Full-temperature-range pressure-swing adsorption method for removing hydrogen sulfide from hydrogen rich gas source

A pressure swing adsorption method, pressure swing adsorption technology, applied in the direction of sulfur compounds, chemical instruments and methods, sulfur preparation/purification, etc., can solve the problem of large consumption of regeneration gas and heat, difficulty in matching adsorption time, water vapor recycling, etc. problems, to achieve long life of the adsorbent, reduce energy consumption and material consumption, and solve the effect of adsorption and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

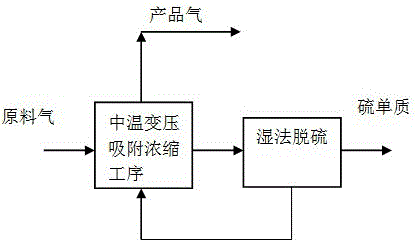

[0038] Such as figure 1 As shown, a full-temperature pressure swing adsorption method for removing hydrogen sulfide from a hydrogen-rich gas source includes the following steps:

[0039] A. Medium temperature pressure swing adsorption concentration process, the temperature is 120~150℃, H 2 Hydrogen-rich gas with an S concentration of 1-2% (volume ratio, the same below) enters the medium-temperature pressure swing adsorption concentration system through the inlet pipeline as raw material gas. The medium-temperature pressure swing adsorption concentration system adopts a 4-tower series process with alternating cycles Operation, the operating temperature of the adsorption is 120~150°C, vacuum desorption after the adsorption is completed, the medium temperature pressure swing adsorption concentration system divides the raw material gas into H 2 Intermediate gas with S content less than 1~10ppm and rich in H 2 Two parts of concentrated gas of S (≥10~25%);

[0040] B. product gas...

Embodiment 2

[0044] Such as figure 1 As shown, a full temperature range pressure swing adsorption (FTrPSA) method for removing hydrogen sulfide from a hydrogen-rich gas source includes the following steps:

[0045] A. Medium temperature pressure swing adsorption concentration process, the temperature is 80~110℃, H 2 The hydrogen-rich gas with an S concentration of 1-2% (volume ratio, the same below) enters the medium-temperature pressure swing adsorption system through the inlet pipe as the raw material gas. The medium-temperature pressure swing adsorption system adopts a 4-tower series process, and 1 tower is adsorbed. The remaining 3 towers are in regeneration stages such as evacuation, desorption, etc., alternate cycle operation, the operating temperature is 80 ~ 110 ℃, vacuum desorption after the adsorption is completed, the medium temperature pressure swing adsorption concentration system divides the raw material gas into H 2 Intermediate gas with S content less than 1~10ppm and ric...

Embodiment 3

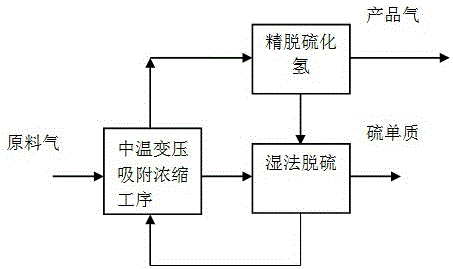

[0050] Such as figure 2 As shown, a full temperature range pressure swing adsorption (FTrPSA) method for removing hydrogen sulfide from a hydrogen-rich gas source includes the following steps:

[0051] A. Medium-temperature pressure swing adsorption concentration process, the flow rate is greater than 10,000 to 20,000 standard cubic meters per hour, the temperature is 50-80 ° C, H 2 The hydrogen-rich gas with an S concentration of 10-15% enters the medium temperature pressure swing adsorption concentration system through the intake pipe as the raw material gas. The medium temperature pressure swing adsorption system adopts a 10-tower process, 3 towers are adsorbed, and the remaining 7 towers are in evacuation, desorption, etc. In the regeneration stage, the 3 towers in the adsorption process adopt a process of 1 tower in series and 2 towers in parallel, thereby realizing the alternate cycle operation of adsorption regeneration, the operating temperature is 50-80°C, vacuum des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com