Method of processing organic contaminant waste-water difficult to biochemical degradation using tetravalent manganese compounds

A technology of organic pollutants and tetravalent manganese, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high consumption of chemicals, materials and energy, high treatment costs, Difficulty in wide application and other problems, to achieve the effect of cheap medicaments, low cost of wastewater treatment, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

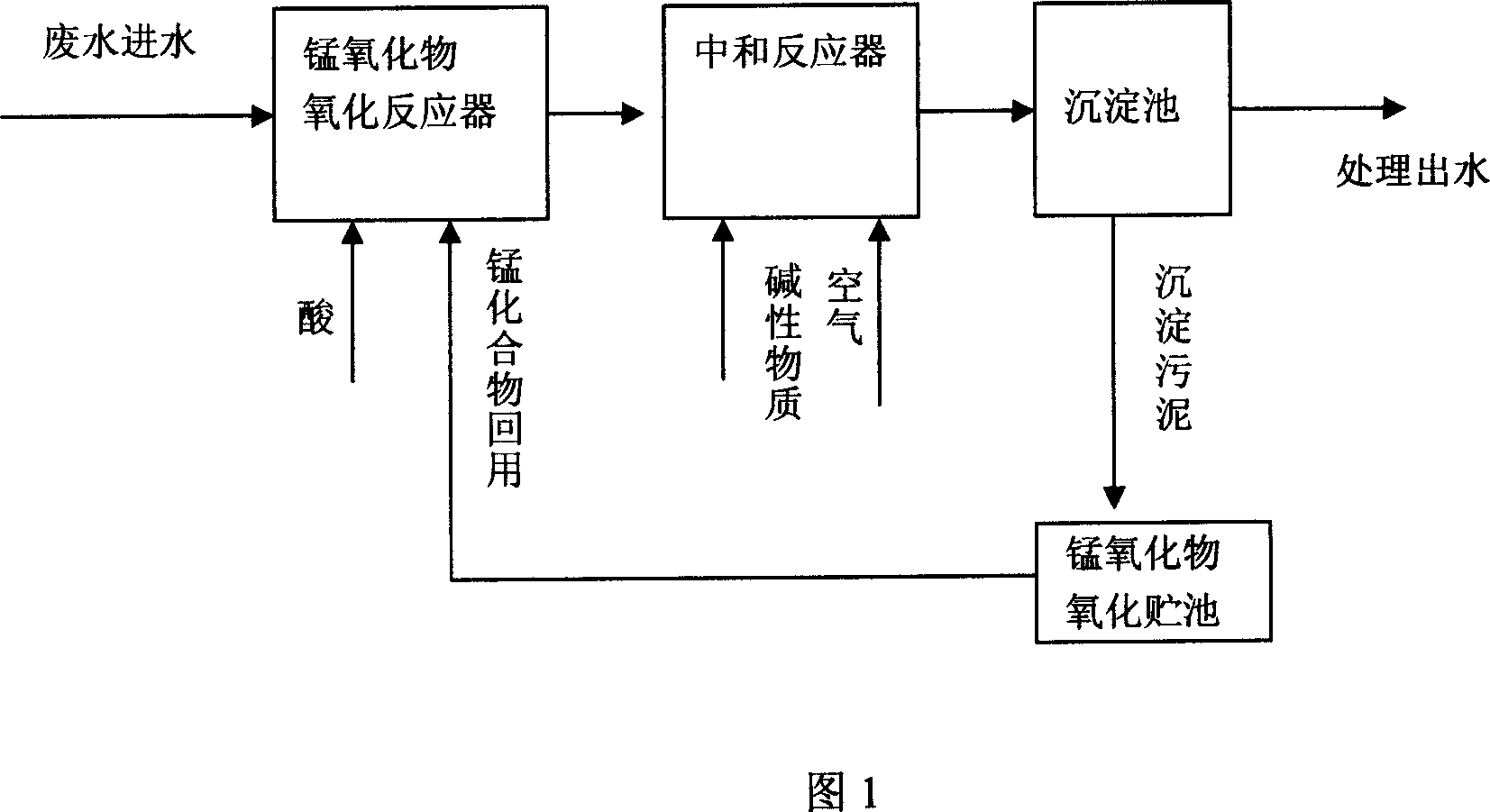

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Acid Scarlet Dye

[0048] Acid scarlet dye is used as a representative of fuel and its intermediate compounds. Prepare the aqueous dye solution with industrial pure acid scarlet. Take five 250ml conical flasks, add 40mg / L acid scarlet solution to 250ml, and add 0.75g pyrolusite powder to adjust the pH value of the solution to 2.0, 3.0, 4.0, 5.0, 6.0. Then seal the Erlenmeyer flask and place it in an oscillator whose speed is adjusted to 200r / min. After the reaction is carried out for 1 hour, samples are taken and centrifuged respectively, and the absorbance is measured at a wavelength of 500nm by a spectrophotometer, and the measured absorbance values are compared. Curve or into the linear equation to calculate the concentration of acid scarlet in the solution after a period of reaction, and calculate its decolorization rate. The results are shown in Table 1 and Figure 5

[0049] Dye solution pH

Embodiment 2

[0050] Embodiment 2 printing and dyeing wastewater

[0051] Assemble the experimental device according to Figure 4, fill the reaction column with manganese ore particles, the particle size is 1-3mm, the diameter of the reaction column is 10mm, the height is 100cm, and the height of the packed layer is 60cm. The wastewater treated in the experiment is the production wastewater discharged from the printing and dyeing factory, and the COD concentration of the wastewater is 622mg / L. The waste water passes through the reaction column filled with duromanganese ore in an upward flow, and the flow rate and flow rate of the treated waste water are adjusted through the peristaltic pump 1, and the acid dosage is adjusted through the peristaltic pump 2, so as to control the pH value of the solution in the reaction column. Use two 10-liter plastic containers as water storage tanks, and simultaneously serve as a neutralization regeneration tank. When the water storage in one plastic bucket ...

Embodiment 3

[0053] Example 3 Sulfide (S 2- )

[0054] Assemble the experimental device according to Figure 4, fill the reaction column with pyrolusite ore particles, the particle size is 1-3mm, the diameter of the reaction column is 10mm, the height is 100cm, and the height of the packed layer is 60cm. Experimental treatment The aqueous solution containing sulfur ions was prepared with analytically pure sodium sulfide, and the initial concentration was 102mg / L. The sulfur-containing aqueous solution passes through the reaction column filled with duromanganese ore by ascending flow, the flow rate and flow rate of the sulfur-containing aqueous solution are adjusted through the peristaltic pump 1, and the acid dosage is adjusted through the peristaltic pump 2, so that the pH value of the solution in the reaction column is controlled within the range of 2.0-6.0 , to compare the effect of solution pH on the oxidation removal rate of sulfur ions. Use two 10-liter plastic containers as water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com