High furnace burden face measurement and control system based on industrial phased array radar

A phased array radar and control system technology, applied in measuring devices, liquid/fluid solid measurement, liquid level indicators, etc., can solve the problems of only 3-10 points, low imaging resolution, and many auxiliary units, etc. Achieve the effect of fast scanning speed, high resolution, and little influence of standing waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

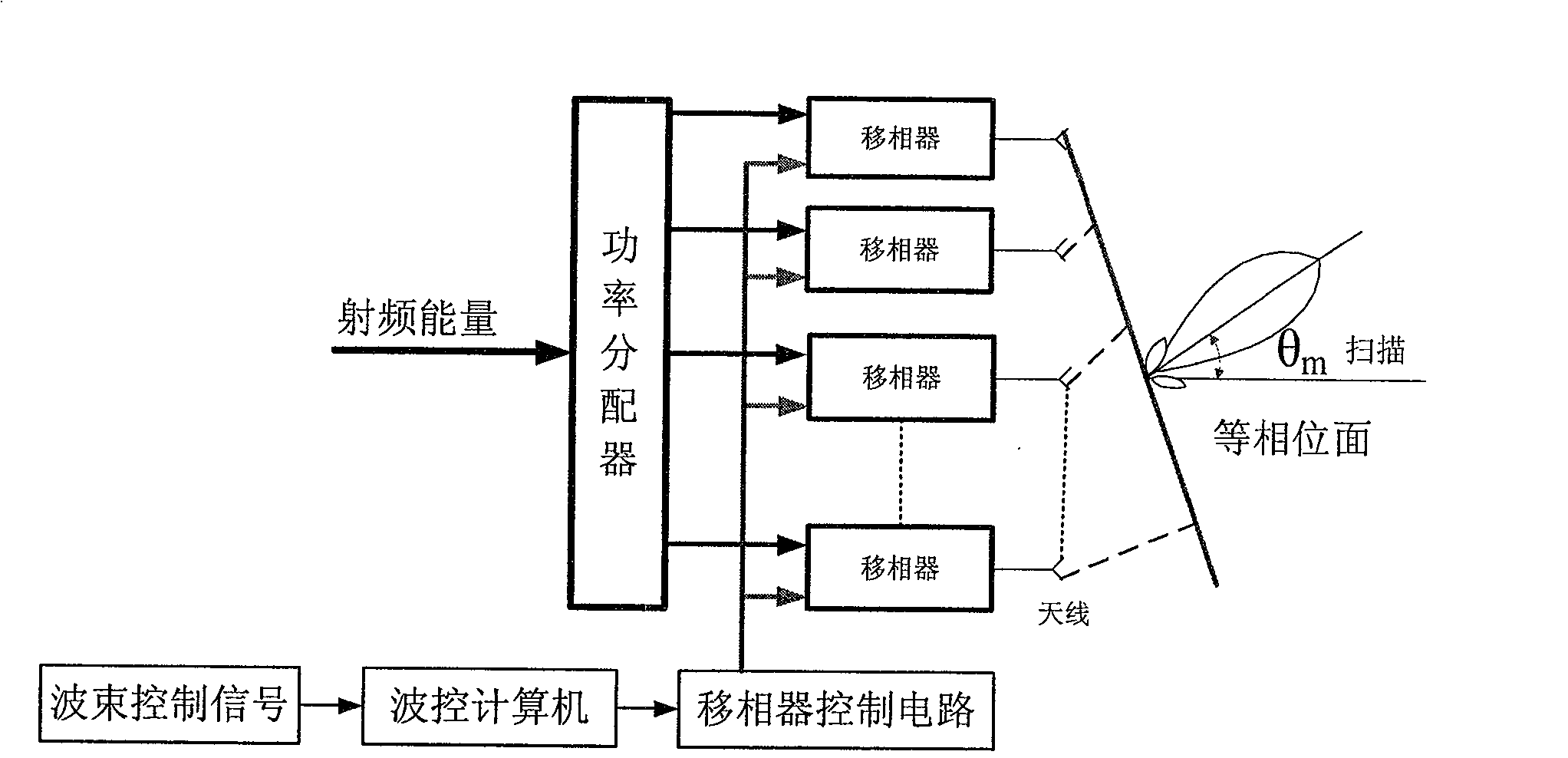

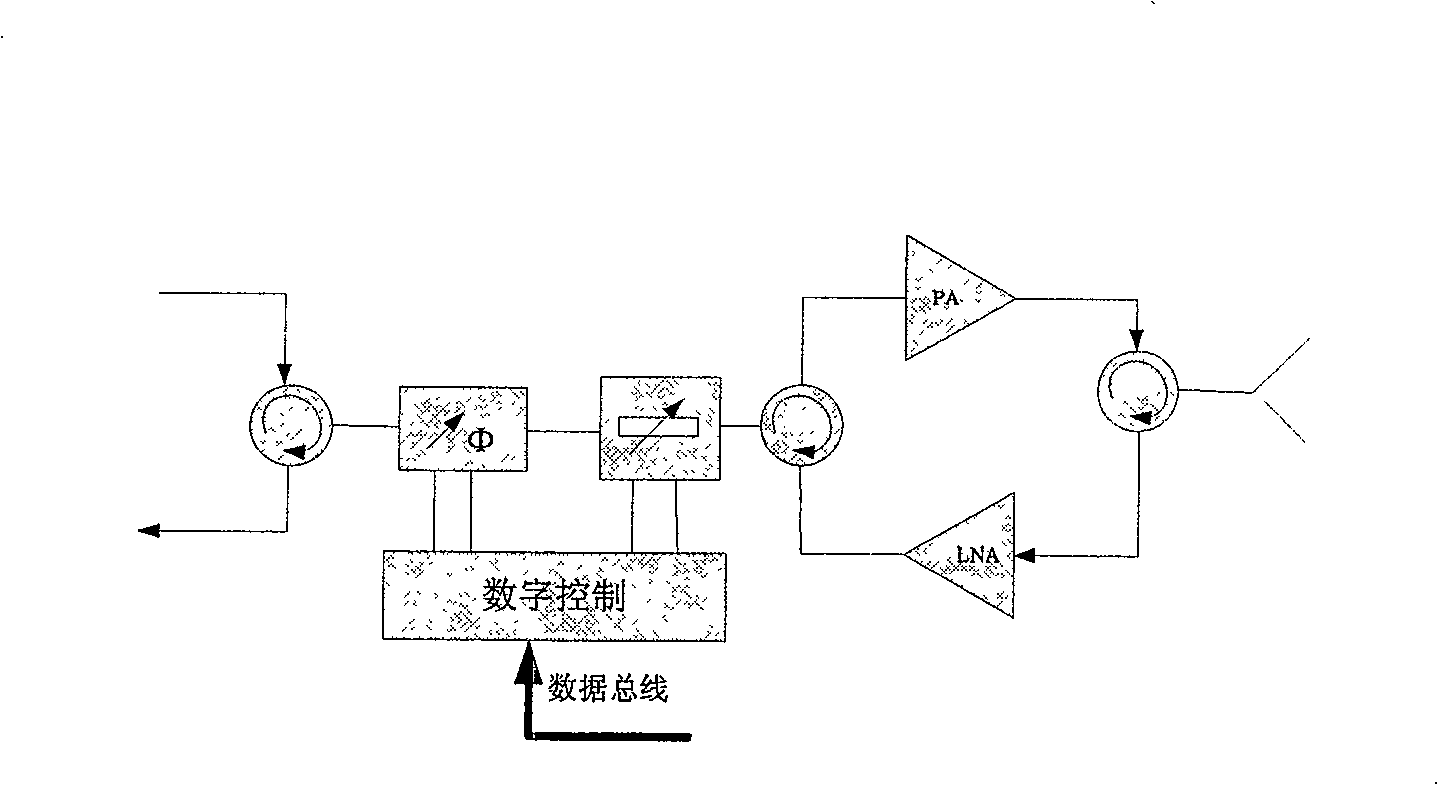

Method used

Image

Examples

Embodiment Construction

[0052] Figure 6 It is an implementation example of industrial phased array radar distribution analysis and chain control system on blast furnace.

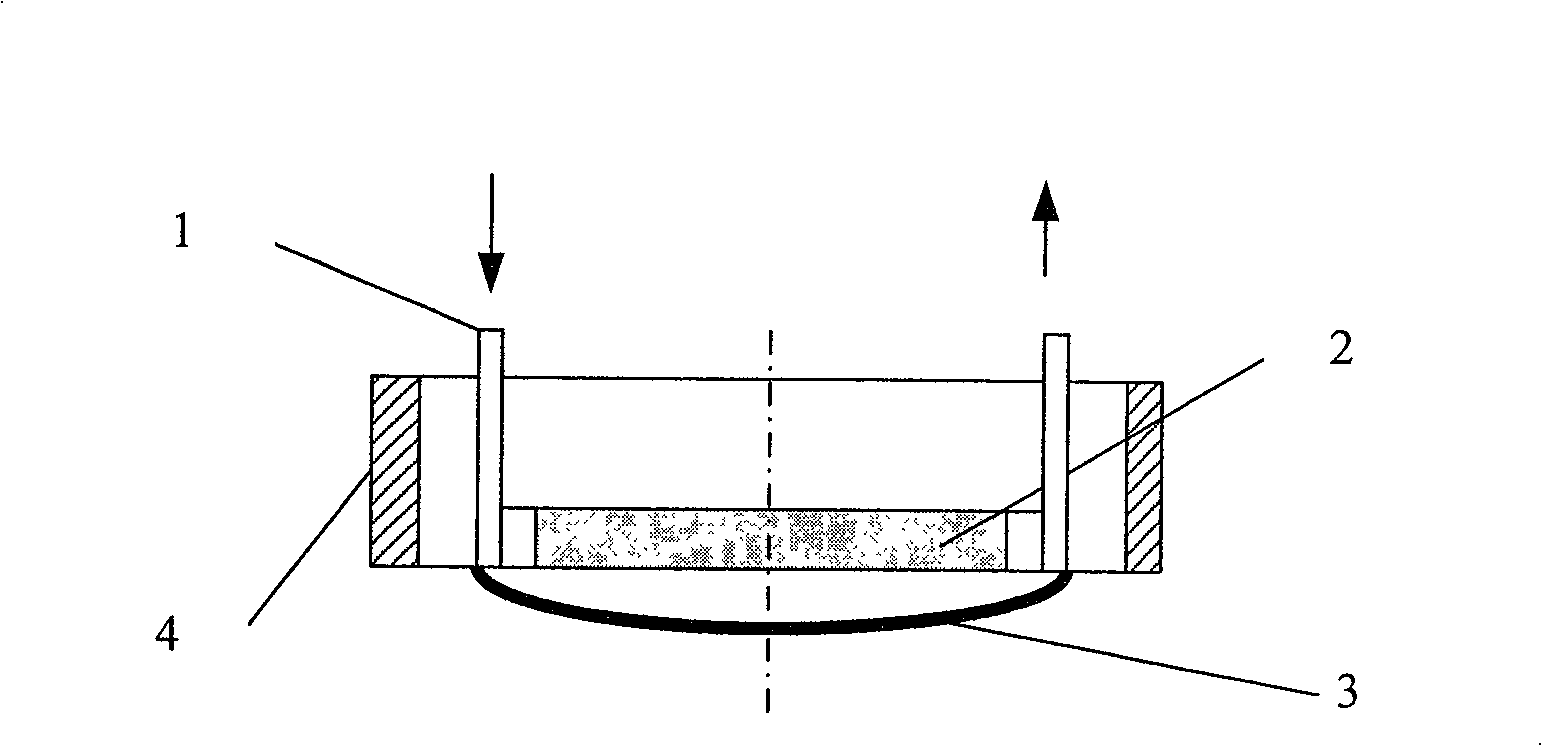

[0053] The industrial phased array radar is installed on the windshield hole of the blast furnace, and the selected installation angle is inclined downward, so that the coverage of the radar scan includes as much as possible all the material surface points to be scanned. at 2000m 3 Take the blast furnace as an example. Generally, the zero material surface of the blast furnace is used as the starting point. The normal material surface is generally about 1.5 meters away from the starting point of the zero material surface. The included angle of the radar scan is ±30°, and the effective diameter of the scan is about 8 meters. Phased array radar The angle between the cover and the horizontal plane is about 15°, which can be scanned Figure 6 Height information of the entire material level below 1.5 meters in the blast furnace.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com