Catalyst and preparation method of coated catalyst

A catalyst and coating technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of expensive materials, low light utilization rate, high energy consumption, etc., and achieve simple and convenient preparation process. Improved decomposition rate and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

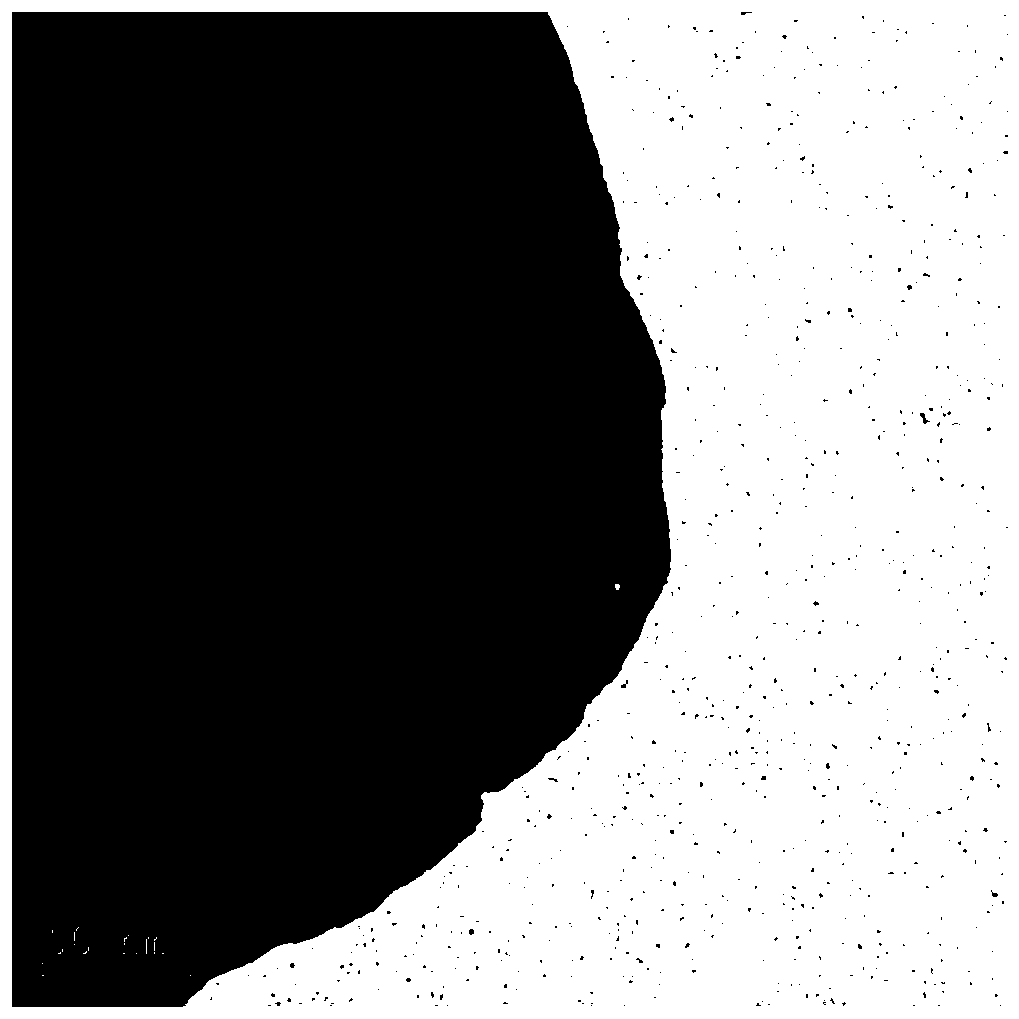

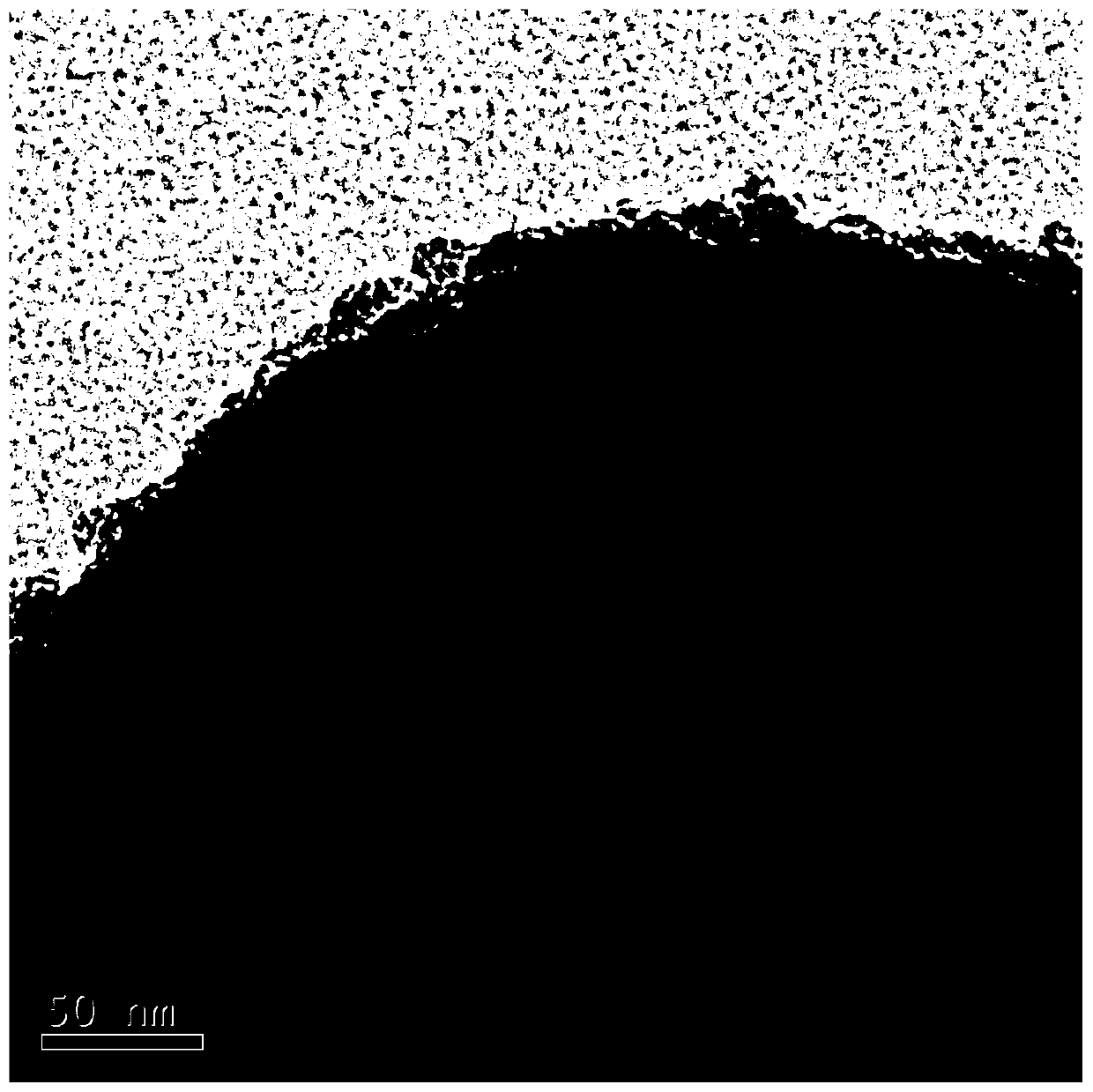

[0042] A preparation method of a silica-coated molybdenum-based compound catalyst.

[0043] The molybdenum-based compound core structure can be prepared by various methods, or directly purchase commercially available molybdenum disulfide, molybdenum carbide and molybdenum nitride.

[0044] The preparation method of molybdenum carbide and molybdenum nitride is as follows:

[0045] The first step is to weigh a certain amount of molybdate and put it into the crucible, then put the crucible with molybdate into the muffle furnace. Time, the ideal temperature of the muffle furnace is 450°C-700°C, the heat preservation treatment time is 2-8h, and then cooled to room temperature to obtain molybdenum trioxide.

[0046] The second step is to put the molybdenum trioxide obtained in the first step into the porcelain boat, then put the porcelain boat into the tube furnace, set the heating rate of the tube furnace, and then feed NH 3 Purge, the purge time is 10-25min, warm up the tube fur...

Embodiment 2

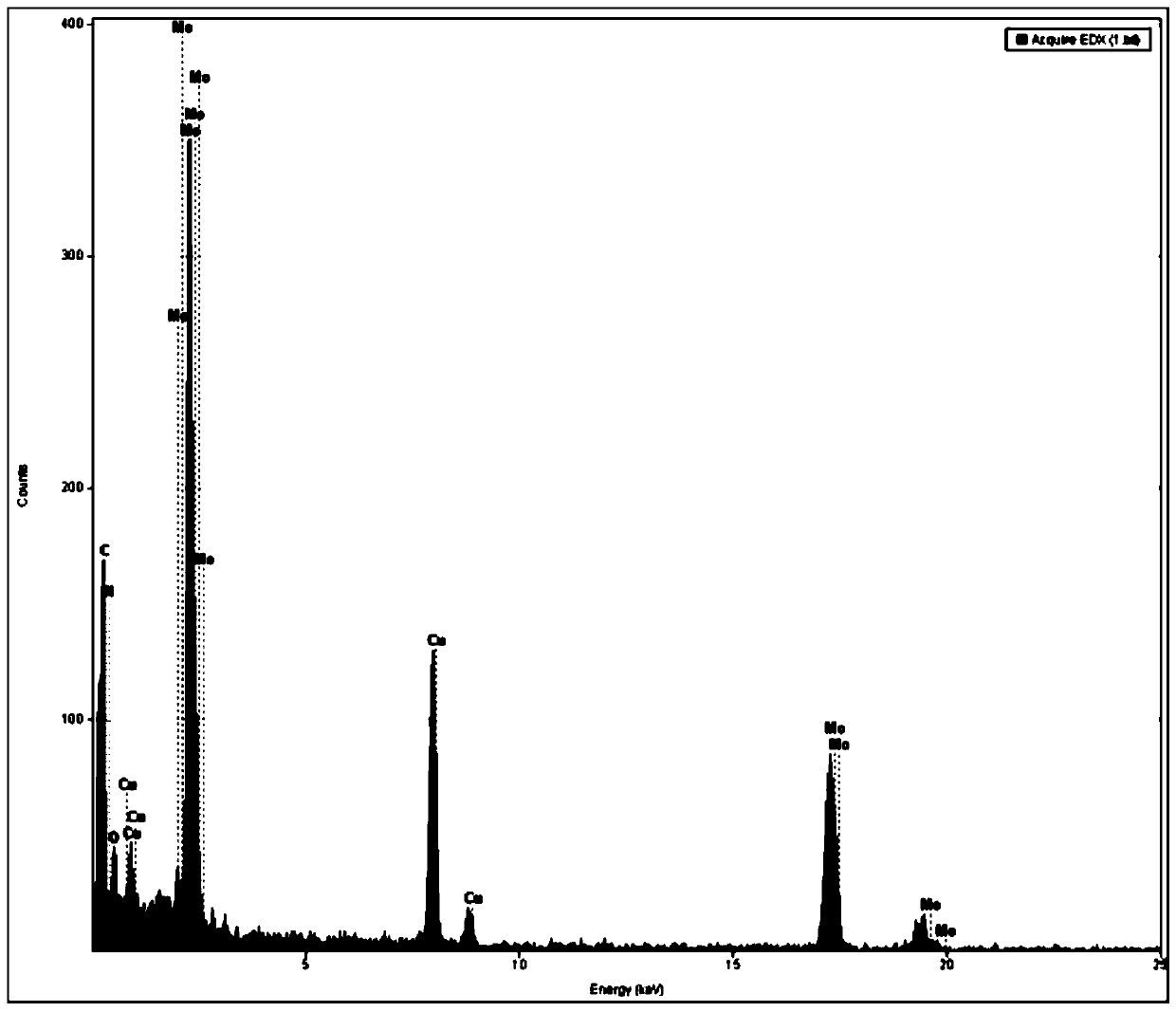

[0055] The catalyst prepared according to Example 1 is applied to the decomposition of catalyzed hydrogen sulfide, specifically: first asbestos is filled in the reaction quartz tube of the microwave reactor to facilitate the fixing of the catalyst bed, and then the catalyst in Example 1 is put into the quartz tube A microwave catalyst bed is formed in the tube, a thermocouple is inserted into the center of the catalyst bed for temperature measurement, and then mixed gas of hydrogen sulfide is introduced to cause a gas-solid phase catalytic reaction to achieve the purpose of decomposing hydrogen sulfide.

[0056] The mixed gas is provided by Dalian Date Gas Co., Ltd., and the waste gas is composed of nitrogen and hydrogen sulfide, wherein the content of hydrogen sulfide is 15vol%. The gas chromatograph was GC-7890A manufactured by Agilent Corporation, USA. The range of microwave power is 0-1350w, preferably 300-800W, and the frequency is 2450MHz.

[0057] In this example, diff...

Embodiment 3

[0062] In this embodiment, the microwave catalyst is MoN x @SiO 2 , the quality is 2g, the waste gas containing hydrogen sulfide (using 15vol% H in the present invention 2 S and 85vol% N 2 The mixed gas was tested) the inlet flow rate was 60ml / min, and the reaction pressure was normal pressure. The influence of different microwave input powers (set to 700W, 750W, and 800W) on the decomposition of hydrogen sulfide was investigated. The experimental results are shown in Table 2, Table 2 It is the effect of the same catalyst used in hydrogen sulfide decomposition experiments under different microwave input powers.

[0063] Table 2

[0064]

[0065] It can be seen from Table 2 that with the continuous increase of microwave input power, the temperature of the catalyst bed is also continuously increased, and the corresponding decomposition rate of hydrogen sulfide is also continuously increased. When the input power is 700W, the bed The temperature can reach 584°C, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com