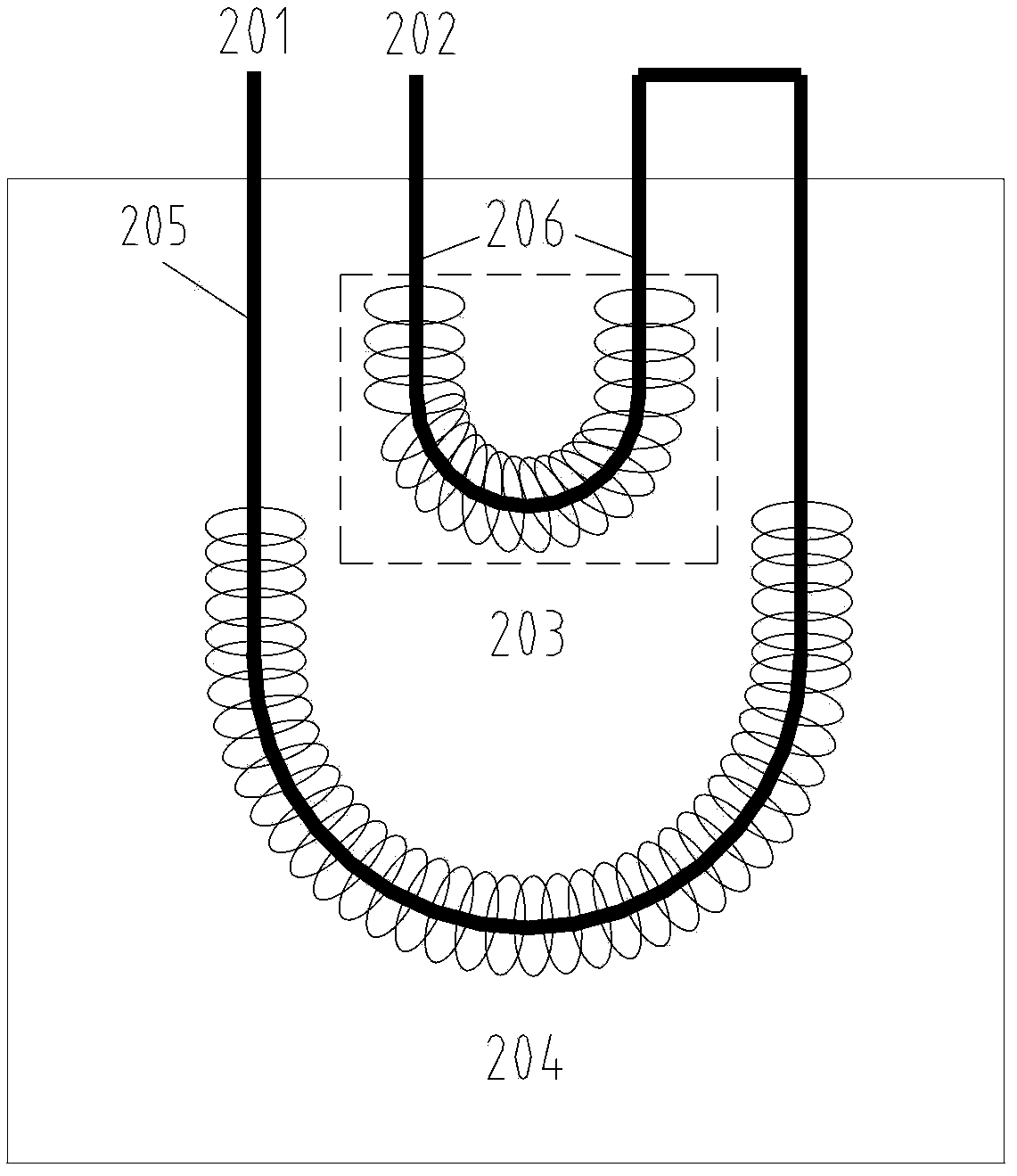

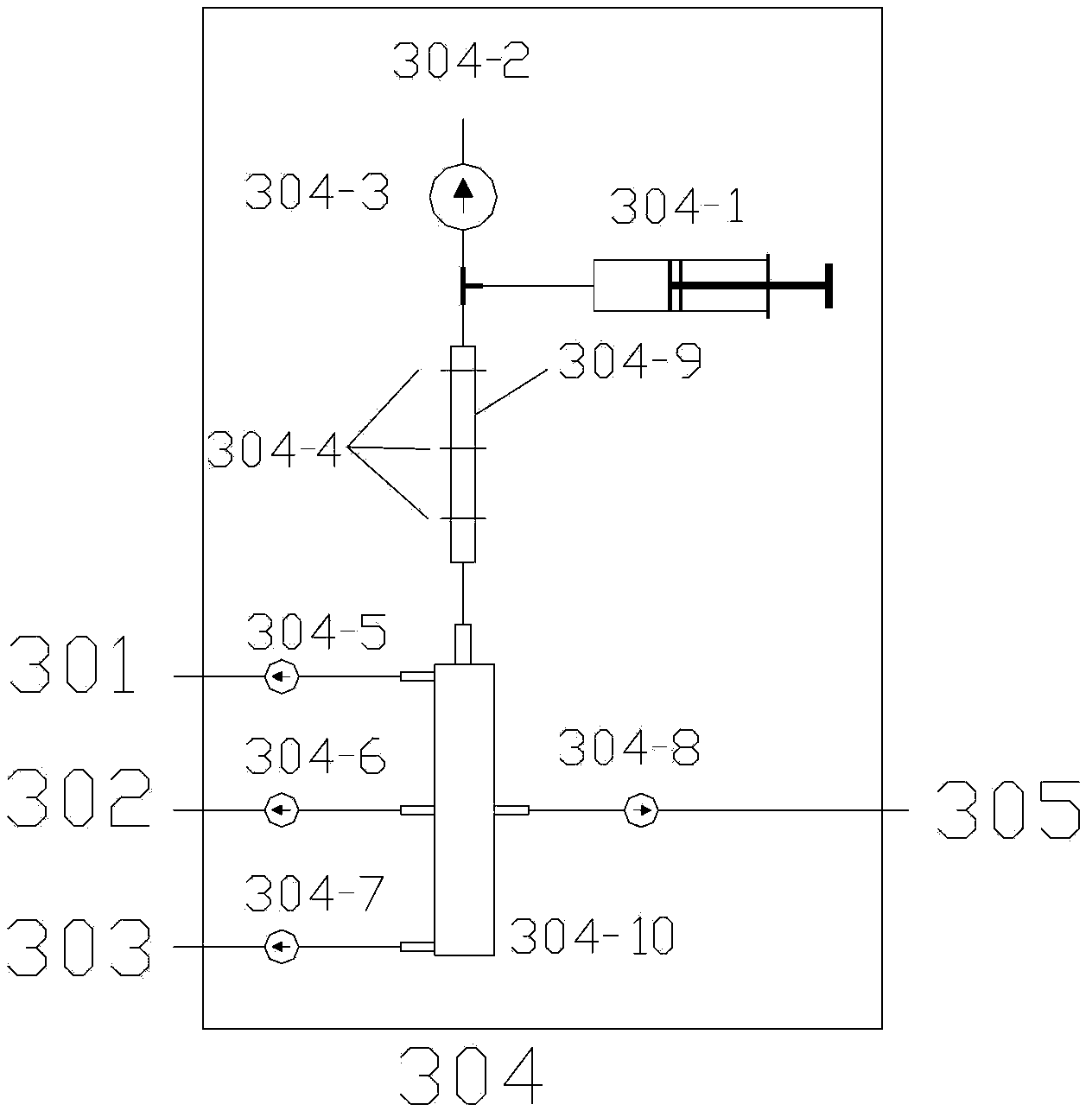

Online pretreatment device for detecting VOCs (volatile organic compounds) in water

ActiveCN104122403AConducive to on-site continuous monitoringEasy to operatePreparing sample for investigationSingle sampleSolvent

The invention discloses an online pretreatment device for detecting VOCs (volatile organic compounds) in water, wherein VOCs is an abbreviated form of volatile organic compounds. Steps such as sampling, sample pretreatment, automatic sample feeding, washing and the like can be completed by controlling the state of an electromagnetic valve and utilizing a single sample scavenging conduit, and the continuous water sample pretreatment technology is realized; compared with the prior art that manual sampling and manual sample releasing are needed, the water sample can be automatically fed; the entire process is controlled by adopting programs, the manual sampling is not needed, the procedures for getting the water sample, getting a standard sample and washing the sample can be automatically realized, and the in-situ continuous monitoring can be facilitated; the online pretreatment device is simple and convenient in operating flow and high in enrichment factor, and no solvent is used.

Owner:LIHE TECH (HUNAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com