Method for removing bottom slag and dross in zinc pot

A technology of zinc pot and scum, applied in the direction of coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problem of clear explanation of the principle of zinc slag removal, general effect of zinc slag removal, no mention of the temperature of the zinc solution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

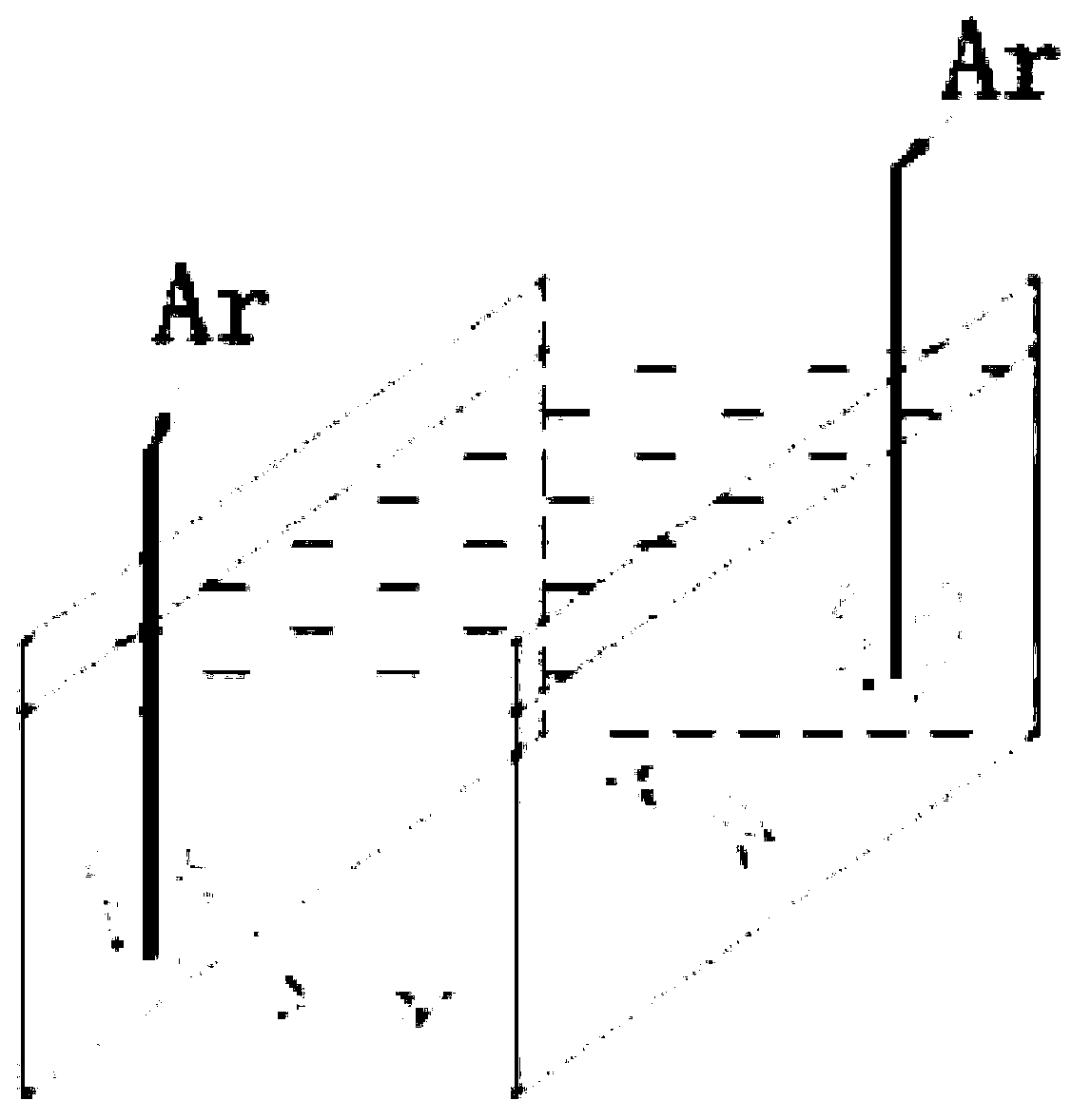

[0018] For a hot-dip galvanizing production line, the size of the zinc pot used for hot-dip galvanizing is 4.1m (length) × 3.9m (width) × 2.5m (depth). The zinc pot is fixed, and the design process layout is as follows figure 1 .

[0019] (1) Utilize downtime maintenance time, the strip steel soaked in the zinc solution is extracted out, reduce the dissolving of Fe in the strip steel in the zinc solution; (2) the zinc solution aluminum content is brought up to 0.32%, the zinc solution aluminum content is by 0.18% was increased to 0.32%; (3) the temperature of the zinc solution was reduced to 448°C, and the temperature of the zinc solution was reduced from 462°C to 448°C. (4) The argon injection pipeline is arranged diagonally in the zinc pot, the diameter of the pipeline is 18mm, the depth is 4 / 5 of the depth of the zinc pot, and the argon injection pressure is controlled at 2bar. (5) Control the time of one diagonal spraying at 60 minutes, and then switch to the other side f...

Embodiment 2

[0021] For a hot-dip galvanizing production line, the size of the zinc pot used for hot-dip galvanizing is 4.1m (length) × 3.9m (width) × 2.5m (depth). The zinc pot is fixed, and the design process layout is as follows figure 1 .

[0022] (1) Utilize downtime maintenance time, the strip steel soaked in the zinc solution is extracted out, reduce the dissolving of Fe in the strip steel in the zinc solution; (2) the zinc solution aluminum content is brought up to 0.40%, the zinc solution aluminum content is by 0.24% is increased to 0.40%; (3) The temperature of the zinc solution is reduced to 452°C, and the temperature of the zinc solution is reduced from 458°C to 452°C. (4) The argon injection pipeline is arranged diagonally in the zinc pot, the diameter of the pipeline is 20mm, the depth is 4 / 5 of the depth of the zinc pot, and the argon injection pressure is controlled at 5bar. (5) Control the time of one diagonal spraying at 100 minutes, and then switch to the other side for...

Embodiment 3

[0024] For a hot-dip galvanizing production line, the size of the zinc pot used for hot-dip galvanizing is 4.1m (length) × 3.9m (width) × 2.5m (depth). The zinc pot is fixed, and the design process layout is as follows figure 1 .

[0025] (1) Utilize downtime maintenance time, the strip steel soaked in the zinc solution is extracted out, reduce the dissolving of Fe in the strip steel in the zinc solution; (2) the zinc solution aluminum content is brought up to 0.34%, the zinc solution aluminum content is by 0.20% is increased to 0.34%; (3) The temperature of the zinc solution is reduced to 450°C, and the temperature of the zinc solution is reduced from 460°C to 450°C. (4) The argon injection pipeline is arranged diagonally in the zinc pot, the diameter of the pipeline is 19mm, the depth is 4 / 5 of the depth of the zinc pot, and the argon injection pressure is controlled at 3bar. (5) Control the time of one diagonal spraying at 90 minutes, and then switch to the other side for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com